Patents

Literature

118results about How to "Save construction site" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Supporting arch hidden digging top-down construction method

ActiveCN101338678AFew construction divisionsIncrease the construction work areaUnderground chambersTunnel liningClerestoryFloor slab

The present invention relates to a one time supporting arch subsurface excavation reversed construction method. The steps of the method are as follows: at least a pair of upper guide hole and lower guide hole are respectively excavated in a top body and a bottom body corresponding with an underground structure design space; each pair of guide holes forms one span; then the hole wall is processed for primary supporting; the bottom of the lower guide hole is laid with a waterproof layer; the waterproof layer is casted with an underlayer frame structure soleplate; a slope stake and a middle upright post are constructed from the upper guide hole; the arc top of the upper guide hole is laid with the waterproof layer, and an arc top permanent structure is cast; then a midspan soil body is excavated between two upper guide holes by a subsurface excavation method to form a midspan upper guide hole and to be constructed as a midspan upper guide hole arc top permanent structure; the primary support at the bottom of the upper guide hole is chiseled and removed; a soil body is excavated downwards, and a structure lateral wall and a middle floor slab are cast; the rest partial solid between the primary support at the top of the lower guide hole and the middle floor slab is excavated, at the same time, the primary support at the top of the lower guide hole is chiseled and removed, the rest lateral wall structure is cast, and an even span structure soleplate is closed. The method has small construction risk, large construction field and fast construction speed, uses few big guide holes and solves the technical problems of the large amount of the guide hole, the small size of the guide hole, small construction space, multiple times of structure stress conversions, the repeated perturbation of wall rock, etc of the traditional subsurface excavation method.

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO

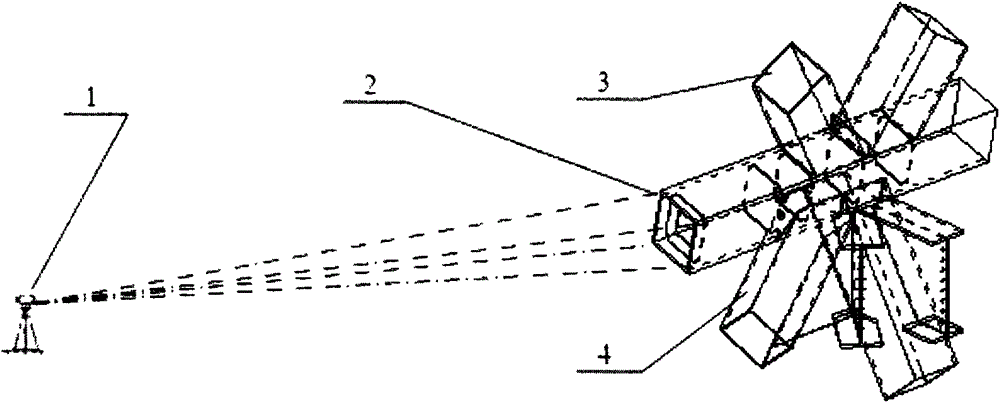

Steel structure three-dimensional scanning observe and control method

ActiveCN101413348AReduce construction investmentSave construction siteBuilding material handlingSpecial data processing applicationsMeasurement pointComputer aid

The invention relates to a computer aided construction method for a steel structure, in particular to a three-dimensional scanning, measuring and controlling method for pre-assembled or mounted steel structures. The method comprises the following steps: using a total station to carry out precise three-dimensional positioning, scanning and measuring for a component, designing N points on the component, inputting the measured points to AUTOCAD to build a model, making an actual three-dimensional component model, using a built theoretical model in a computer, compounding the two models to obtain actual processing deviation of the component, then drawing up a finishing proposal according to deviation characteristic, and after the finishing, measuring again, building the model, compounding the models and finishing till to accord with requirements. Compared with the prior method of entity detection and preassemble, the method has the advantages that the method reduces large quantity of construction sites, manpower and mechanical investment, only needs few men to finish measuring and controlling processes of the construction, improves labor productivity greatly, ensures construction quality, reduces construction cost greatly, and achieves low cost, high efficiency and high benefit.

Owner:CHINA 22MCC GROUP CORP

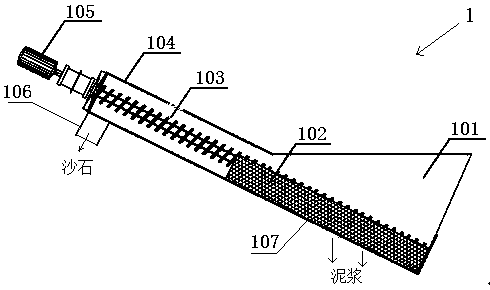

Hole drilling mudjack pile construction method

ActiveCN101215835ATightly boundImprove vertical bearing capacityBulkheads/pilesEngineeringHigh pressure

A high pressure bored pile construction method of the invention belongs to the foundation piling technical field, which comprises: a drilling rig is positioned to drill a hole downward and mud protection is provided; after drilling to a required depth, using clear water for cleaning the hole; lifting a drill rod and dissembling the drill bit and inserting a reinforcement cage as soon as possible and lengthening the drill rod to the end of the hole for first hole bottom grouting; after the grouting, continuously throwing stones while in the drilling status of the drill rod; after stones are thrown in, processing the secondary hole bottom grouting and adopting concrete insertion type vibration rod for pounding to 0.6 to 1.2 m under the hole edge to ensure a dense pile top. The pile body of the invention is of concrete with no sand, has high vertical bearing ability and lateral force resistance ability. The method needs relative small construction equipment and has little construction vibration and noise, needs small construction field, can convert the foundation extension construction into the foundation extension pile construction, greatly improves vertical bearing ability of each pile, and also can process the inclined pile construction.

Owner:ZHEJIANG YIJIAN CONSTR GROUP +1

Construction method for sliding and replacing whole body of jacking and revolving bearing of revolved body of stacker-reclaimer

The invention discloses a construction method for sliding and replacing a whole body of a jacking and revolving bearing of a revolved body of a stacker-reclaimer, and belongs to the technical field of replacing components of the stacker-reclaimer in iron-smelting raw material yards. The construction method comprises the following steps: before machine halt construction, firstly manufacturing jack supporting beams, safe piles and a stirrup, mounting the jack supporting beams, and mounting the stirrup; selecting hydraulic jacks, and erecting the selected hydraulic jacks; sealing the whole body of the revolved body of the stacker-reclaimer, manufacturing a sliding device of the revolving bearing, mounting the manufactured sliding device, and dismounting and removing components which have influence on the horizontal sliding of the revolving bearing; sliding the whole body of the jacking and revolving bearing of the revolved body, replacing the slid whole body of the jacking and revolving bearing of the revolved body, and mounting the components which have influence on the horizontal sliding of the revolving bearing. The construction method has the advantages that the problems that a large-scale vehicle type crane needs to be used during replacing the revolving bearing of the stacker-reclaimer in the iron-smelting raw material yards, the construction time is long, the occupied site is large, the construction cost is high and influence on the production is great; the method is simple and easy to operate, and the construction cost is reduced; the construction site is reduced, the whole construction time of jacking and sliding is shortened, and influence on the production is reduced; double safety facilities of the sealed whole body and the safe piles are adopted, so that the safety guarantee is supplied.

