Patents

Literature

100results about How to "Reduce downtime loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

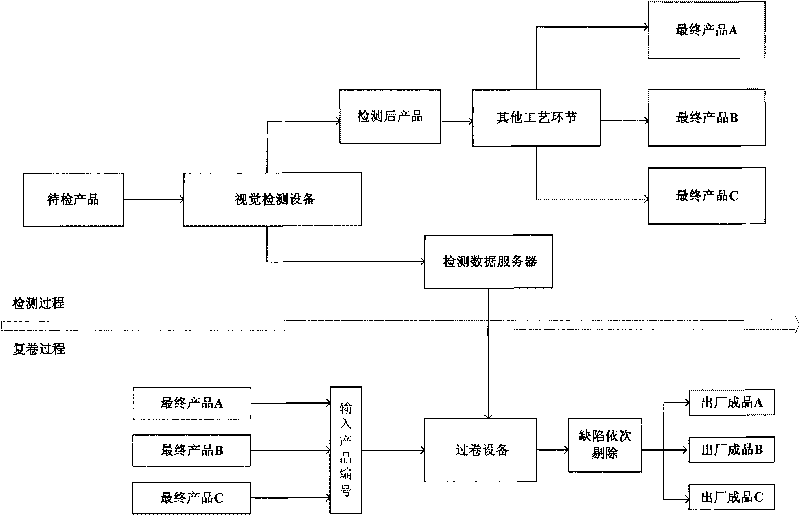

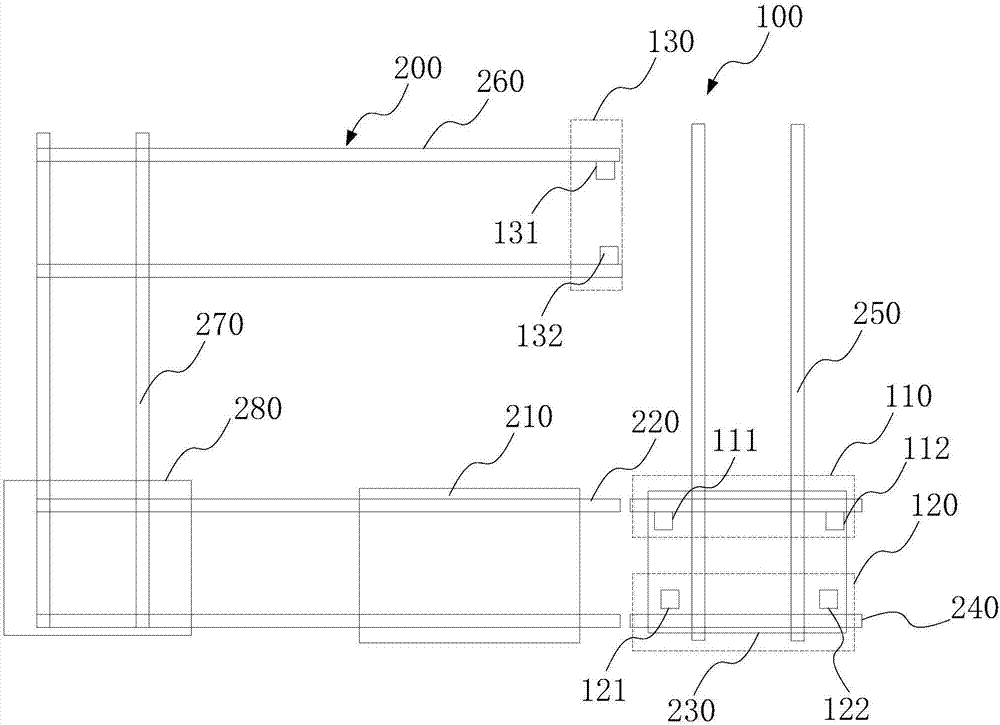

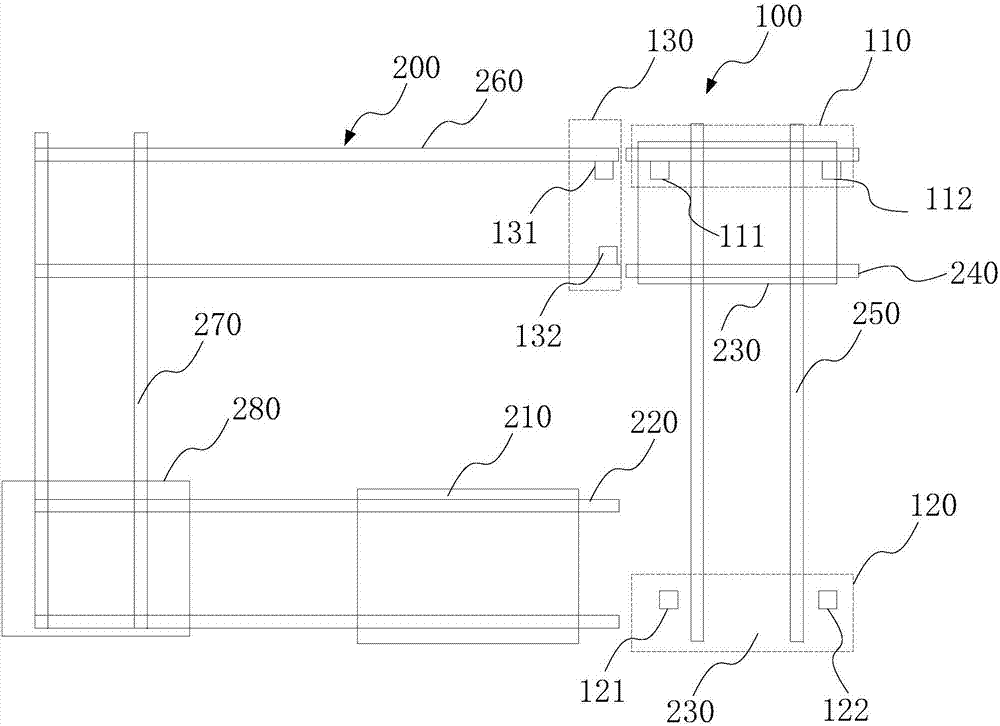

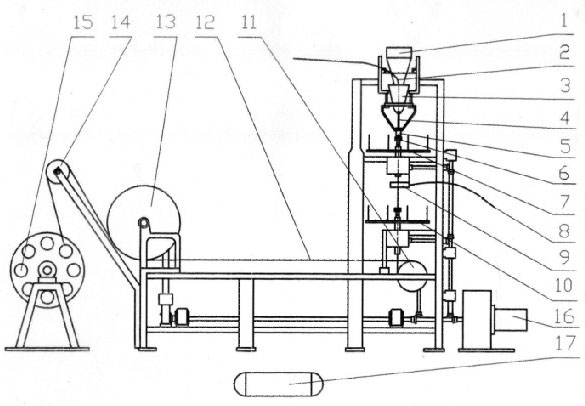

Recheck platform and quality inspection system of prints

InactiveCN101738396AReduce the burden onEasy to operateOptically investigating flaws/contaminationMicrocontrollerLocation detection

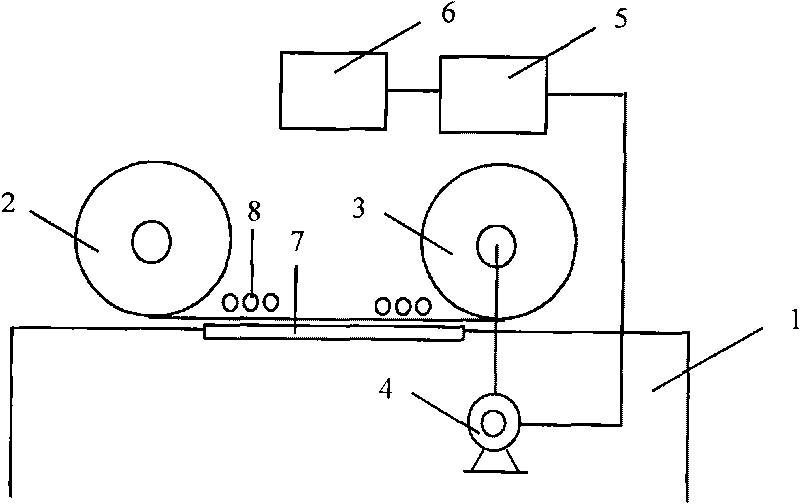

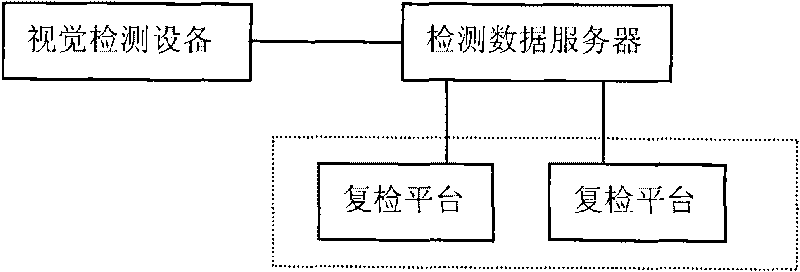

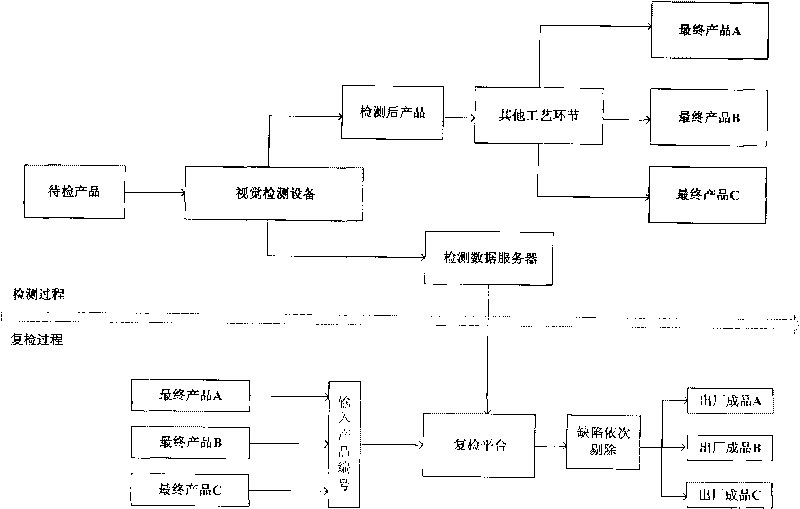

The invention discloses a recheck platform which is used for rechecking defects in quality inspection of prints and comprises a rack, a working table, an unwinding wheel, a winding wheel, a position detection device, a power device and a microcontroller, wherein, the unwinding wheel and the winding wheel are arranged on the rack; the unwinding wheel transmits the prints to the winding wheel to rewind the prints; the winding wheel is connected with a power device; the position detection device detects the position to which the prints are transmitted and is connected with the microcontroller; the microcontroller stores the position information of defects of the prints and compares with the information of the position when the prints are transmitted to control the power device. The recheck platform can lighten the burden of visual sense detection device, thus the visual sense detection device is only responsible for detection, reconstructs the detection process, separates the process links such as time consuming stopping rejection and label supplementing and the like from the detection process, lowers cost and improves the efficiency of quality detection. The invention also relates to a system adopting the platform to detect the quality of prints.

Owner:BEIJING LUSTER LIGHTTECH

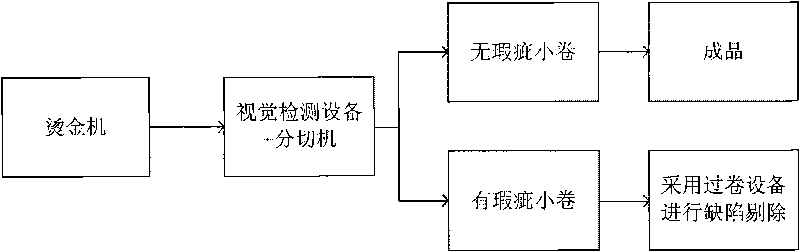

Process for testing quality of presswork

InactiveCN101738397AImprove accuracyImprove detection efficiencyOptically investigating flaws/contaminationTest qualitySoftware engineering

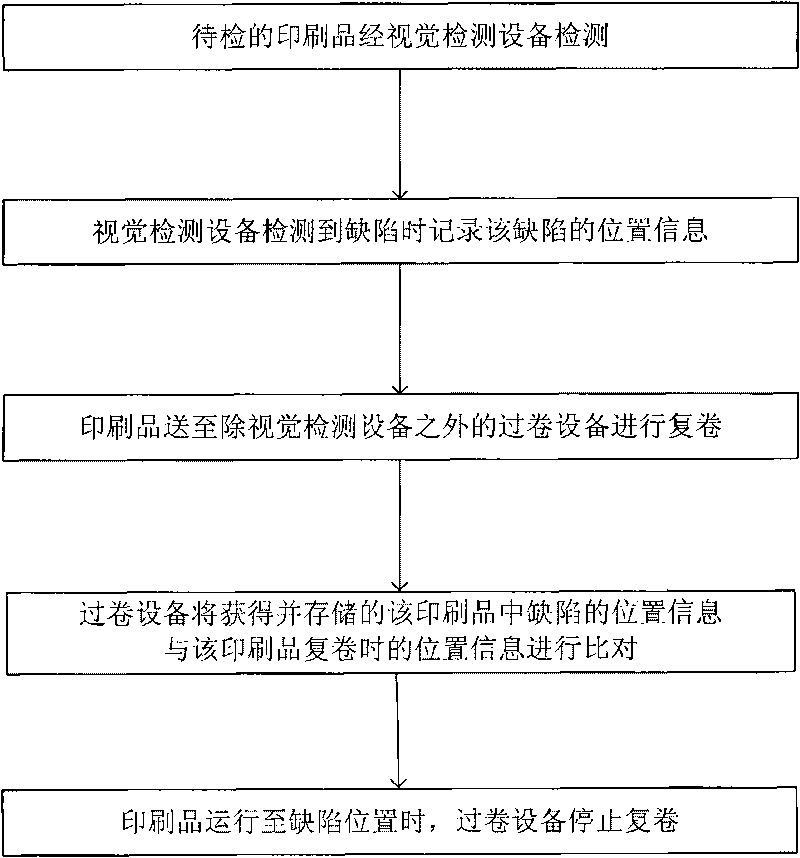

The invention relates to a process for testing quality of presswork. The process comprises the following steps that: A, a visual testing device tests the presswork to be detected; B, if any defect is tested, the visual testing device records position information of the defect in the presswork; C, the presswork is transferred to overwinding equipment besides the visual testing device for rewinding, and the overwinding equipment acquires and stores the position information of the defect in the presswork in the step B; D, the overwinding equipment compares the stored position information of the defect in the presswork with the position information acquired when the presswork is rewound; and E, when the presswork is transferred to the defect position, the overwinding equipment stops rewinding. The process for testing the quality of the presswork realizes separation of detection and treatment, and can lighten burden of the visual testing device, so the visual testing device is only responsible for detection, and then the presswork is placed to another overwinding equipment for special rechecking and treatment of the defect to ensure that the efficiency of presswork quality testing is improved.

