"Pile first method" interpolated jacket foundation construction system for implantable rock-socketed pile

A technology of rock-socketed piles and jackets, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve problems such as grout leakage that is difficult to remedy, and achieve the effects of ensuring construction quality, reducing construction risks, and providing construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The idea, specific structure and technical effects of the present application will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present application.

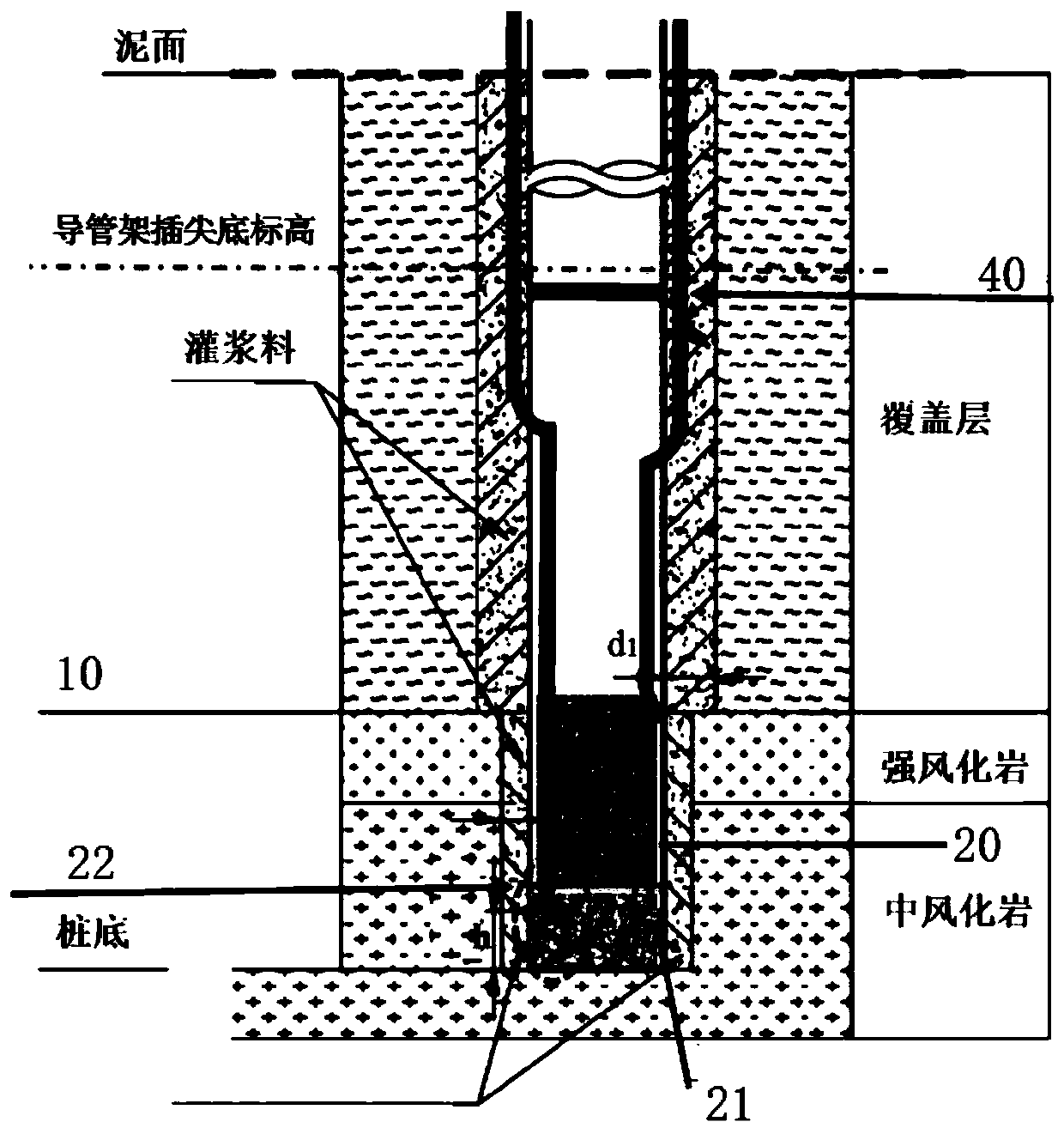

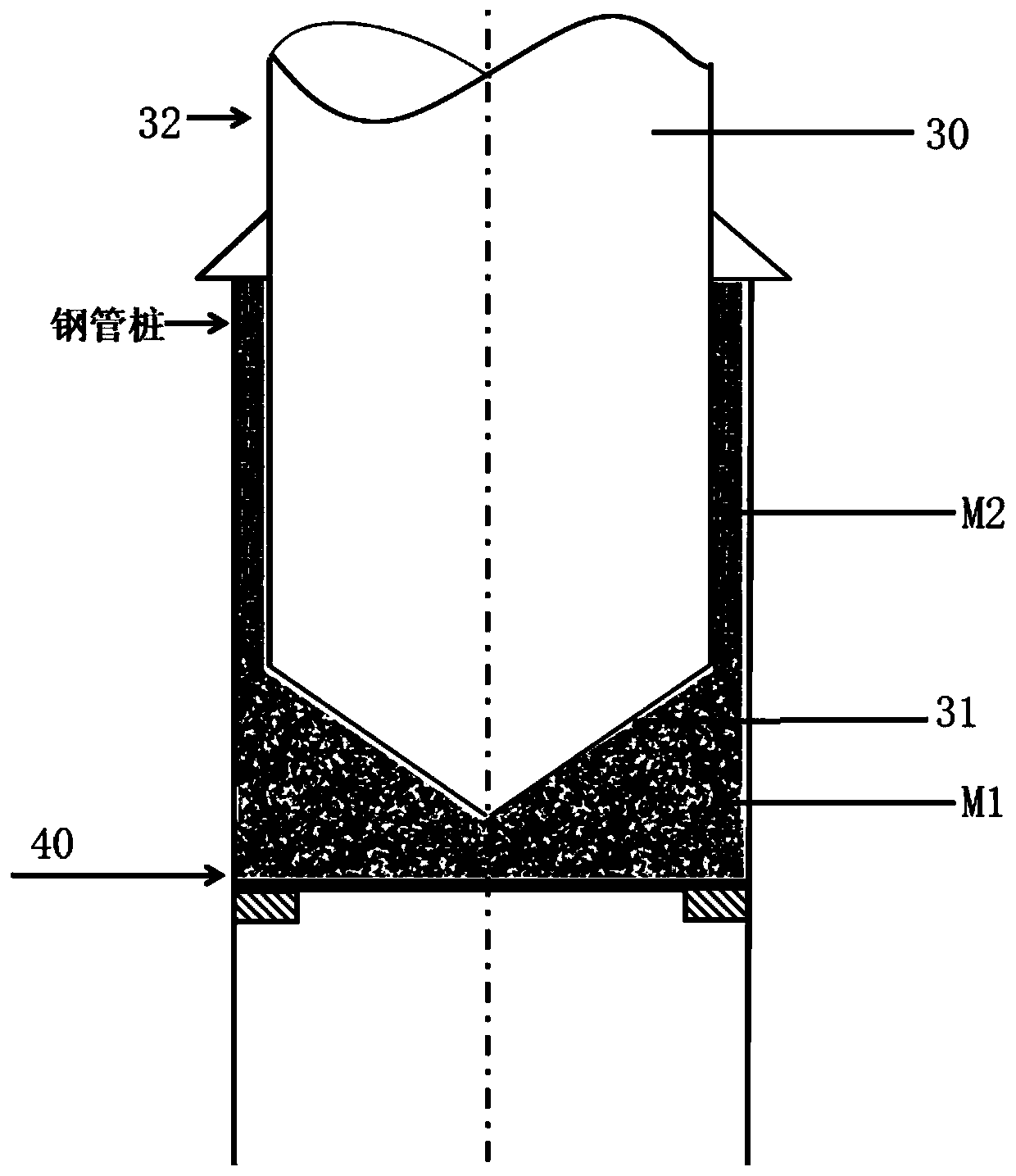

[0030] Such as figure 1 with figure 2 As shown, in one of the embodiments of this application, the "pile first method" interpolation jacket foundation construction system of implanted rock-socketed piles,

[0031] The construction system includes: a steel casing 10, a steel pipe pile 20 prefabricated with pile core bottom-sealing concrete 21, and a jacket 30;

[0032] The steel casing 10 is piled to a preset position, and the steel pipe pile 20 prefabricated with pile core bottom sealing concrete 21 is implanted inside the steel casing 10, the bottom of the steel pipe pile 20, the steel pipe The first annular space between the pile 20 and the wall of the rock-socketed hole, and the second annular space between the steel pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com