Owner:BEIJING SHOUGANG CONSTR GROUP

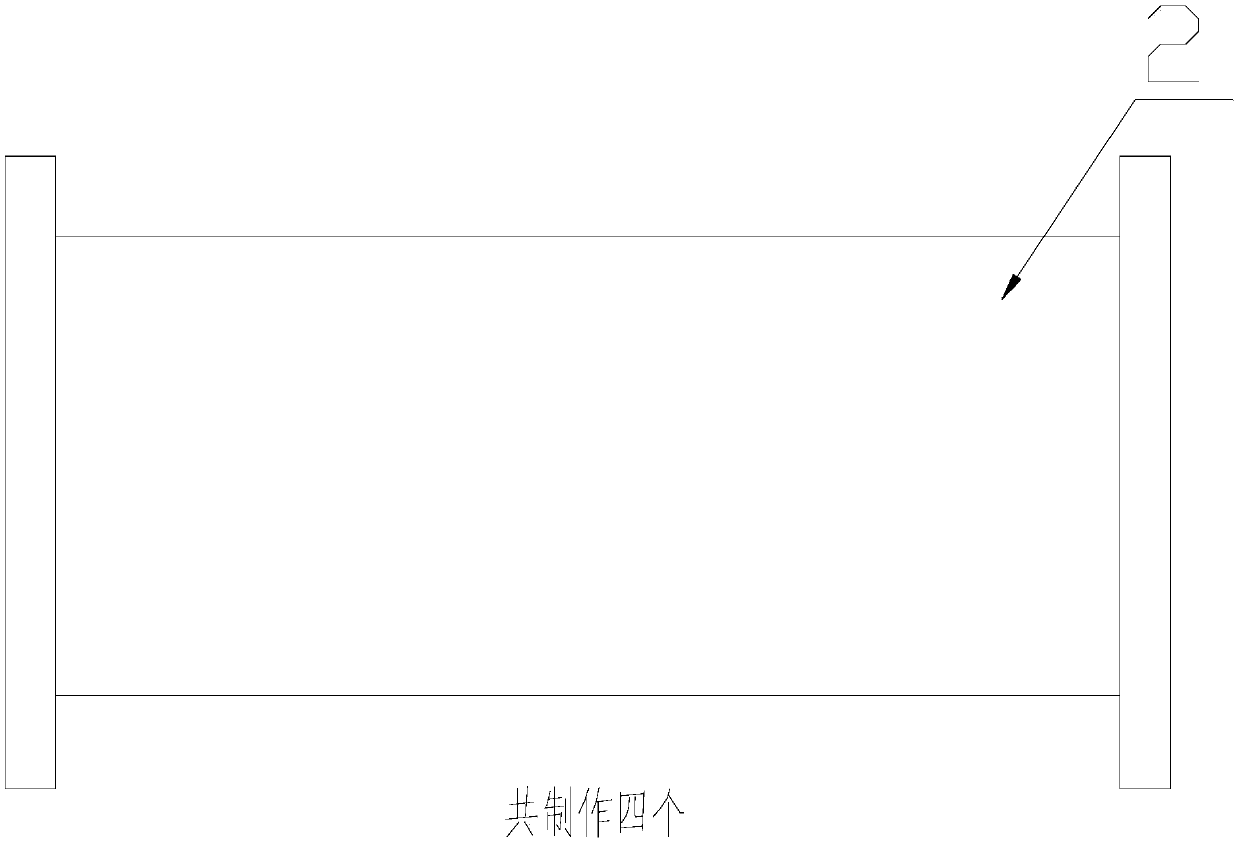

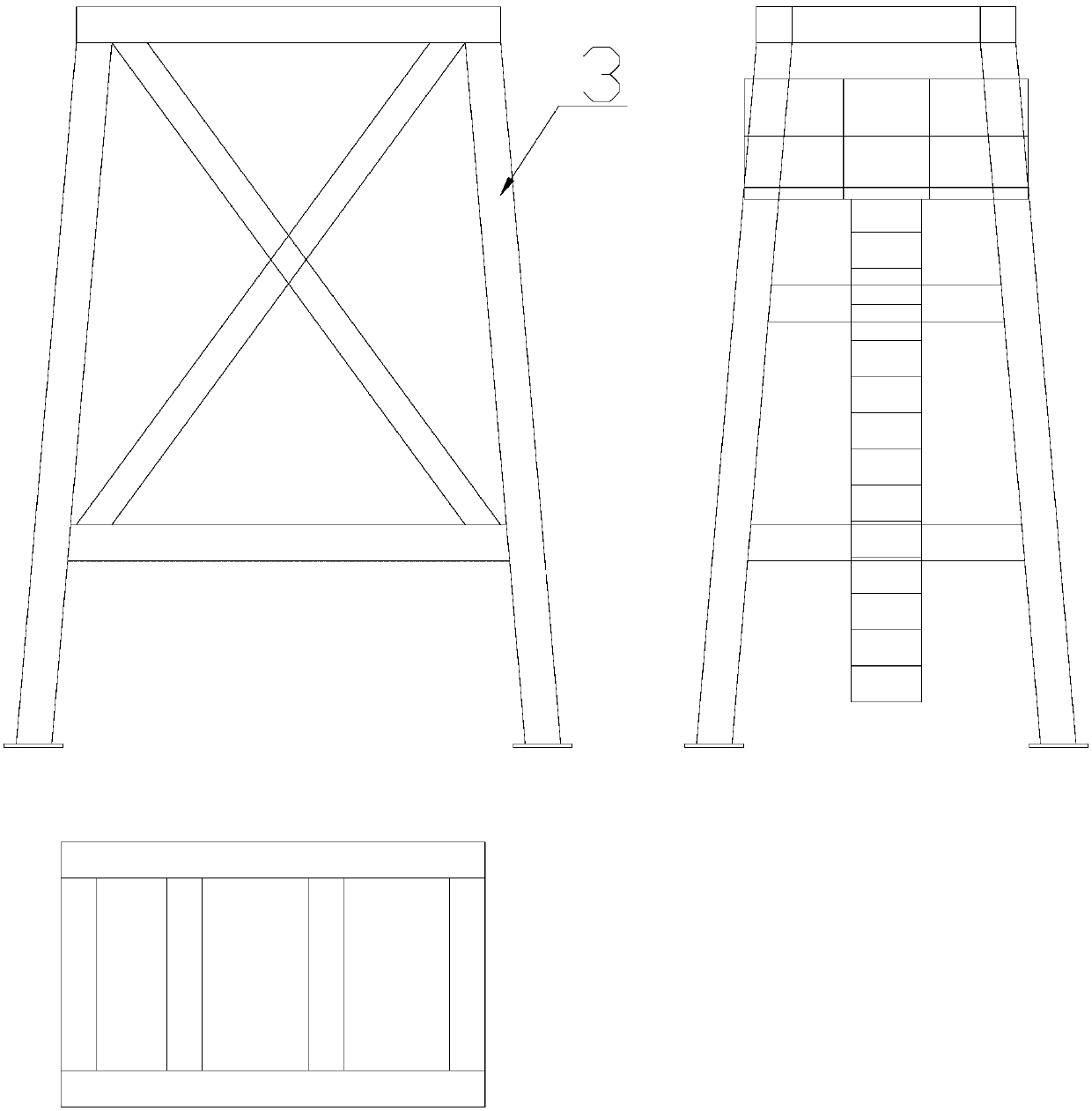

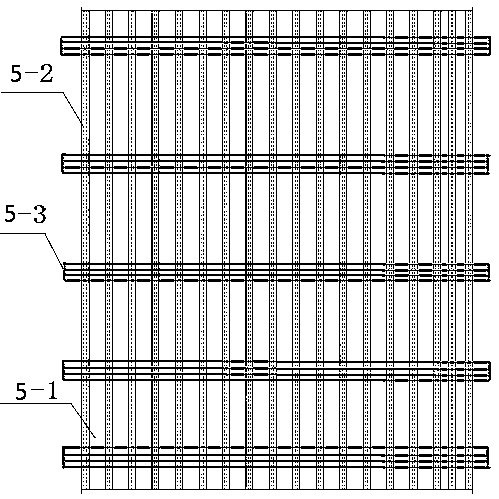

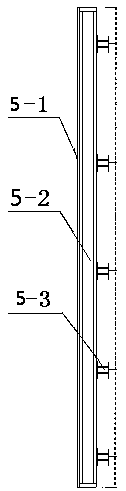

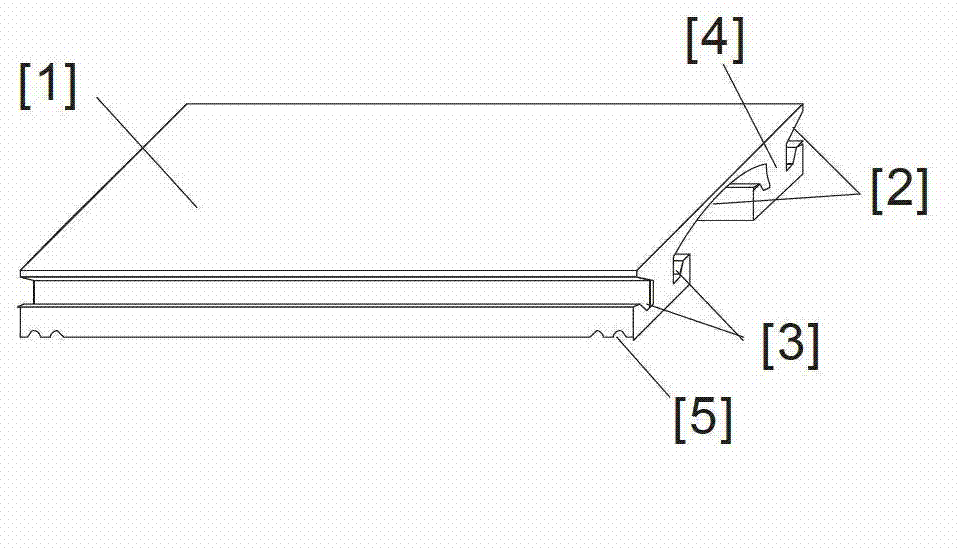

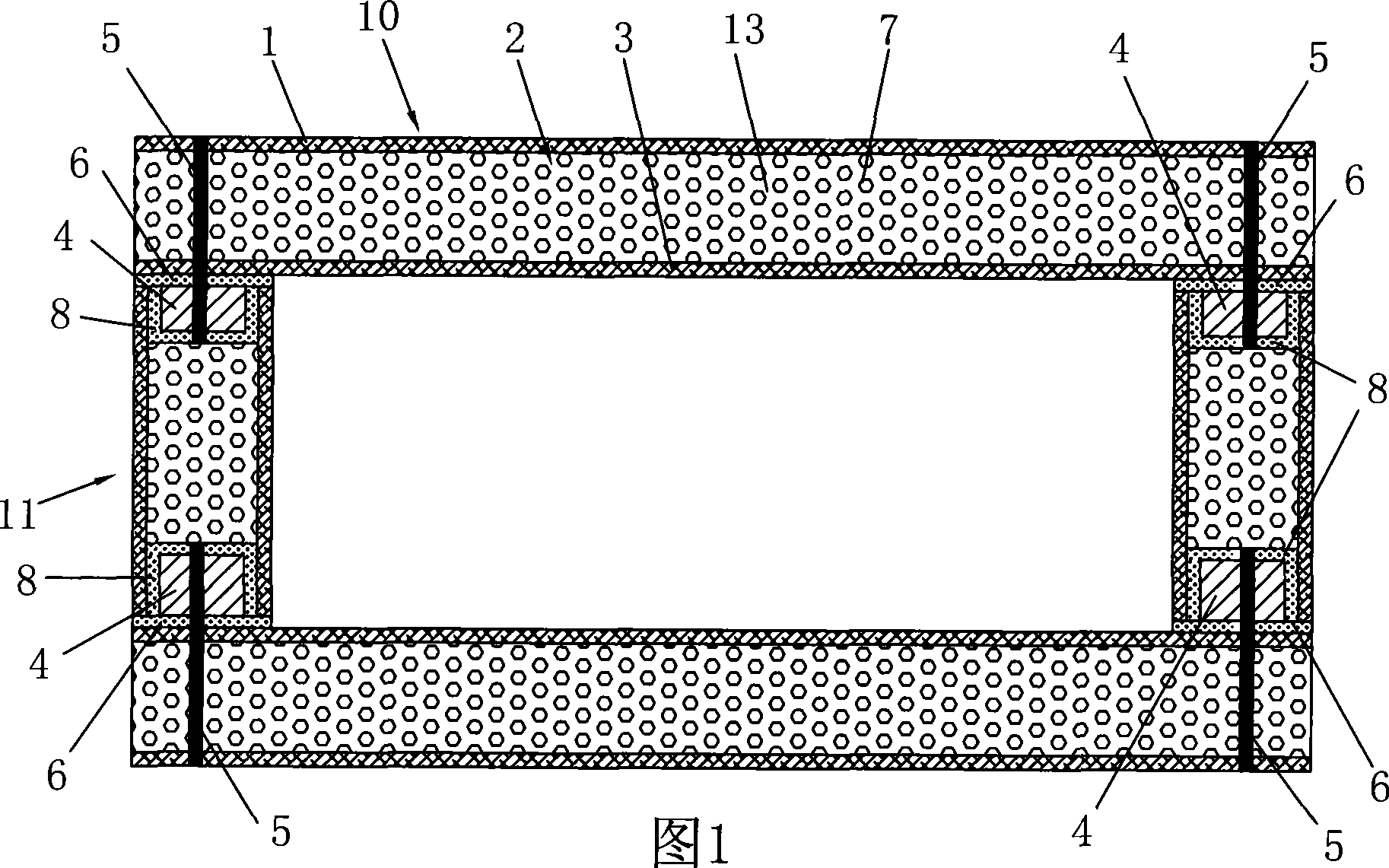

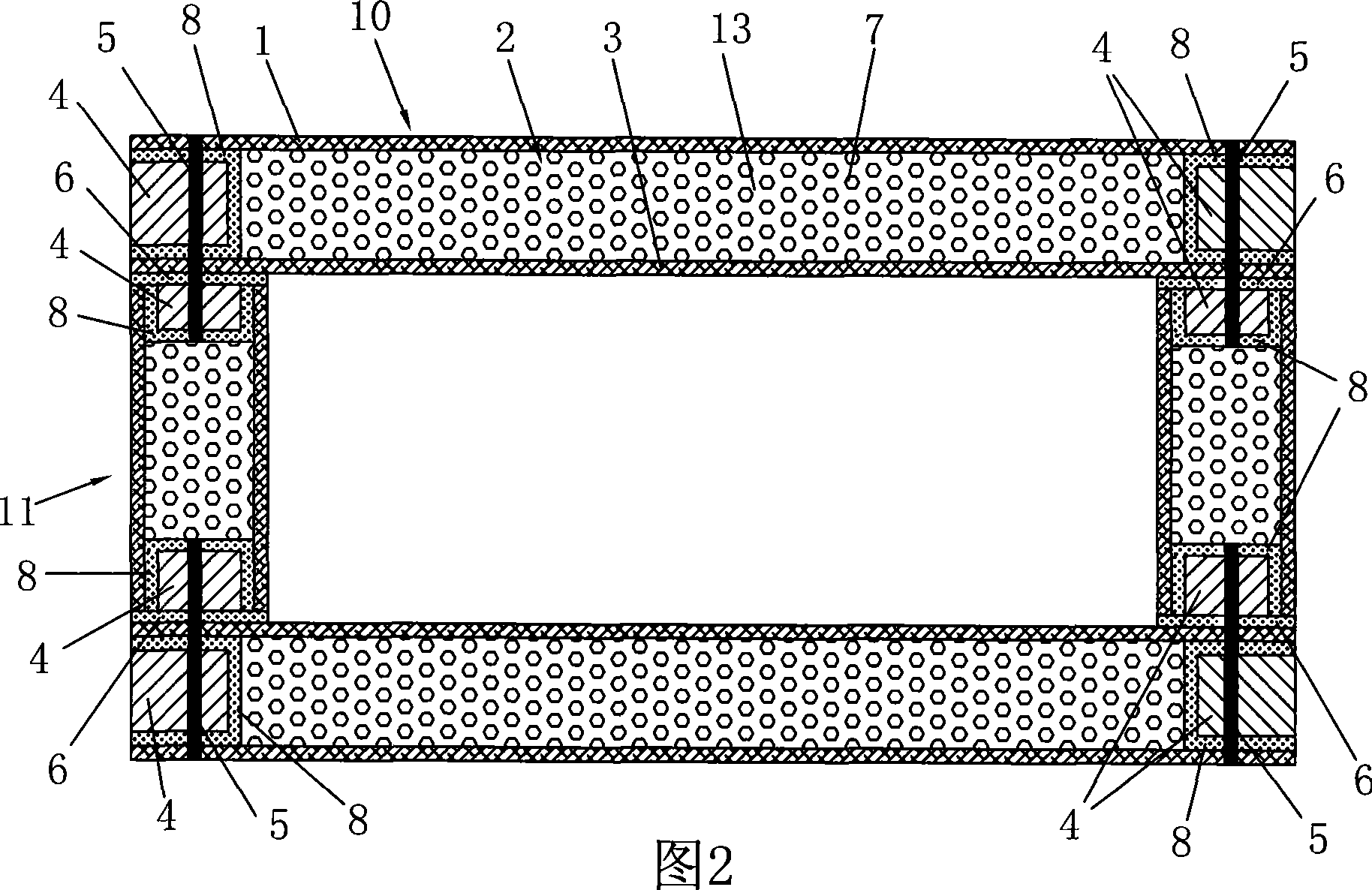

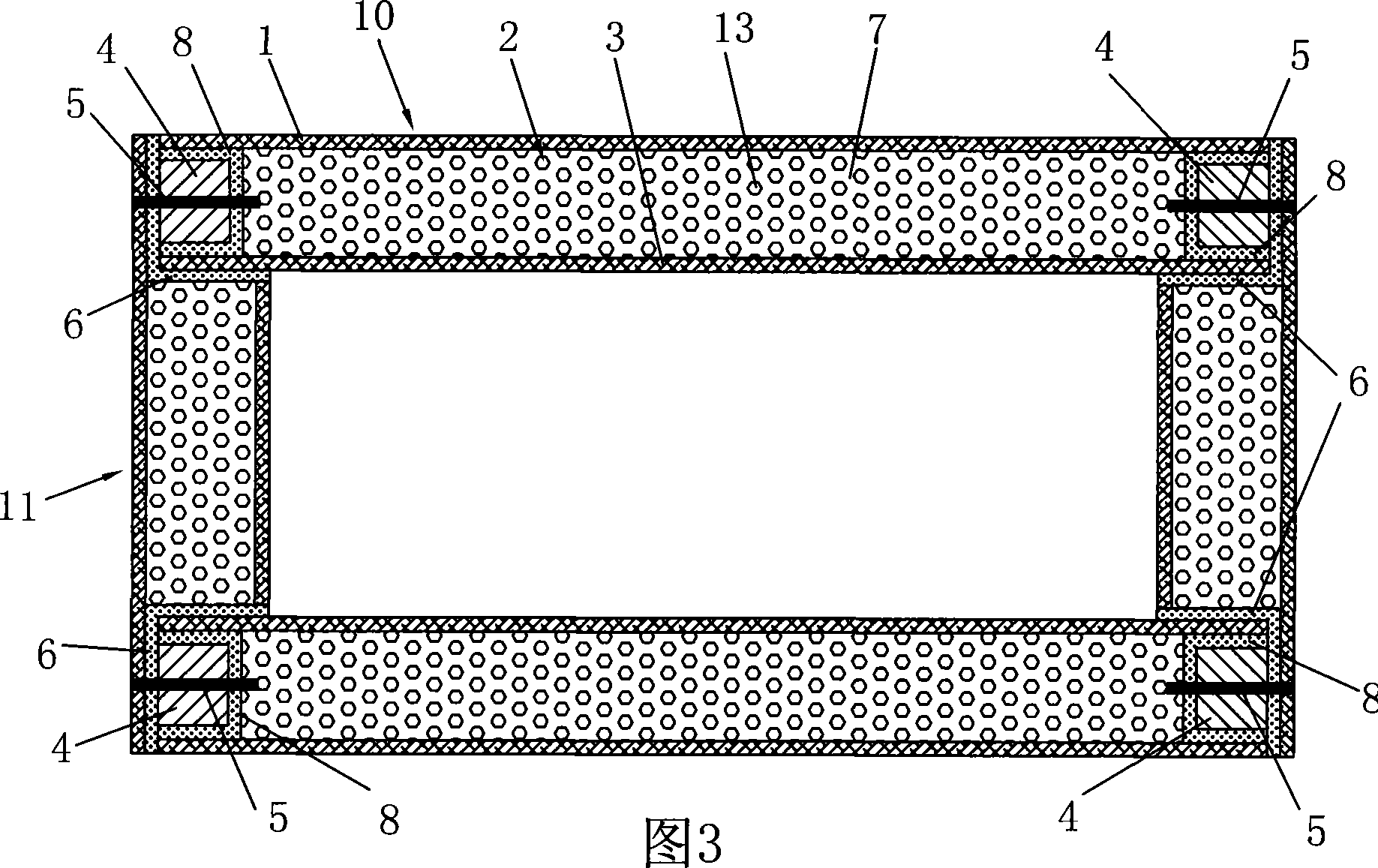

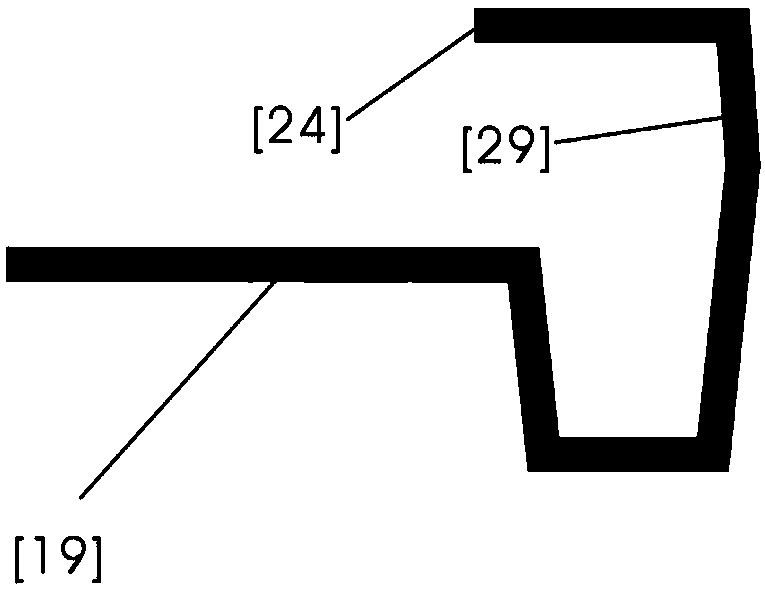

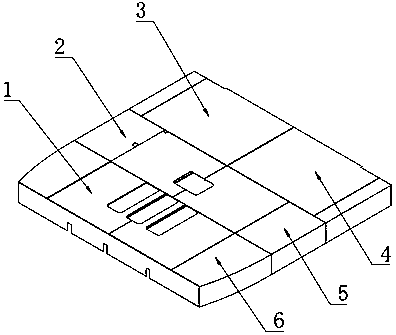

Section-adjustable rectangular column framework assembly

ActiveCN102979300ASave materialSave construction siteForms/shuttering/falseworksSurface plateBatch processing

The invention provides a section-adjustable rectangular column template assembly, belonging to the technical field of building construction members. The section-adjustable rectangular column template assembly comprises four detachable rectangular templates, wherein each template is formed by a panel fixed on the inner surface of a plate frame; at least two horizontal fillets which are distributed up and down are fixed in the plate frame, the plate frame at the end parts of the horizontal fillets is fixedly connected with vertical fillets vertical to the horizontal fillets to form an L-shaped back fillet, one of each horizontal fillet and each vertical fillet is provided with bolt holes, and the other of each horizontal fillet and each vertical fillet is provided with bolt holes or slotted holes which are distributed at intervals; and in the construction process, the four rectangular templates form a template enclosure frame in which a cavity is matched with the section of a rectangular column to be poured, in a mode of selecting the fixedly connecting positions of the vertical fillets of one of two adjacent templates and the horizontal fillets of the other of two adjacent templates. Therefore, multiple troubles, such as material wasting, difficulty in management, and inconvenience for construction caused by batch processing according to the section size of each column, can be eliminated.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