Owner:BEIJING LUSTER LIGHTTECH

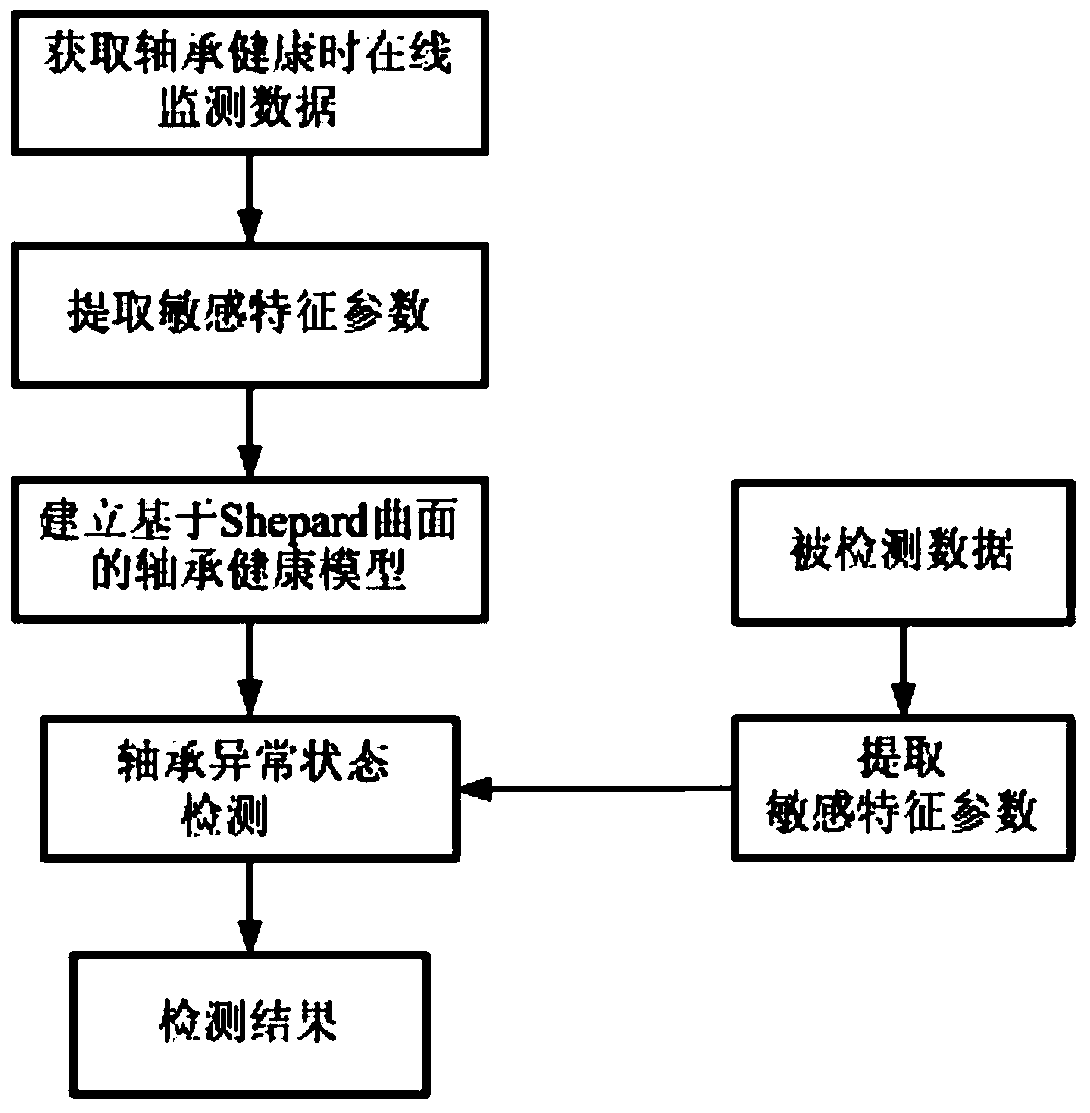

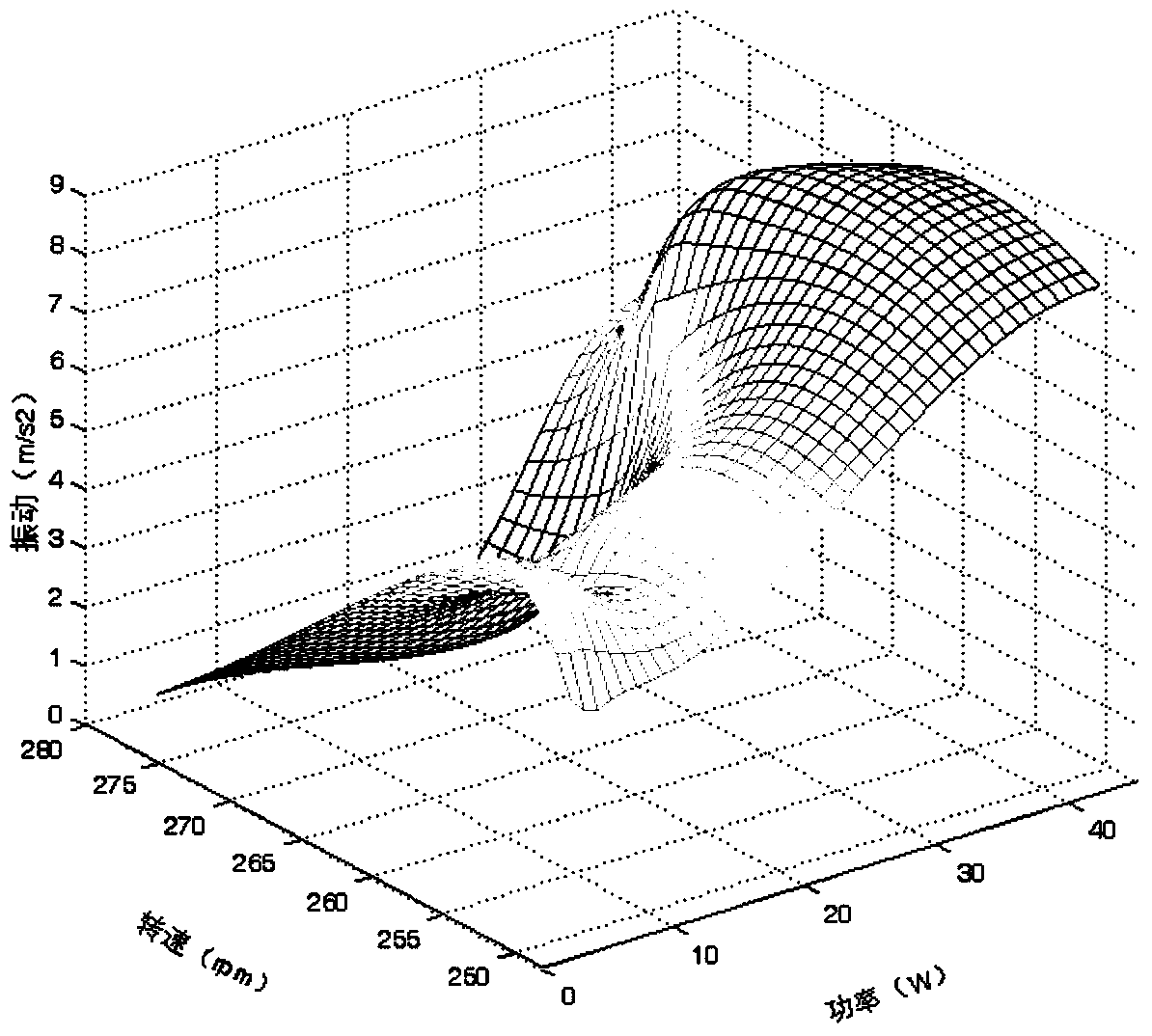

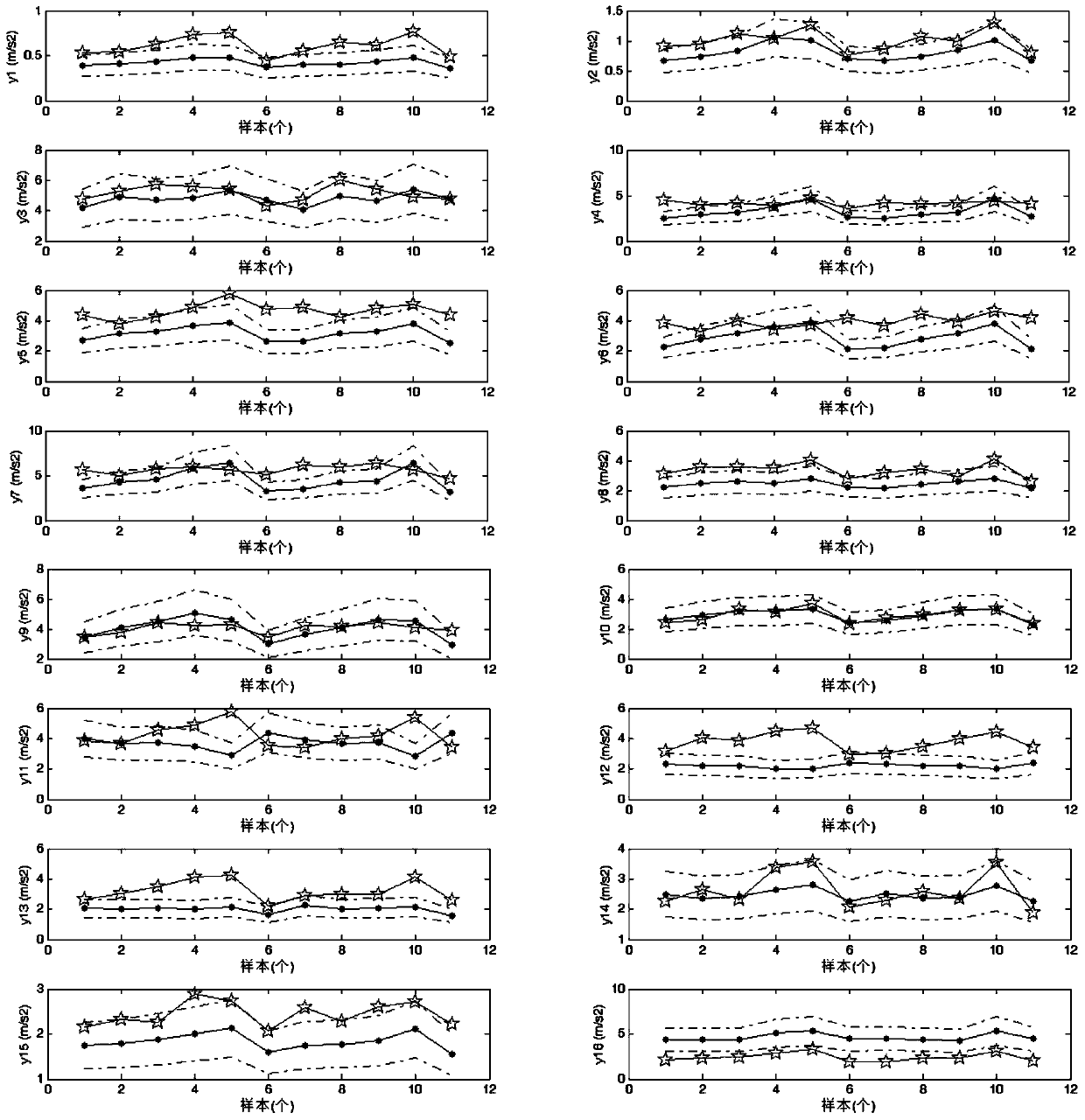

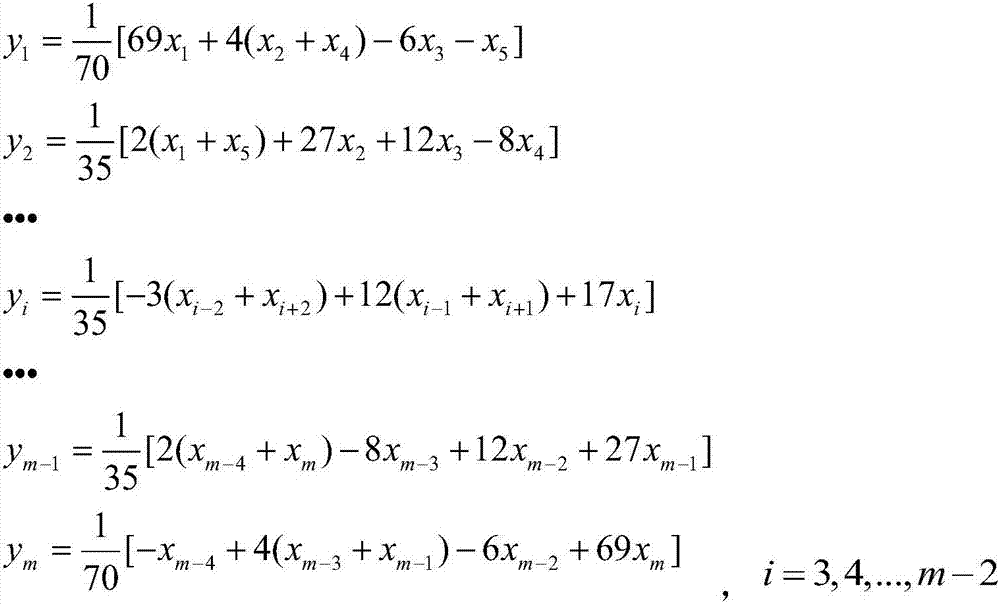

Self-adaptive anomaly detection method for rolling bearing of wind generator set under variable working conditions

