Multidimensional space steel structure installation joint positioning construction method

A technology of node positioning and multi-dimensional space, which is applied in the direction of building structure, construction, and building material processing, can solve problems such as personal casualties, adverse social impacts, and property damage, and achieve easy installation precision control, improve labor productivity, Guarantee the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

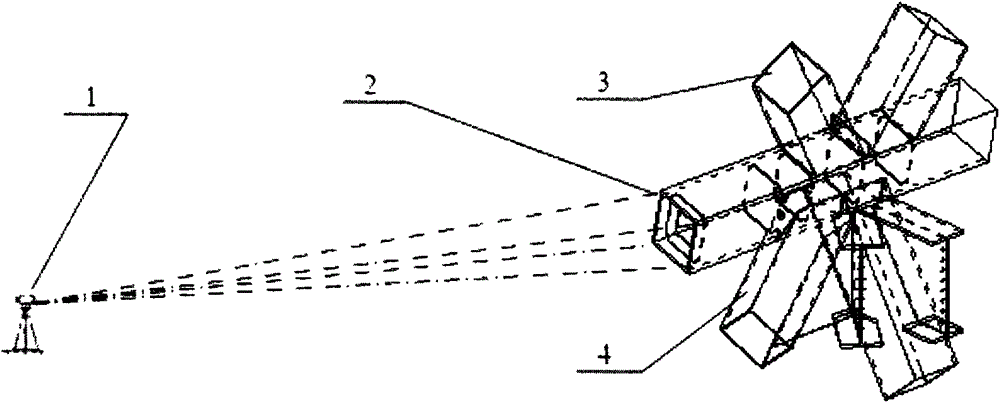

[0028] Example: as attached figure 1 As shown, in this embodiment;

[0029] 1) Through the dimensional relationship between the working point of node 4 and the center point of each port 3 given by the design, the design coordinate values of each port 3 of node 4 are obtained, and a three-dimensional space model of the node is established;

[0030] 2) Use the measuring instrument 1 to detect the external dimensions of the node 4 entity, and measure the coordinates of each port of the node 4, and the relative coordinate value obtained is automatically converted into a geometric figure, that is, a solid model, through the drawing software;

[0031] 3) Fitting the physical model and the design model, that is, the combination of the theoretical value coordinate point and the line connecting the point, node 4, that is, the physical model diagram converted from the measured coordinate value and the design model diagram converted from the design value are compared with each other. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com