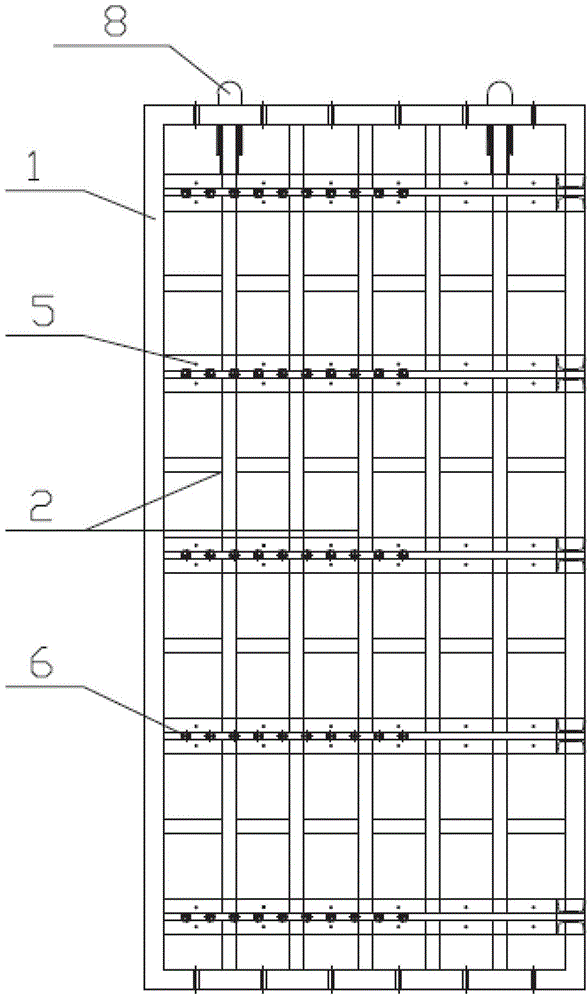

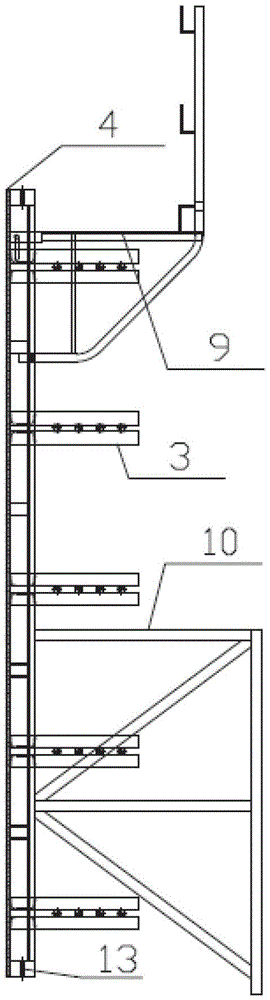

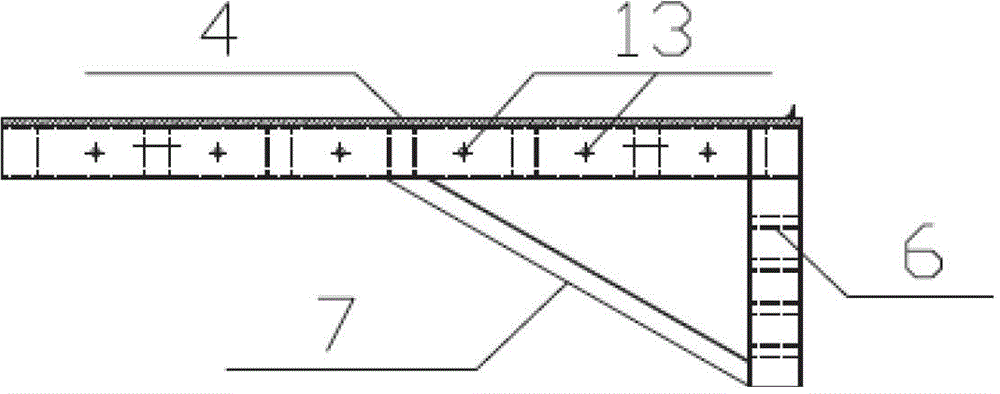

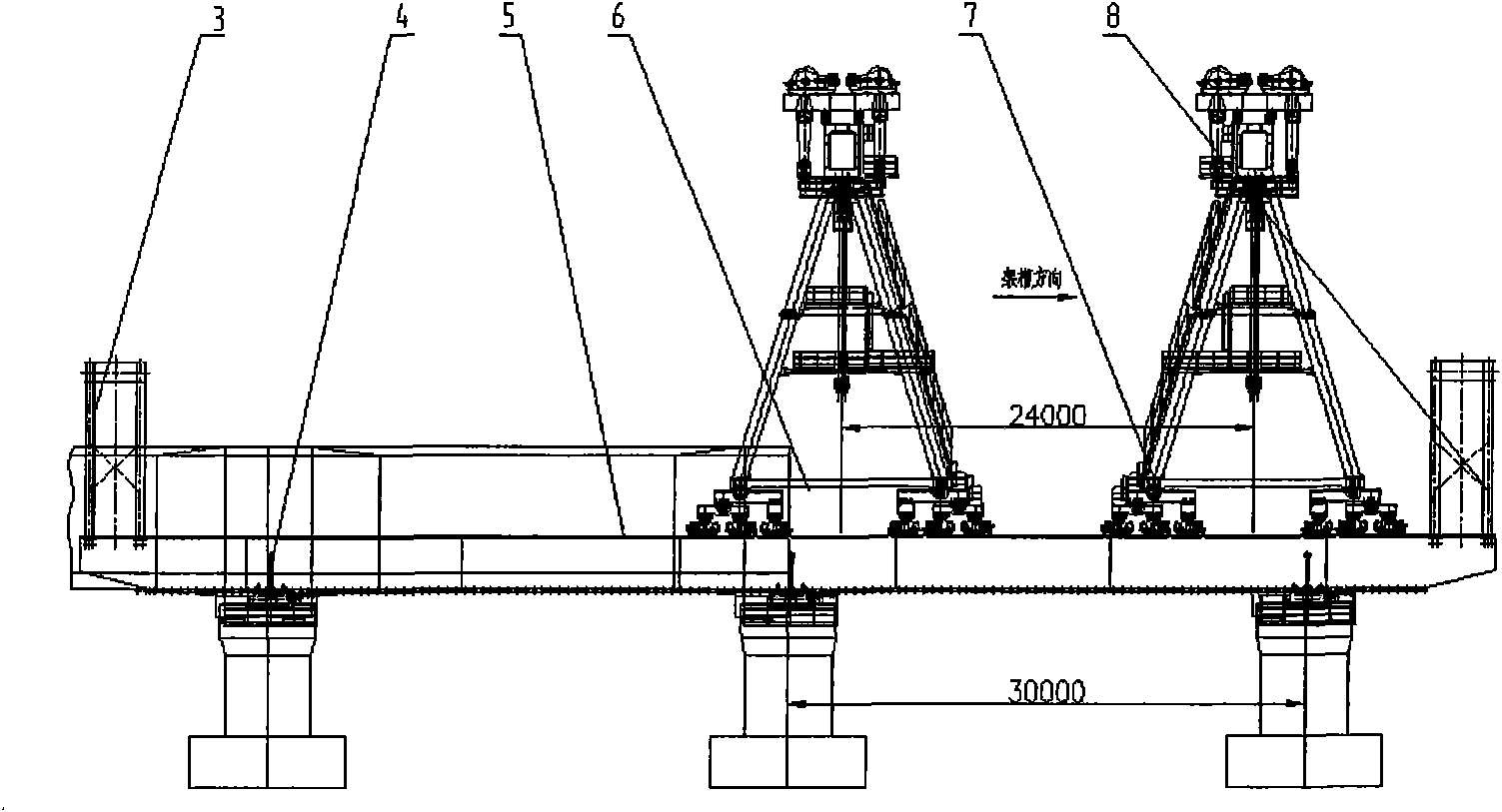

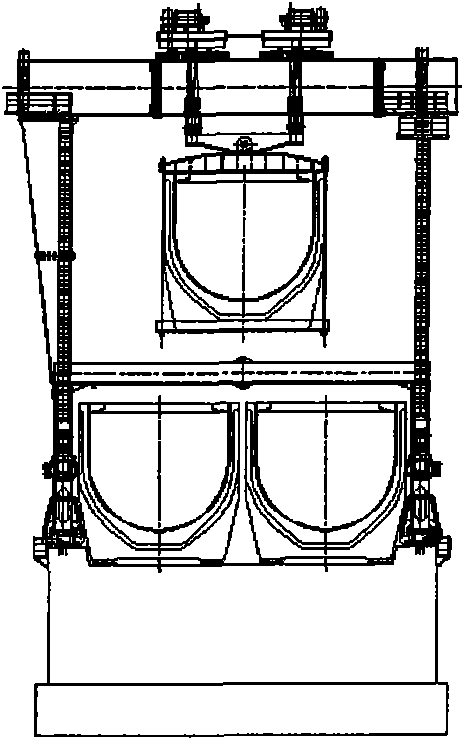

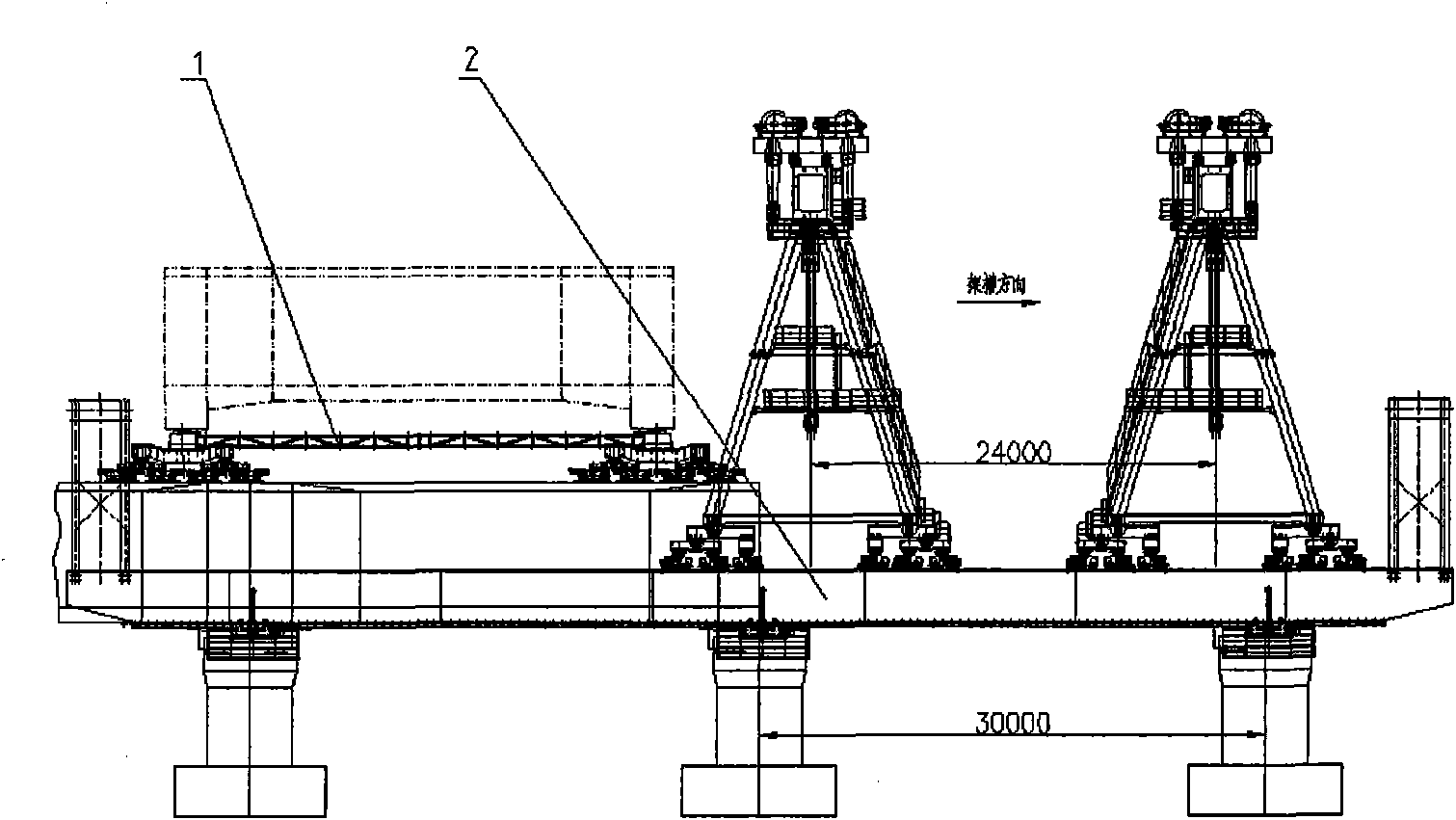

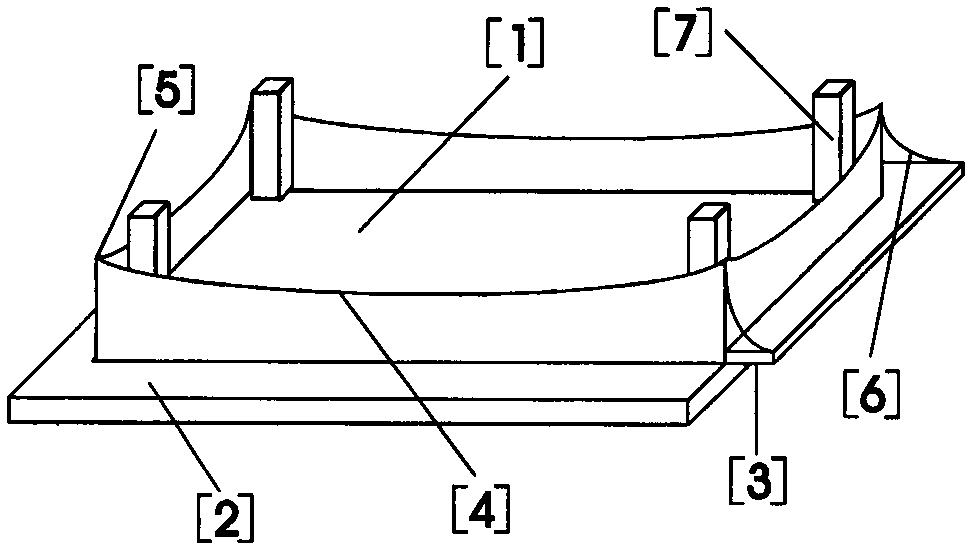

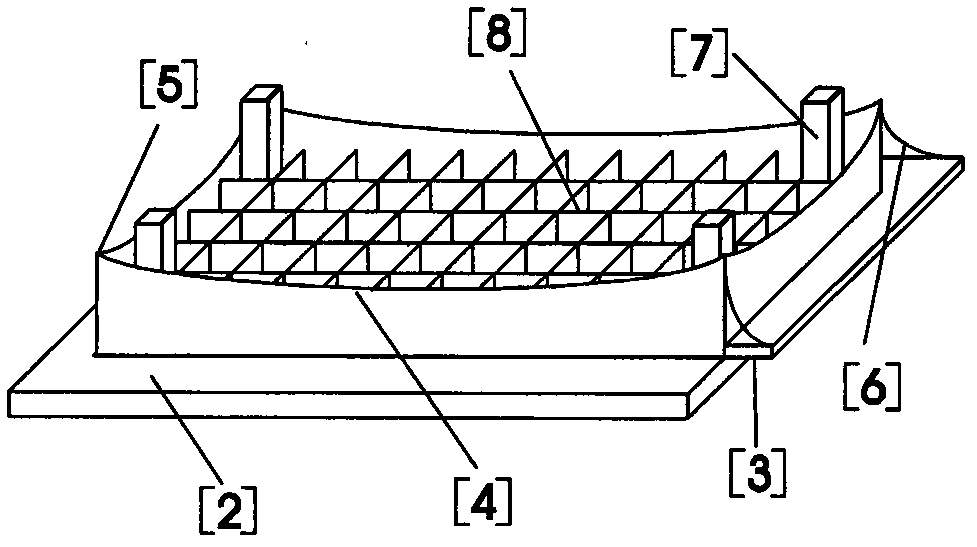

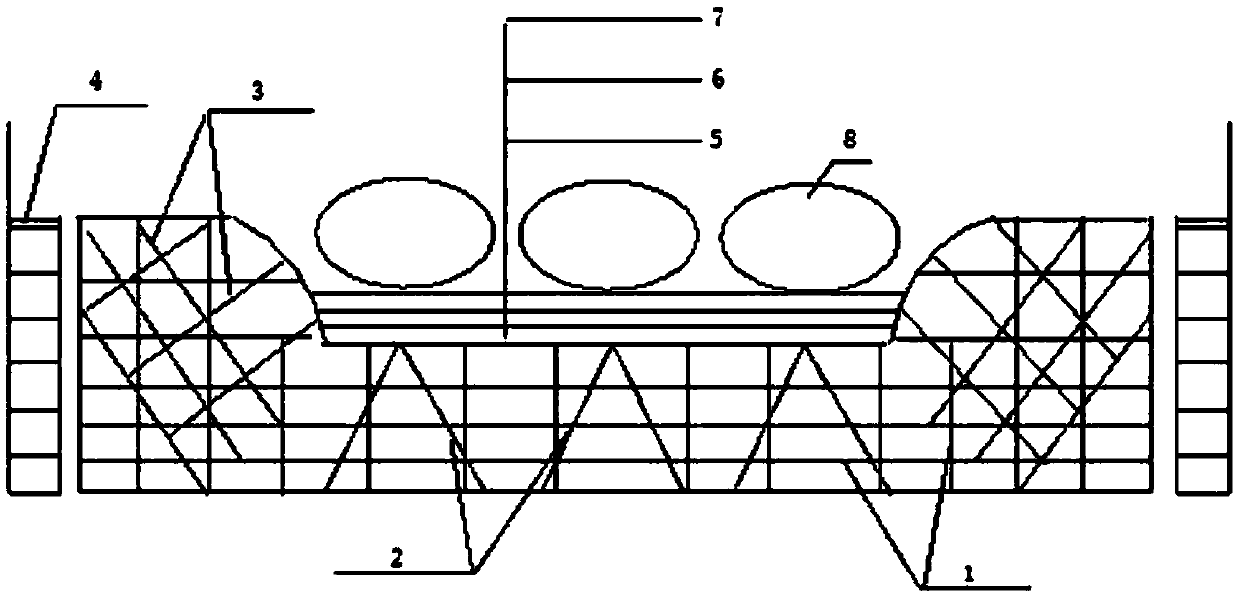

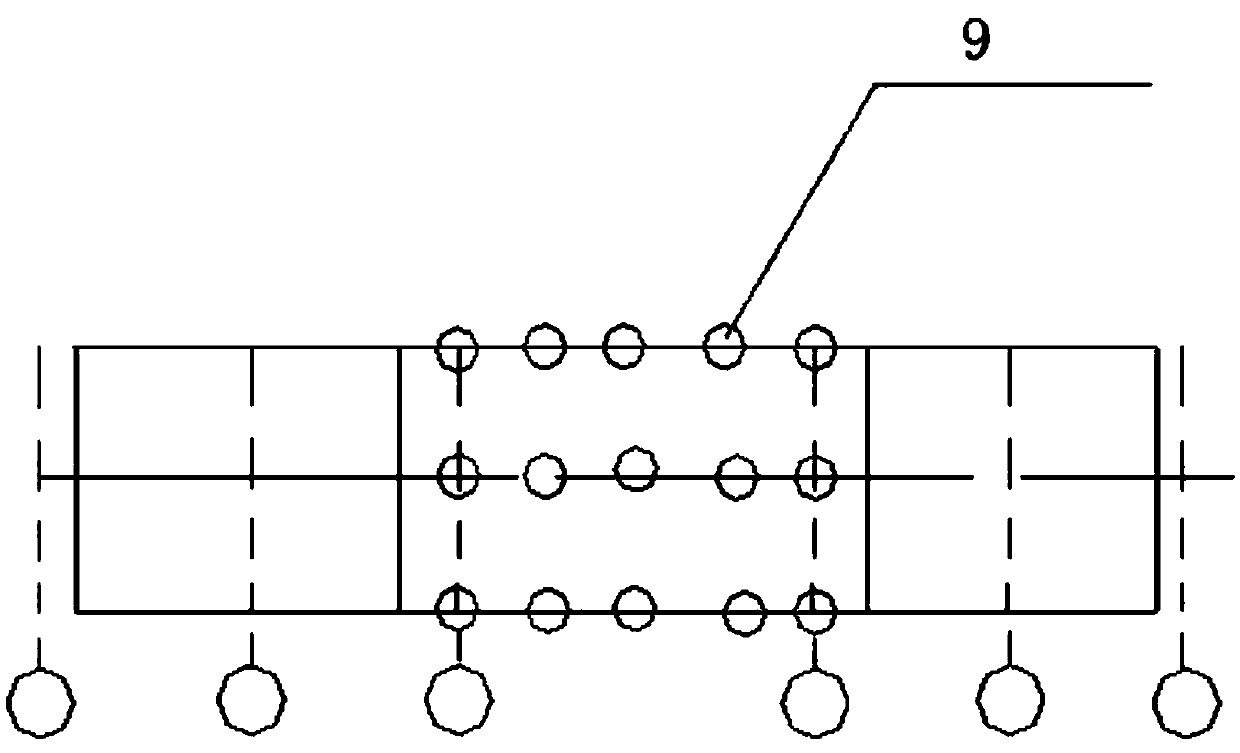

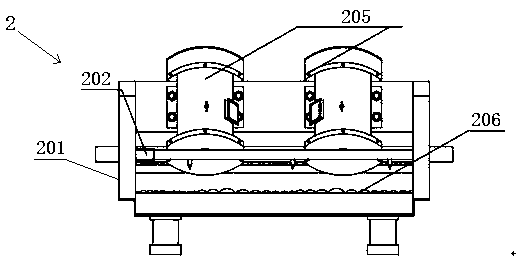

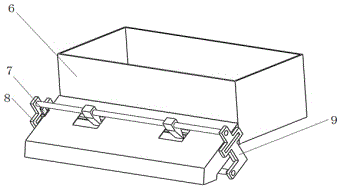

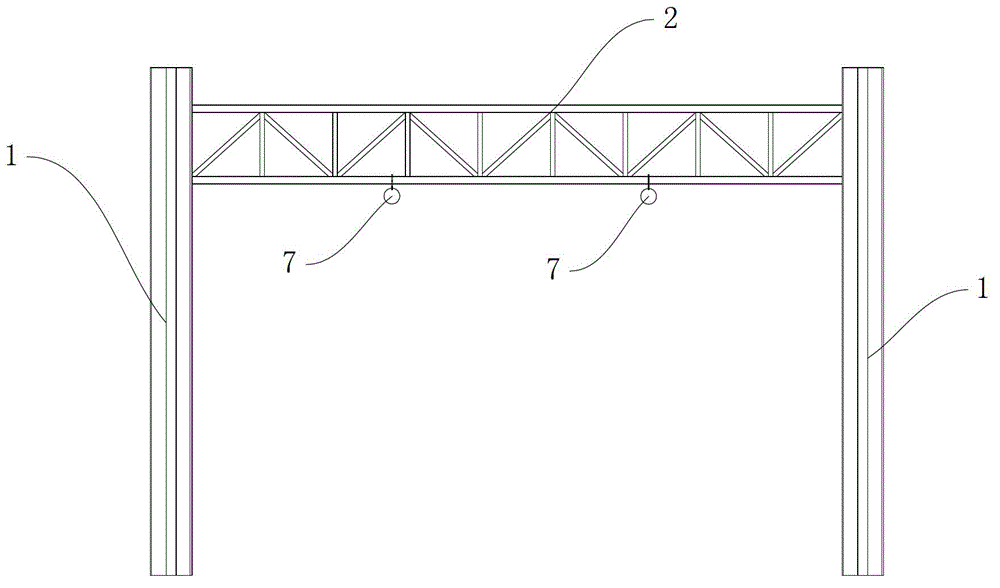

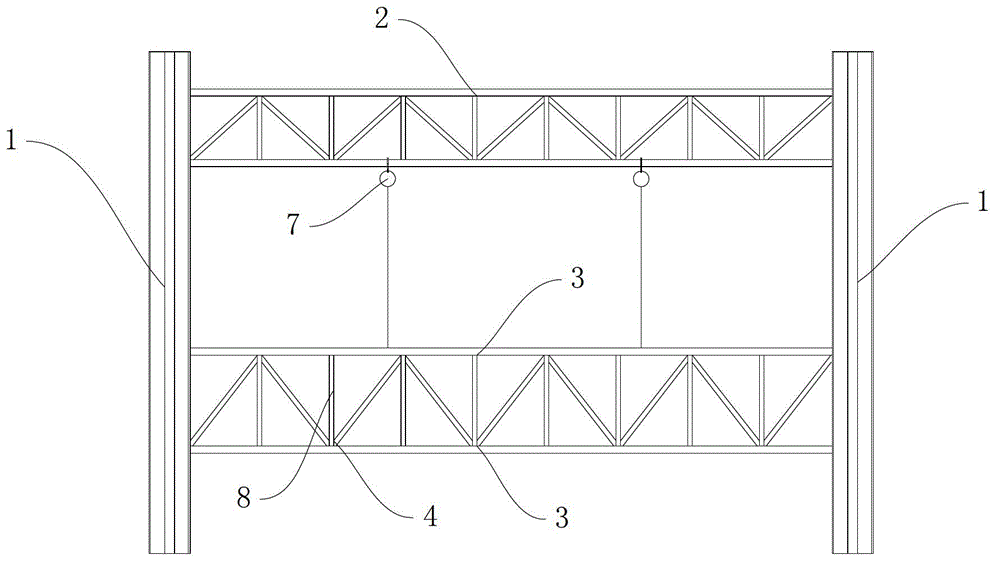

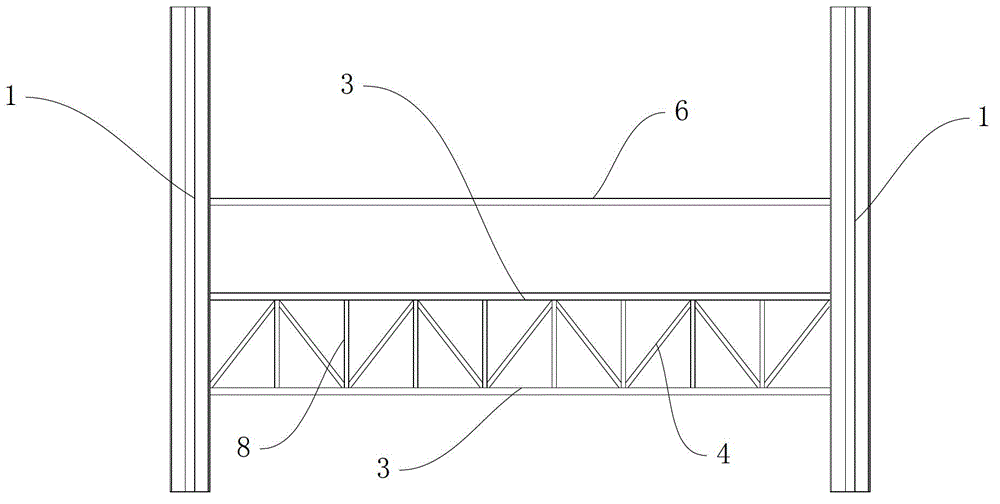

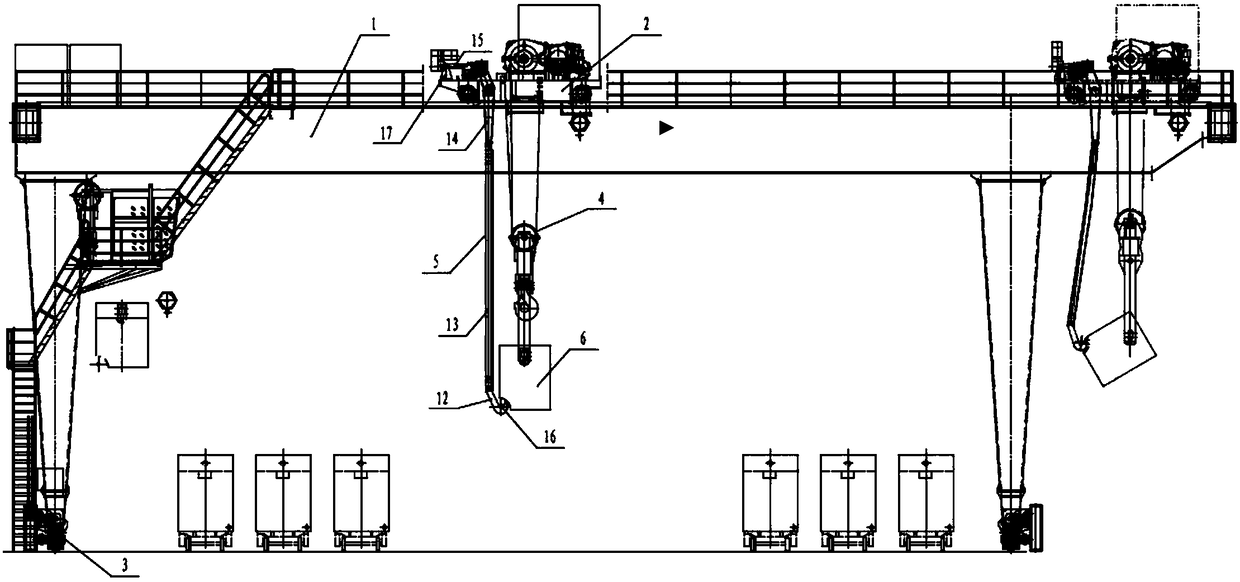

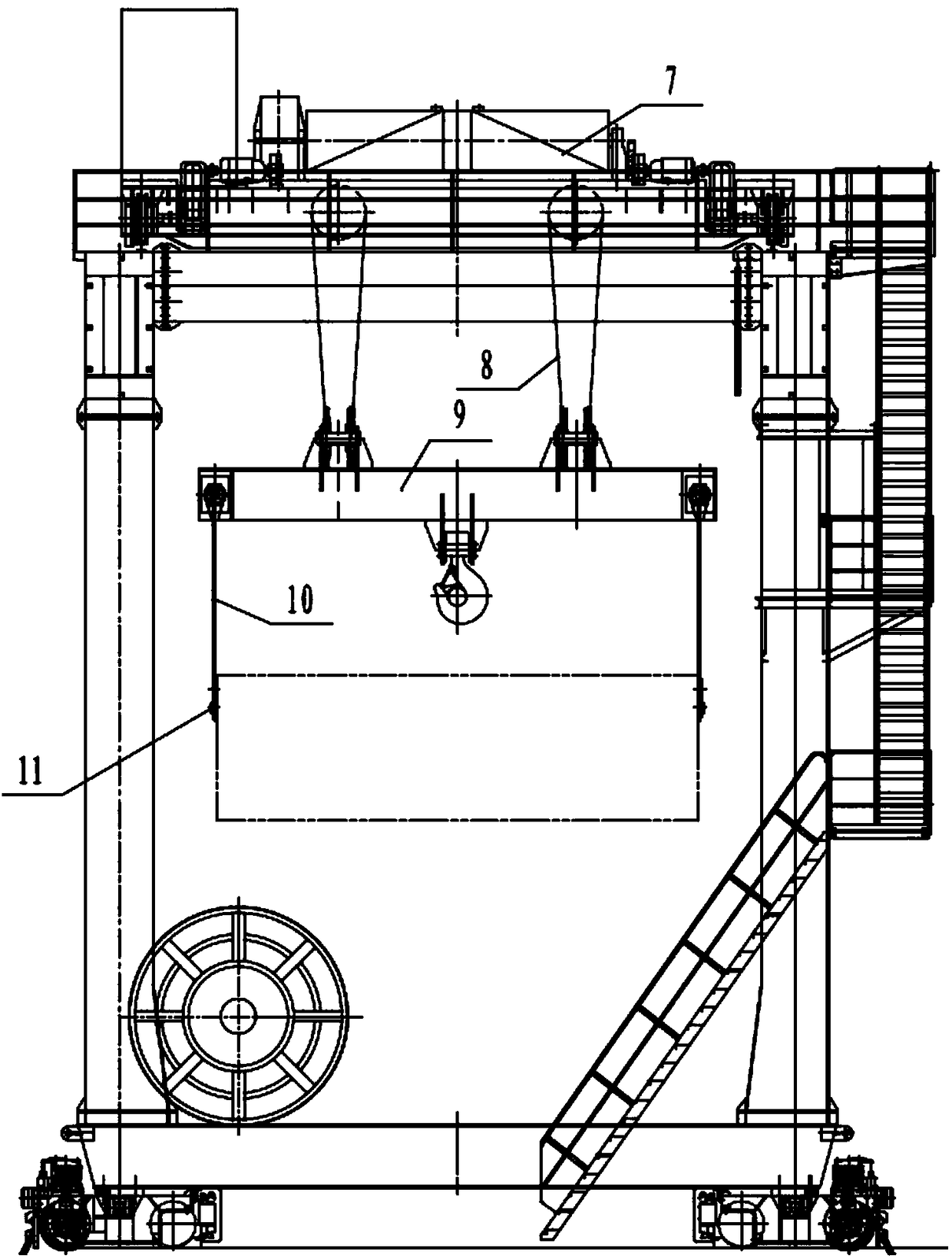

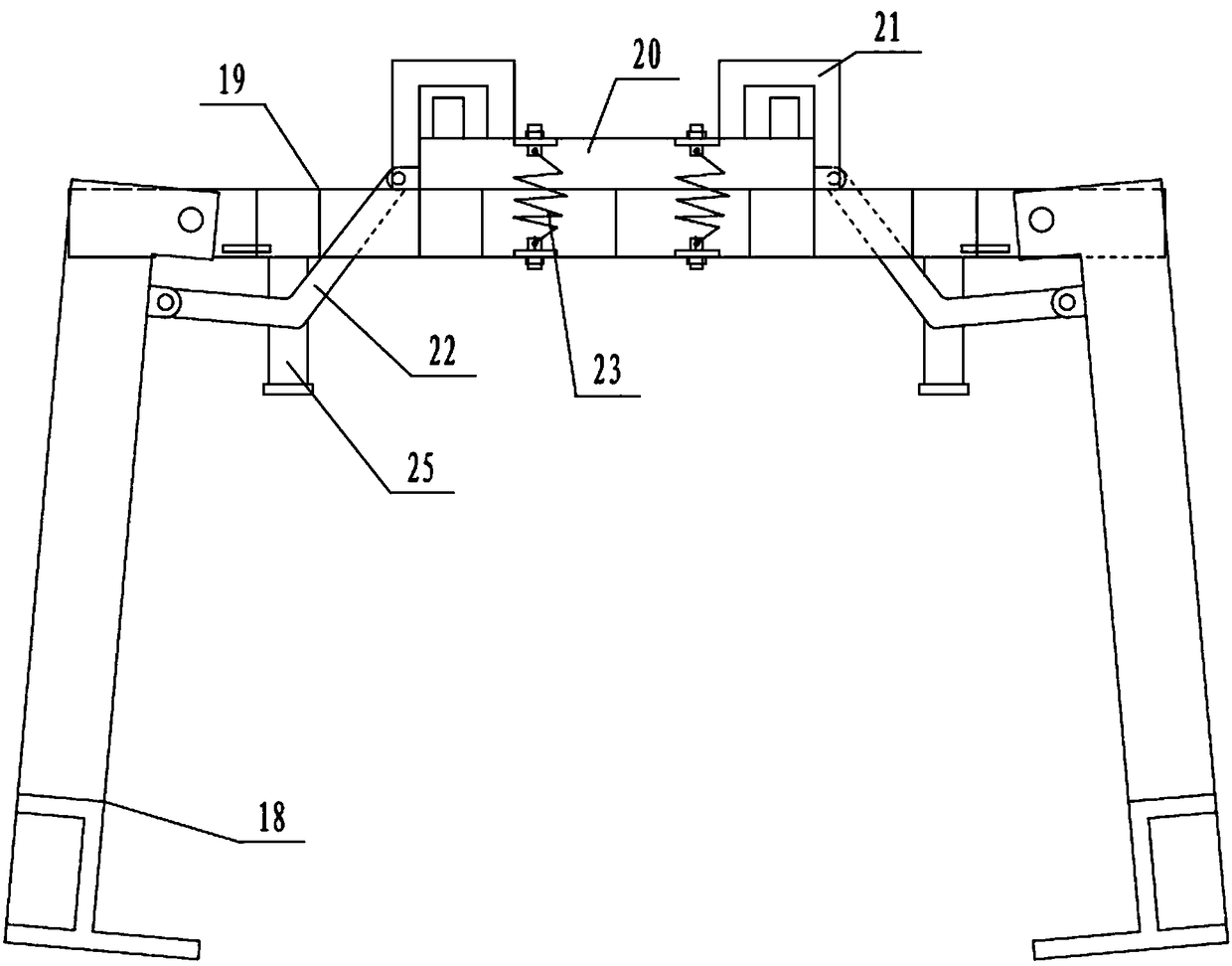

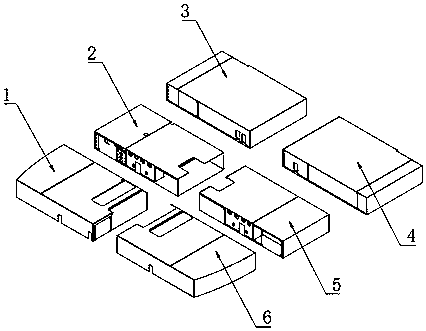

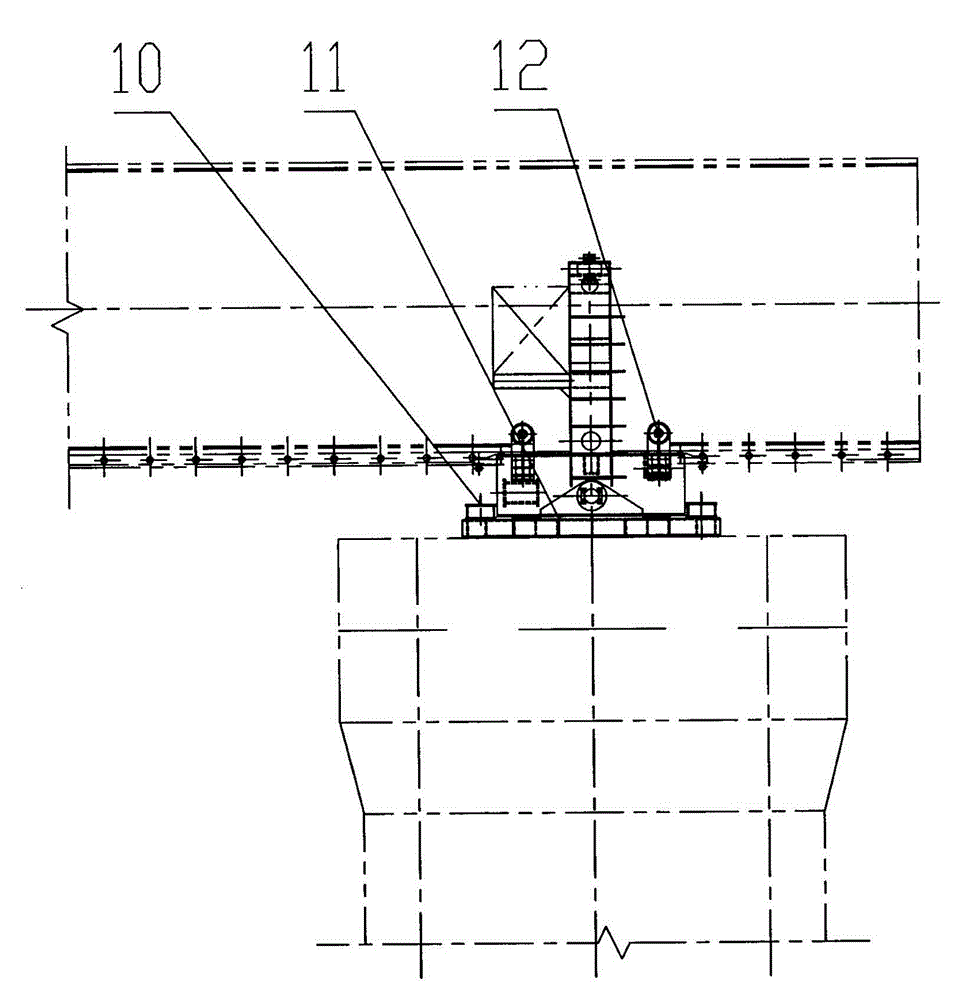

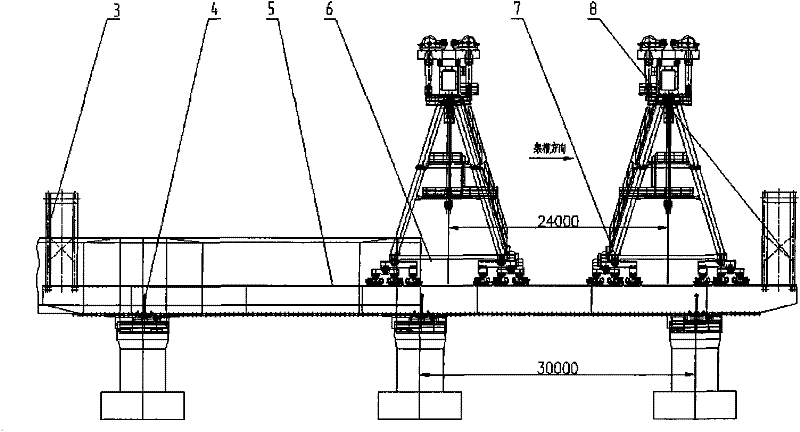

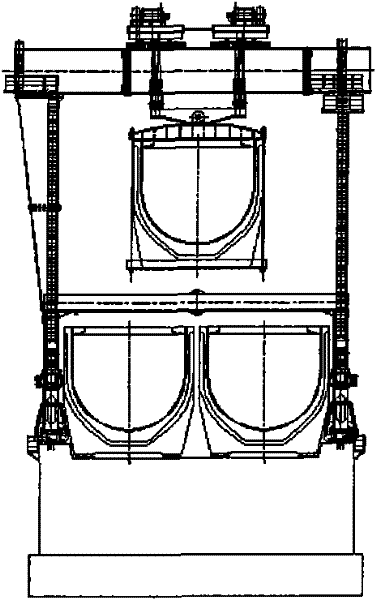

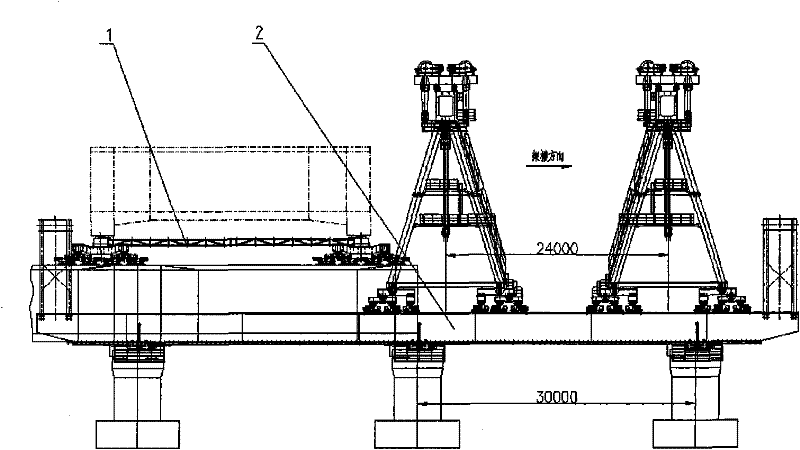

1200 tonner water conservancy aqueduct transportation and erection equipment

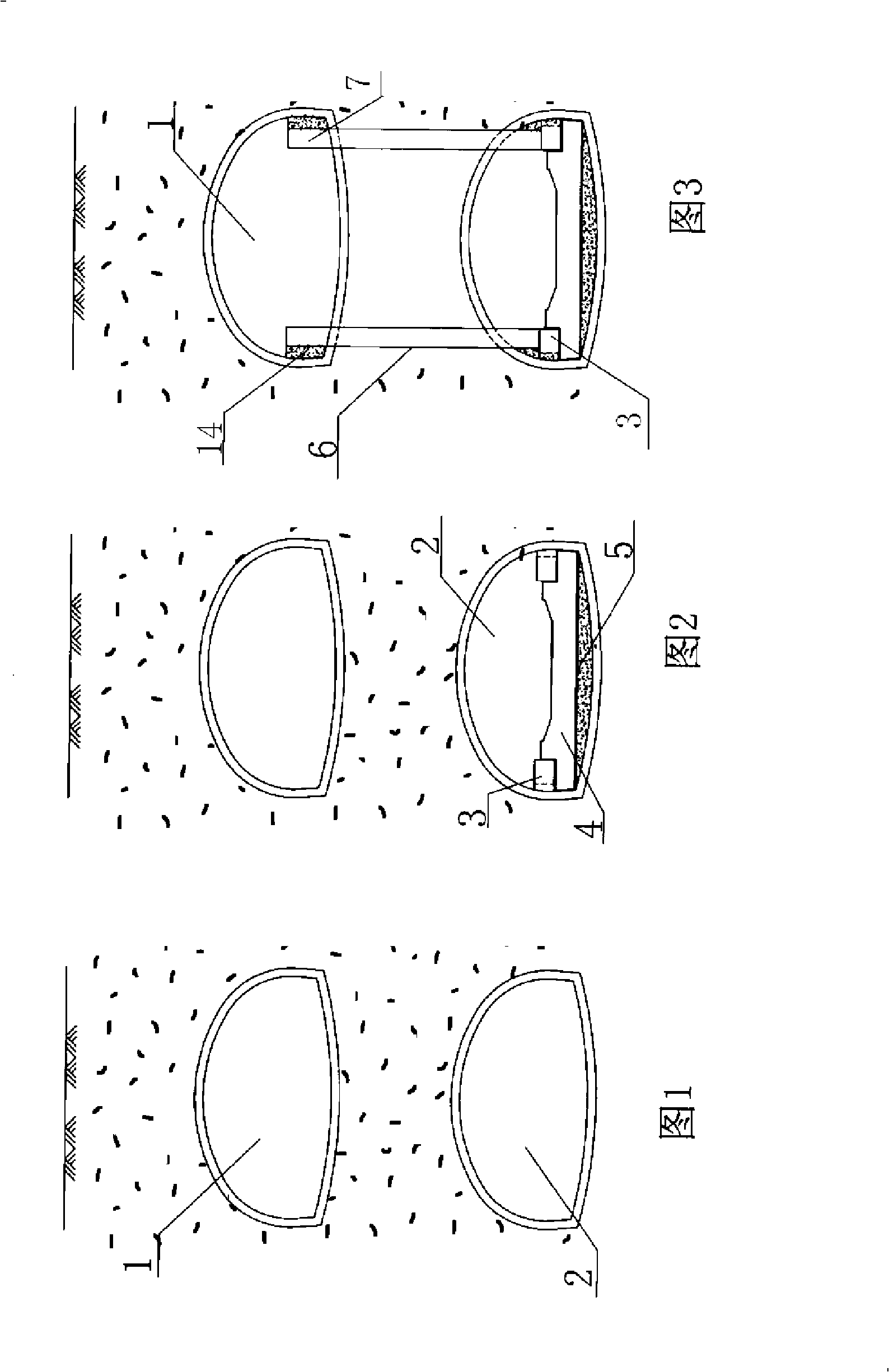

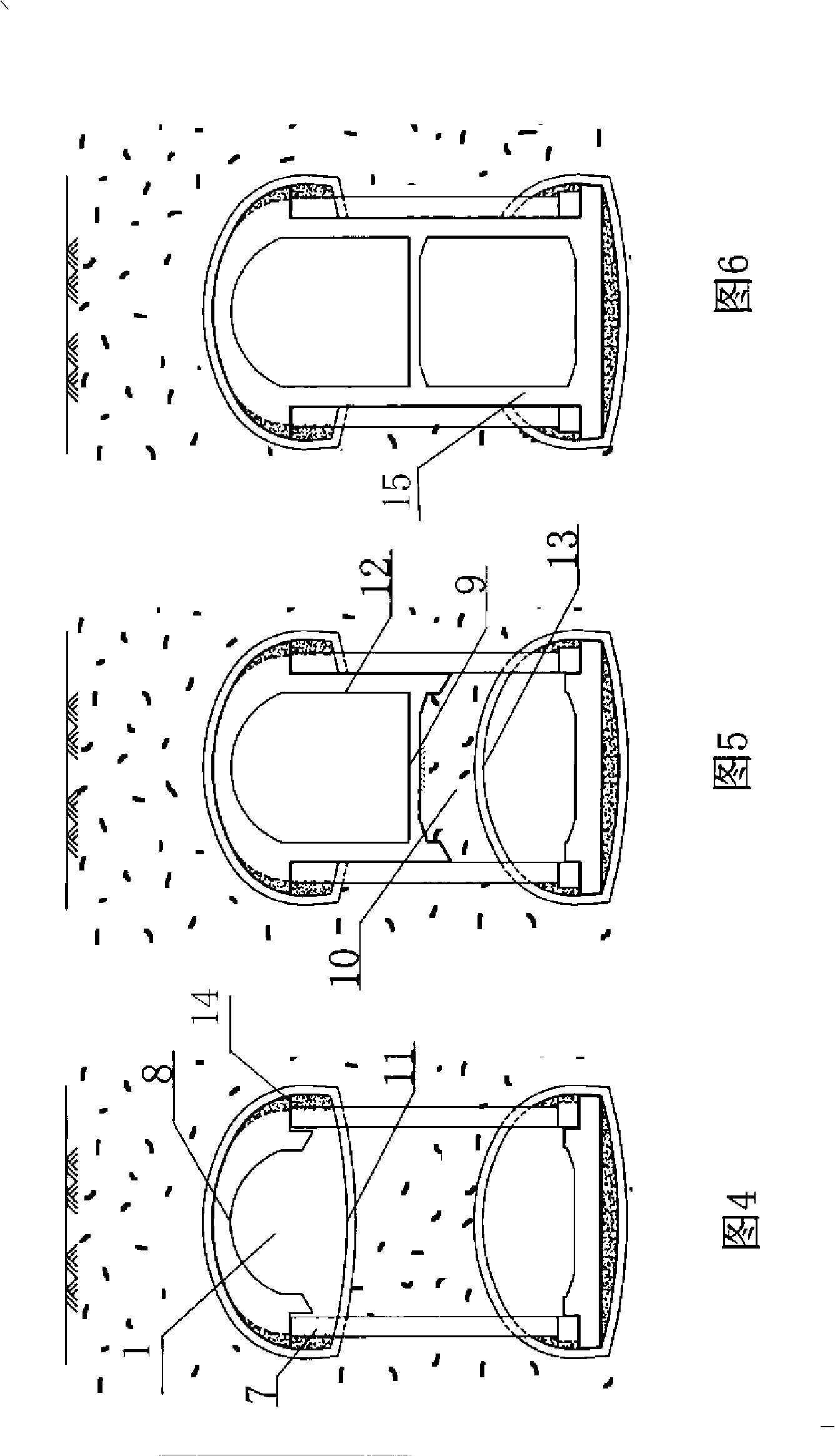

ActiveCN101831888ASave construction siteSave time for disassembly and installationArtificial water canalsBridge erection/assemblyGantry craneDouble support

The invention relates to 1200 tonner water conservancy aqueduct transportation and erection equipment which is characterized by comprising a wheel-track type aqueduct transportation vehicle (1) and an aqueduct erecting machine (2), wherein the aqueduct erecting machine (2) comprises left and right lower guide beams (5) arranged above an aqueduct pier in a parallel erecting mode through a supporting pedestal (4) as well as a lower guide beam closable connecting beam (3), a single-hanging-point aqueduct lifting gantry crane (6), a double-hanging-point aqueduct lifting gantry crane (7) and a fixing and connecting beam (8) which are sequentially arranged on the left and right guide beams (5) from front to back along an aqueduct conveying direction; and the wheel-track type aqueduct transportation vehicle (1) comprises a track sequentially arranged on the upper edge ports of the left side wall and the right side wall of the erected aqueduct along the aqueduct conveying direction from front to back, a single-support-point aqueduct transportation trolley (9) and a double-support-point aqueduct transportation