InactiveCN103940611AHigh precisionAchieve couplingMachine bearings testingElectricityAnomaly detection

The invention relates to a self-adaptive anomaly detection method for a rolling bearing of a wind generator set under variable working conditions. The self-adaptive anomaly detection method comprises the steps that firstly, when the wind generator set runs normally, vibration data of the rolling bearing at different rotating speeds and different powers are collected; secondly, sensitive vibration characteristic parameters of the rolling bearing are selected; thirdly, a health model of the rolling bearing based on a Shepard curved surface is established; fourthly, the degree of deviation of the abnormal state of the rolling bearing is calculated, and self-adaptive anomaly detection of the rolling bearing is realized. According to the self-adaptive anomaly detection method, the influences of active power and rotating speed on the vibration characteristic of the rolling bearing are taken into comprehensive consideration, the evolution process of the running state of the rolling bearing of the wind generator set over time can be traced in real time, and self-adaptive detection of the abnormal state of the rolling bearing under different working conditions of the wind generator set is realized. The self-adaptive anomaly detection method can be widely applied to the field of abnormal state detection of the wind generator set.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

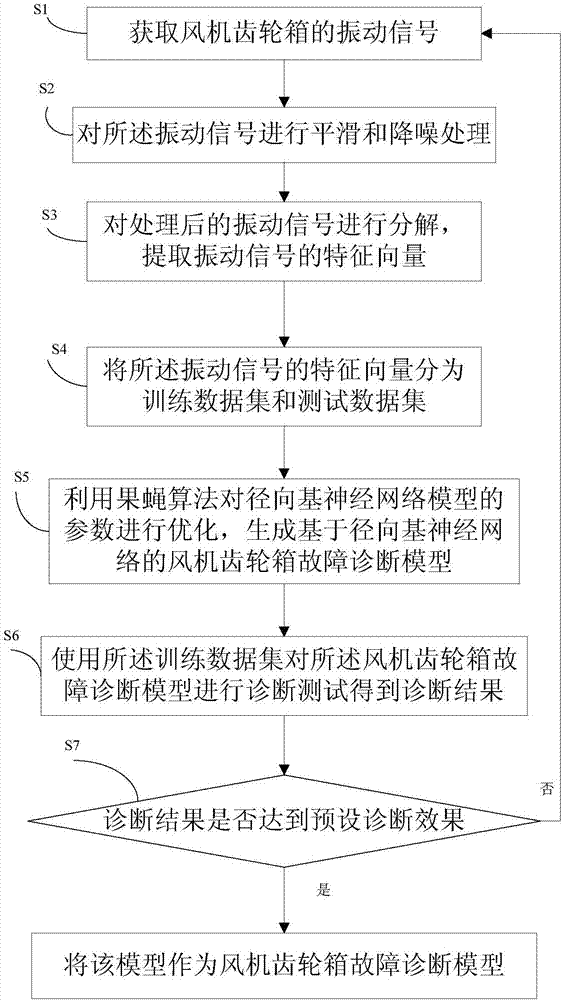

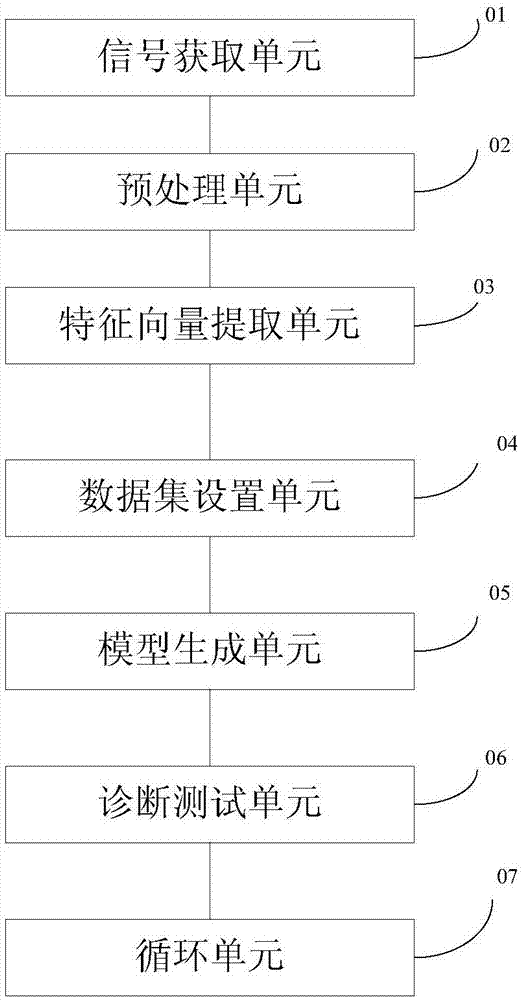

Fan gear box fault diagnosis model establishing method and device

InactiveCN106932196AImprove fault diagnosis abilityImprove accuracyMachine gearing/transmission testingNeural learning methodsFeature vectorData set

The invention provides a fan gear box fault diagnosis model establishing method used for establishing a fan gear box fault diagnosis model. The method comprises a step of obtaining a vibration signal of a fan gear box and then carrying out smoothing and denoising processing on the vibration signal, a step of decomposing the processed vibration signal and extracting the characteristic vector of the vibration signal, a step of dividing the characteristic vector of the vibration signal into a training data set and a testing data set, and a step of using a Drosophila algorithm to optimize a parameter of a radial basis function (RBF) neural network model, inputting the characteristic vector of the vibration signal in the training data set to obtain the optimal value of the parameter, generating the fan gear box fault diagnosis model based on a radial basis function neural network and carrying out test. In the scheme, the optimization algorithm is introduced for the characteristic of the RBF neural network, through introducing the artificial intelligence analysis technology, the extracted characteristic value is processed further, thus the efficiency of fault diagnosis is improved, and stop losses caused by faults are reduced.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Processing technology for recycling hot-rolled aluminum plate mill roll

The invention relates to a processing technology for recycling a hot-rolled aluminum plate mill roll. The processing technology comprises the following processing steps: selecting the used hot-rolled aluminum plate mill roll as a mother mill roll; roughly processing and quenching a roll sleeve; spraying the outer circle of the roll sleeve by high-pressure water spray, cooling and quenching; spraying the inner circle of the roll sleeve by low-pressure water spray and cooling; tempering the roll sleeve after quenching the roll sleeve; turning and grinding the roll sleeve, so that the technological requirement of processing drawing is met; turning and grinding the outer circle of the mother mill roll, so that the outer circle of the mother mill roll has the size matched with that of the inner circle of the roll sleeve in a thermal mode; heating the roll sleeve, preserving the heat, taking out the roll sleeve, matching and compounding the roll sleeve with the mother mill roll to form an integrated mill roll; tempering the integrated mill roll and eliminating the internal stress; turning and grinding the integrated mill roll, so that the technological requirement of processing drawing is met; and packaging and putting the products into a storage after the products are detected to be qualified. By the processing technology, the waste mill roll can be used reasonably and repeatedly, the service life of the hot-rolled aluminum plate mill roll can be prolonged, and the production cost of enterprises can be reduced.

Owner:WUXI SANFANG ROLLER

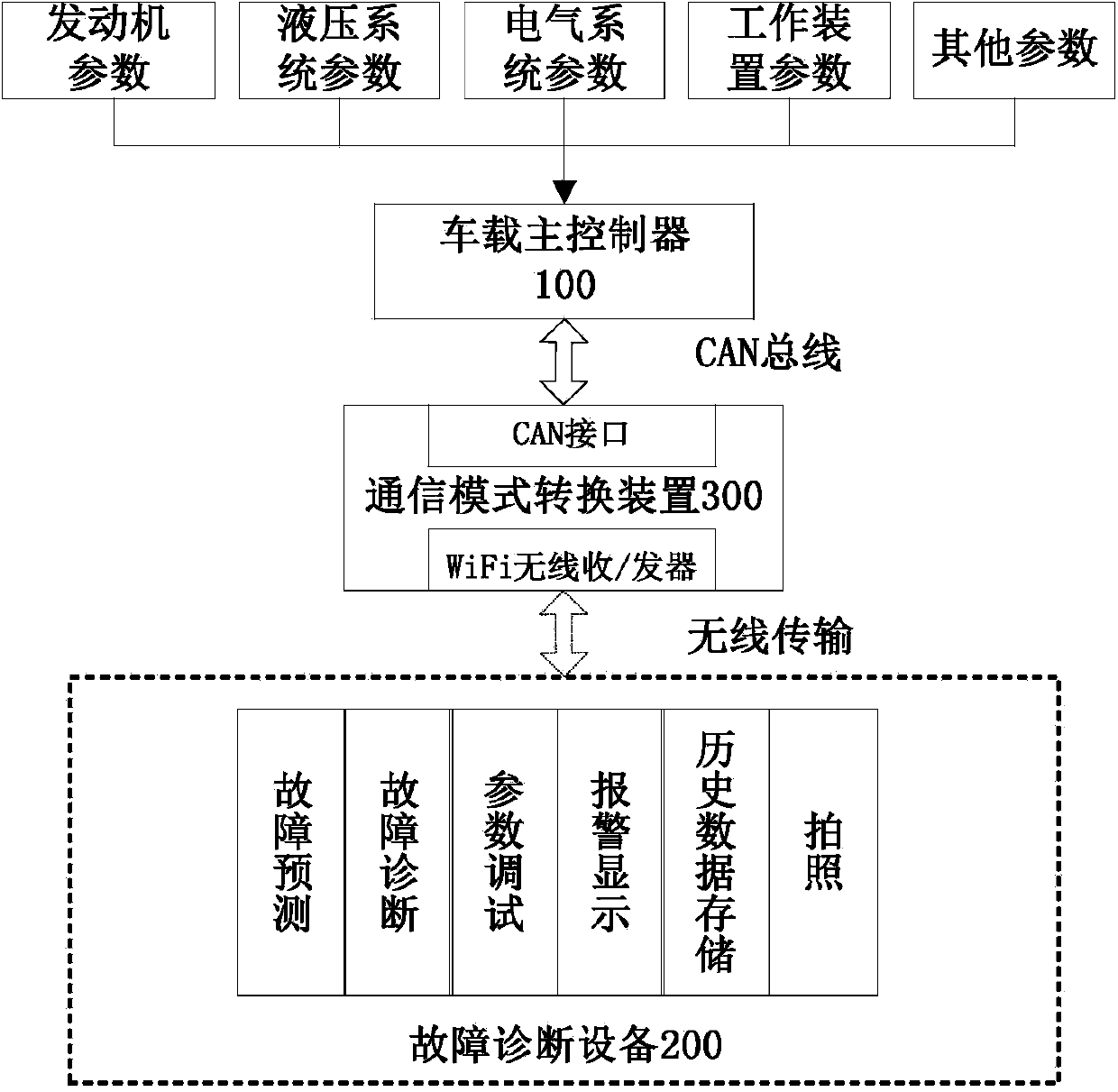

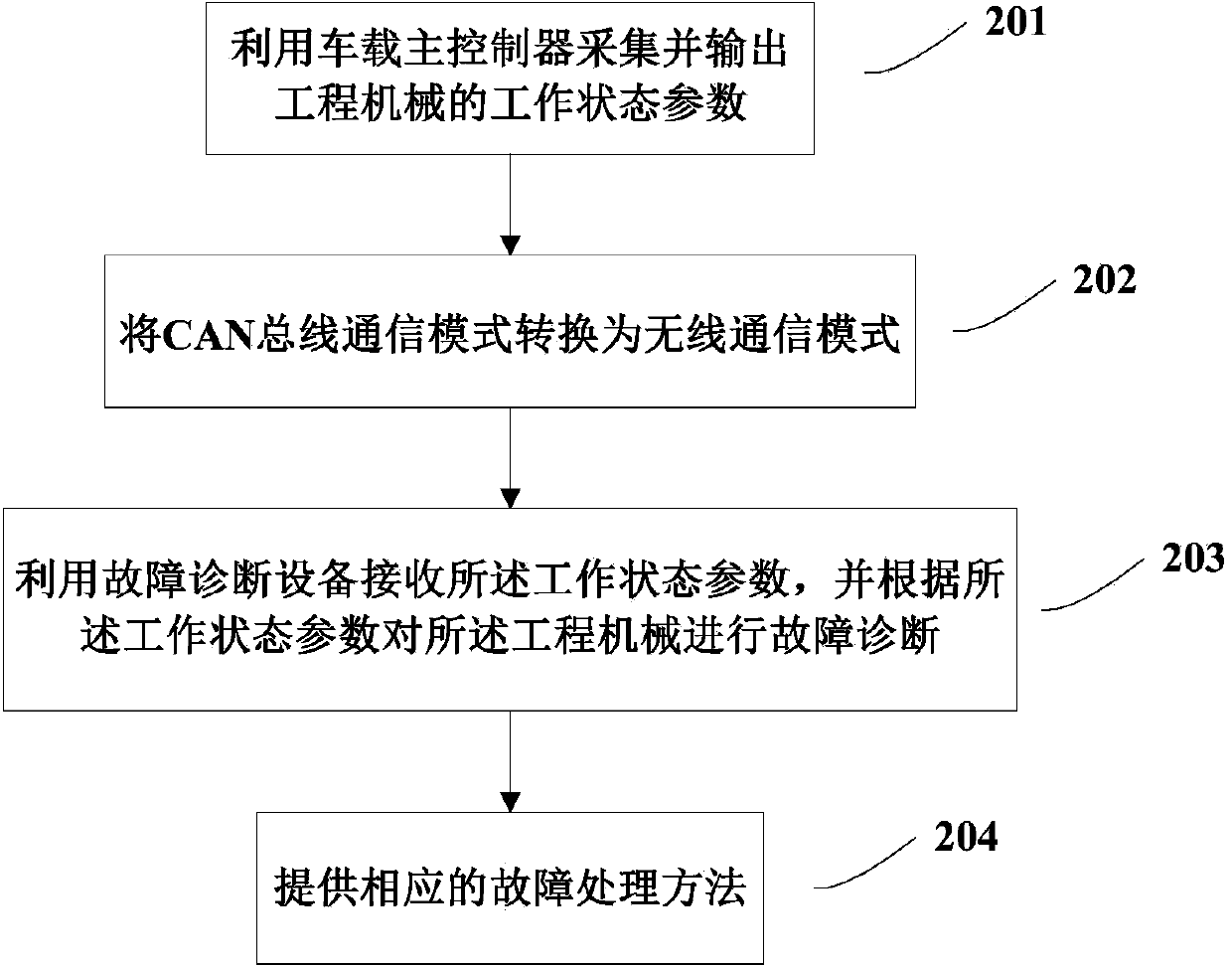

Engineering machine intelligent fault diagnosis system and method and engineering machine

