Tunnel secondary lining structure and construction method thereof

A secondary lining and tunnel technology, applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of increased labor intensity, low degree of mechanization, and low construction efficiency, and achieve improved working conditions, strong protection performance, and improved construction efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

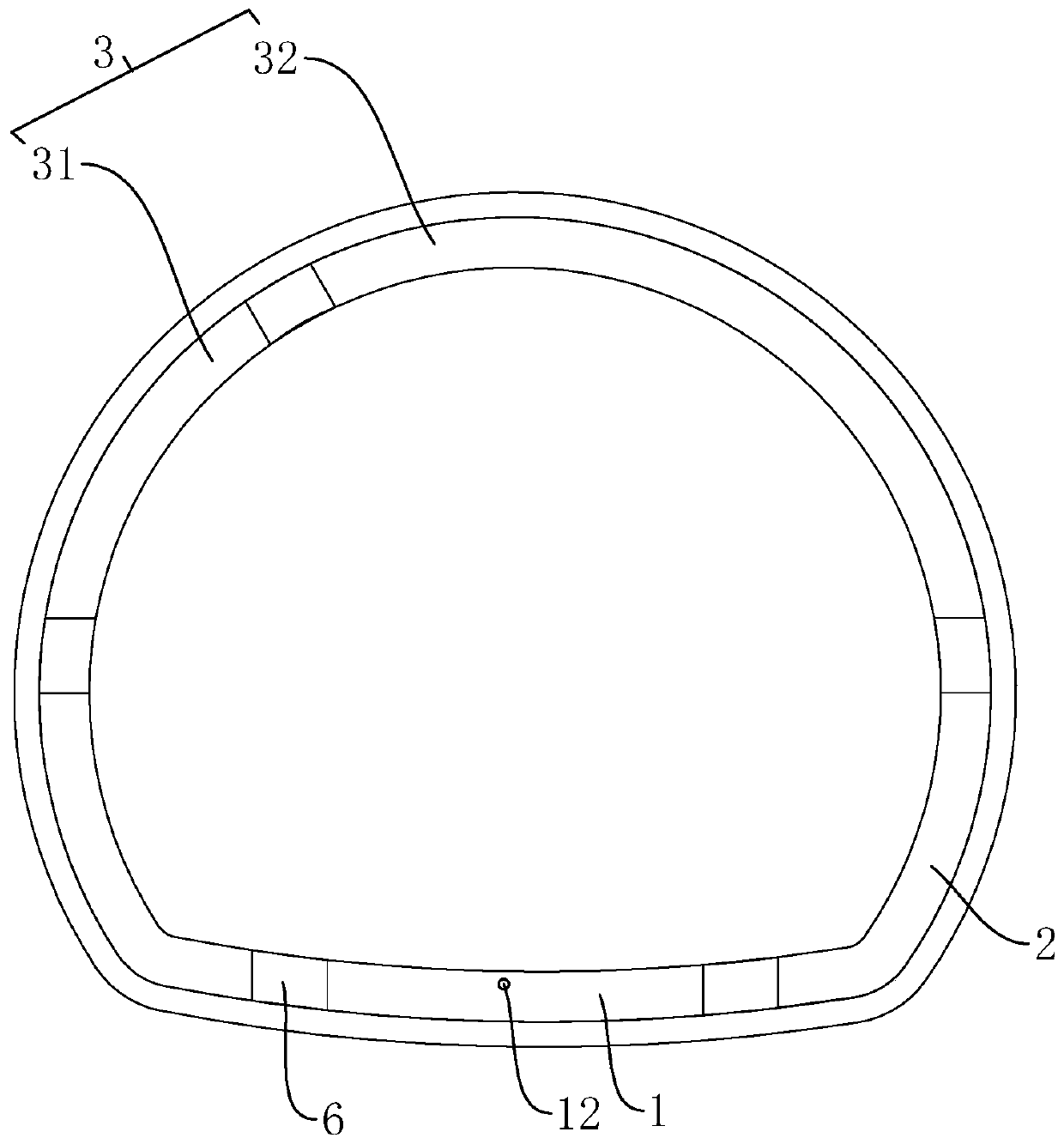

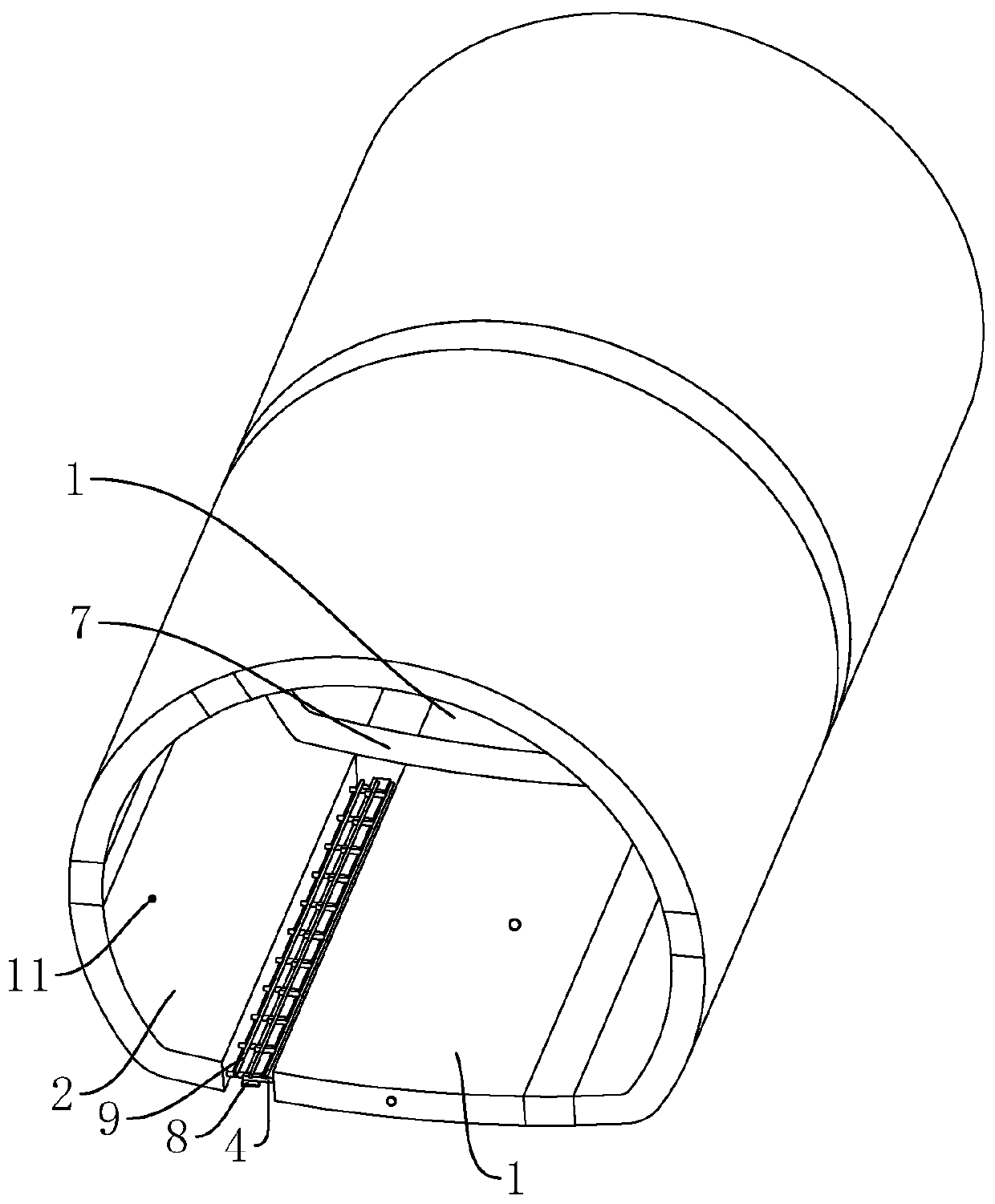