trolley (11), which are capable of doing longitudinal displacement motions along the upper edge port of the left side wall and the right side wall of the aqueduct, as well as a trolley connecting beam (10) connected between the single-support-point aqueduct transportation trolley (9) and the double-support-point aqueduct transportation trolley (11) in a demountable mode.

Owner:ZHENGZHOU NEW DAFANG HEAVY IND & TECH

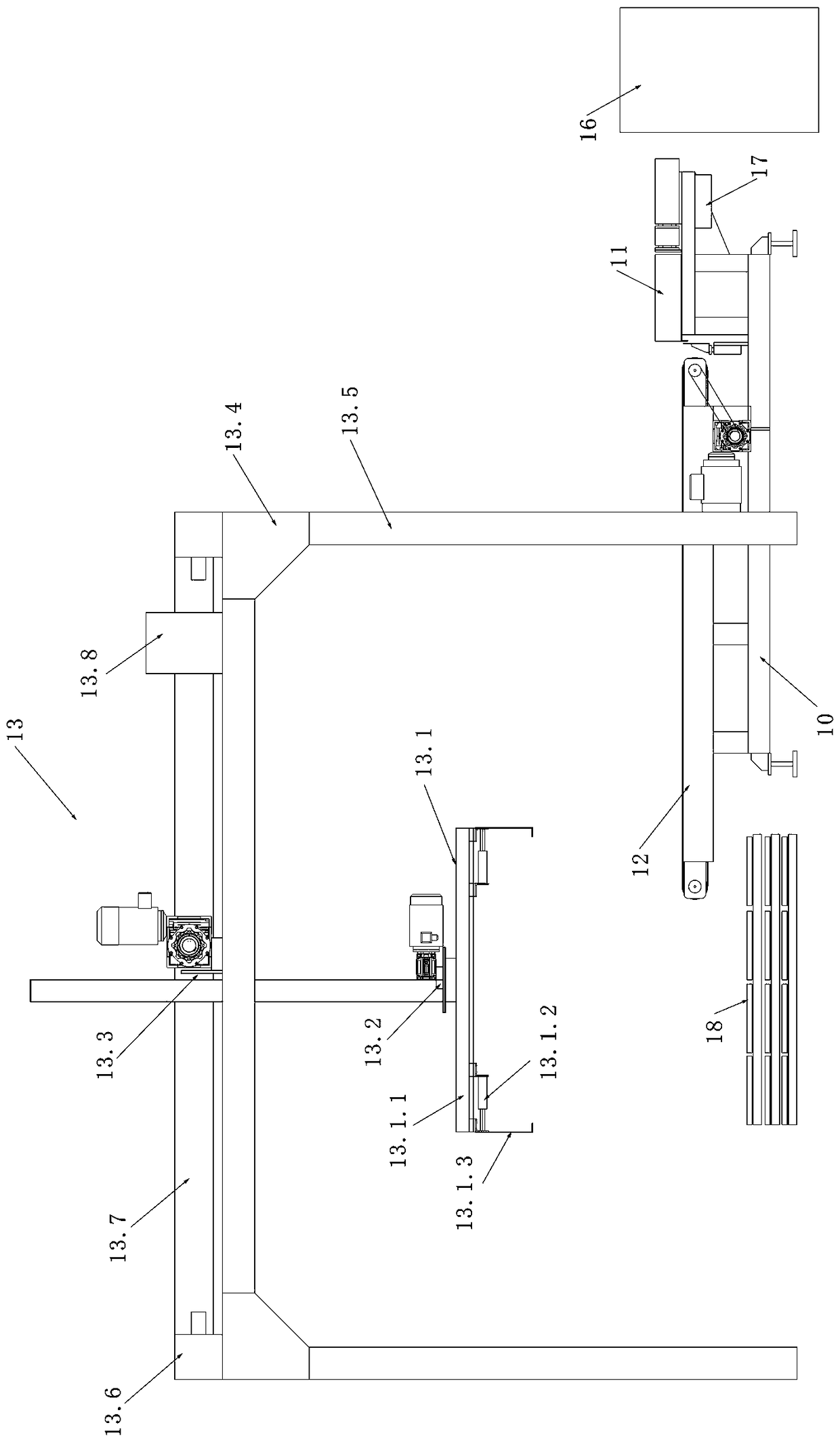

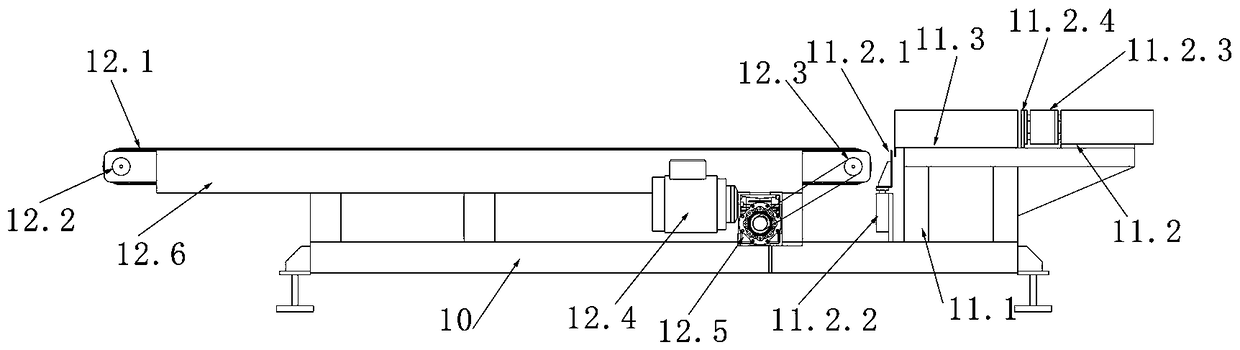

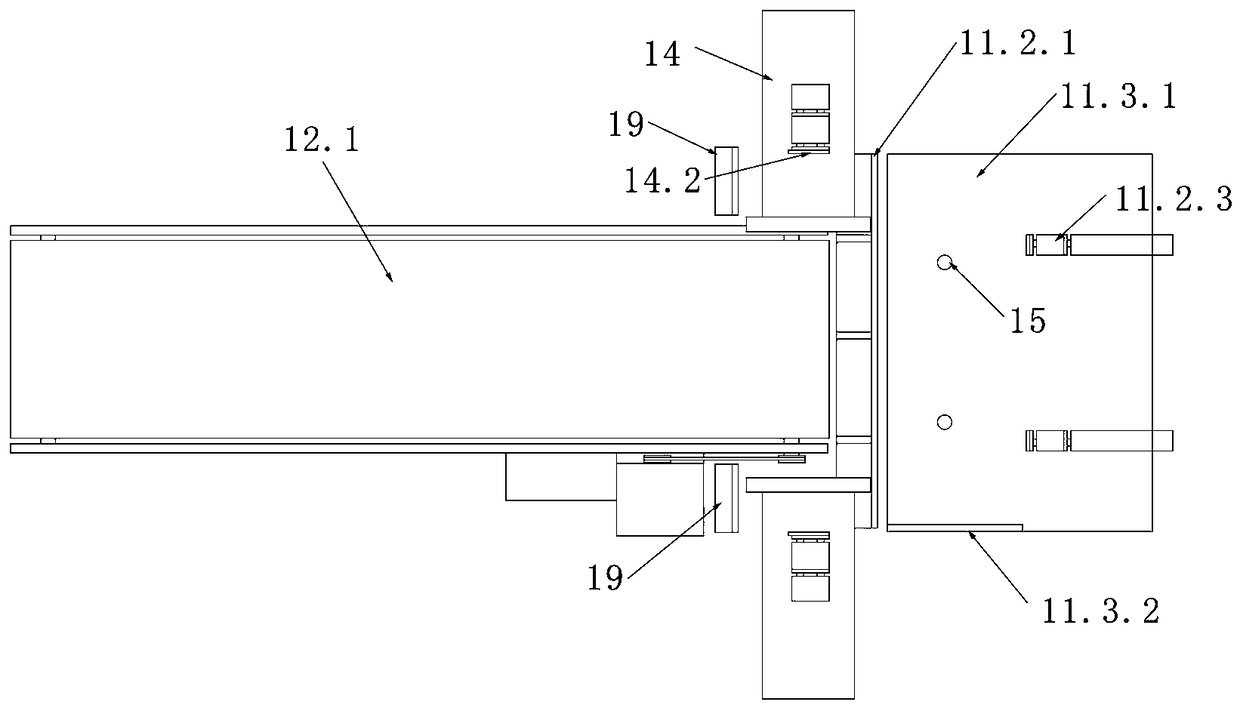

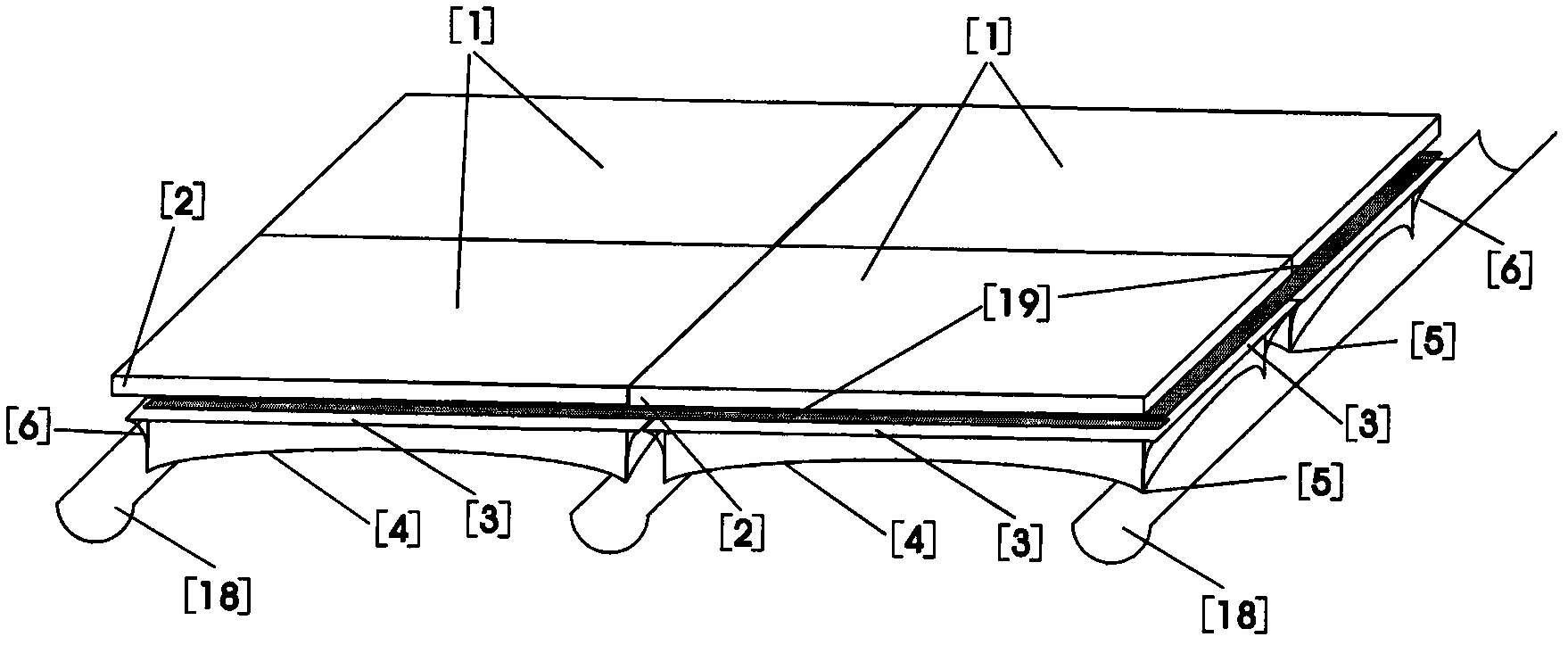

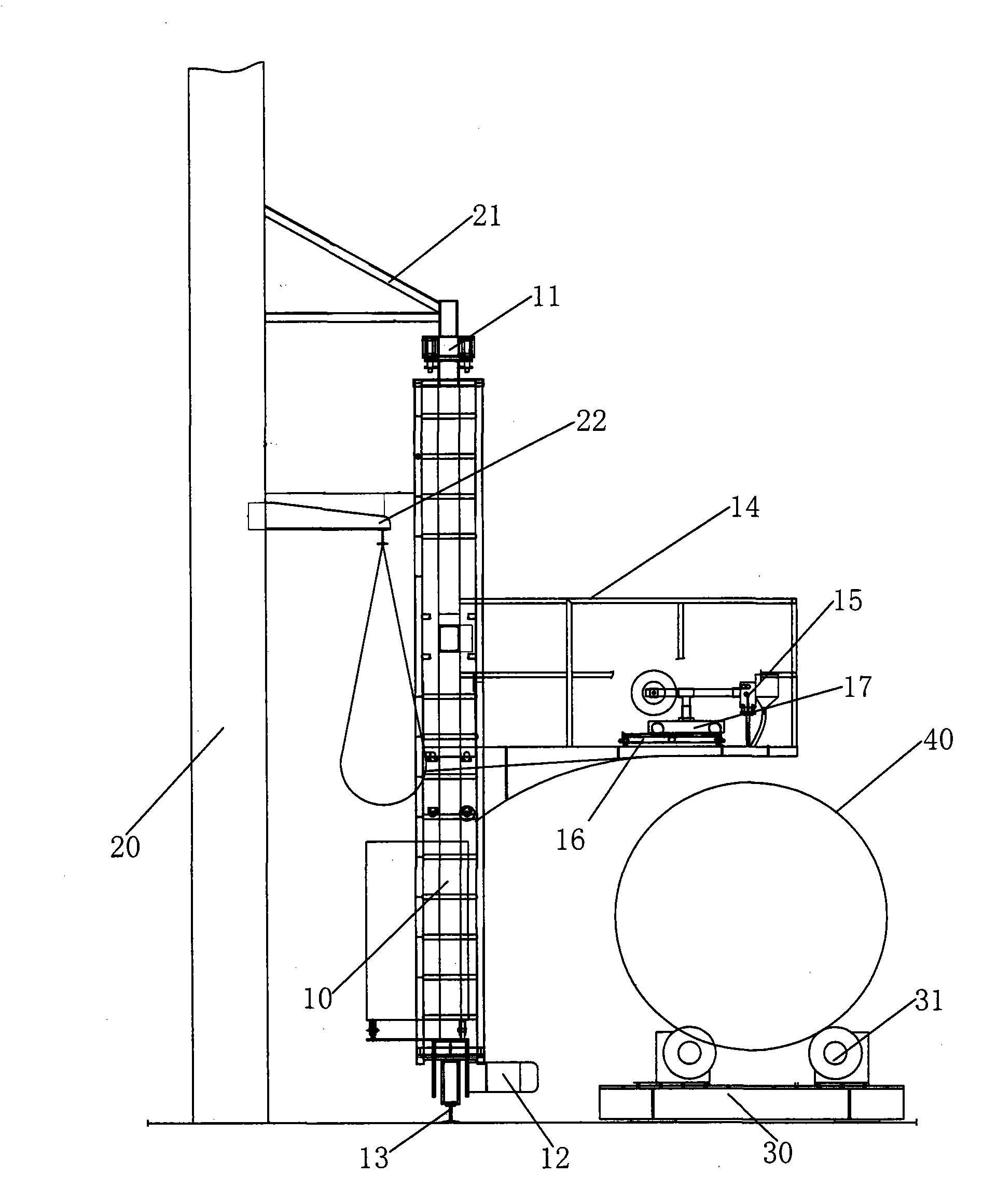

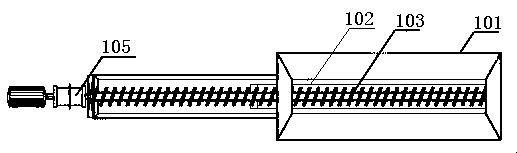

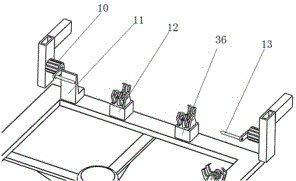

Wood floor stacking machine and floor cutting production line

ActiveCN108582266AIncrease heightEasy to useFeeding devicesPile receiversProduction lineStack machine

The invention relates to a wood floor stacking machine. The front end of a floor conveying mechanism serves as a conveying end, and the rear end of the floor conveying mechanism serves as an output end. A floor bearing mechanism is located on the front side of the output end of the floor conveying mechanism, and a stacking mechanism is located above the output end of the floor conveying mechanism.The floor bearing mechanism comprises a bearing platform frame, a first alignment device and a front bearing platform. The first alignment device and the front bearing platform are installed on the bearing platform frame, and the front bearing platform and an alignment push plate A push device are installed on the upper surface of the bearing platform frame. A first alignment baffle lifting device which is vertically arranged is installed on one side of the bearing platform frame, and a first alignment baffle is arranged on the first alignment baffle lifting device. An alignment push plate Ais arranged on the alignment push plate A push device. The invention further discloses a floor cutting production line. The wood floor stacking machine and the floor cutting production line have the following beneficial effects that the wood floor stacking machine is beneficial to increase the stacking speed and improve the stacking effect; and by the adoption of an upper-and-lower multifunctionaladjustable seamless saw, the saw cutting efficiency is improved, and the labor intensity of workers is reduced.