InactiveCN103439944AEffective fault diagnosisLow costTotal factory controlProgramme total factory controlWork statusControl equipment

The invention discloses an engineering machine intelligent fault diagnosis system and method and an engineering machine. The engineering machine intelligent fault diagnosis system comprises a vehicle-mounted main controller and a fault diagnosis device, wherein the vehicle-mounted main controller is used for collecting and outputting work state parameters of the engineering machine, and the fault diagnosis device is used for receiving the work state parameters and carrying out fault diagnosis on the engineering machine according to the work state parameters. By means of the technical scheme, the vehicle-mounted main controller inside a cab in the engineering machine can be directly used for collecting the work state parameters for the fault diagnosis, a single-chip microcomputer or other control devices are not required to be additionally arranged for collection, the cost is low, the development period is short, the fault diagnosis can be effectively carried out on the engineering machine, the maintenance level is improved, and the machine-stop losses are reduced.

Owner:ZOOMLION HEAVY IND CO LTD

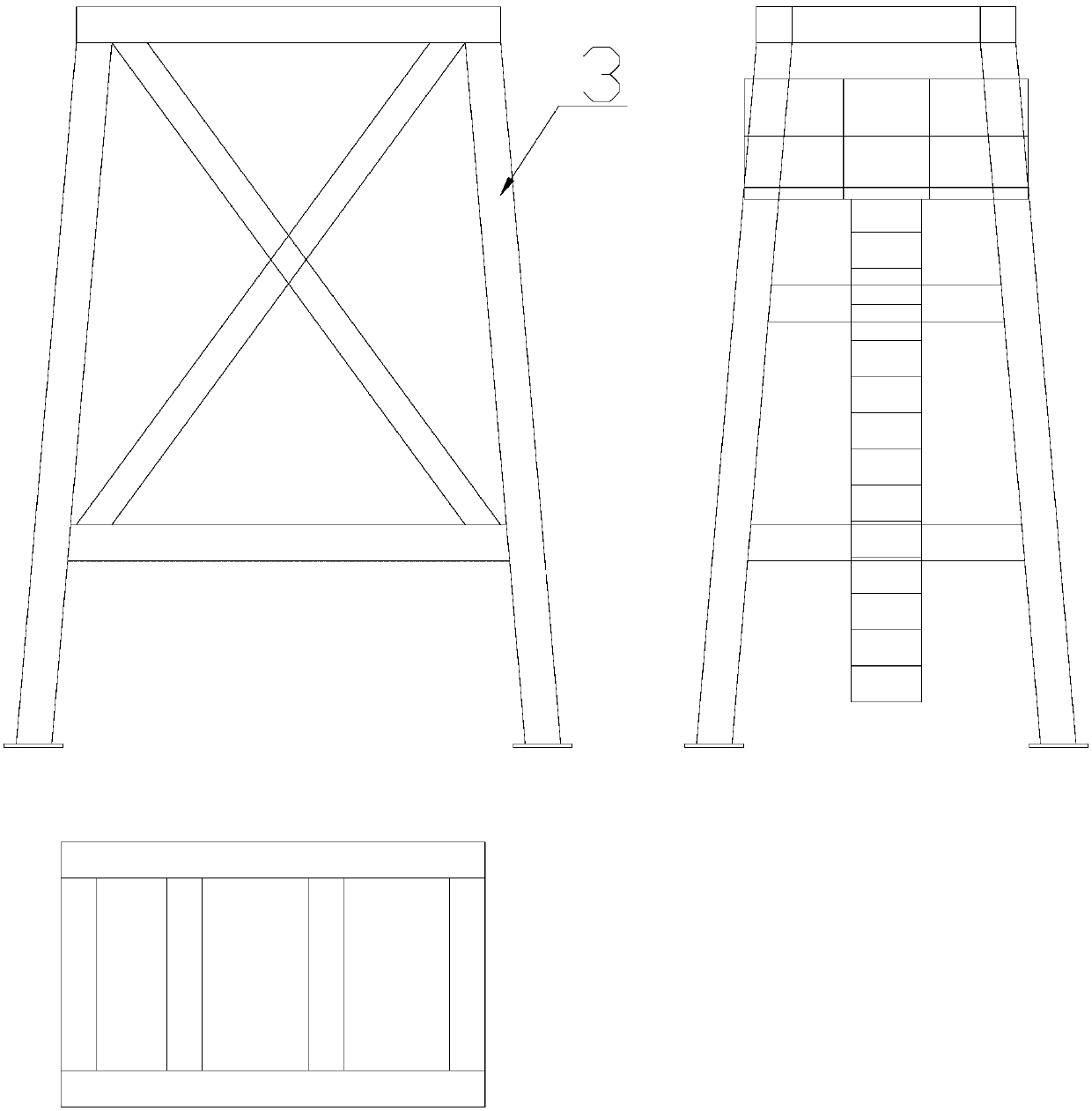

Construction method for sliding and replacing whole body of jacking and revolving bearing of revolved body of stacker-reclaimer

The invention discloses a construction method for sliding and replacing a whole body of a jacking and revolving bearing of a revolved body of a stacker-reclaimer, and belongs to the technical field of replacing components of the stacker-reclaimer in iron-smelting raw material yards. The construction method comprises the following steps: before machine halt construction, firstly manufacturing jack supporting beams, safe piles and a stirrup, mounting the jack supporting beams, and mounting the stirrup; selecting hydraulic jacks, and erecting the selected hydraulic jacks; sealing the whole body of the revolved body of the stacker-reclaimer, manufacturing a sliding device of the revolving bearing, mounting the manufactured sliding device, and dismounting and removing components which have influence on the horizontal sliding of the revolving bearing; sliding the whole body of the jacking and revolving bearing of the revolved body, replacing the slid whole body of the jacking and revolving bearing of the revolved body, and mounting the components which have influence on the horizontal sliding of the revolving bearing. The construction method has the advantages that the problems that a large-scale vehicle type crane needs to be used during replacing the revolving bearing of the stacker-reclaimer in the iron-smelting raw material yards, the construction time is long, the occupied site is large, the construction cost is high and influence on the production is great; the method is simple and easy to operate, and the construction cost is reduced; the construction site is reduced, the whole construction time of jacking and sliding is shortened, and influence on the production is reduced; double safety facilities of the sealed whole body and the safe piles are adopted, so that the safety guarantee is supplied.

Owner:BEIJING SHOUGANG CONSTR GROUP

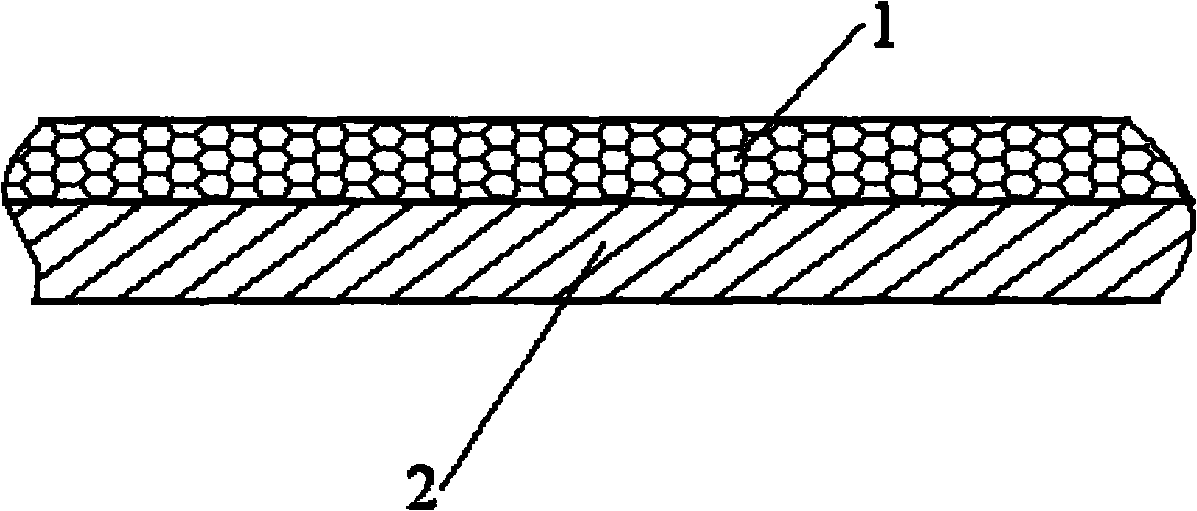

Wear-resistance composite board of metal machine part and repair process thereof

InactiveCN101774288AExtended service lifeLow running costArc welding apparatusMetal layered productsMachine partsWear resistant

The invention discloses a wear-resistance composite board of a metal machine part. An overlaying wear-resisting layer (1) is arranged on the surface of an ordinary steel plate (2); and the overlaying wear-resistant layer (1) is made of hypereutectic high-chromium alloy. The invention also discloses a repair process of the wear-resistant composite board of the metal machine part. The wear resistance of a wear-resistance plate machined by adopting the technical scheme is 12 to 18 times higher than that of low-carbon steel, 5 times higher than that of stainless steel and high manganese steel and1 time higher than that of as-caststate high ferrochrome; and simultaneously, the wear-resistant plate improves the service life of the machine part and reduces the maintenance cost, machine halt loss and the like of equipment, and the performance-price ratio of the wear-resisting plate is 2 to 4 times higher than that of other materials. Due to reasonable utilization of materials, the cost of the wear-resisting overlaying composite board is reduced by 50 percent compared with the cost of manual overlaying of the same materials. The technology can be popularized and applied in cement enterprises, so that the operating cost of the cement production enterprises is reduced greatly.

