Total precast lower structure of bridge and construction method

A bridge and integral prefabrication technology, applied in the direction of bridges, bridge parts, bridge construction, etc., to achieve the effect of reducing hoisting weight, reducing construction site, and solving complex connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

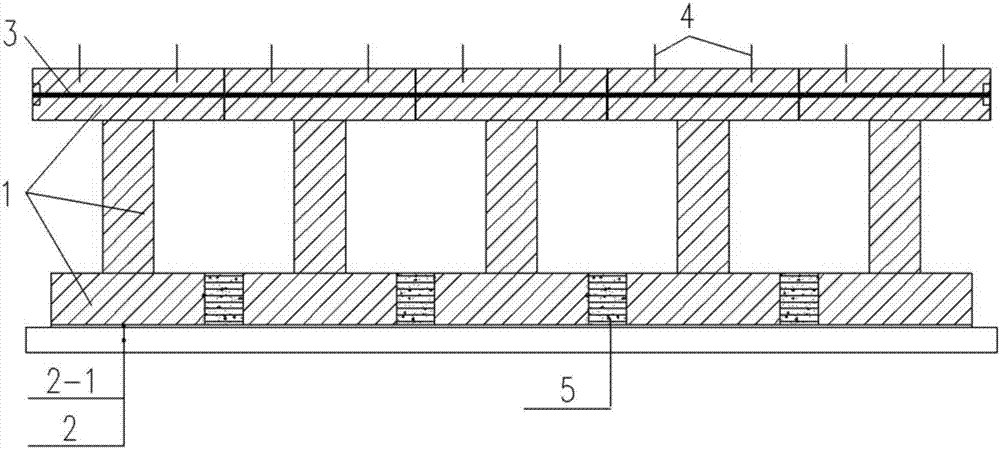

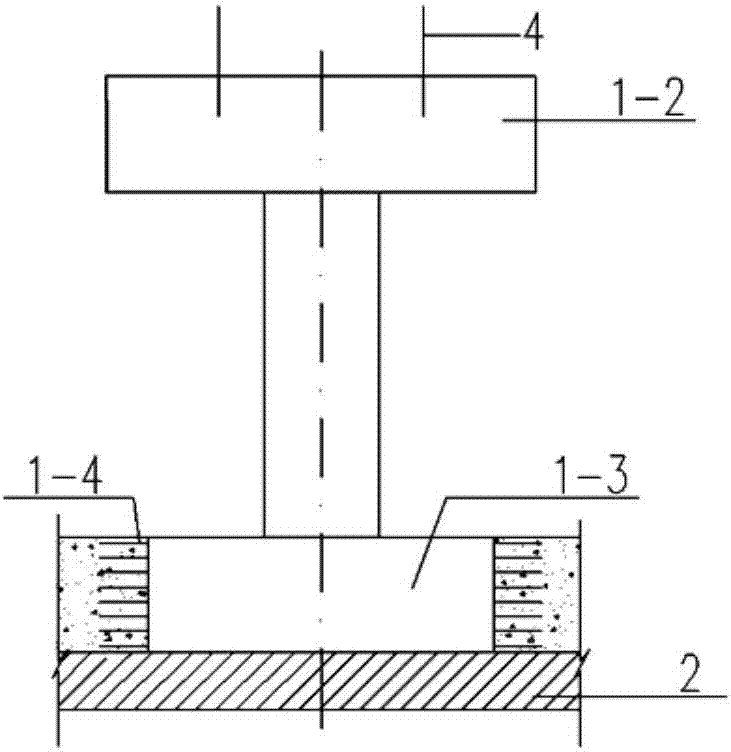

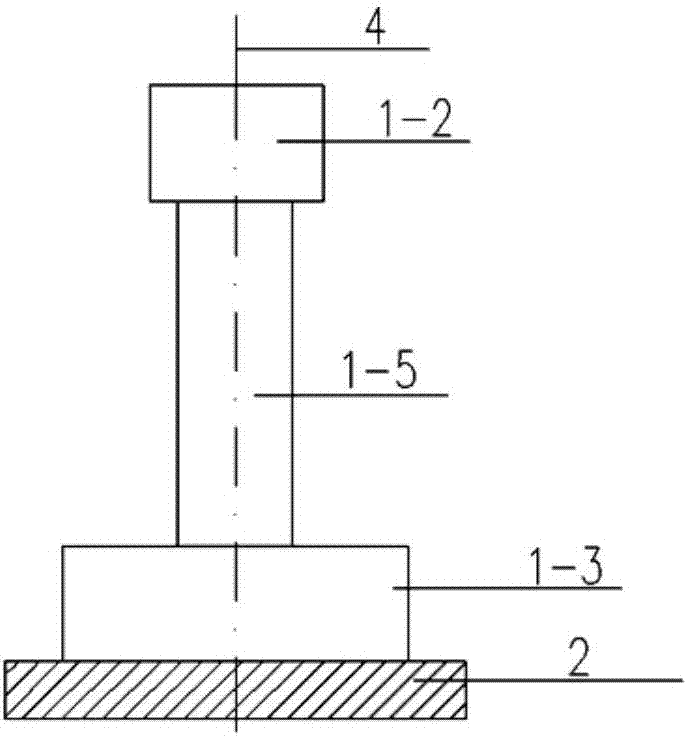

[0033] The overall cross-sectional structure diagram of the lower structure of the present invention is as follows figure 1 As shown, it is mainly composed of an integral prefabricated lower member 1, a prefabricated backing plate 2, a prestressed steel strand 3, and an anti-seismic steel bar 4. The main design principle: For the overall prefabrication of the bridge substructure that can use the enlarged foundation, it can be prefabricated in horizontal blocks according to the hoisting weight and transportation size, and each prefabricated component 1 is transported to the site for assembly. The monolithic prefabricated component 1 is composed of cover beams, pier columns, and enlarged foundation, and the component 1 is prefabricated in a factory as a whole. Bellows are reserved for the cover beam of component 1, and the components are connected in series through prestressed steel strand 3 during on-site assembly to strengthen the horizontal connection between component 1. Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com