Owner:SHANDONG ZHONGXIN MACHINERY

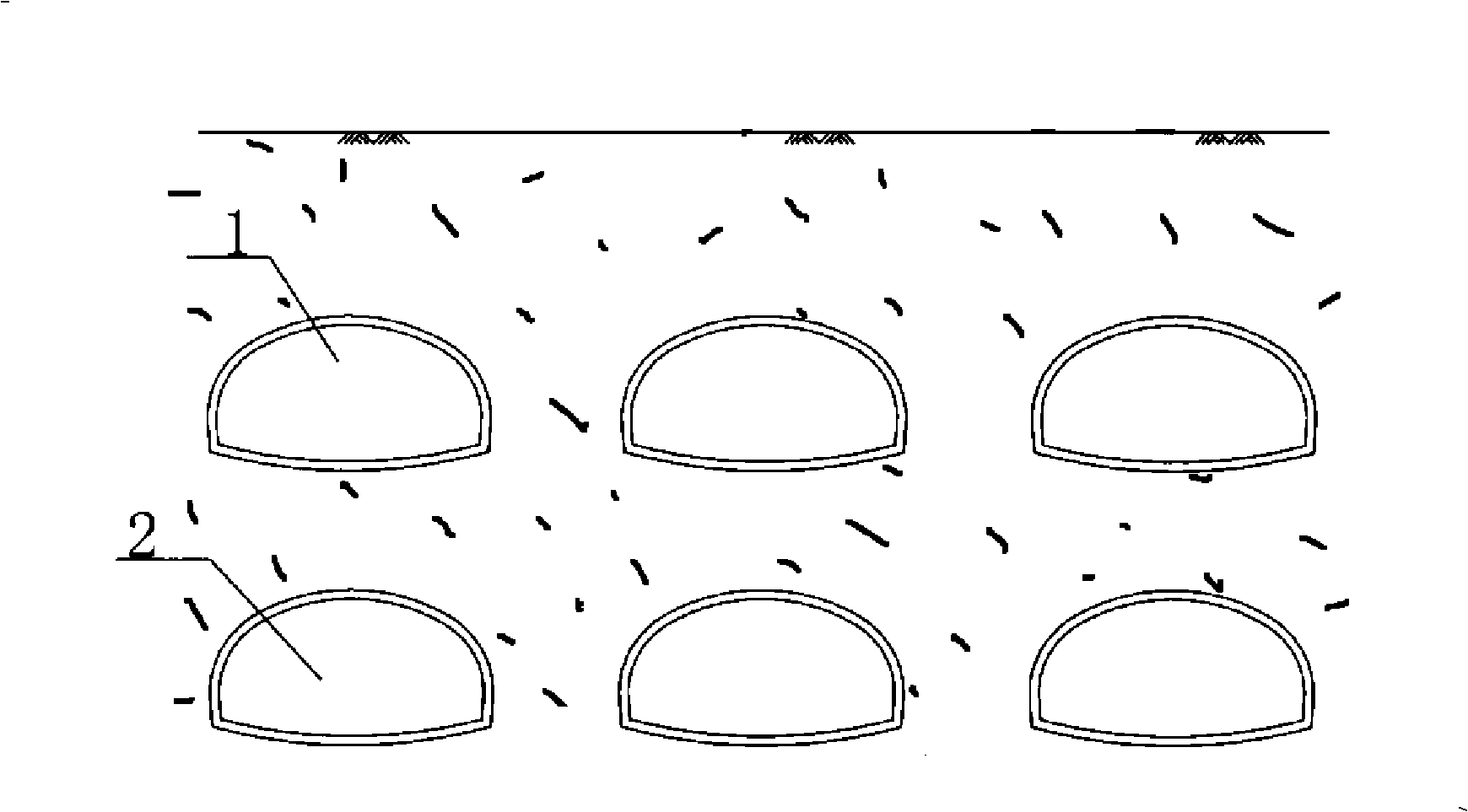

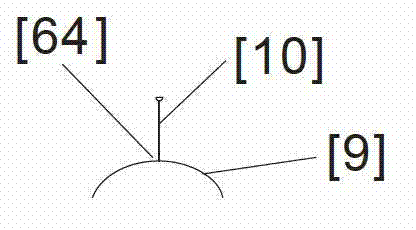

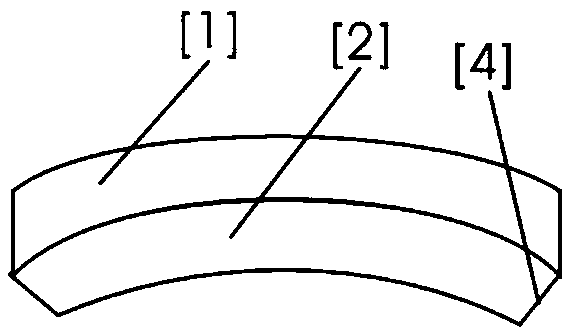

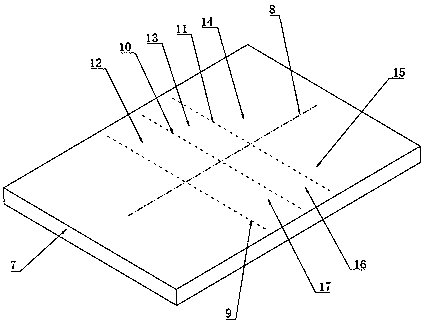

Guidance type waterproof thermal insulation system

InactiveCN102561609AReduce construction difficultyBreak through technical difficultiesRoof drainageRoof covering insulationsThermal insulationOblique line

The invention discloses a guidance type waterproof thermal insulation system, which is characterized in that thermal insulation plates with arc-shaped, spherical, U-shaped or V-shaped smooth cures or covered surfaces, oblique lines or oblique surfaces on the lower portions (skirts) or at the bottoms are mutually connected, and the smooth curves or curved surfaces, the oblique lines or the oblique surfaces serve as guide structures, water-stops, silt, concrete or waterproof materials are filled at the joints of the thermal insulation plates for sealing, rainwater is prevented from leaking from the joints to the maximum extent and led to mainly directly flow into a drainage system from the upper surfaces of the thermal insulation plates, the guide curves or curved surfaces, the oblique lines or the oblique surfaces guide the rainwater leaking from the joints or slits to flow to the lowermost positions of the guide curves or curved surfaces, the oblique lines or the oblique surfaces and then drip or flow into properly sloped or gradient U-shaped collection guide trenches, the rainwater is then centralized to flow into the drainage system, and accordingly combined construction of waterproof and thermal insulation works is achieved. The guidance type waterproof thermal insulation system has low requirements on construction sites, process and weather, the waterproof duration is long, standard parts of the system can be prefabricated, moulds can be used for in-situ casting of the system, and construction difficulty and production cost are reduced greatly.

Owner:龙宏元

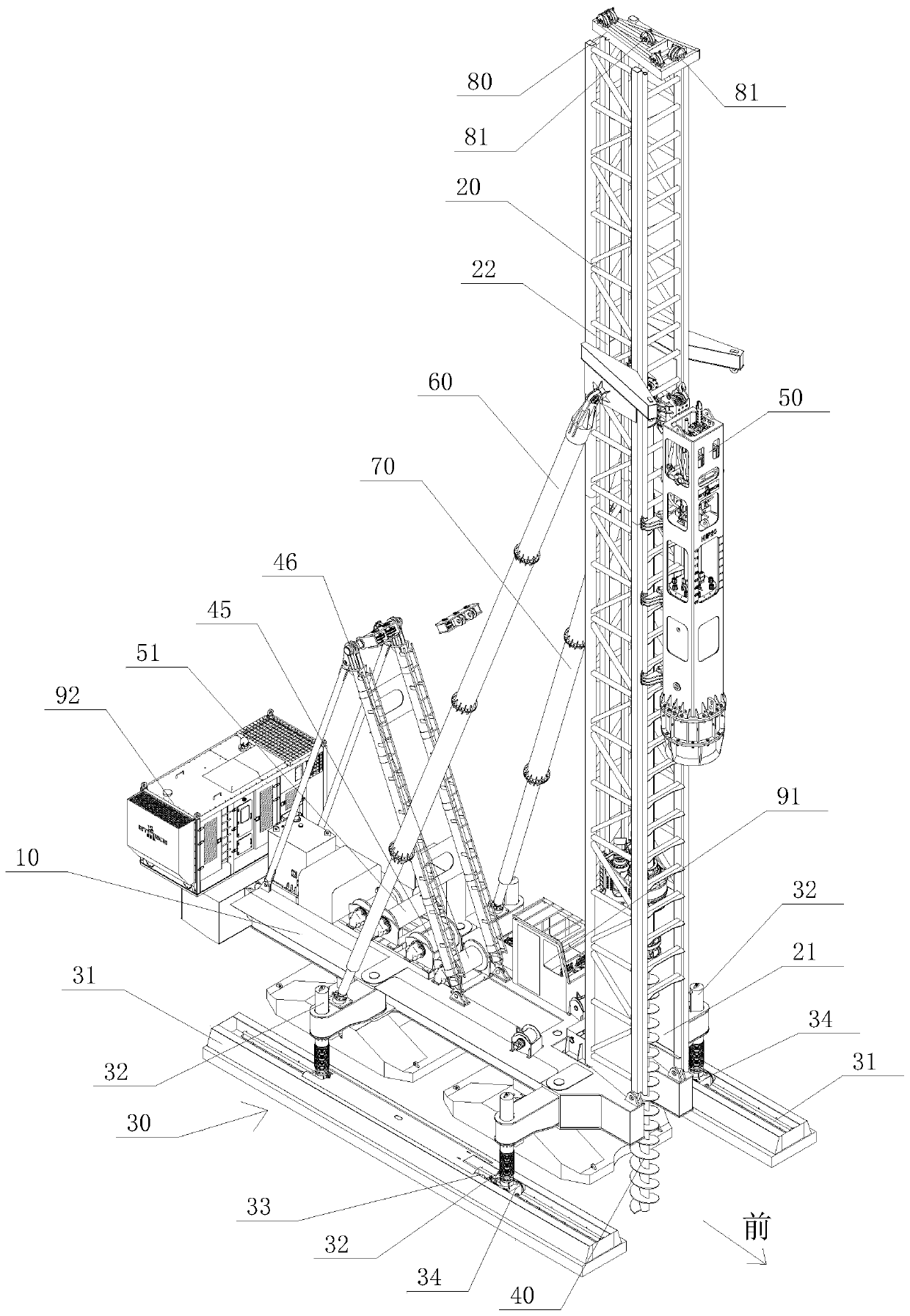

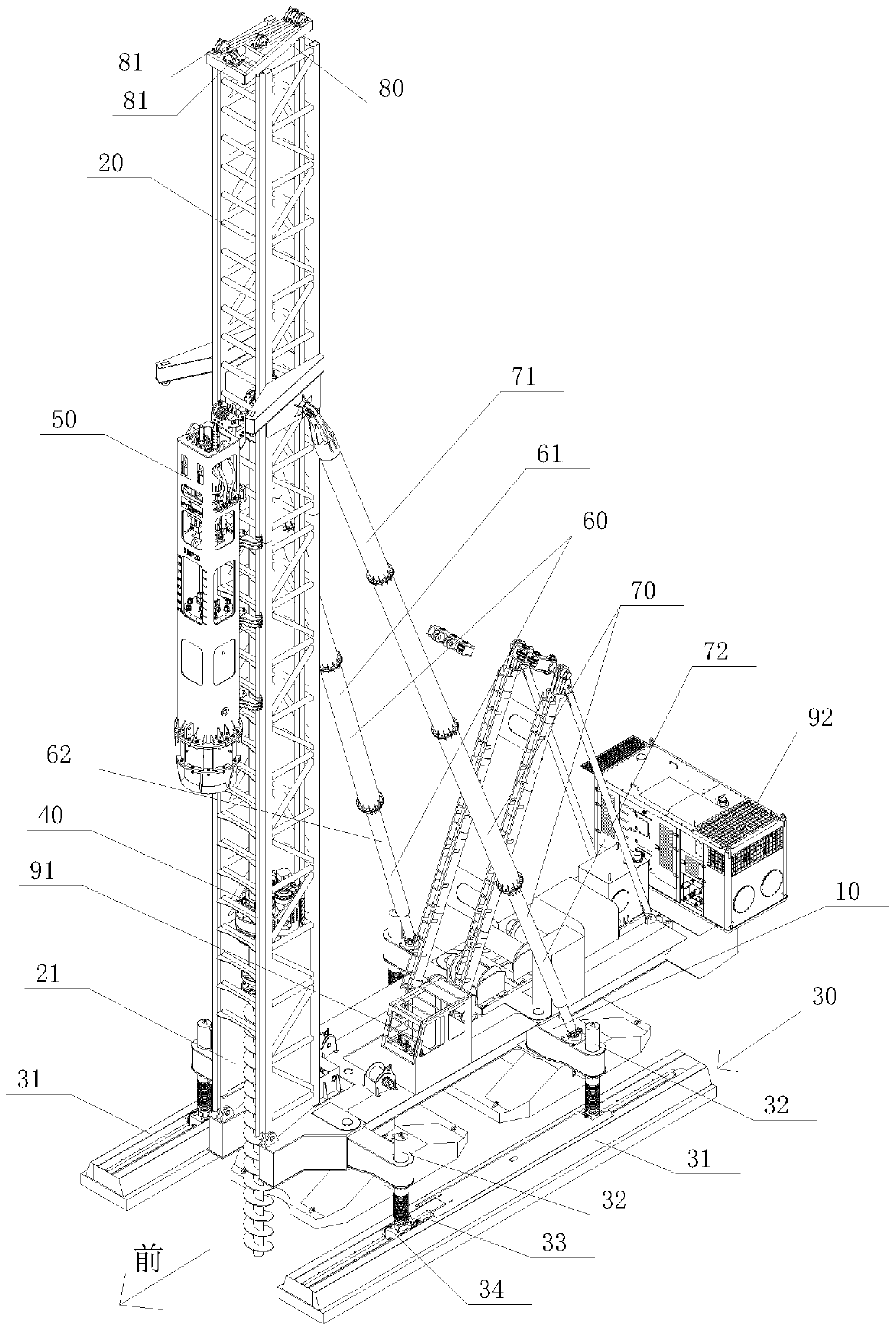

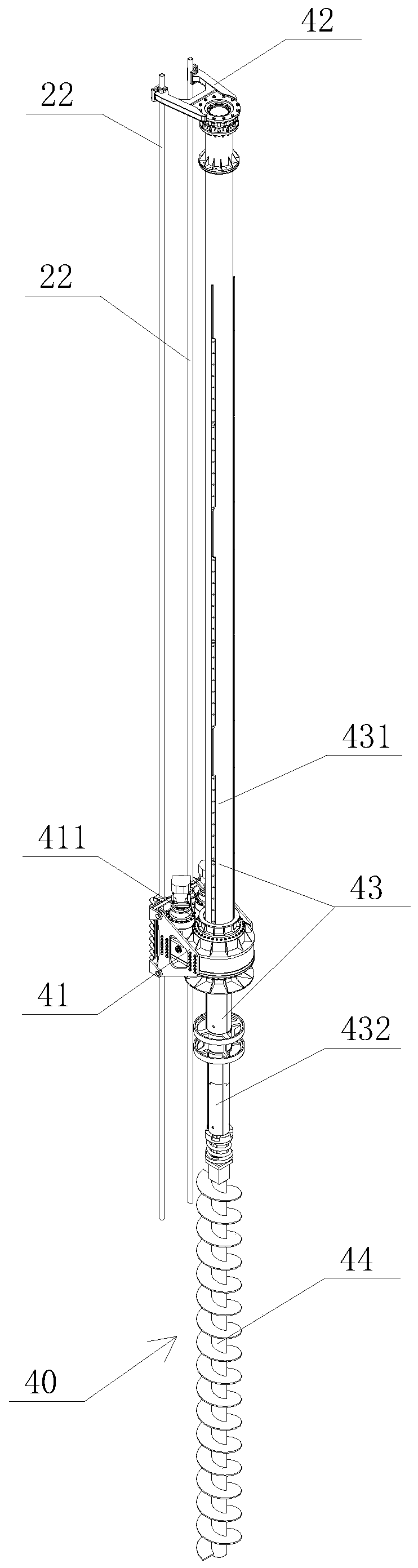

Construction method of big-diameter PHC prefabricated pipe pile and piling machine for implementing method

PendingCN110952552APrecise control of tilt angleSolve difficult-to-sink problemsBulkheads/pilesTowerPipe

The invention discloses a construction method of a large-diameter PHC prefabricated pipe pile. The method comprises the following steps of putting the piling machine in place; regulating an inclination angle; mounting the large-diameter PHC prefabricated pipe pile; performing hammering pile conveyance through a soft soil layer; aligning a guide hole; internally drilling the guide hole; performinghammering alignment; and performing hammering pile conveyance to a hard soil layer. The invention also discloses piling equipment for implementing the method. A hammering mode is used for pile foundation construction in the soft soil layer of a foundation; a large-diameter PHC pipe pile is sunk into the soft soil layer; the lateral friction resistance between the upper part of the pile foundationand the soft soil layer is ensured; the bearing force of the pile foundation is improved; a mode of firstly forming the guide hole and then performing hammering is used on the hard soil layer of the foundation; the problem of a plugging effect of the hard soil layer on the large-diameter PHC pipe file is solved, so that the large-diameter PHC pipe pile can be smoothly sunk into the hard soil layer; by regulating the inclination angle of a tower frame, the inclination angle of the large-diameter PHC pipe file is accurately controlled; and the precise and high-efficiency construction of the large-diameter PHC pipe file with the set inclination angle is realized.

Owner:GUANGDONG LIYUAN HYDRAULIC MACHINERY

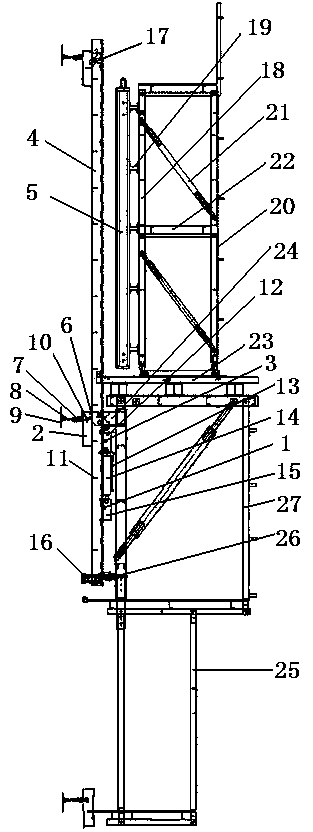

Coastal environment high pier hydraulic self-creeping formwork construction method

PendingCN111119060AEasy to operateImprove securityBridge structural detailsBridge erection/assemblyPurlinShaped beam

The invention discloses a coastal environment high pier hydraulic self-creeping formwork construction method. The method comprises the steps of tower column starting section construction, tower columnfirst section construction, hydraulic creeping formwork installation, tower column second section construction, tower column remaining section construction and creeping formwork removal, the hydraulic creeping formwork comprises an embedded part mechanism embedded in a high pier wall, and a frame body mechanism comprises a lower hanging bracket and a bearing frame; the formwork installation comprises a formwork consisting of a panel, a woodworking I-shaped beam and a steel enclosing purlin, a movable template bracket and a backward moving device; a hydraulic power mechanism comprises an upperreversing box, a lower reversing box, a hydraulic pump and a hydraulic oil cylinder which are connected with the guide rail in a sliding manner; the guide rail is composed of two steel channels and guide rail stair stops, and the upper reversing pawl of the upper reversing box and the lower reversing pawl of the lower reversing box are arranged between the guide rail stair stops. The constructionmethod is convenient to operate, high in safety and convenient to construct, working hours and construction sites are saved, and formwork bumping damage is reduced; and the formwork is recycled, theworkload of hoisting machinery is greatly reduced, and the construction process is stable, synchronous and safe.

Owner:YANJIAN GRP CO LTD +1

Prepressing method of flushing type bridge rubber raft

ActiveCN105369738AAchieve recyclingGood value for moneyBridge erection/assemblyBridge materialsPlate pressureWater source

The invention discloses a prepressing method of a flushing type bridge rubber raft. The prepressing method comprises the following steps: (1) preparatory work; (2) water bag arrangement: marking out in a bottom plate pressure test region according to the sizes and quantity of water bags in the scheme; and sequentially placing the water bags from the low end of a box girder bottom plate to the high end of the box girder bottom plate; (3) measuring tool mounting: mounting a water meter, which is used for recording the amount of delivered water, on a main pipe of each water point, assigning a designated person to each water point for recording data during step loading and adding the amounts of water of the water points to reach a prepressing value; (4) water source connection; and (5) step loading: stacking the water bags of which the weight is 1.2 times the load of a girder span on an erected support according to weight distribution conditions of girder section concrete just above the support, carrying out step prepressing for 72 hours, and observing subsidence by using a level gauge. By the prepressing method of the flushing type bridge rubber raft, continuous prepressing of the flushing type bridge rubber raft and recycling of water can be realized, and the cost-performance ratio is high.

Owner:WUHAN YIYE CONSTR ENG

Flow-guiding waterproof technology

InactiveCN103206048AReduce the difficulty of engineering constructionReduce manufacturing costRoof covering using slabs/sheetsRoof drainageStreamflowWetting

The invention discloses a flow-guiding waterproof technology. Flows leaked from the rooftop or outer wall connecting portions and gaps and leaking rainwater with slow flow rate are guided by a hydrophilic flow-guiding curved surface with a downward opening or an inclined surface to flow to preset drainage facilities or the lowest portions of the flow-guiding curved surface or the inclined surface and then drained out of the outer wall, and the leaking rainwater are all drained out through any wetting and flowing drainage structure and a hydrophobic drainage surface or an inclined surface in the drainage facilities used for stopping the leakage of rainwater, so that waterproof task is completed. With the flow-guiding waterproof technology, technical difficulty of building waterproof construction is solved, strict prevention and tight blocking in the past waterproof construction is developed into combination of blocking and unblocking, engineering construction difficulty and production cost are greatly reduced, the problems that short waterproof year, construction difficulties and high requirements to weather and the like are solved; and the flow-guiding waterproof technology can be used for standardized production of prefabricated parts and pouring on site with molds.