Owner:ANHUI CONCH KAWASAKI EQUIP MFG

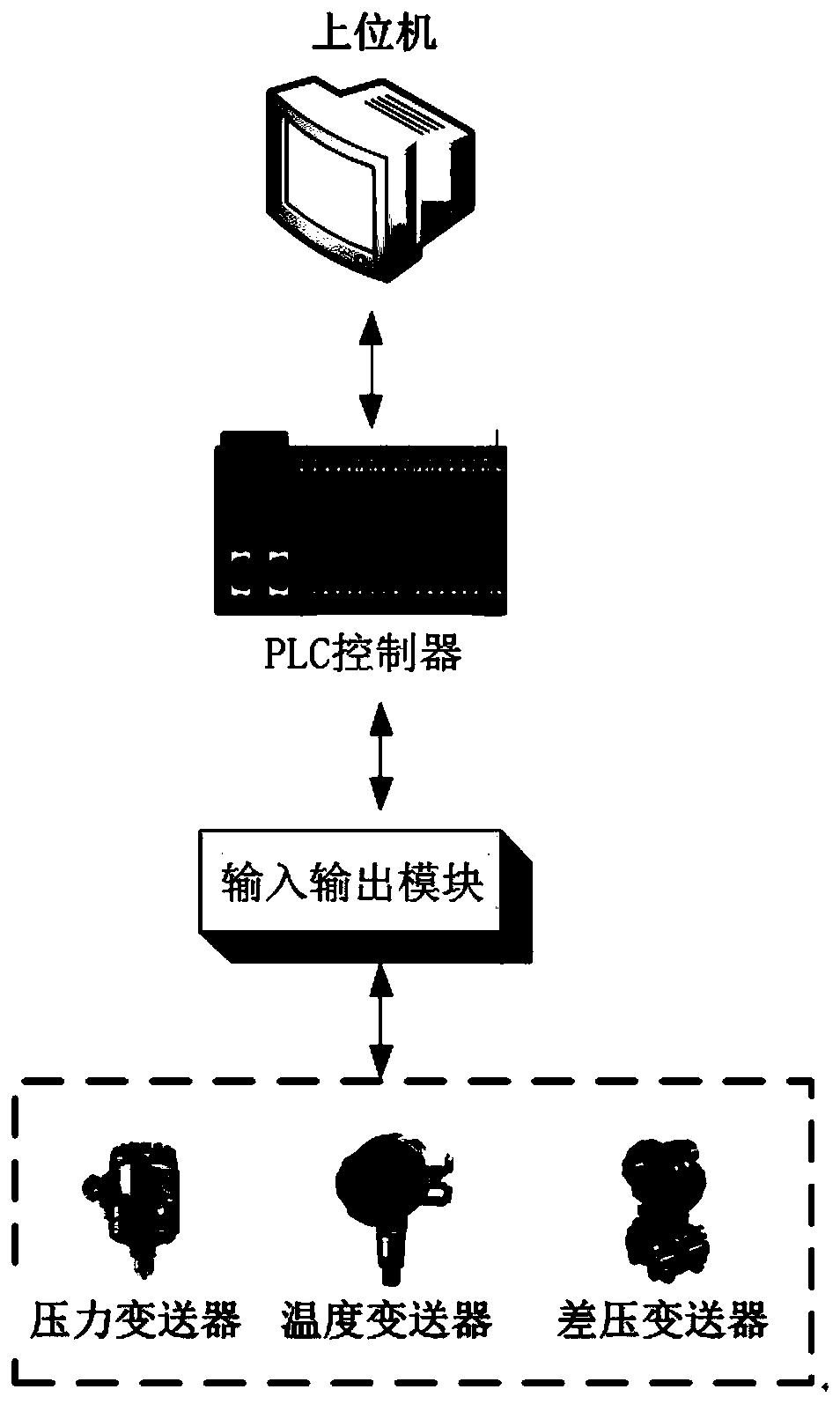

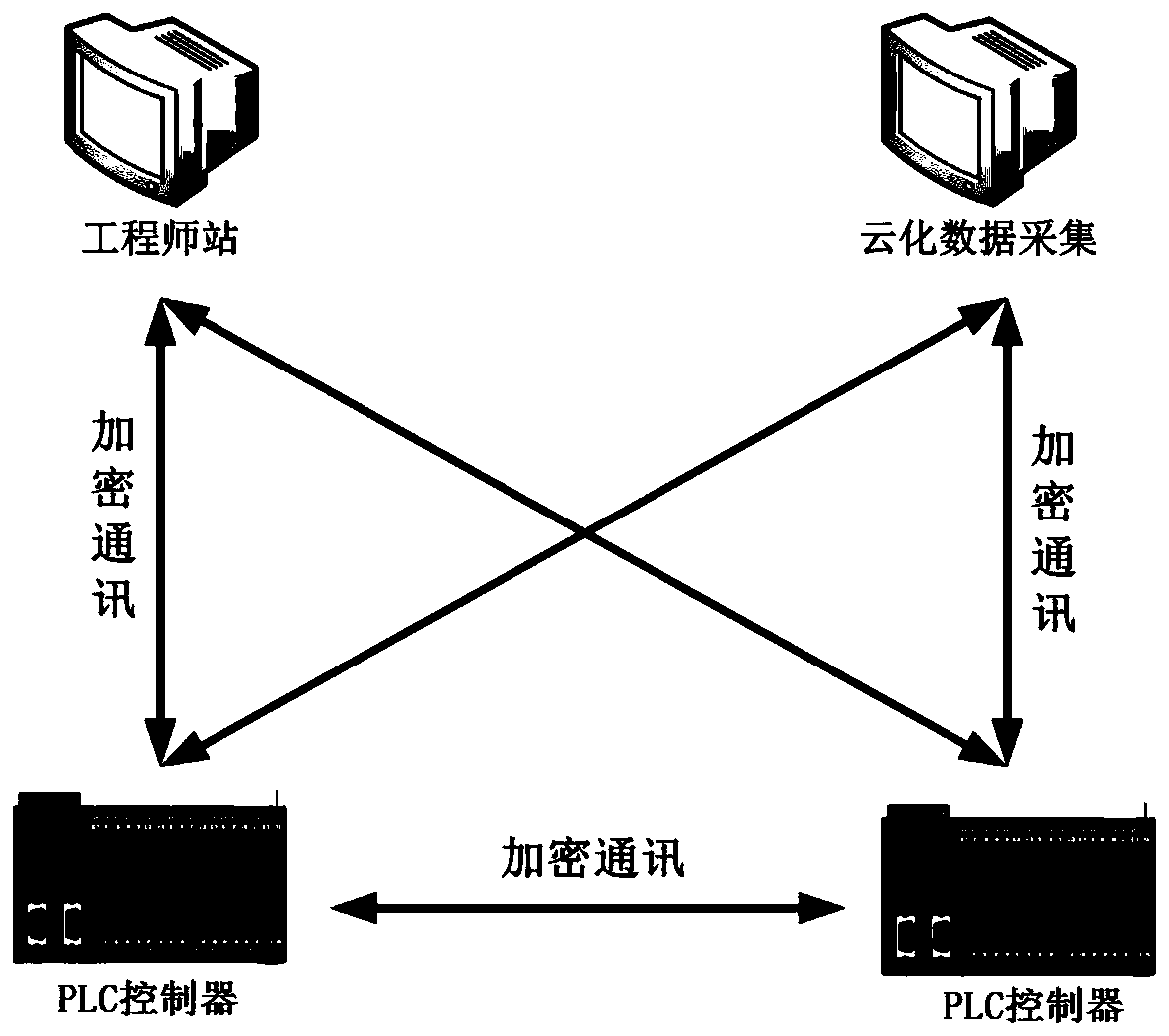

Safety industrial control system based on safety intelligent controller

ActiveCN110891063AIncrease network security protection functionReduce downtime lossTransmissionProgramme control in sequence/logic controllersControl engineeringSecurity Measure

The invention relates to a safety industrial control system based on a safety intelligent controller. The system is composed of a PLC controller, an input and output module and an upper computer. ThePLC controller is the core of the whole system. An independently researched and developed industrial chip is adopted, and a security firewall and a security encryption system are arranged in the industrial chip. Safety protection is realized on an infected main body. An input and output module and an upper computer are matched to form a set of pure industrial control system with safety protection.A safety protection system is arranged in each link of the upper computer, the PLC and the input and output module, multiple protection is achieved, major accidents such as misoperation can be avoided even if one link is attacked, the other two links can be comprehensively verified and judged, fault processing is carried out, and safety measures are immediately taken to prevent accident expansion.

Owner:信联科技(南京)有限公司

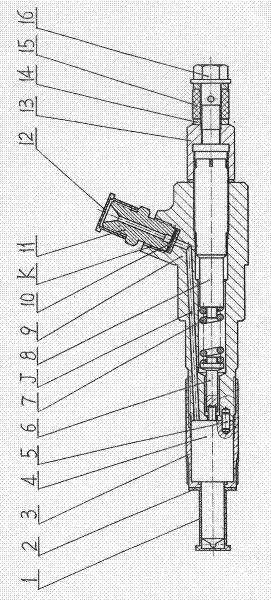

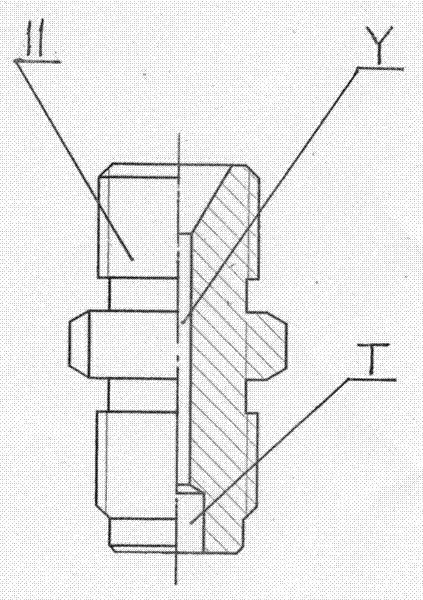

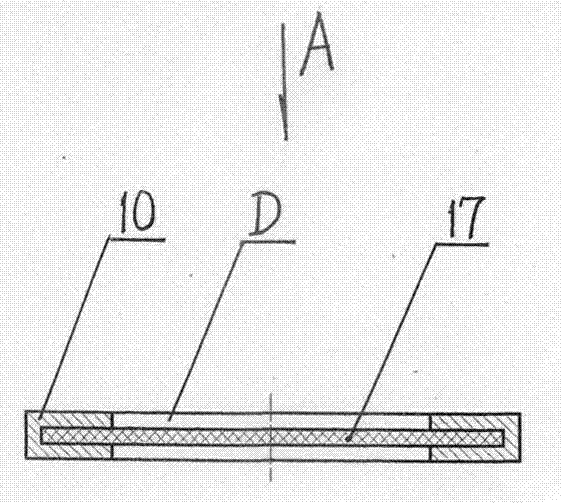

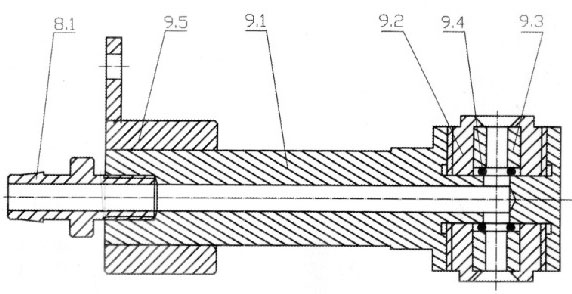

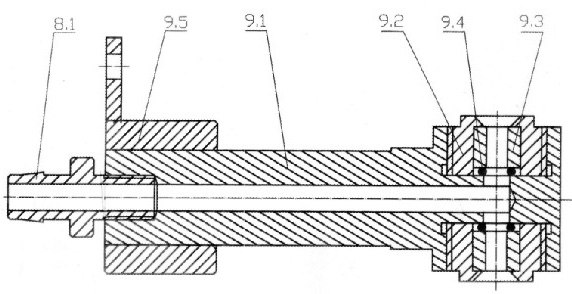

A fuel injector equipped with a fuel filter device

InactiveCN102297064AAvoid enteringExtended service lifeFuel injection apparatusMachines/enginesEngineeringInternal combustion engine

A fuel injector equipped with a fuel filter device, the filter device is matched with a reaming fuel inlet pipe joint (11) and a filter gasket (10), and is installed in the pipe joint connection hole (K) of the fuel injector body (9) Inner, reamed oil inlet pipe joint (11) The inner end of the pipe joint oil inlet hole (Y) is reamed to form a stepped hole (T). The diameter of the stepped hole (T) is φ3~5mm, and the depth is 2~10mm. Gasket (10) is folded inwards by metal ring-shaped thin gasket, and a layer of metal filter screen (17) is sandwiched in the middle to block gasket mesopore (D) to form, and the fineness of metal filter screen (17) is 80~160 orders. When the fuel is fed into the injector body (9) through the reaming inlet pipe joint (11) and the filter gasket (10), the impurity particles in the fuel are blocked by the filter mesh (17) of the filter gasket (10), Stay in the stepped hole (T) of the reaming oil inlet pipe joint (11) to ensure that the fuel injector assembly (4) is not stuck, prolong the service life, reduce the loss of shutdown, and ensure that the fuel injector assembly and the complete internal combustion engine work performance.