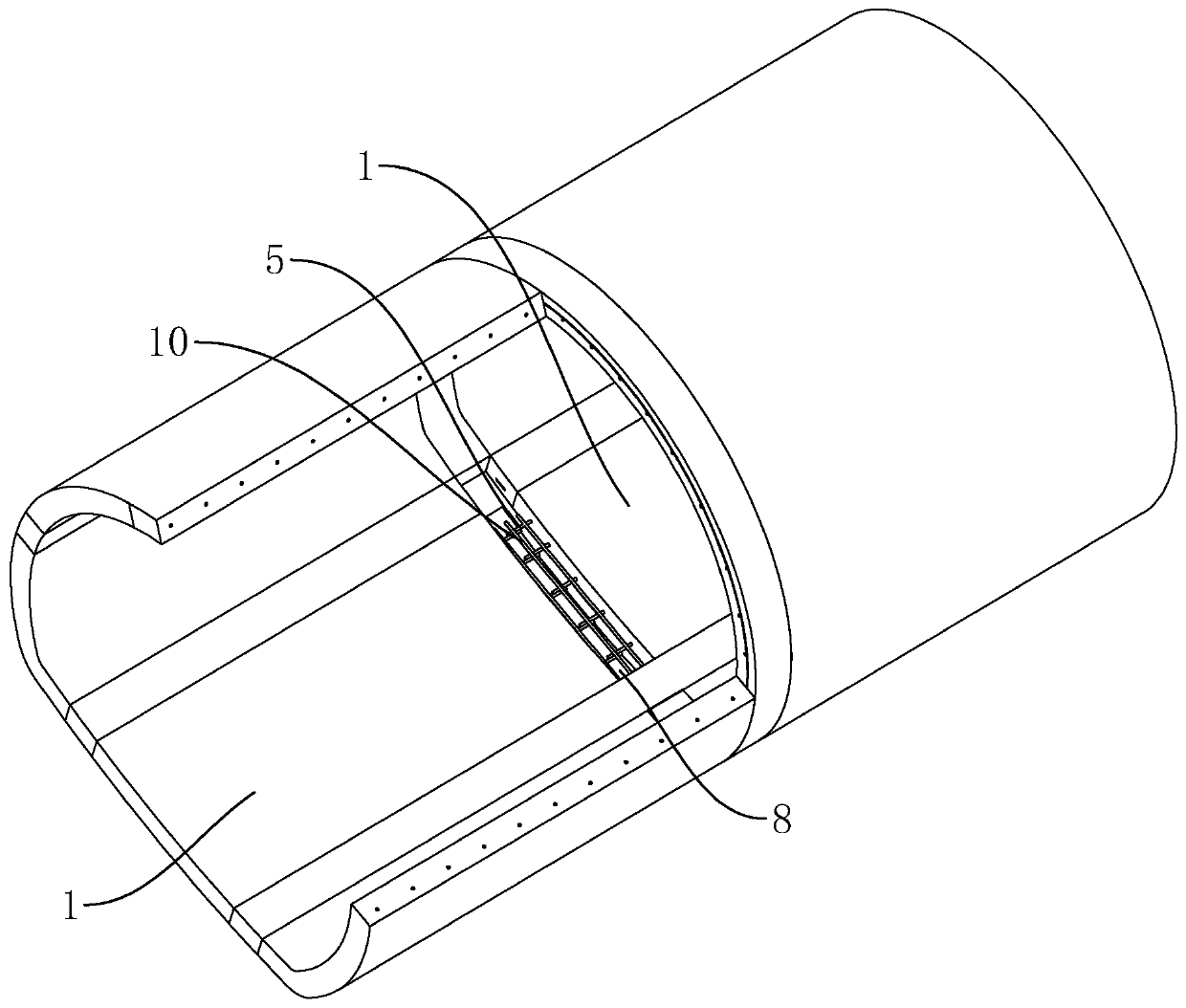

[0039] to combine figure 1 and figure 2 , is the tunnel secondary lining structure disclosed in the present invention, including multiple tunnel units arranged in sequence along the extension direction of the tunnel and connected to each other, each tunnel unit includes an inverted arch 1, and arch walls respectively arranged on both sides of the inverted arch 1 2 and the arch ring 3 arranged on the upper end of the arch wall 2, wherein the inverted arch 1, the arch wall 2 and the arch ring 3 are reinforced concrete structures, and the inverted arch 1, the arch wall 2 and the arch ring 3 are respectively provided with multiple intersecting structures. Horizontal connecting ribs 4 and longitudinal connecting ribs 5, horizontal connecting ribs 4 protrude from the joints of inverted arch 1 and arch wall 2, and arch wall 2 and arch ring 3, and the horizontal co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com