Owner:龙宏元

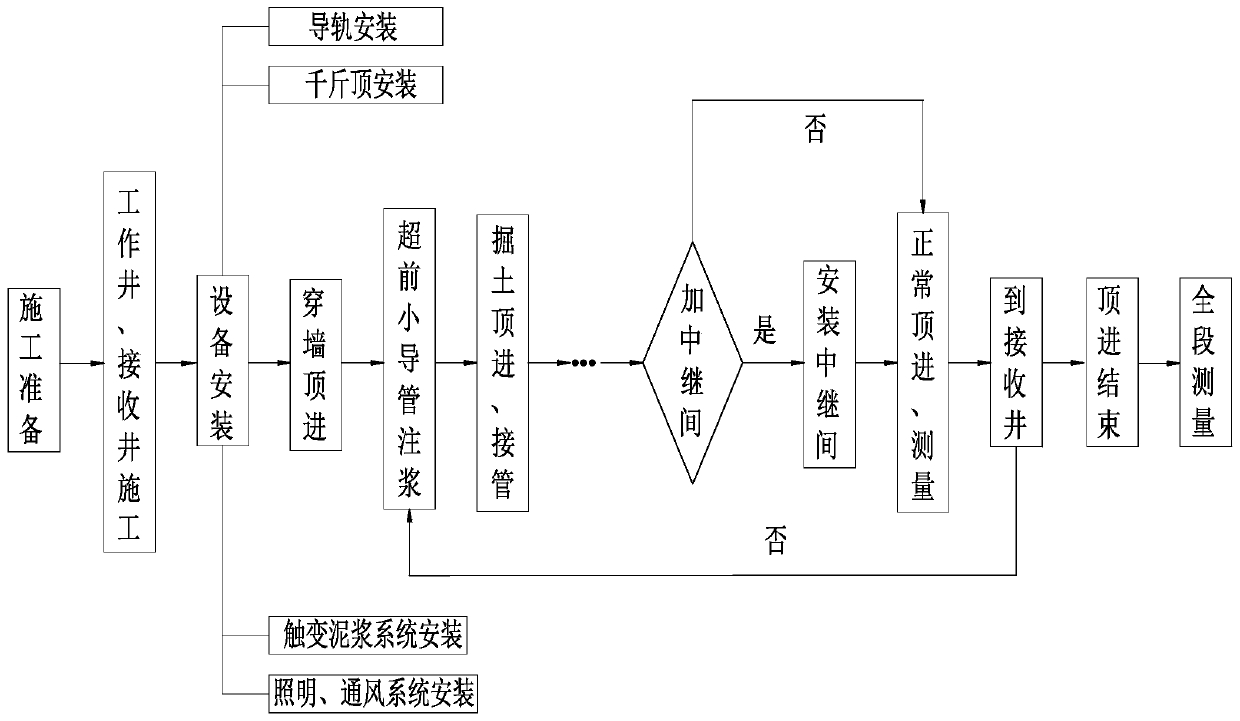

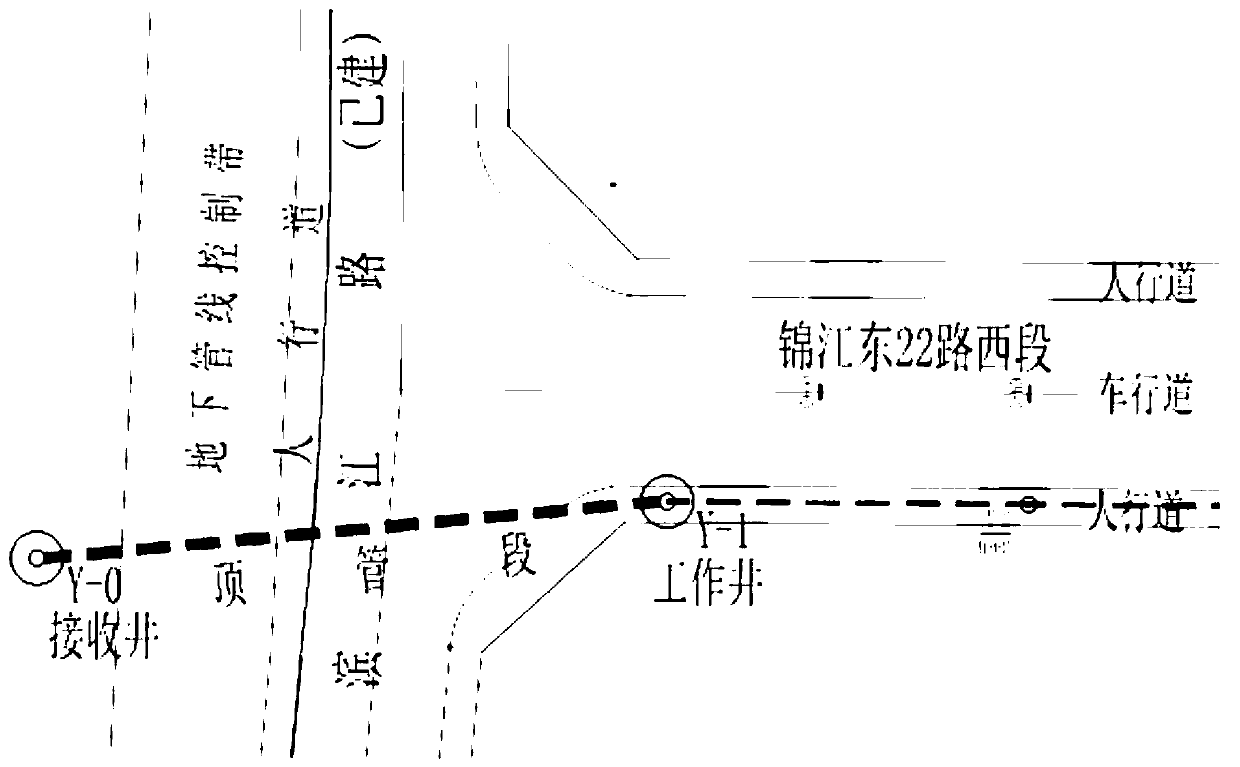

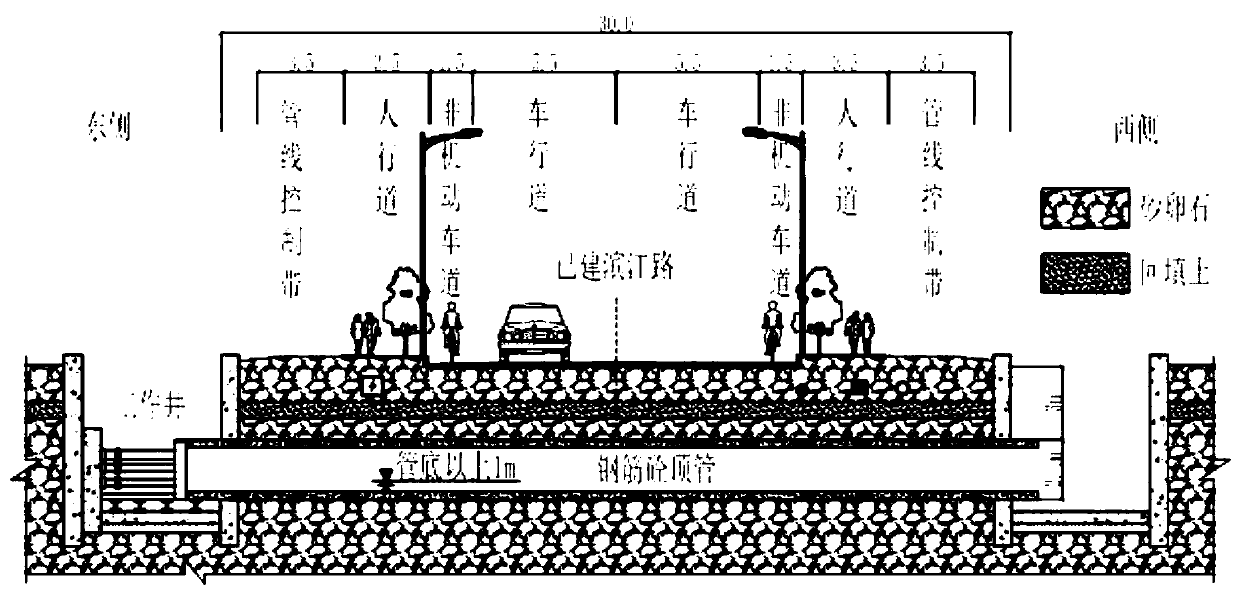

Manual pipe-jacking construction method for shallow covering large-pipe-diameter high-water-level pipe beneath existing road

PendingCN110359540AReasonable designReduce frictional resistancePipe laying and repairFoundation engineeringWork periodGround subsidence

The invention discloses a manual pipe-jacking construction method for a shallow covering large-pipe-diameter high-water-level pipe beneath an existing road. The manual pipe-jacking construction methodfor the shallow covering large-pipe-diameter high-water-level pipe beneath the existing road comprises the following steps that conducting preparation for construction, determining a dewatering scheme, reasonably arranging a dewatering well, digging a pipe-jacking work well, constructing a back wall, installing pipe-jacking equipment, conducting advanced ductule grouting, conducting digging and jacking construction, conducting post-grouting construction and monitoring ground subsidence. The manual pipe-jacking construction method for the shallow covering large-pipe-diameter high-water-level pipe beneath the existing road has the beneficial effects that the construction site is small, the existing road and underground pipelines are prevented from being damaged, recovery is not needed, resource waste is completely eradicated, construction procedures are reduced, the comprehensive cost is effectively lowered, and the work period is effectively shortened; and meanwhile, manual pipe jacking causes quite little disturbance in a pipeline foundation, and therefore the foundation bearing cavity and stability are guaranteed after pipeline installation.

Owner:CHINA RAILWAY CONSTR GRP BEIJING ENG CO LTD +1

Pipeline provided with connecting components and manufacturing method thereof

InactiveCN101373032ANot affected by curing timeImprove connection strengthRigid pipesMechanical engineeringIndustrial engineering

The invention relates to a pipeline with connecting components and a production method thereof. The pipeline comprises transverse pipeline boards and longitudinal pipeline boards for splicing the pipeline. The pipeline board is formed by combining an outer layer, a core layer, and an inner layer; connecting bases are fixedly arranged on the pipeline boards at least in one direction; and the adjacent pipeline boards are connected by connecting pieces, which penetrate the pipeline boards and are inserted into the connecting bases of the adjacent pipeline boards. In addition, the invention also provides the production method based on the structure. The invention has the advantages that (1) by adopting the means of relying on connecting pieces for fixed connection together with the means of adhesion, the invention saves splicing time, avoids the influence of colloid solidification time and reduces construction area; (2) by adopting the components composed of the connecting pieces and the connecting bases, the invention effectively increases connection strength and improves production efficiency; and (3) the production method is easy and the operation is reliable.

Owner:支亮

Welding method and welding device for outer ring weld joints of steel pipe piles

InactiveCN104227197AReasonable designFlexible operationWelding/cutting auxillary devicesArc welding apparatusButt jointEngineering

The invention relates to a welding method and a welding device for the outer ring weld joints of steel pipe piles. The welding method comprises the following steps: the butted steel pipe piles are placed on a rotary support device, a movable operating platform is adopted, and welding equipment is arranged on the movable operating platform and conducts outer ring weld joint welding operations above or beside the butt joints of the steel pipe piles. The welding method and the welding device for the outer ring weld joints of the steel pipe piles are reasonable in design and flexible to operate, and are adapted to simple and fast up-and-down adjustment of steel pipe piles of different diameters; and the welding equipment moves fast, is simple and convenient to operate, has stable properties, relieves the labor intensity of operators, improves the working efficiency and the welding quality, fully utilizes the height of the space in a workshop, and saves the ground construction field.

Owner:天津港航安装工程有限公司

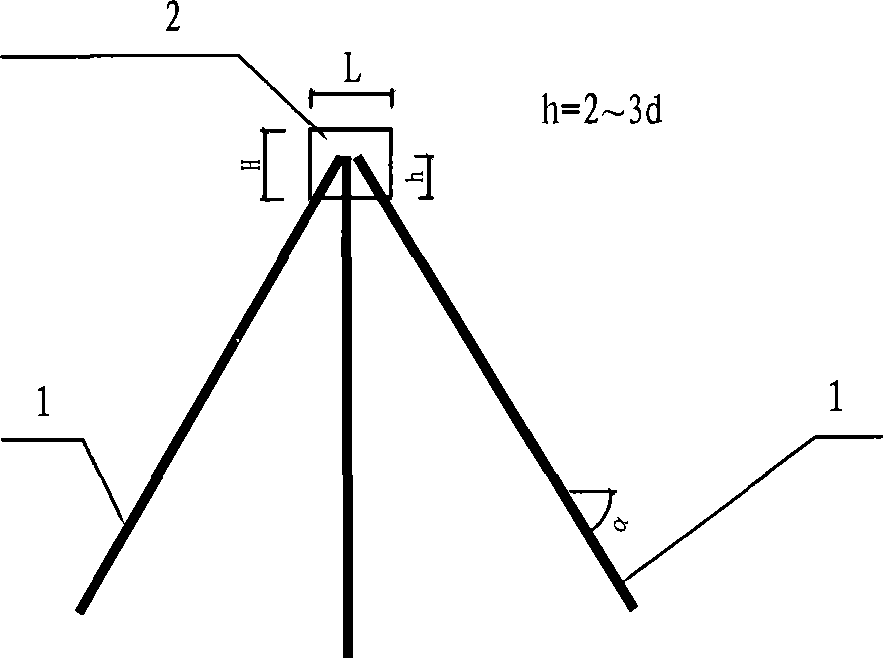

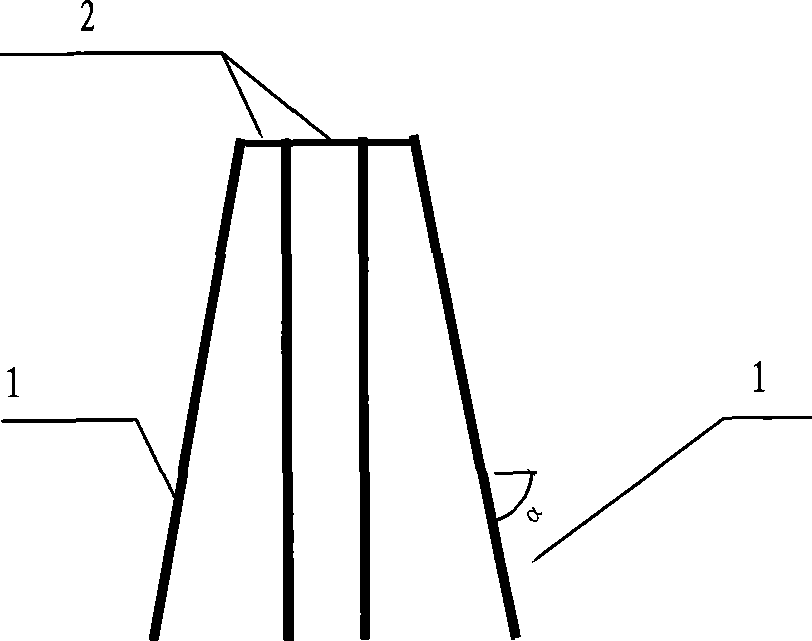

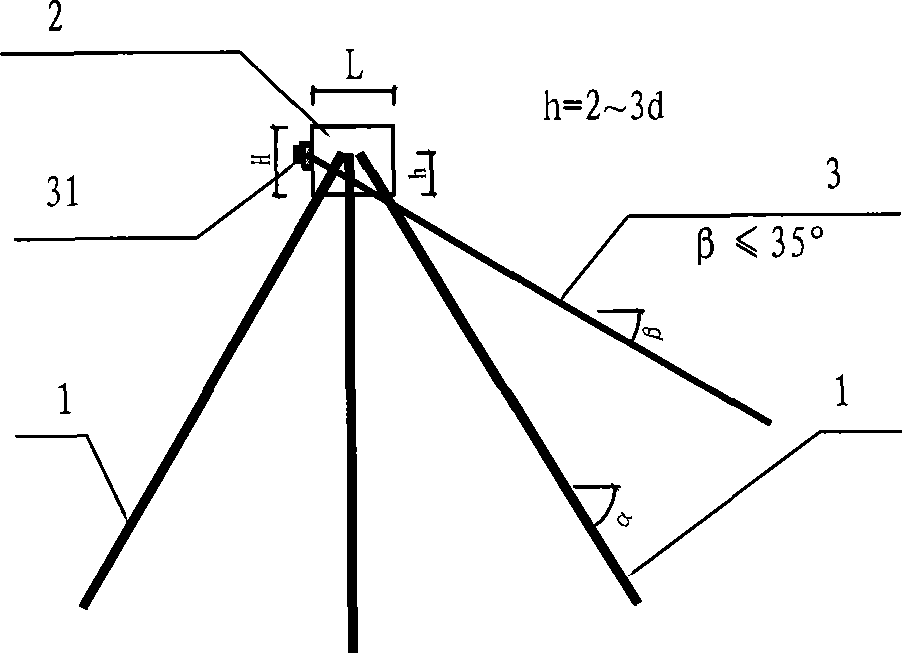

Anchor pipe skeleton and its support method

The invention discloses an anchor pipe timber support and a timbering method. The timbering method includes the following steps: (a1) fixing the place on a slope for an anchor pipe timber support and setting aside a place for a construction platform through temporary brushing and filling; and (a2) constructing an anchor pipe timber support on the construction platform, including: (a21) boring a plurality rows of holes on the strong-strength layers with good stability in different angles on the construction platform, (a22) placing reinforcement ribs in the plurality rows of holes, (a23) injecting slurry in the plurality rows of holes in which the reinforcement ribs are placed to form a plurality rows of steel tube piles, and (a24) building a top beam for the timber support at the top parts of the plurality rows of steel tube piles and prearranging anchorage cable holes. The main body of the anchor pipe timber support can be constructed mechanically; the construction is quick, safe and reliable and cannot cause big damage to the environment; the construction plant is small and after the project is finished, the ecology can be recovered. In addition, the whole body of the anchor pipe timber support bears stress, so the anchor pipe timber support is more reasonable in stress strain and is more reliable.

Owner:NORTHWEST RES INST CO LTD OF C R E C

Shield muck treatment method and equipment

PendingCN109761396ASave water for cleaningAvoid pollutionMultistage water/sewage treatmentFlocculationBelt filter

The invention discloses a shield muck treatment method and equipment. The method comprises the steps that stones, sand and mud in the muck transported out in the shield construction process are subjected to vibrate separation under impact of water, the separated big sand is accumulated concentratedly through conveying equipment, meanwhile the separated thin sand and mud mixture is subjected to twisting separation, the thin sand is discharged, the separated mud is subjected to one flocculation treatment through a flow guiding tank or pipe, the mud subjected to flocculation treatment settles ina mud pool so as to separate mud and clear water, the clear water is drained into a clear water pool to serve as construction recycling water, the mud is pumped into a con ave-convex mud conveying pipe to be subjected to second flocculation treatment, and the mud subjected to second flocculation treatment is sent into a belt filter press to obtain dry mud cakes. The solid-liquid separation effectof the equipment is good, the automation degree is high, shield construction water is recycled, cleaning water for externally transported mud is greatly reduced, water is saved by50% or above in the whole construction process, and city pollution brought by external transportation of shield muck is thoroughly solved.

Owner:邓为成

Novel scaffold putting-up robot

InactiveCN104612400AQuick and automatic buildEfficient and automatic constructionBuilding material handlingComputer moduleEngineering

The invention discloses a novel scaffold putting-up robot which comprises a storage and separation module, a transfer module and a putting-up module. The storage and separation module is formed by a single-tube separation mechanism and an adjusting alignment mechanism, and therefore cross rods can be stored and output quantitatively in a directional mode. The transfer module can transfer the output cross rods to the putting-up module. The putting-up module can finish putting up a scaffold. The robot mainly aims at the direct inserting type scaffold, is capable of finishing putting up the scaffold fast, improves the scaffold putting-up efficiency, saves labor force, and is capable of meeting the technical requirement of engineering construction.

Owner:胡镔

Long-span steel structure corridor construction method

ActiveCN103061514AStable structureReasonable designBuilding material handlingArchitectural engineeringLong span

The invention provides a long-span steel structure corridor construction method. Support steel columns on two sides of a span are firstly installed, then transverse horizontal steel beams are hoisted, support steel beams and oblique support steel beams among the transverse horizontal steel beams are installed, a vertical horizontal steel beam and a striding horizontal draw rod are further installed between two transverse horizontal steel beams, and finally transverse steel beams required by construction are installed. The long-span steel structure corridor construction method is characterized in that auxiliary trusses are installed between the support steel beams after the support steel beams are installed, and the auxiliary trusses serve as hanging points to hoist the transverse horizontal steel beams and then dismantled after the support steel beams and the oblique support steel beams are further installed between the transverse horizontal steel beams. The long-span steel structure corridor construction method has the advantages of utilizing the auxiliary trusses to install the transverse horizontal steel beams with largest volume, adopting a spare part hoisting mode for an overall steel structure and reducing the field requirement of surrounding construction and the requirement for a crane.

Owner:ZHEJIANG BADA CONSTR GRP

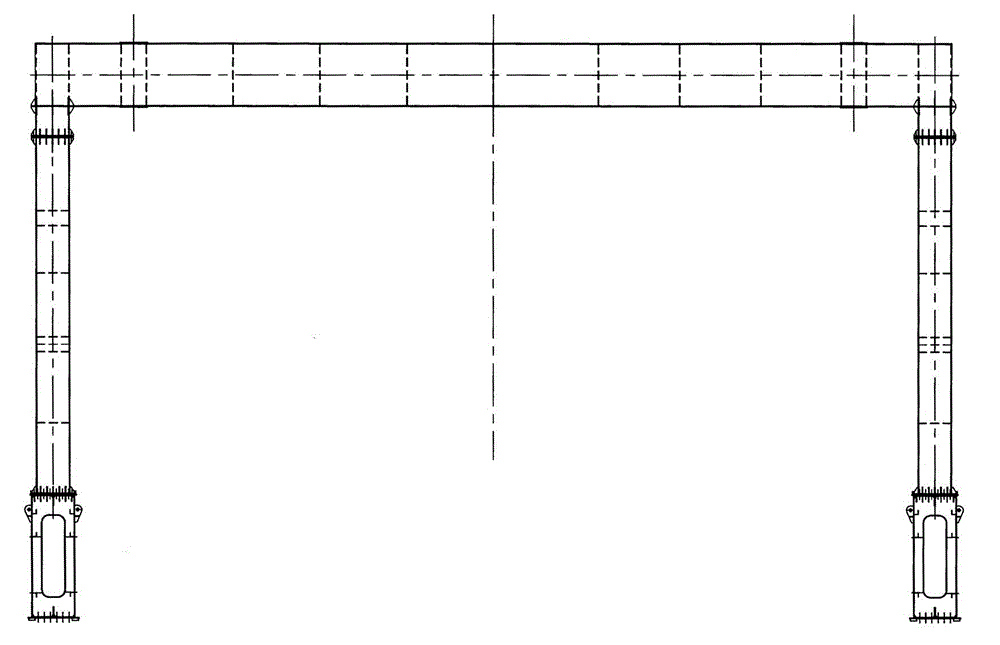

Intelligent remote-control full-automatic subway construction vertical conveying system

PendingCN108249315AImprove securityReduce labor intensityTrolley cranesTrolleysRemote controlHigh energy

The invention discloses an intelligent remote-control full-automatic subway construction vertical conveying system. The intelligent remote-control full-automatic subway construction vertical conveyingsystem comprises a gantry frame; a trolley running mechanism is disposed at the top of the gantry frame, and a cart running mechanism is disposed at the bottom of the gantry frame; a lifting mechanism and a slag turnover device are installed on the trolley running mechanism; the lifting mechanism is detachably connected to a slag box; and the slag turnover device drives the slag box to turn overand mix materials. According to the invention, the lifting mechanism with a sling spanning hook and the slag turnover device disposed in the trolley running mechanism are used to realize t hanging, moving and unloading of the slag box; no manual auxiliary operation is required at a loading and unloading site, and no auxiliary facilities are needed on the ground, thereby saving a construction siteand changing the high-energy-consumption movement which affects the construction progress and increases the mechanical facilities due to a narrow space and a narrow site during the subway construction. Two or more sets of vertical conveying equipment can be operated by one person in a central control duty room, which reduces the on-site operation and ground support personnel, reduces the labor intensity of workers, promotes safe production, enables the tunnel slag discharge safer and reduces the labor intensity.

Owner:上海和平发展起重设备厂有限公司

Multidimensional space steel structure installation joint positioning construction method

InactiveCN104594508AMeet connection security requirementsEasy to install precision controlBuilding material handlingMan-hourSpatial structure

Provided is a multidimensional space steel structure installation joint positioning construction method. A tester is adopted for detecting the boundary dimension of an entity joint, dynamic fitting comparison is continuously performed between a joint design model with the assigned end face and the boundary dimension of the entity joint, the entity joint is continuously corrected and positioned further, the method is mainly applicable to accurate measurement positioning of complex variable space structure large multi-branch joints without operating control points, multi-direction adjustment positioning can be achieved, and installation precision can be conveniently controlled. The method has wide applicability, operation is easy and convenient, the safe connection requirement in a joint area can be met, lots of construction plant, manpower and mechanism input is reduced, manpower, instrument equipment and man hours needed for completing the construction measurement control process are little, labor productivity is improved and construction quality is guaranteed.