Owner:SHANDONG XINYA IND

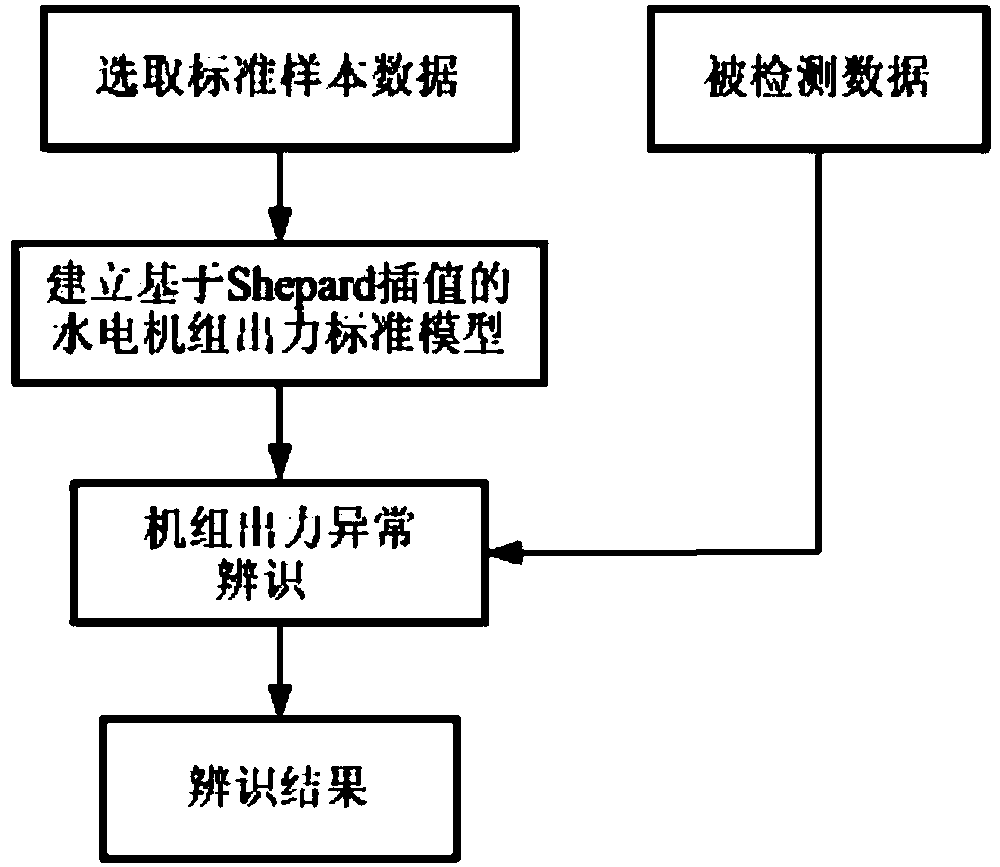

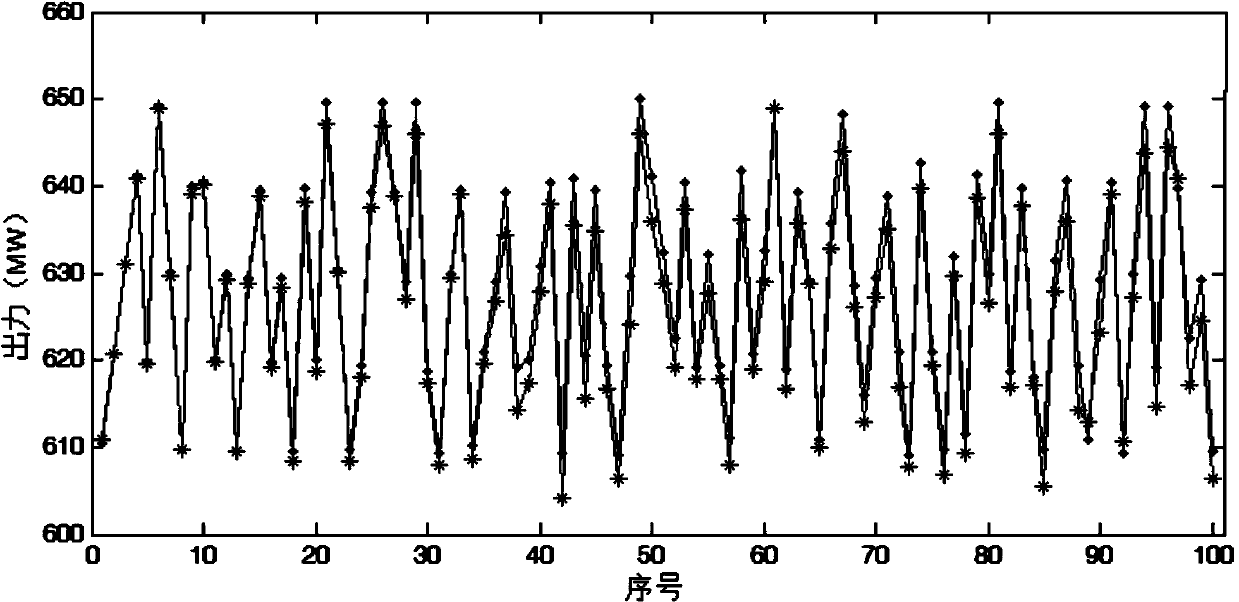

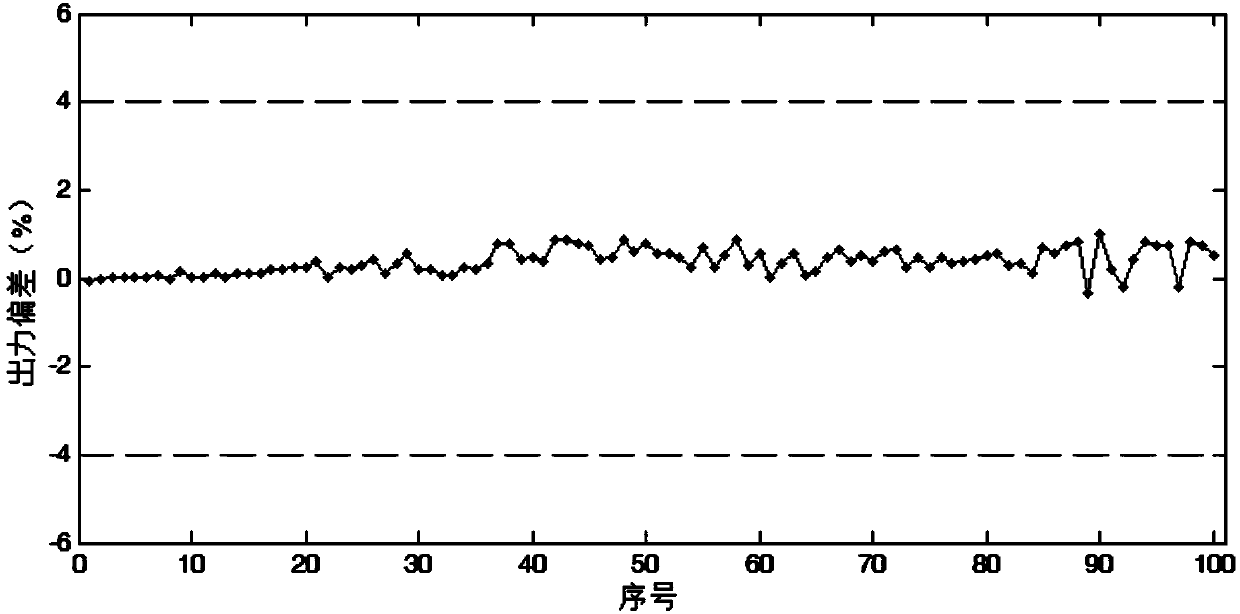

Method for detecting output abnormity of mixed-flow hydroelectric generating set

The invention relates to a method for detecting output abnormity of a mixed-flow hydroelectric generating set. The method includes the steps that firstly, output data of the hydroelectric generating set are collected when output of the hydroelectric generating set is normal and the upper level and the lower level of a hydroelectric station are different and guide vane openings of a water turbine are different, and the output data serve as standard samples; secondly, based on the Shepard curved surface interpolation method, a standard hydroelectric generating set output model P = f(Hupper, Hlower and D) is established according to the standard samples; thirdly, real-time online data, obtained by detecting the set state in real time, of the guide vane openings, the upper level and the lower level are substituted into the standard hydroelectric generating set output model, the standard set output value p(i) in the current working condition is calculated, the current set output deviation Od(i) is obtained, and an alarm is given when the absolute value of the output deviation Od(i) is larger than a preset output deviation threshold. Standard set output values under different working conditions are established through historical sample data, online state evaluation can be effectively, truly and reliably conducted, and early warning of set output abnormity is achieved. The method can be widely applied to the field of detection of the operating state of the hydroelectric generating set.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

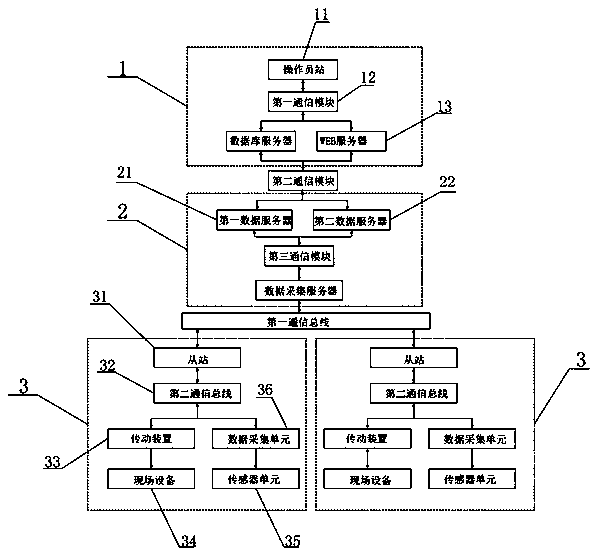

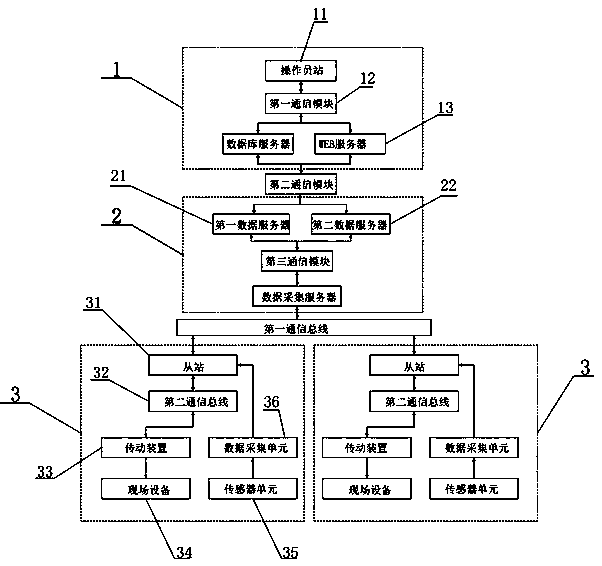

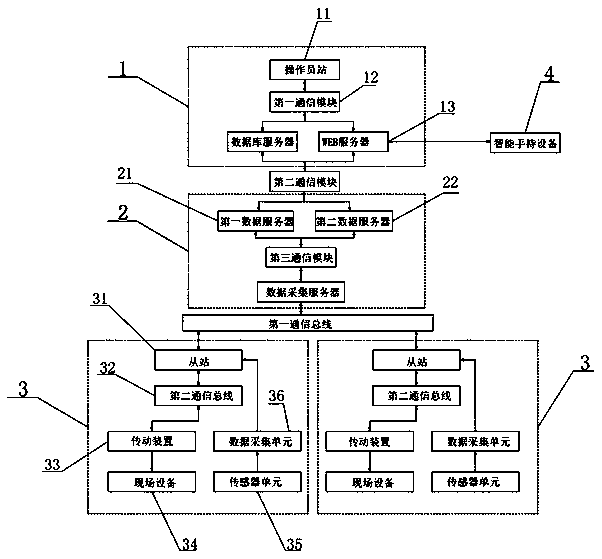

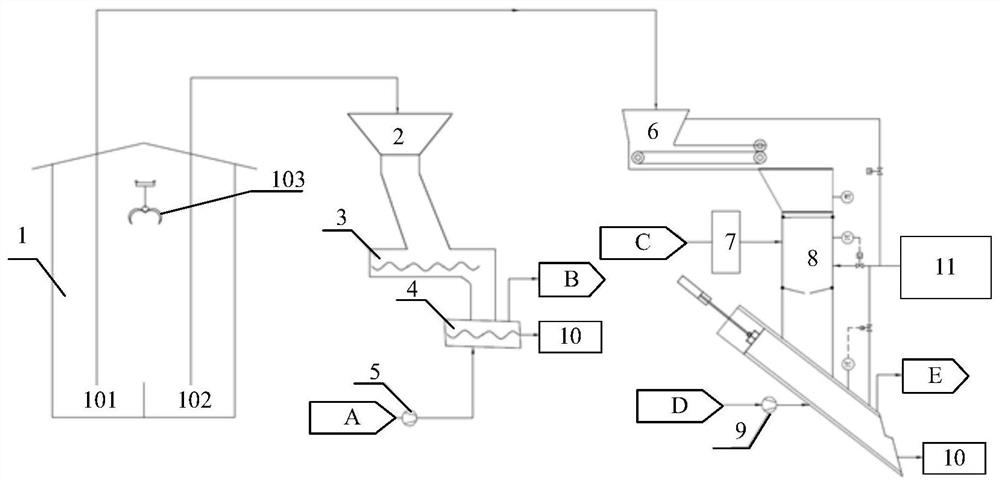

Continuous rolling and transmission monitoring system based on PLC (Programmable Logic Controller) and monitoring method of continuous rolling and transmission monitoring system

ActiveCN105511440AAchieve layered flowImprove stabilityTotal factory controlProgramme total factory controlThree stageProgrammable logic controller

The invention discloses a continuous rolling and transmission monitoring system based on a PLC (Programmable Logic Controller) and a monitoring method of the continuous rolling and transmission monitoring system. The continuous rolling and transmission monitoring system comprises an upper monitoring unit, a middle network unit and a plurality of in-situ monitoring units, wherein the upper monitoring unit is communicated with the middle network unit through a second communication module; the middle network unit is communicated with the in-situ monitoring units through a first communication bus. The invention discloses the continuous rolling and transmission monitoring system based on the PLC and the monitoring method of the continuous rolling and transmission monitoring system; according to set control parameters and set operation parameters, a working state of a steel rolling set is controlled by controlling a transmission device through the PLC; working state data of the steel rolling set can be transmitted to an operator station in the upper monitoring unit through a network. A control system and the monitoring system are of a three-stage network structure. data communication between each two network structures is realized through a switch, and layered flowing of monitoring information streams can be conveniently realized; the continuous rolling and transmission monitoring system and the monitoring method, provided by the invention, are suitable for meeting control requirements of different types of management.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

Carrier backflow device

InactiveCN107954166AAvoid damage and scrapReduce downtime lossElectrical testingControl devices for conveyorsButt jointDelayed time

The invention provides a carrier backflow device. The carrier backflow device comprises a first carrier sensing part, a transferring platform position sensor and a second carrier sensing part; the first carrier sensing part is used for detecting whether a carrier exists on a transferring platform or not, the transferring platform position sensor is used for detecting whether a transferring track is located at the position where the transferring track is butted joint with a testing track or not, and the second carrier sensing part is used for detecting whether the carrier exists on the transferring platform or not when the transferring track is moved to the place where the transferring track is butted joint with a backflow track; when the first carrier sensing part does not sense the carrier and the transferring platform position sensor senses the transferring track, the carrier is conveyed from a testing platform to the transferring platform; and when the first carrier sensing part does not sense the carrier and after the second carrier sensing part senses the carrier and when the second carrier sensing part does not sense the carrier within the preset delay time, the transferringplatform is conveyed to the position where the transferring platform is butted joint with the testing track. According to the carrier backflow device, collision between the transferring track and a board or falling of the board can be effectively avoided, the situation that the carrier is clamped, damaged and scraped is avoided, and the loss of stopping line is reduced.

