Construction method for sliding and replacing whole body of jacking and revolving bearing of revolved body of stacker-reclaimer

A technology of slewing bearings and construction methods, which is applied in the direction of lifting frames, lifting devices, manufacturing tools, etc., can solve the problems of large production impact, large site occupation, and long construction time, so as to reduce impact, save construction site, and shorten construction time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

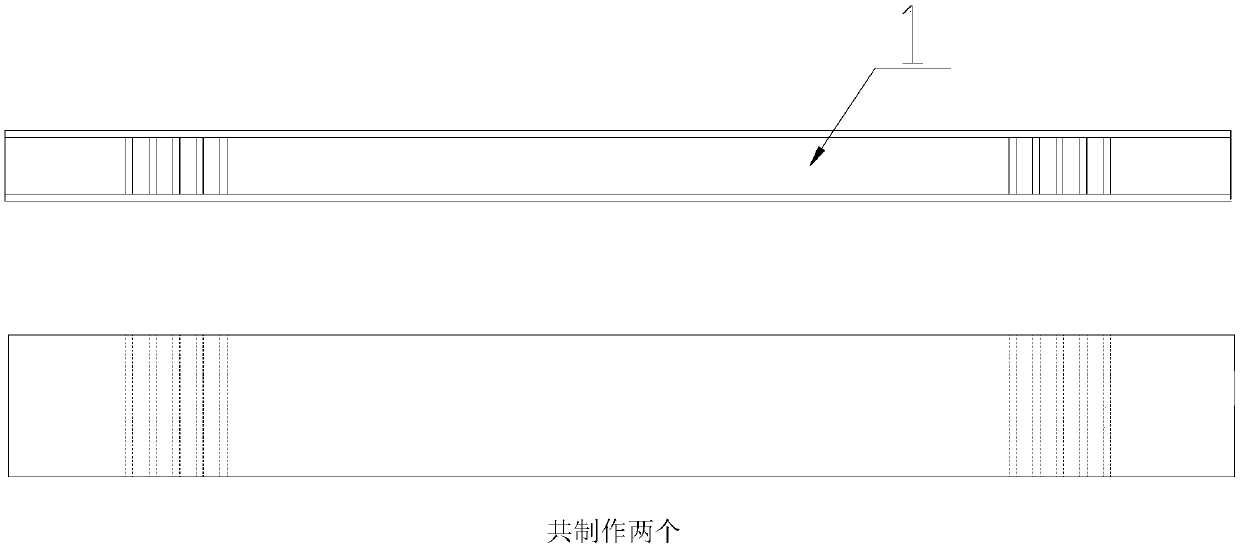

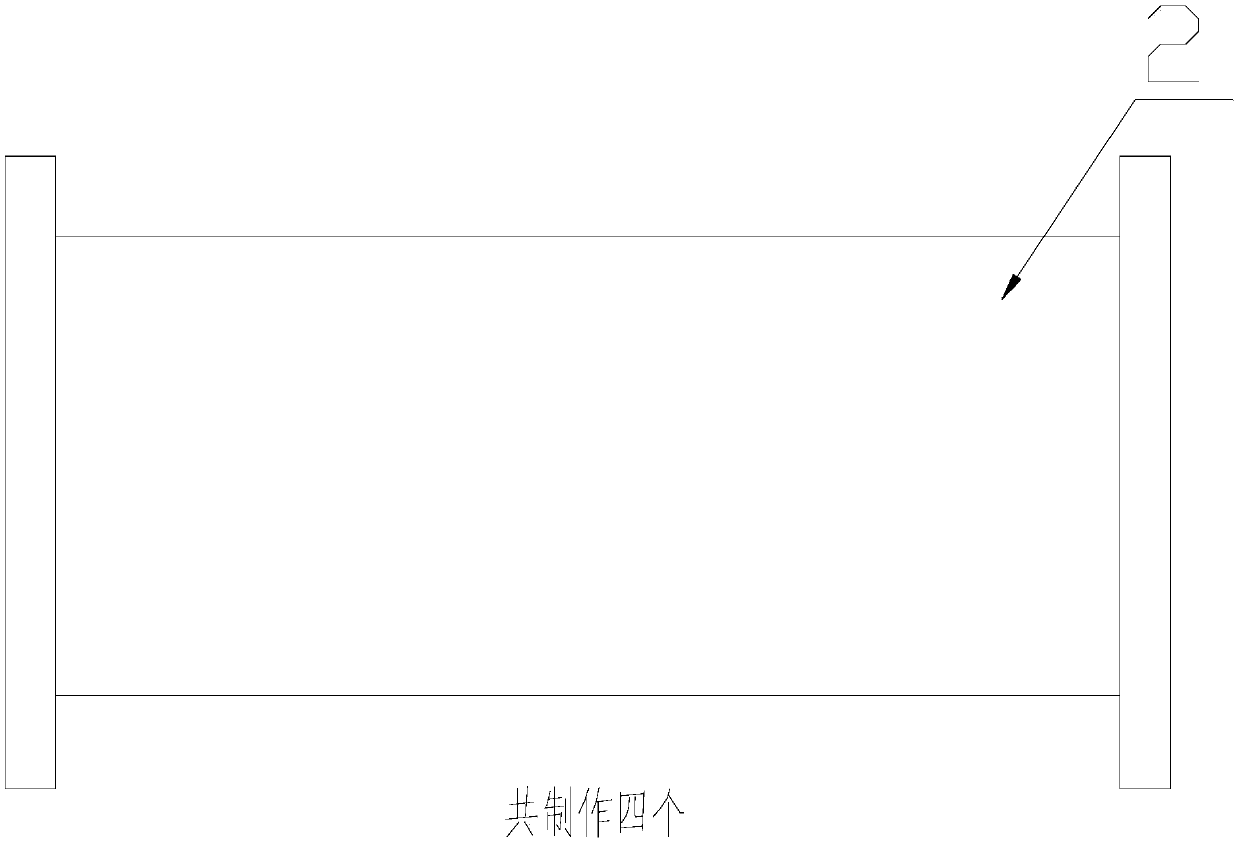

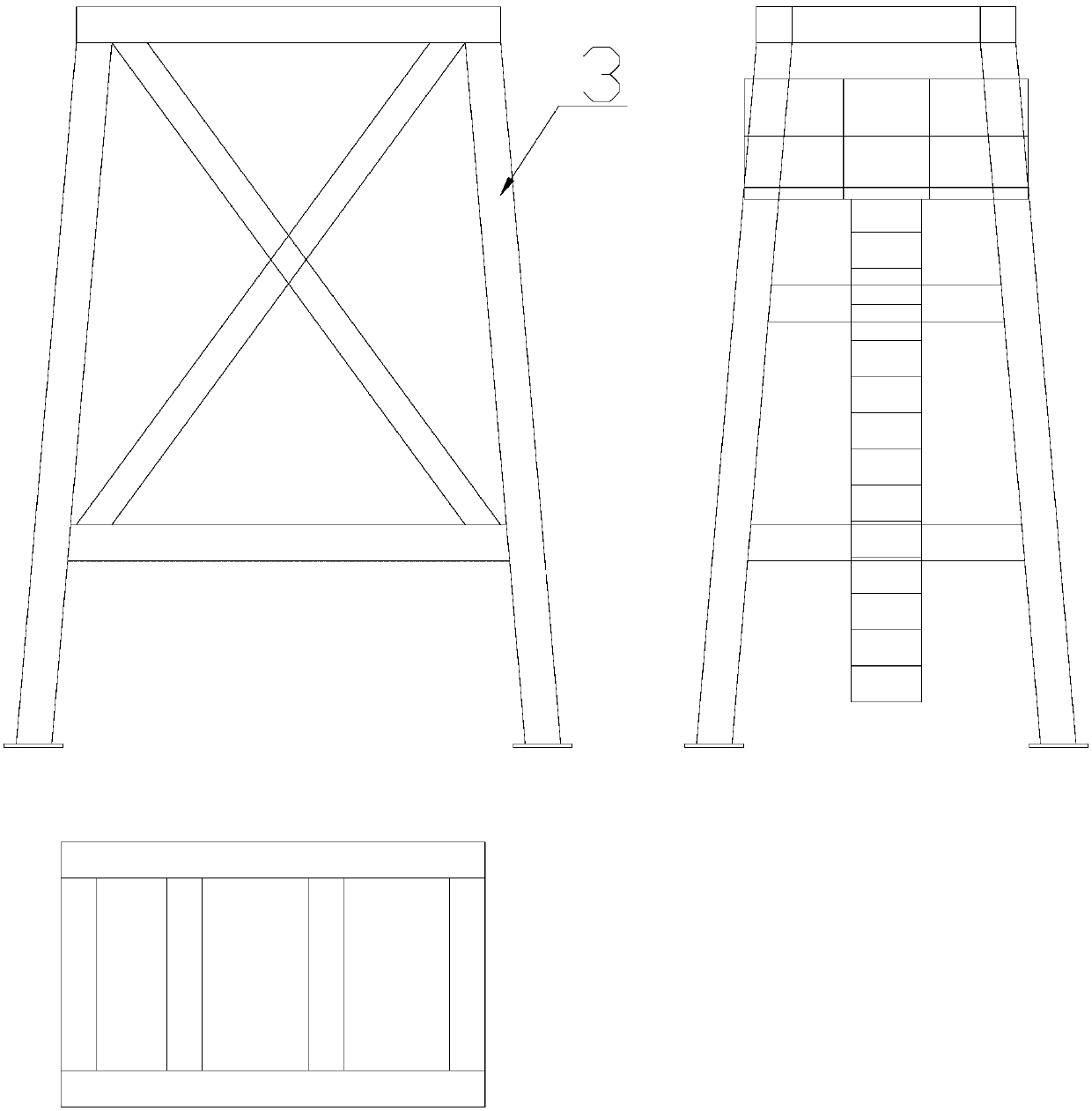

Image

Examples

Embodiment 1

[0041] The slewing bearing of the 3# stacker-reclaimer in the raw material area of an iron-making plant has expired, and now there are abnormal noises and inflexible rotation, so it needs to be replaced. The stacker-reclaimer has two main functions. The first is stacking, that is, unloading the raw materials conveyed by the raw material conveyor belt and stacking them in the raw material yard; Above all, the raw materials are transported to the blast furnace through the belt, so the stacker-reclaimer plays an extremely important role in the raw material supply of the entire iron-making blast furnace. It needs to be completed by loaders and transport vehicles, the production cost is high, and it will also affect the blast furnace production. The stacker-reclaimer is mainly composed of body base, slewing bearing, rotator and running transmission. The overall height of the stacker-reclaimer is 25 meters, the stacker-reclaimer arm is 30 meters long, the counterweight arm is 15 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com