Owner:YONGSHENG CONSTR GRP +1

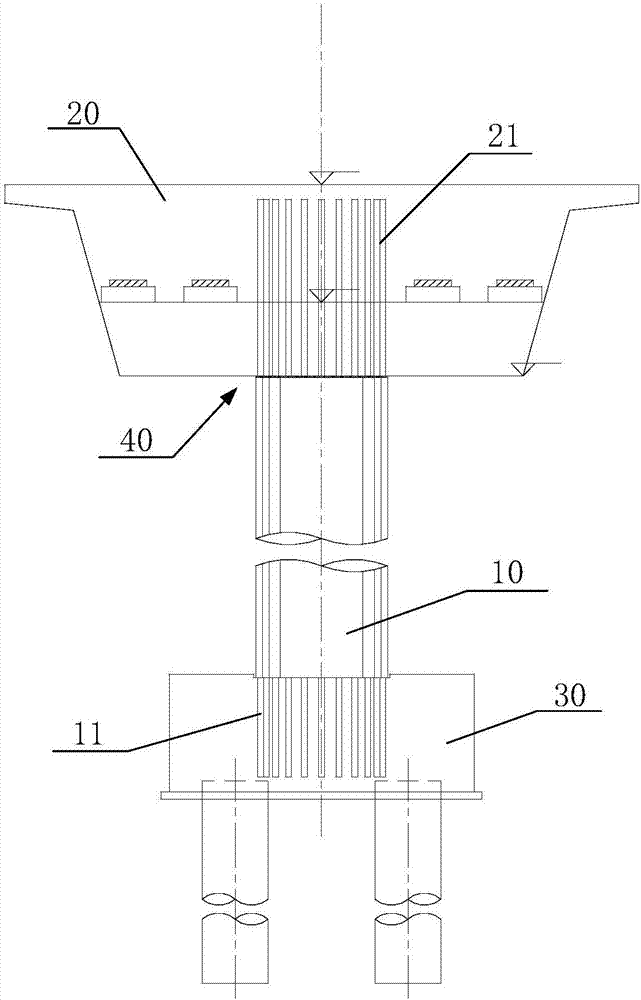

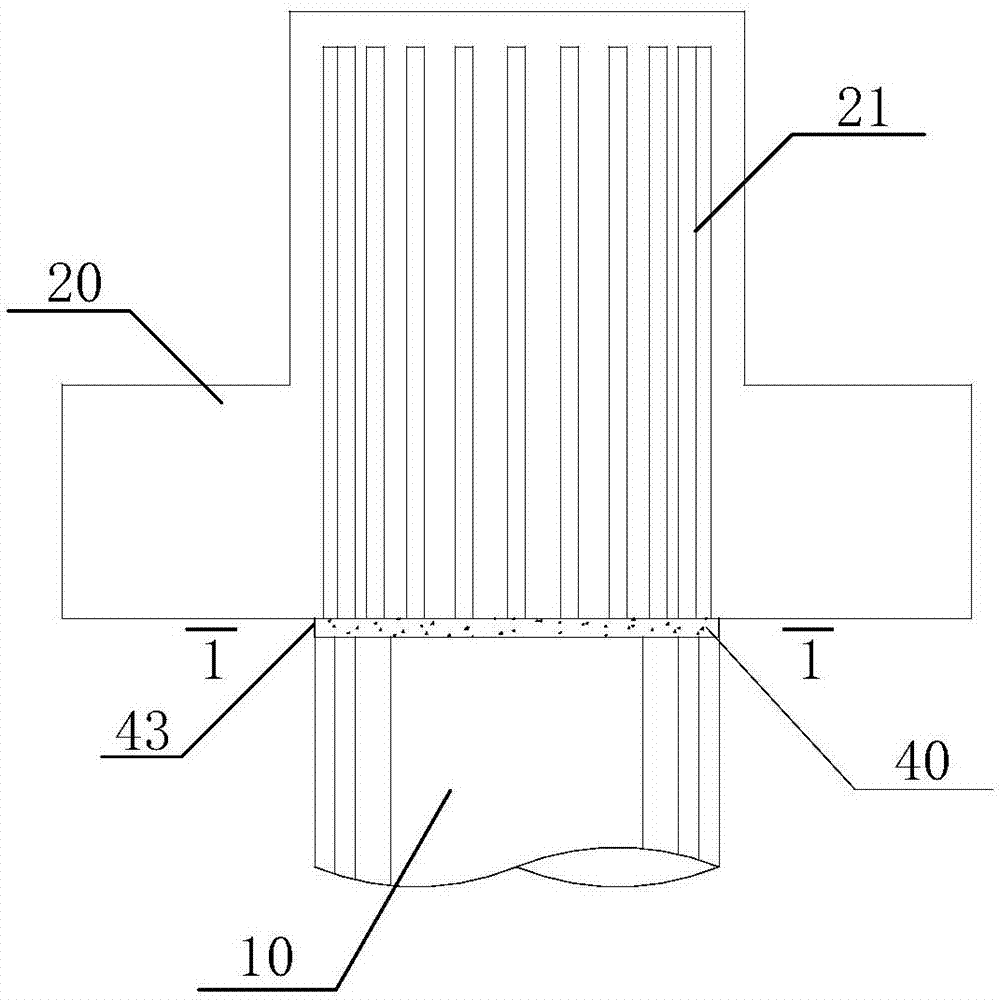

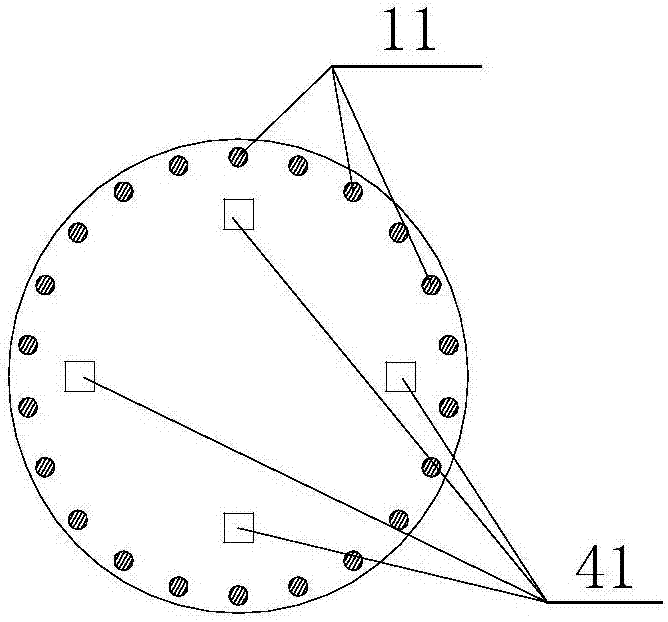

Stand column and cover beam splicing structure

InactiveCN106906747AShorten the on-site construction periodSave construction siteBridge structural detailsBridge erection/assemblyArchitectural engineeringRebar

The invention relates to a stand column and cover beam splicing structure used for splicing of a stand column and a cover beam. The bottom of the stand column is fixed to a bearing platform. A plurality of steel bars extend out of the top of the stand column. A plurality of metal corrugated pipes are embedded in the cover beam. The bottoms of the metal corrugated pipes are flush with the bottom face of the cover beam. The metal corrugated pipes correspond to the steel bars in position. A splicing joint between the stand column and the cover beam is filled with high-strength mortar or epoxy splicing glue. Grouting channels arranged in the cover beam. The two ends of each metal corrugated pipe communicate with a mortar inlet and a mortar outlet through the grouting channels correspondingly. According to the stand column and cover beam splicing structure, a traditional bridge building mode is changed, no bracket or formwork exists on a construction site, the site construction period is greatly shortened, the labor intensity of workers is relieved, and requirements for the construction site are reduced; the procedures of bracket foundation processing and bracket formwork erection on the site are omitted, and the economical efficiency is good; and meanwhile, adverse impact on the surroundings is reduced.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP +1

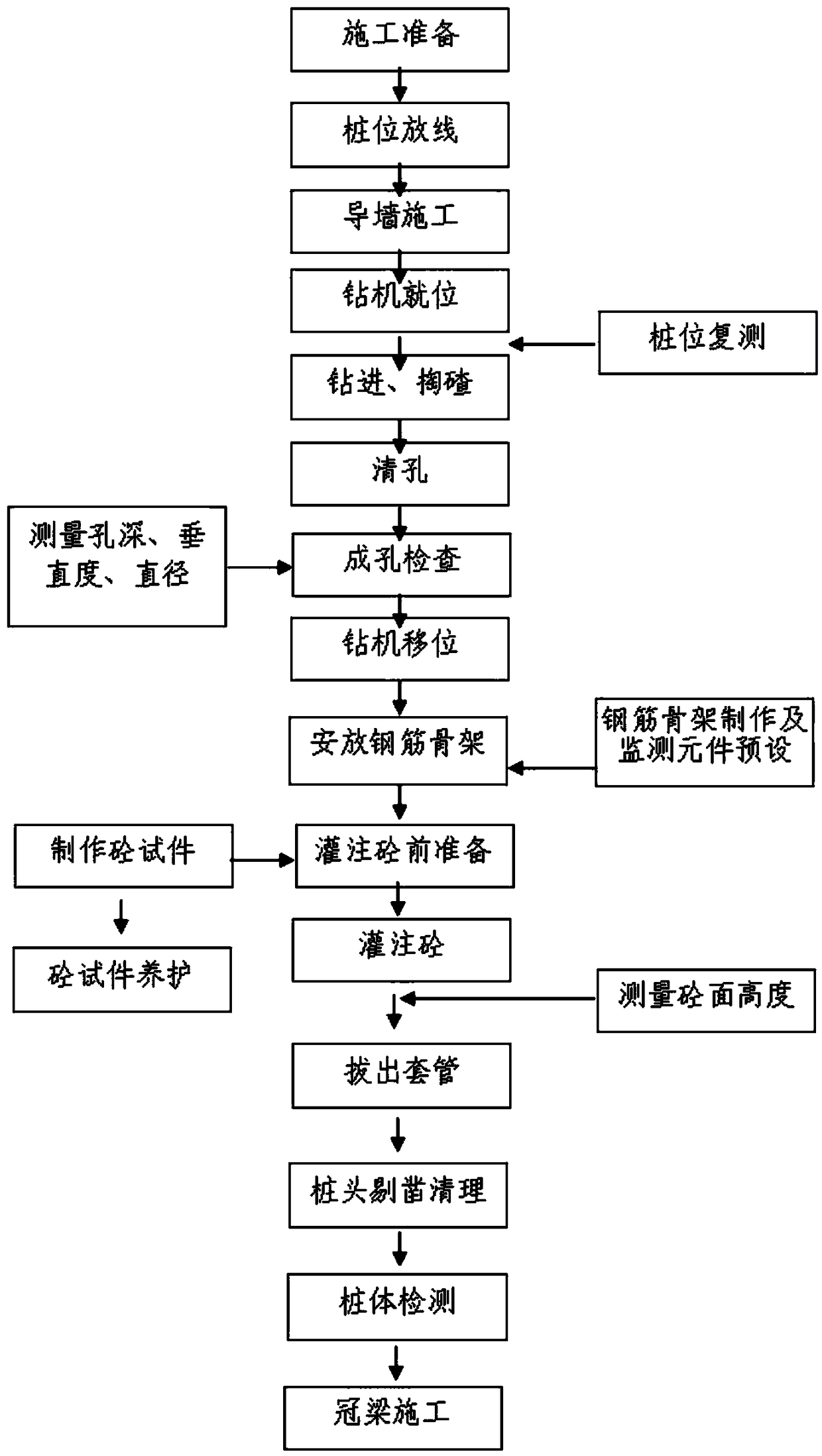

Hard cutting type construction method of secant pile in karst region

InactiveCN108625369AEliminate the problem of non-continuous operationNo pollution in the processBulkheads/pilesReinforced concreteKarst

The invention provides a hard cutting type construction method of a secant pile in a karst region, and belongs to the field of urban mass transit construction. The method specifically comprises the processes of preparing for constructing; paying off in pile positions; constructing a guide wall; arranging a drilling machine in place; drilling and removing ballast; cleaning a hole; examining the finished hole; displacing the drilling machine; arranging a reinforcement framework; pre-preparing for concrete pouring; pouring concrete; drawing out a sleeve; chiseling a pile head, and cleaning; detecting a pile body; and constructing a top beam, wherein pure concrete piles and reinforced concrete piles are sequentially alternatively arranged at the pile positions; the secant pile is constructed by the steps of sequentially constructing the pure concrete piles at regular intervals of every three concrete piles; sequentially constructing the rest pure concrete piles; sequentially constructing the reinforced concrete piles at regular intervals of every three concrete piles; and the constructing the rest reinforced concrete piles. With the adoption of the method, a plurality of problems in secant pile construction in karst developed old cities can be solved.

Owner:CHINA RAILWAY ERJU 1ST ENG

Drainage type waterproof system

ActiveCN109577495AOvercome technical difficultiesReduce the difficulty of engineering constructionRoof drainageRoof covering insulationsPondingWater flow

The invention discloses a drainage type waterproof system, which fully utilizes the surface performance of hydrophilicity and hydrophobicity of substances to drain, guide and separate water flow on avertical wall surface or accumulated water in a drainage ditch which has weak hydrophobicity and hydrophilicity with hydrophilic substances, or process each interface or the vicinity of each interfaceof the vertical wall surface and the inner side of the outer side wall or the upper edge of the inner side of the outer side wall of the drainage ditch into a hydrophobic surface, so as to prevent water flow from leaking into the interface or prevent the water surface slightly higher than the side wall of the drainage ditch from overflowing from the side wall of the drainage ditch, so that the drainage performance of the vertical wall surface and the drainage ditch is improved, the technical problems of the existing flooding technology, such as high quality requirements for construction technology, meteorology and sealing materials, short waterproof life and drainage of accumulated water in the middle of the drainage ditch are successfully solved, and all products can be produced with standardized profiles or prefabricated components.

Owner:怀化沃普环保科技有限公司

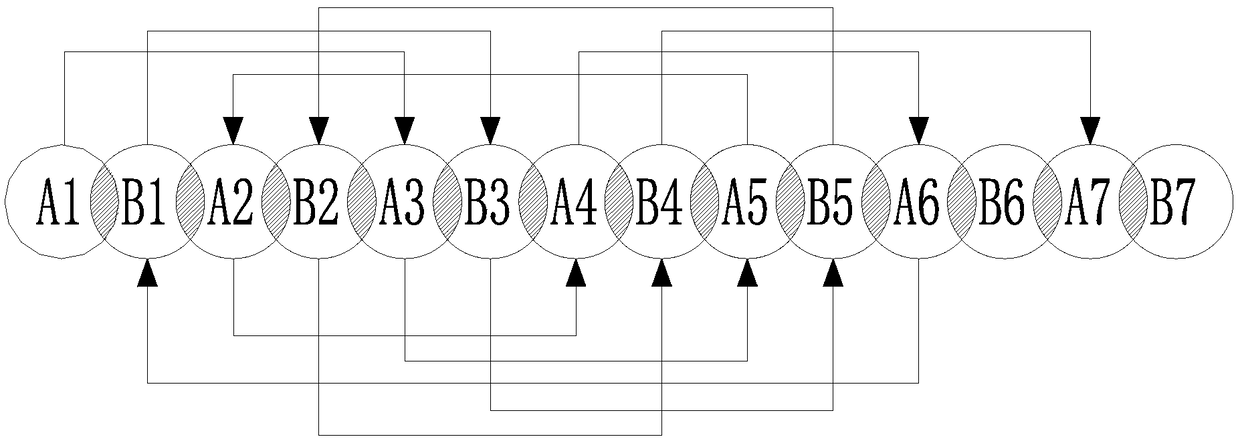

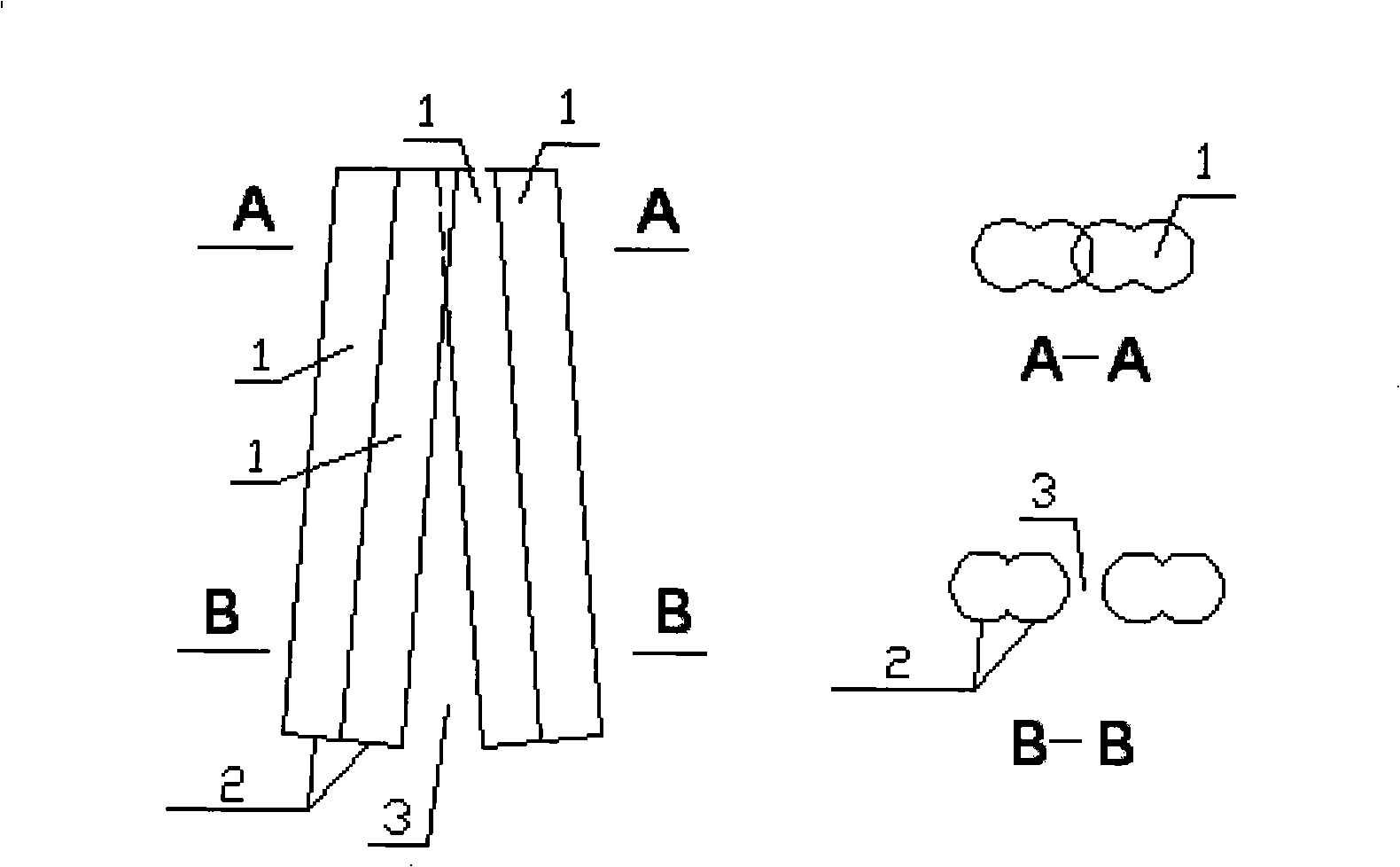

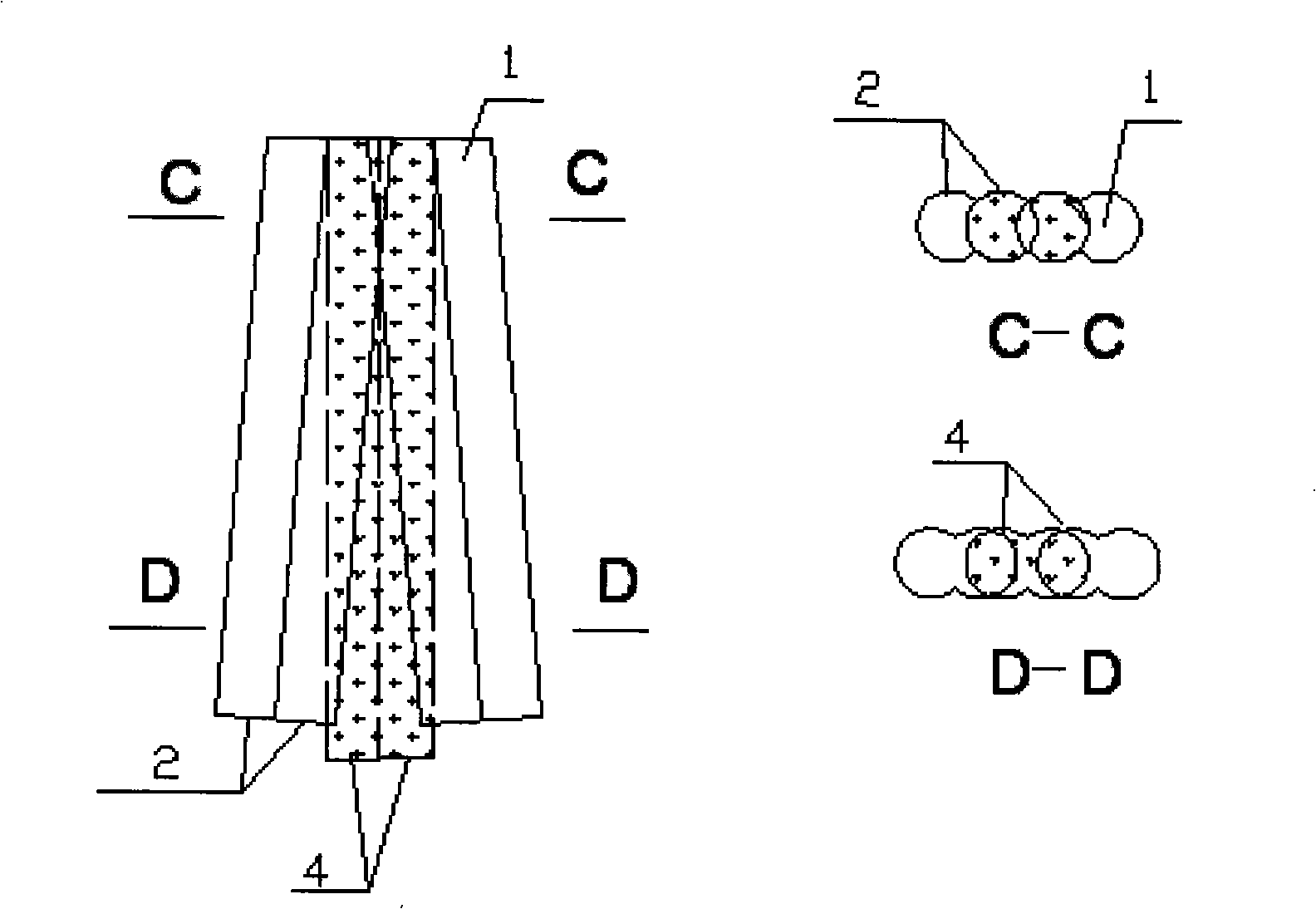

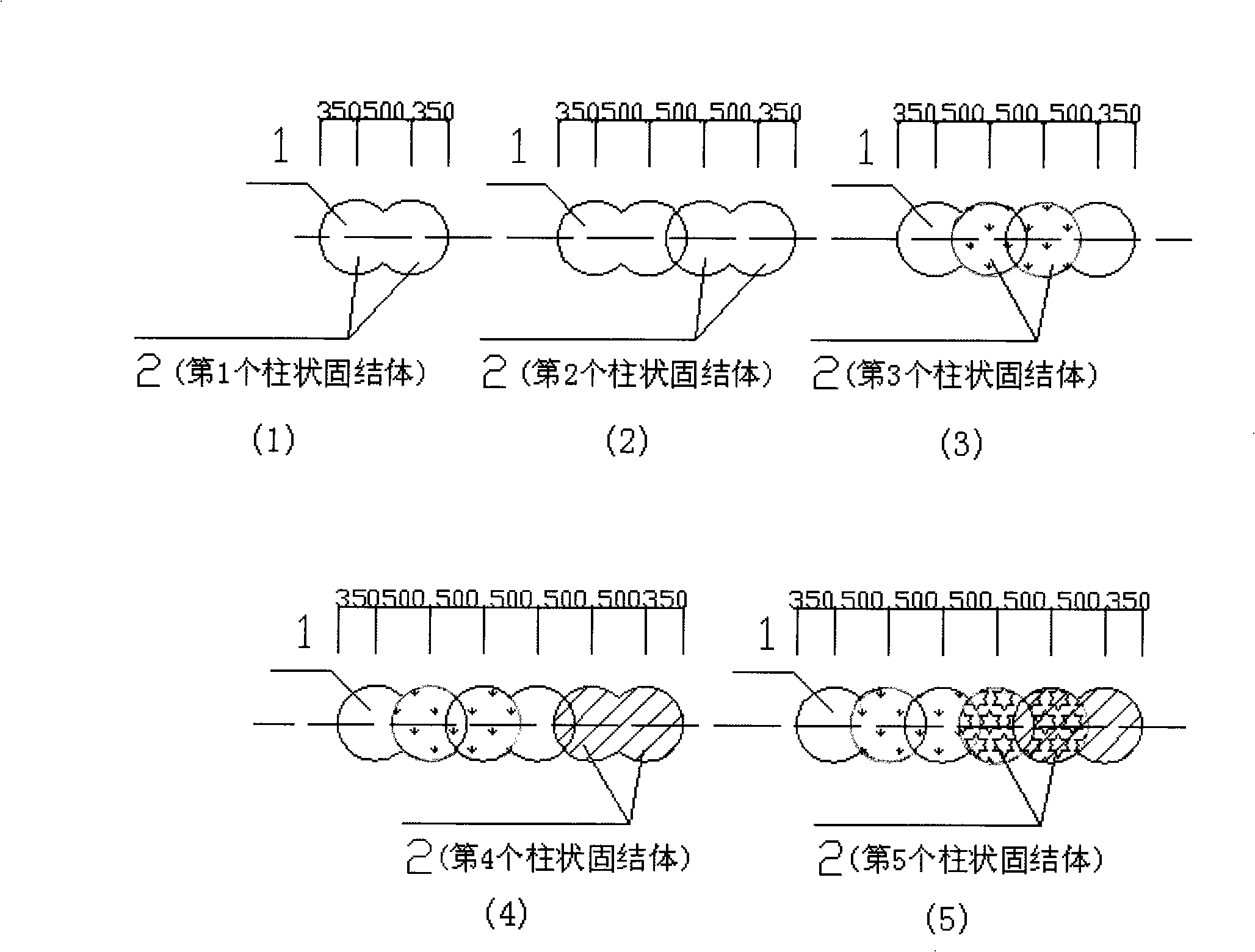

Construction method of ikebana socket water stop curtain for dual spindle soil-cement stirring mill

The invention relates to a construction method for a water-seal curtain being crosswise sleeved on a biaxial soil cement agitator. The construction method comprises the following steps: first step, a field is leveled; second step, a biaxial soil cement agitator is positioned; third step, agitation is performed for the first time and an agitator head is descended to the depth of a pile; fourth step, agitation is performed for the second time and the agitator head is ascended to the top of the pile; fifth step, agitation is performed for the third time and the agitator head is descended, and the third step is repeated; sixth step, agitation is performed for the fourth time and the agitator head is ascended, and the fourth step is repeated to form a first columnar induration; seventh step, a mortar feeding tube is cleaned; eighth step, the agitator is advanced for two pile positions; ninth step, the third, the fourth, the fifth and the sixth steps are repeated to form a second columnar induration; tenth step, the seventh step is repeated; eleventh step, the mortar is dropped back for a pile position, then the third and the fourth steps are repeated, crosswise sleeve joint is performed to the two columnar indurations, and a branching between the two columnar indurations is eliminated; twelfth step, the seventh step is repeated; thirteenth step, the agitator is advanced for three pile positions, then the fourth, the fifth and the sixth steps are repeated, and the construction of a fourth columnar induration is carried out; fourteenth step, the tenth, the eleventh, the twelfth and the thirteenth steps are repeated in sequence, and non-branching water-seal curtain is continually accomplished. The method greatly enhances the integrity and the barrier property of the water-seal curtain, saves space, and saves the construction cost.