Owner:INVENTEC CHONGQING

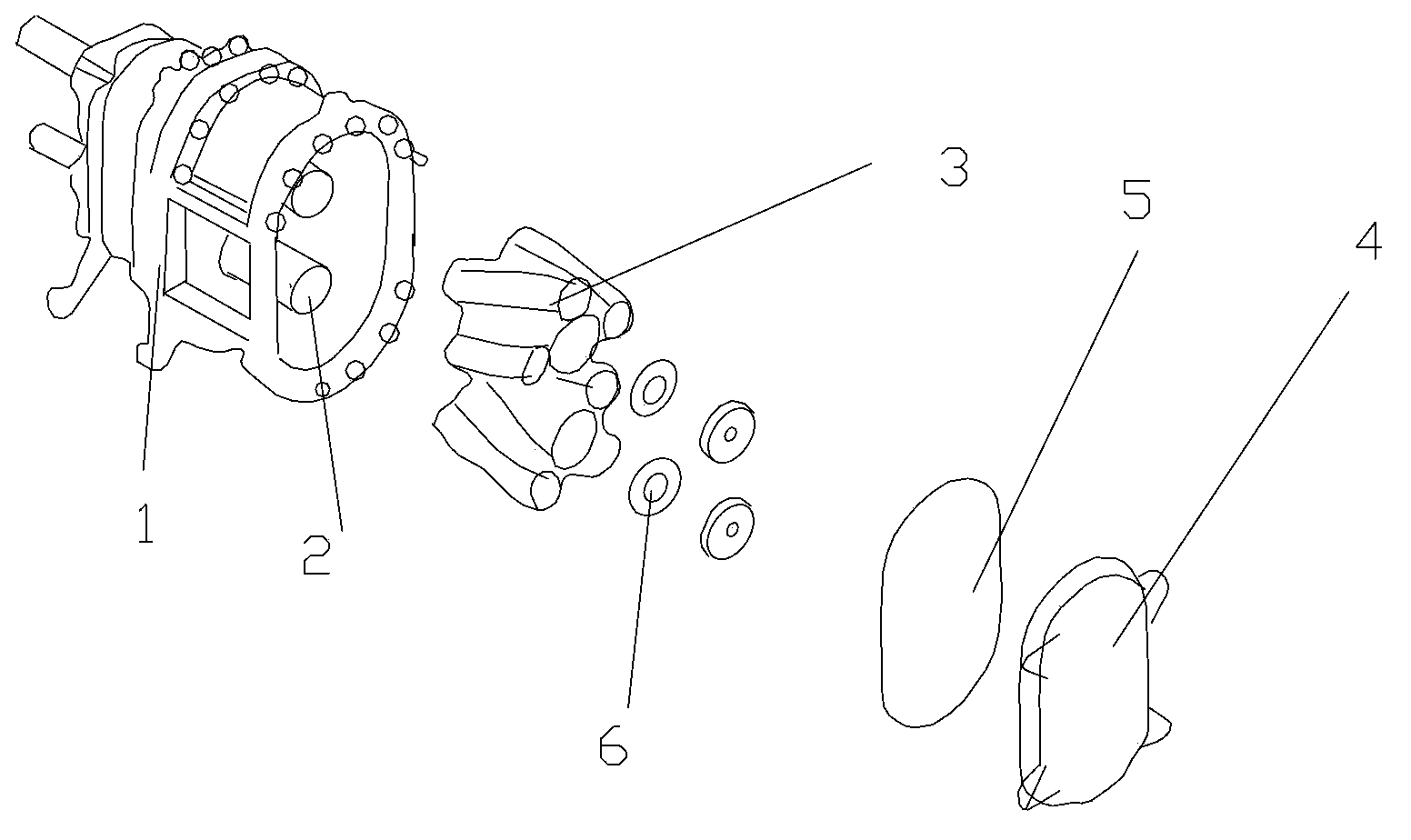

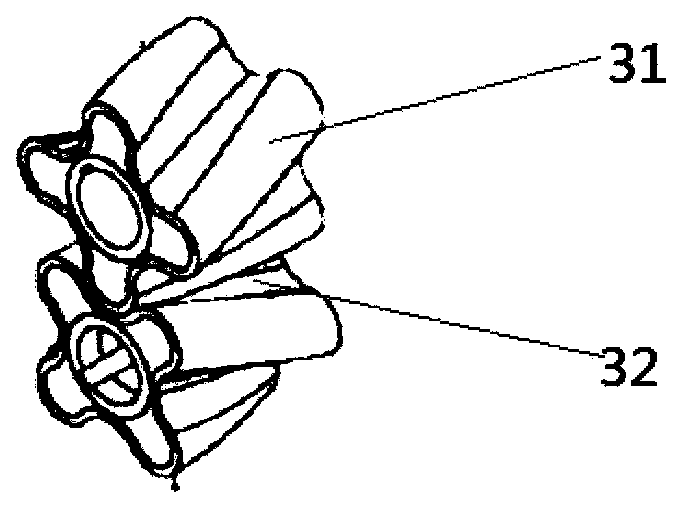

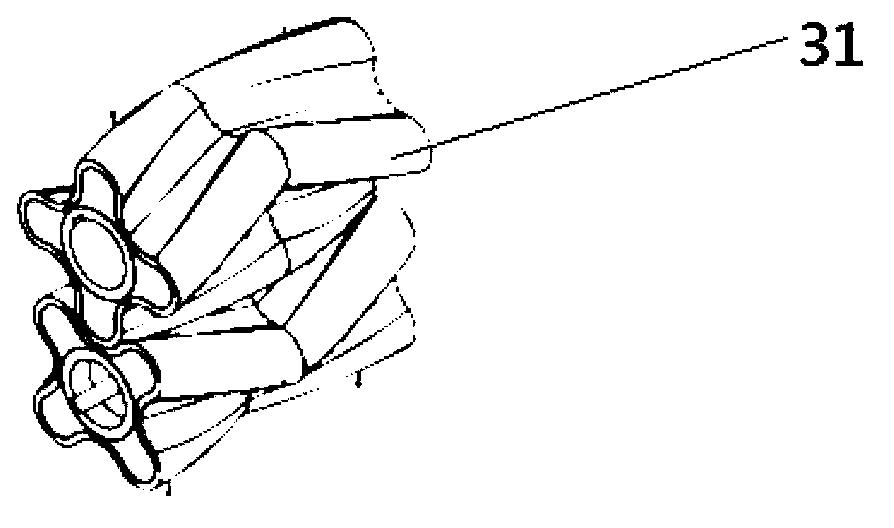

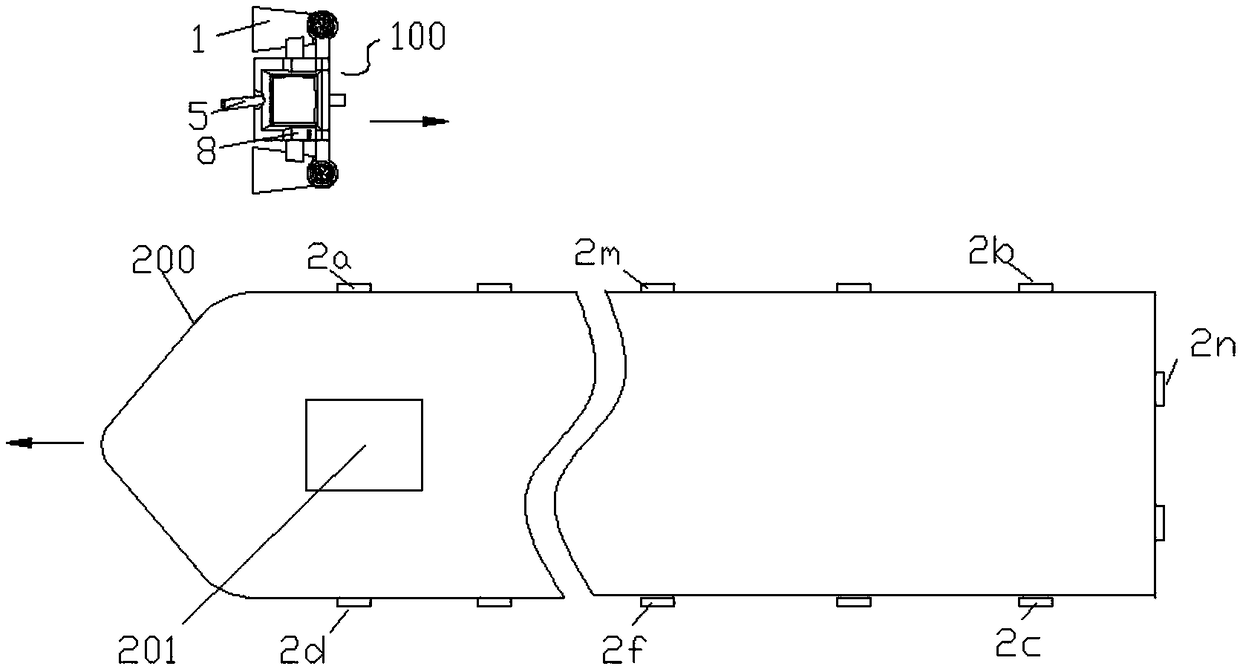

Pulseless rotor pump

InactiveCN103850932AGuaranteed pulsation-free deliveryImprove efficiencyRotary piston pumpsRotary piston liquid enginesPipe fittingWear resistant

The invention discloses a pulseless rotor pump (Q type). The pulseless rotor pump comprises a rotating shaft and a bearing connected with the rotating shaft, and is characterized in that the rotating shaft and the bearing are arranged in parallel, at least one spiral rotor is arranged on the rotating shaft, and the spiral rotors are uniformly distributed on the rotating shaft. The pulseless rotor pump disclosed by the invention can be quickly repaired on the site, and wearing parts at the part of a pump chamber, including the rotors, a wear-resistant plate and machinery can be sealed by axially moving an end cover easily, so as to realize replacement on the site under the situation of not detaching pump inlet and outlet pipe fittings and a pump body.

Owner:上海易昆机械工程有限公司

A method and apparatus for cleaning ships sail in that sea

PendingCN109263828AReduce downtime lossEnhanced seagoing capabilitiesVessel cleaningHullsMarine engineeringMarine navigation

The invention discloses a method and apparatus for cleaning a ship navigating in an ocean comprising setting a plurality of RFID tags on both sides of that ship navigating in the ocean for navigate the movement of a robot, setting a plurality of RFID tags on both sides of the RFID tags, and setting a plurality of RFID tags on both sides of the RFID tags for navigating the movement of the robot. The robot is provided with an RFID tag reader and writer for respectively exchanging information with a plurality of RFID tags on the ship. The robot placed on the ship is released into the sea along the ship side, and the robot moves on the ship side according to the signal sent by the ship in response to the RFID tag reader / writer. When the robot moves on one side of the ship, it washes the ship according to the signal it detects to wash the ship. The method of the invention can carry out contactless line inspection cleaning on ships in navigation, get rid of the restriction of docks and wharves, reduce the loss of ship stopping navigation, prolong the life of the ship, enhance the capability of ocean navigation of the ship, and increase the navigation mileage.