Owner:江苏华东建设基础工程有限公司

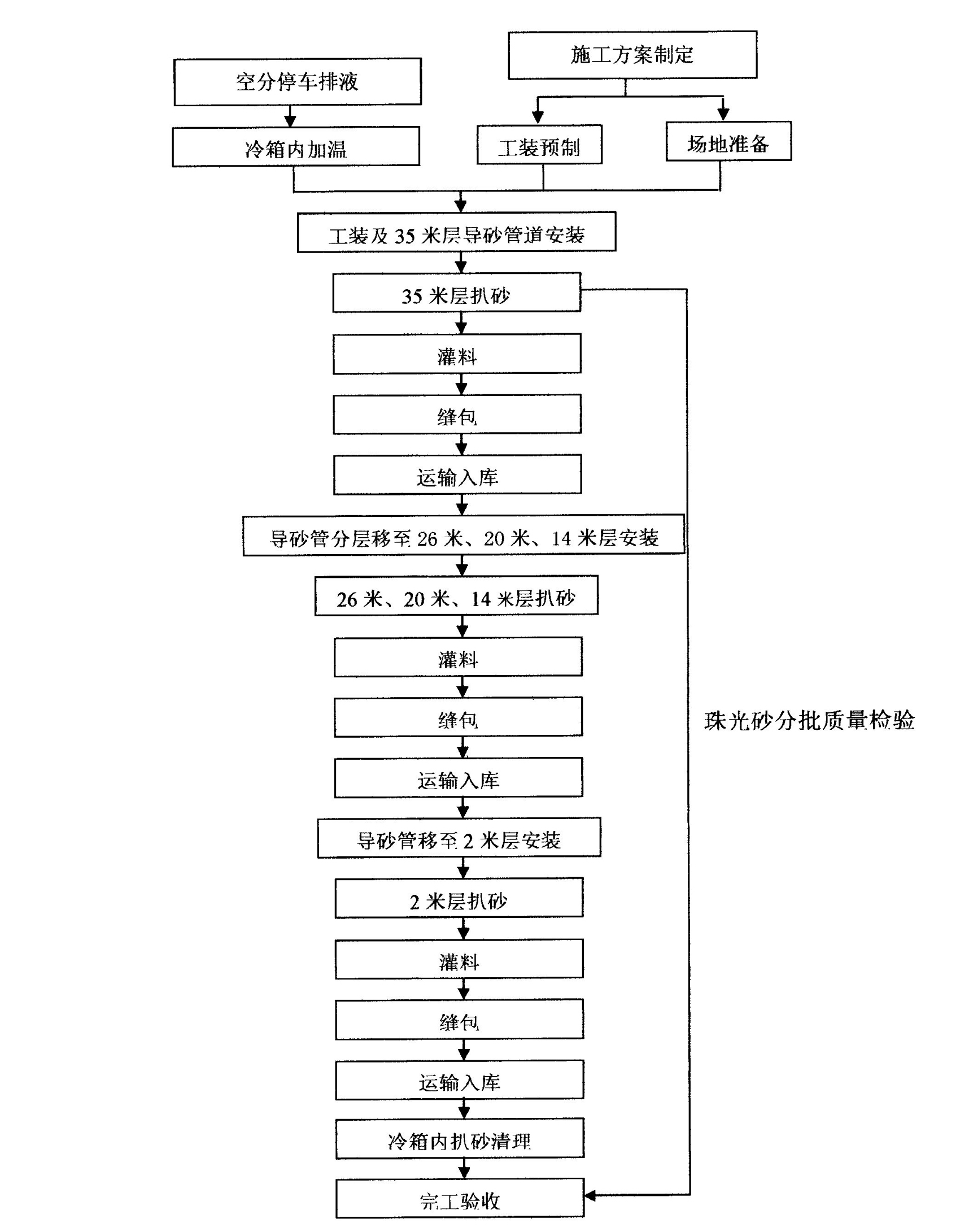

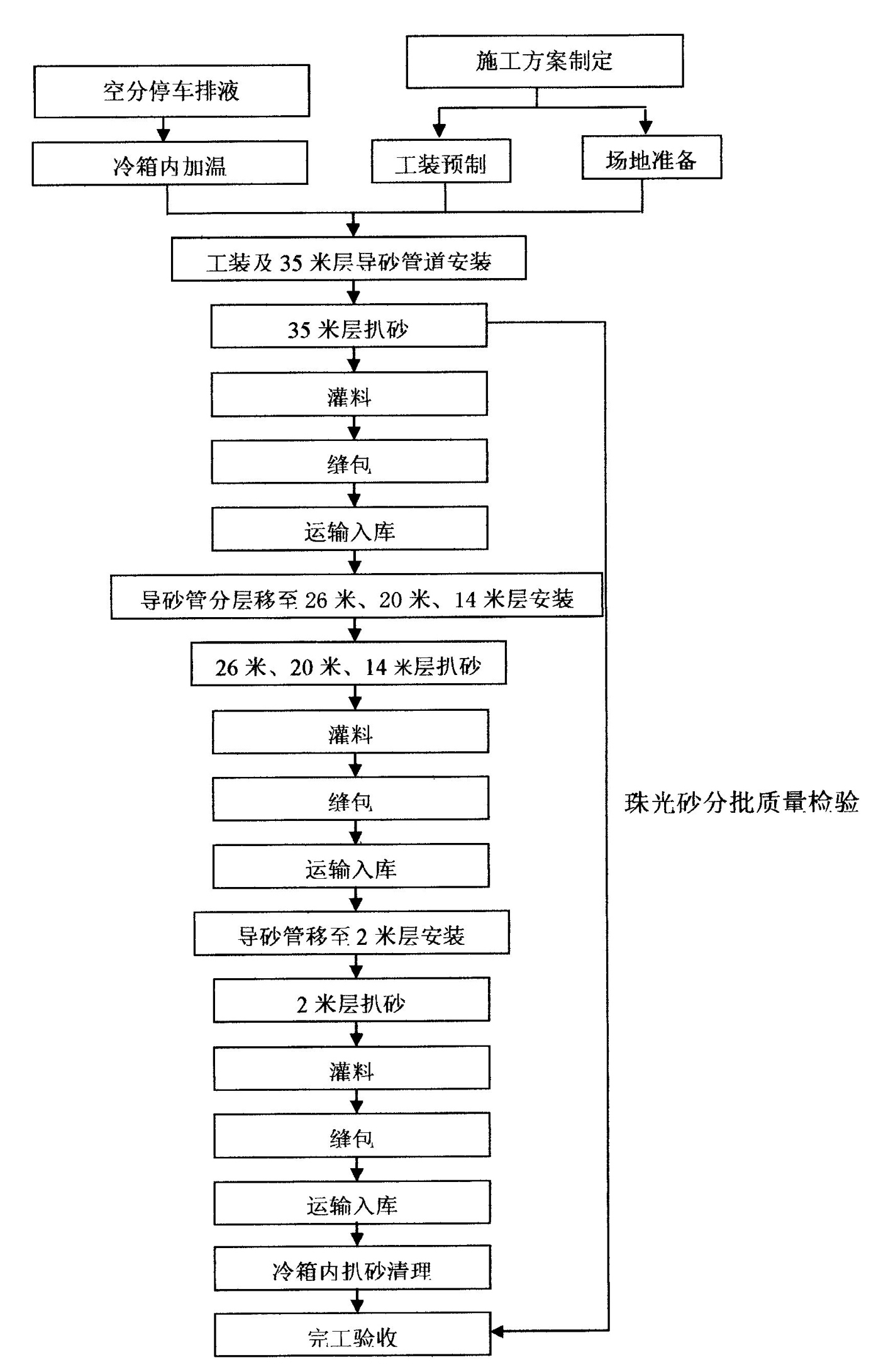

Air separation cooling box layering haling method

ActiveCN101858684AImprove the speed of fillingReduce labor intensitySolidificationLiquefactionPerliteAir separation

The invention relates to a method for haling medium in pipeline, in particular to an air separation cooling box layering haling method. The method of the invention concretely includes the following steps: A, cooling box prophase treatment before haling is carried out, including cooling box stopping for liquor discharge and warming in the cooling box; B, haling place is selected, and tools for haling including a discharge opening swing head, a feeding pipe, a material collecting frame and an emptying sack are manufacture and mounted; C, step-by-step selective layering haling is carried out from the discharge opening at the uppermost layer of the cooling box; D, step-by-step haling is carried out until brilliant expansion perlite in the cooling box is discharged to the safe material level, the inlet at the bottom of the cooling box is opened, and haling in cooling box is carried out by entering the interior of the cooling box; E, finally quality of brilliant expansion perlite scratched out from the cooling box is checked, and the brilliant expansion perlite is packaged and stored after being checked to be qualified and is waited to be transported. The method of the invention greatly improves the safety of haling construction, thus not only protecting equipment and pipeline in the cooling box but also guaranteeing life safety of operational personnel.

Owner:中国化学工程第四建设有限公司

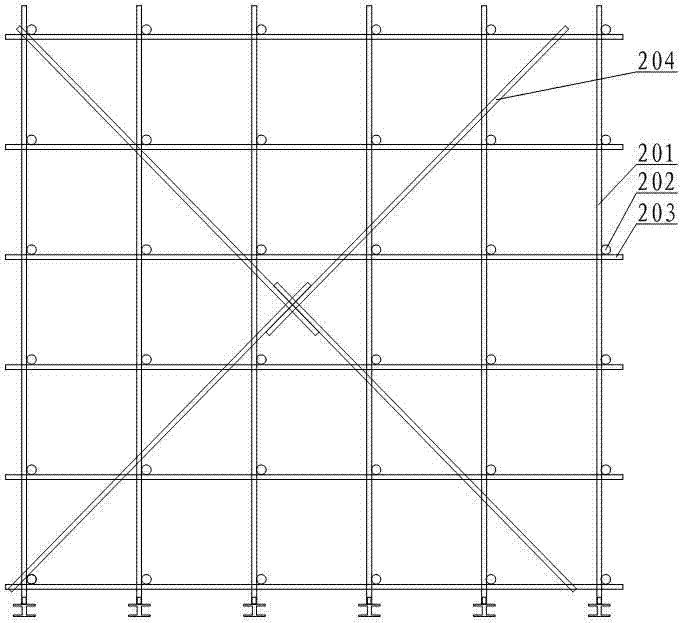

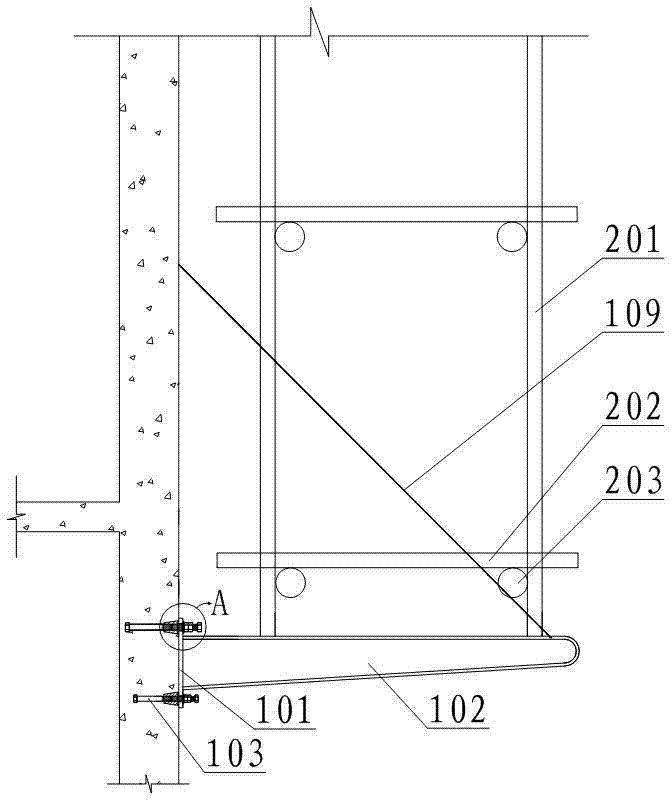

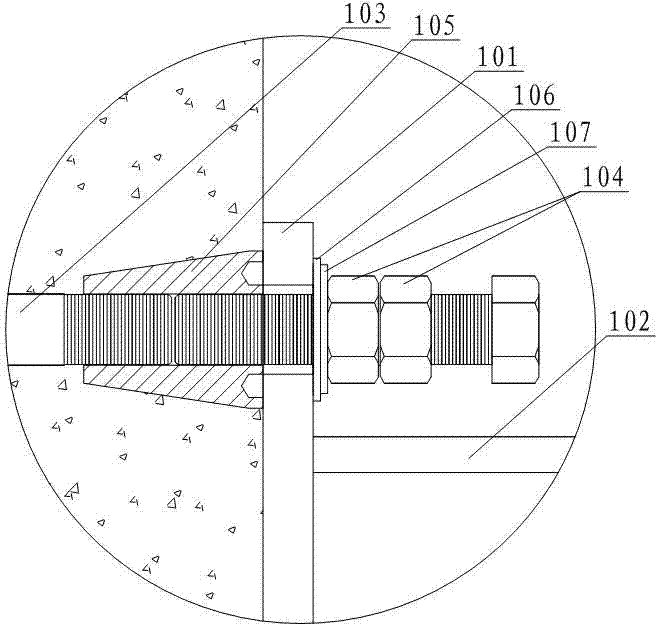

Bracket type overhanging scaffold and construction method thereof at erection time

ActiveCN103485524ASimple structureEasy to install and removeScaffold accessoriesBuilding support scaffoldsEngineeringShear wall

The invention discloses a bracket type overhanging scaffold which comprises a scaffold body and a plurality of overhanging supporting seats. Each overhanging supporting seat comprises a connecting plate, a threaded connecting piece, and an outer limiting nut arranged on the threaded connecting piece in a sleeved mode, wherein one end of the threaded connecting piece is connected with an upper steel beam on the end face of the connecting plate, the other end of the threaded connecting piece penetrates through the connecting plate and is embedded into a shear wall, and the connecting plate is located between the shear wall and the outer limiting nut. The scaffold body comprises transverse horizontal rods, longitudinal horizontal rods and a plurality of rows of vertical rod sets. Each row of vertical rod sets comprises vertical rods the same as the overhanging supporting seats in number. The vertical rods in each row of vertical rod sets are arranged on steel beams in a one-to-one correspondence mode. A plurality of vertical rods arranged on the same steel beam are connected with one another through a plurality of transverse horizontal rods. A plurality of vertical rods in each row of vertical rod set are connected with one another through a plurality of longitudinal horizontal rods. The invention further discloses a construction method for the bracket type overhanging scaffold. The bracket type overhanging scaffold is simple in structure, convenient to install and detach, and has little influence on the strength of a building structure at utilization time.

Owner:四川省第四建筑有限公司

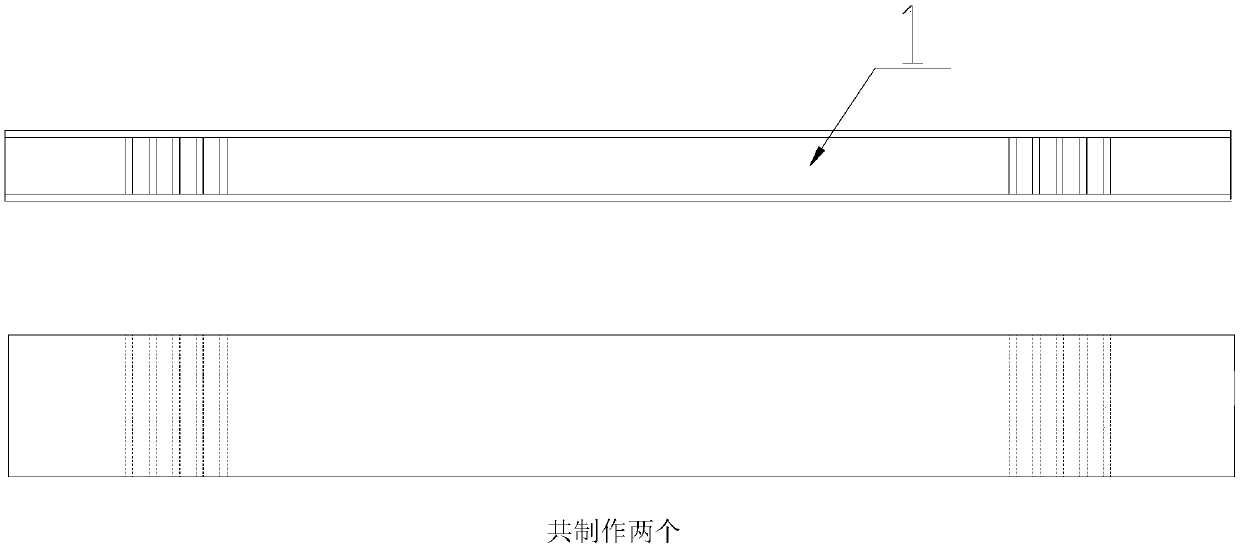

LNG ship engine room upper portion flat straight region multi-segment connecting construction type construction method

ActiveCN108146577APrecise positioningEliminate accumulated errorsVessel partsArchitectural engineeringMulti segment

The invention discloses an LNG ship engine room upper portion flat straight region multi-segment connecting construction type construction method and belongs to the technical field of ship construction. The construction method includes the steps of bottom board lofting manufacture, line drawing region division of a construction platform, molding bed arrangement, bottom board laying, bottom board gap location conducted by gap clamping pieces, bottom board line drawing, segmental construction, border trimming and the like. The construction method is used for constructing six segments in an engine room upper portion flat straight region, the six segments share one construction platform, line drawing and construction are conducted at the same time, the accumulative errors generated in the construction process of the LNG ship engine room upper portion flat straight region are reduced, it is guaranteed that the relative positions among the six segments are accurately positioned, and following lifting is convenient.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

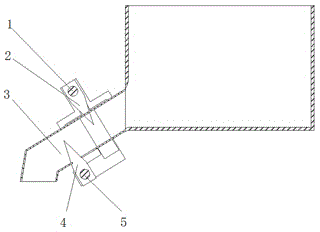

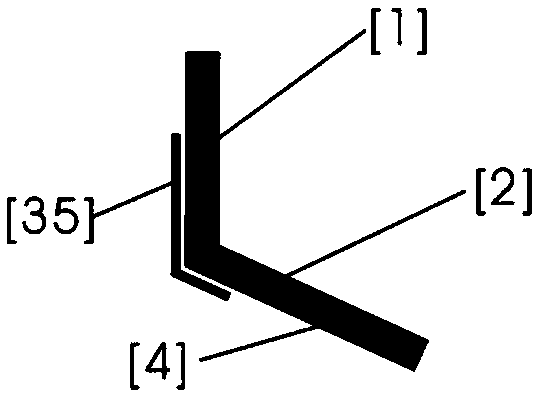

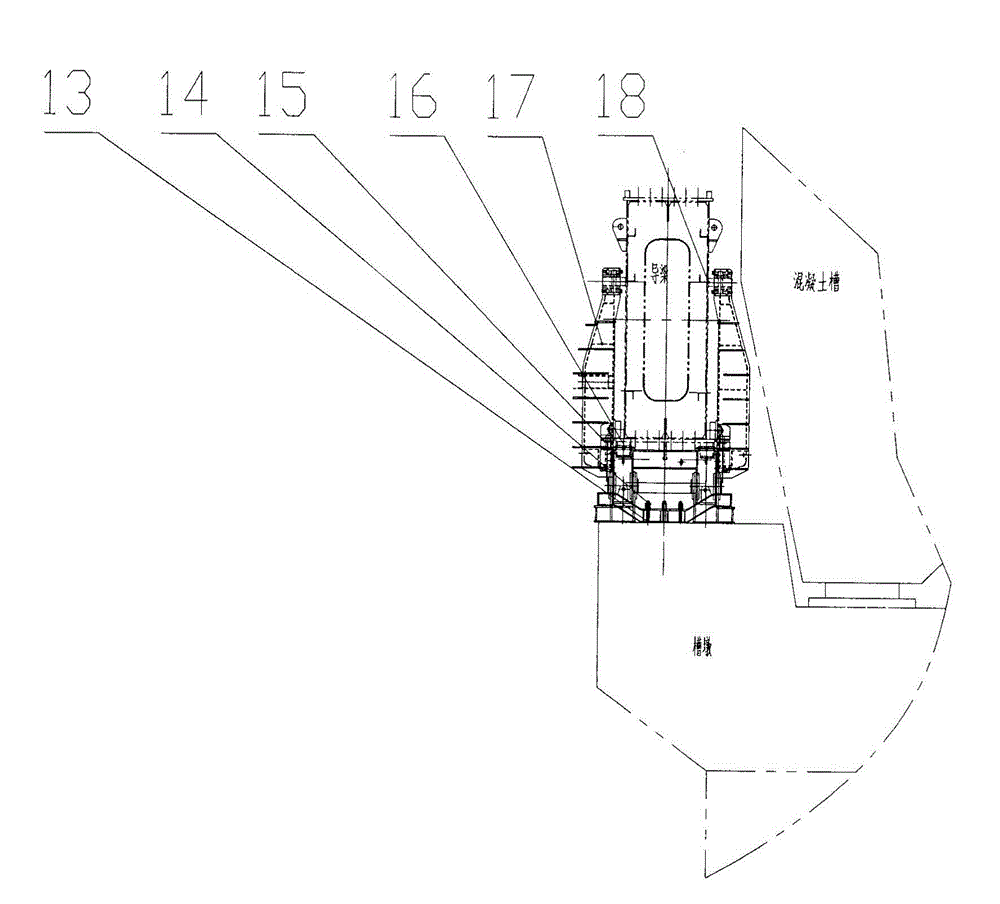

Special aqueduct erecting machine for erecting water conservation aqueduct

InactiveCN102747692AAchieve vertical viasGuarantee the lifting qualityBridge erection/assemblyGeneral purposeEngineering

A special aqueduct erecting machine for erecting a water conservation aqueduct is characterized by comprising a lower guide beam (1) located on aqueduct piers, a general purpose gantry crane (2) and a general purpose gantry crane (3) with a double-hanging-point lifting appliance, wherein the general purpose gantry crane (2) is arranged on a track above the lower guide beam through a walking mechanism and provided with a single-hanging-point lifting appliance. The lower guide beam comprises a left guide beam (5), a right guide beam (5), rear connecting frames (4), a plurality of support seats (6), front connecting frames (8) and a pushing mechanism (7) and traction mechanisms (9), wherein the left guide beam (5) and the right guide beam (5) are parallel to each other, the rear connecting frames (4) are installed at rear ends of the left guide beam (5) and the right guide beam (5), the plurality of support seats (6) are arranged below the left guide beam (5) and the right guide beam (5) respectively and matched with the corresponding aqueduct piers, the front connecting frames (8) are installed at front ends of the left guide beam (5) and the right guide beam (5), and the pushing mechanism (7) is arranged between the guide beams and the support seats and used for pushing the guide beams to perform displacement movement relative to the support seats, and the traction mechanisms (9) are installed at the front end and the rear end of the lower guide beam respectively. The front connecting frames and the rear connecting frames enable the left guide beam (5) and the right guide beam (5) parallel to each other to be fixedly connected together through connecting pieces.

Owner:ZHENGZHOU NEW DAFANG HEAVY IND & TECH

1200 tonner water conservancy aqueduct transportation and erection equipment

ActiveCN101831888BHigh speedSave construction siteArtificial water canalsBridge erection/assemblySingle supportEngineering

The invention relates to 1200 tonner water conservancy aqueduct transportation and erection equipment which is characterized by comprising a wheel-track type aqueduct transportation vehicle (1) and an aqueduct erecting machine (2), wherein the aqueduct erecting machine (2) comprises left and right lower guide beams (5) arranged above an aqueduct pier in a parallel erecting mode through a supporting pedestal (4) as well as a lower guide beam closable connecting beam (3), a single-hanging-point aqueduct lifting gantry crane (6), a double-hanging-point aqueduct lifting gantry crane (7) and a fixing and connecting beam (8) which are sequentially arranged on the left and right guide beams (5) from front to back along an aqueduct conveying direction; and the wheel-track type aqueduct transportation vehicle (1) comprises a track sequentially arranged on the upper edge ports of the left side wall and the right side wall of the erected aqueduct along the aqueduct conveying direction from frontto back, a single-support-point aqueduct transportation trolley (9) and a double-support-point aqueduct transportation trolley (11), which are capable of doing longitudinal displacement motions alongthe upper edge port of the left side wall and the right side wall of the aqueduct, as well as a trolley connecting beam (10) connected between the single-support-point aqueduct transportation trolley(9) and the double-support-point aqueduct transportation trolley (11) in a demountable mode.

Owner:ZHENGZHOU NEW DAFANG HEAVY IND & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com