Owner:高溯

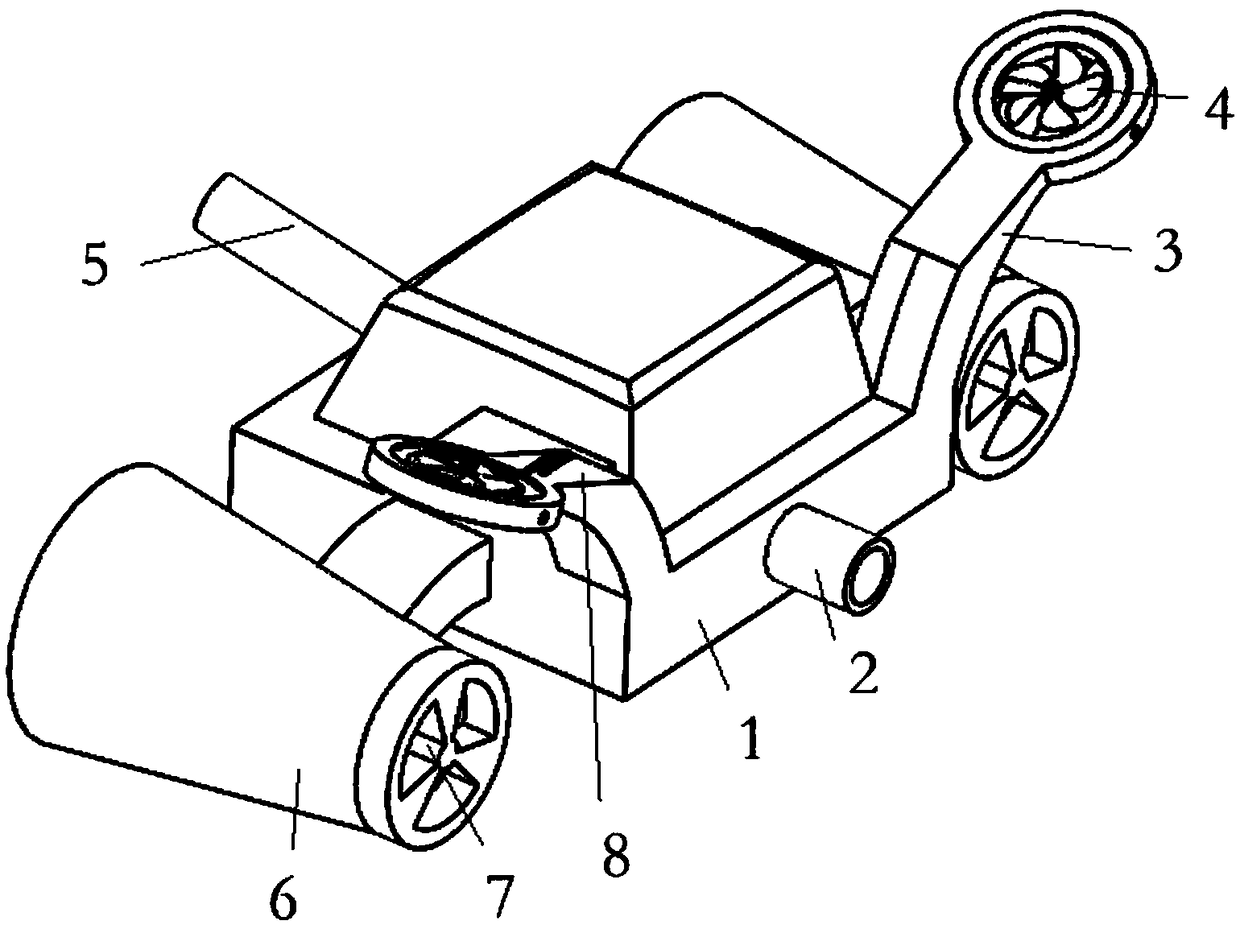

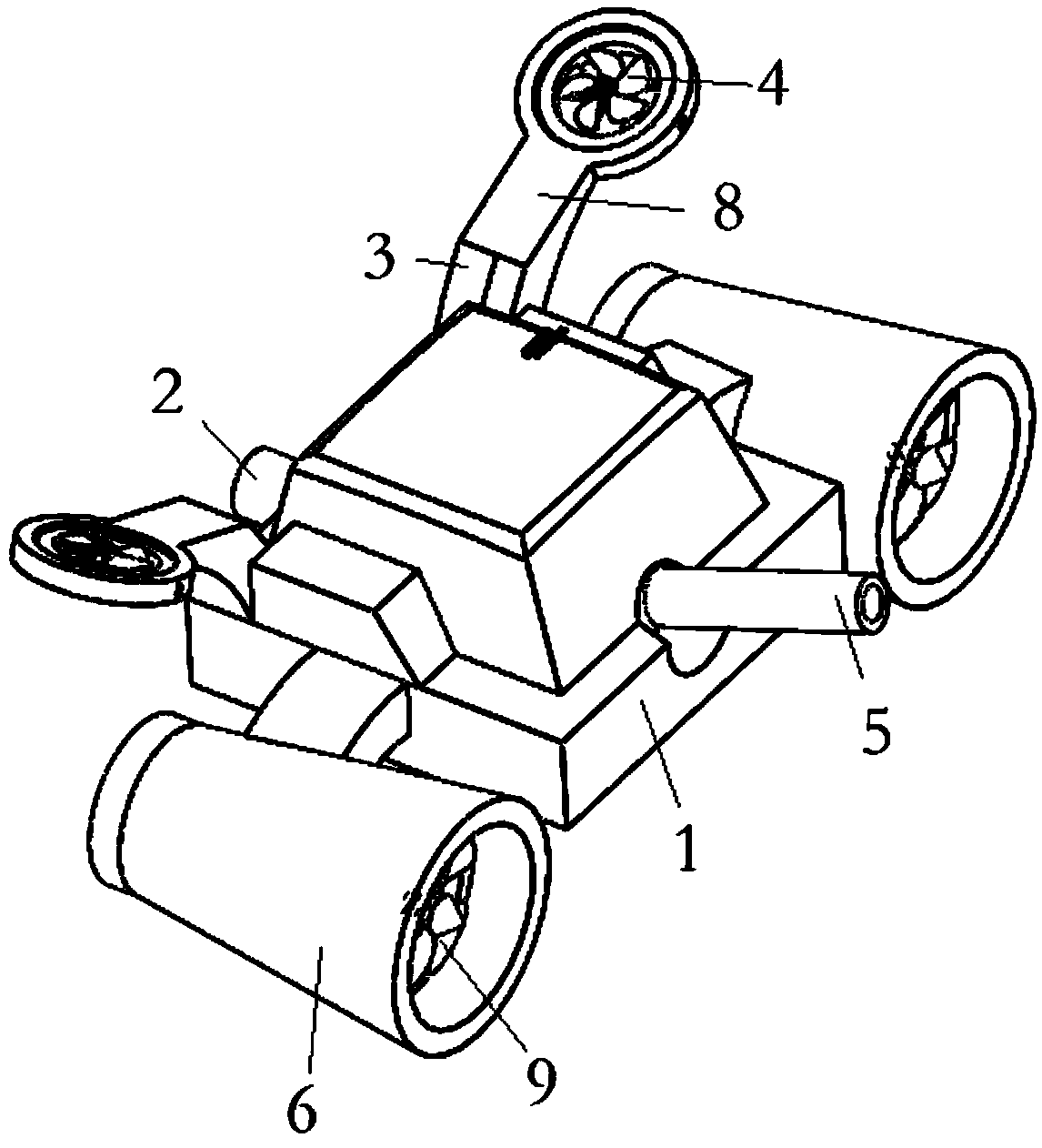

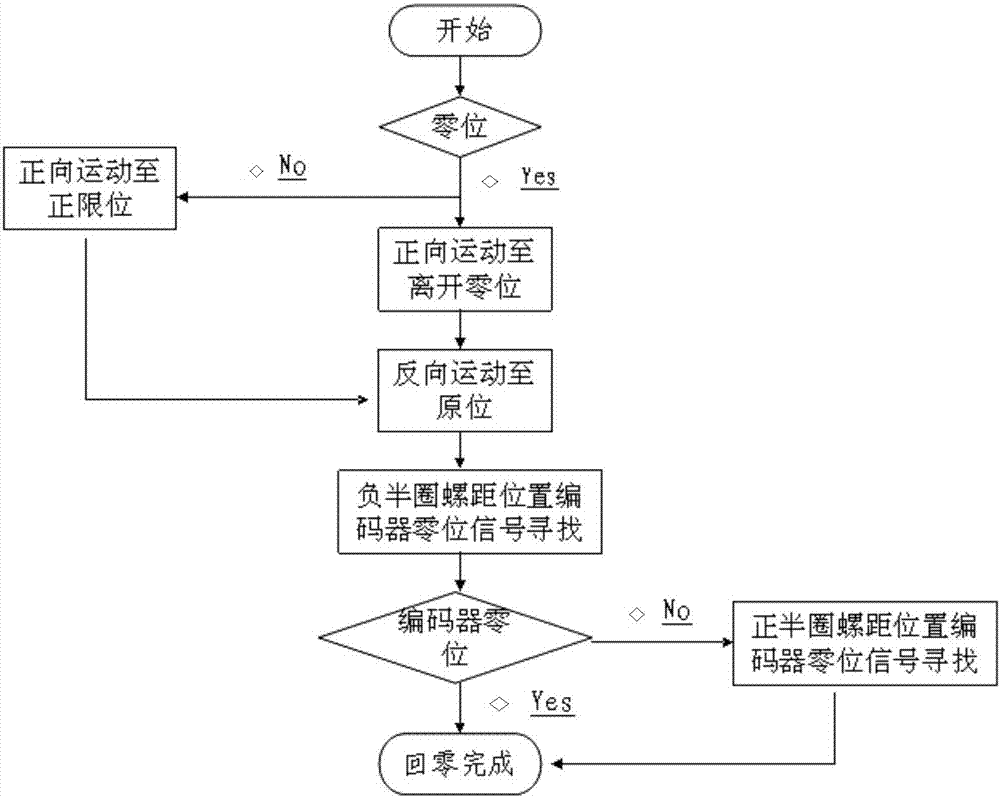

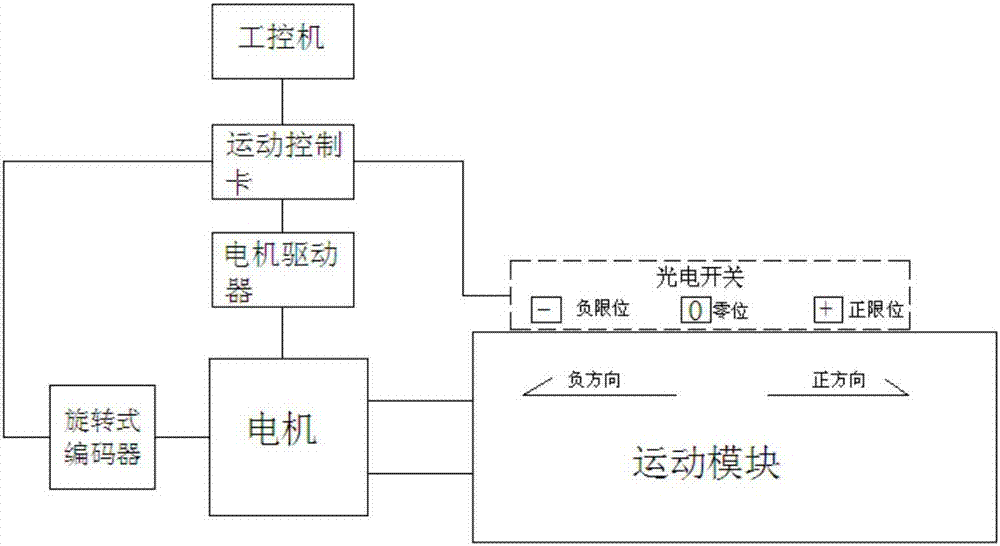

Return-to-zero system and method for electric discharge machining machine tool

InactiveCN106975805AAvoid workpiece damageReduce machine downtime lossesElectric circuitsReturn-to-zeroPersonal computer

The invention discloses a return-to-zero system and a return-to-zero method for an electric discharge machining machine tool. The system comprises an industrial personal computer, a motor driver, a motion control card, a motion module, a rotary coder, a photo-electronic switch and a motor, wherein the industrial personal computer is used for controlling the motion control card; the motion control card is connected with the motor driver, the rotary coder and the photo-electric switch respectively; the motor driver is used for controlling a shaft to move by virtue of the motor and driving the motion module; the rotary coder is used for feeding back the motion information of the shaft to the motion control card in real time; and the photo-electric switch is used for receiving signals and feeding back the signals to the motion control card. By adopting the method, high consistency of a zero position is realized; the consistency of a coordinate system of the machine tool which is repeatedly powered and powered off is guaranteed; the repeat accuracy is guaranteed; collision caused by machining or program running is prevented; damages and scrapping of work pieces and precision reduction of the machine tool are prevented, so losses caused by shutdown of the machine tool are reduced, the machine debugging cost is lowered, the cost for replacing shaft accessories and dismounting the shaft is lowered, the work efficiency is improved, the maintenance cost is lowered, and durable machining precision of the machine tool is guaranteed.

Owner:WUXI MICRO RES PRECISE MACHINERY TECH CO LTD

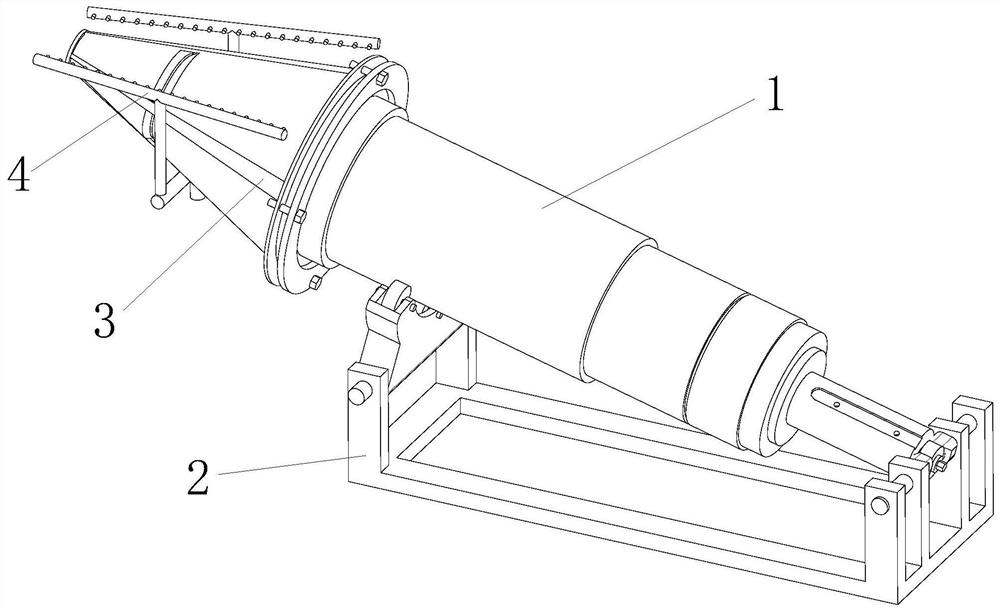

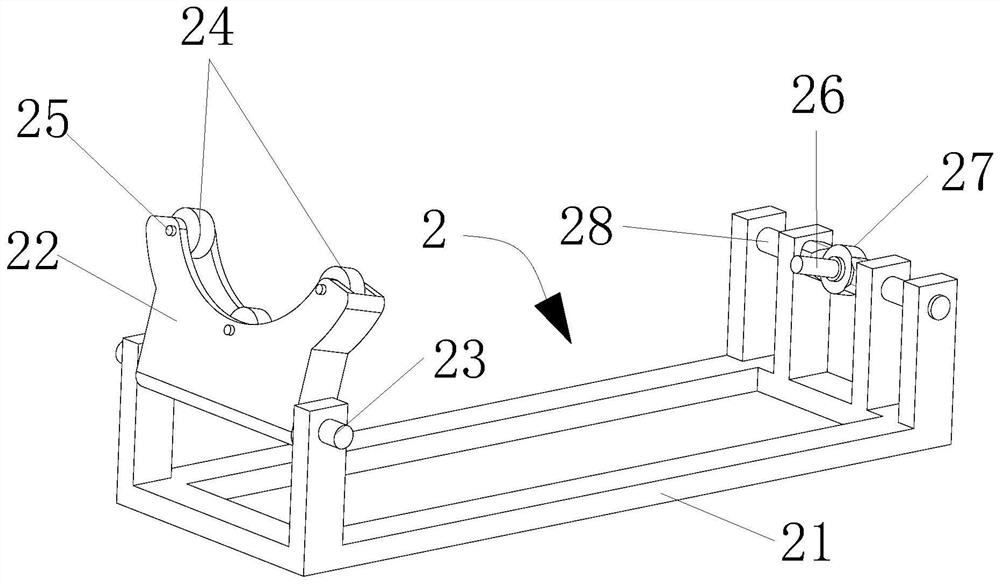

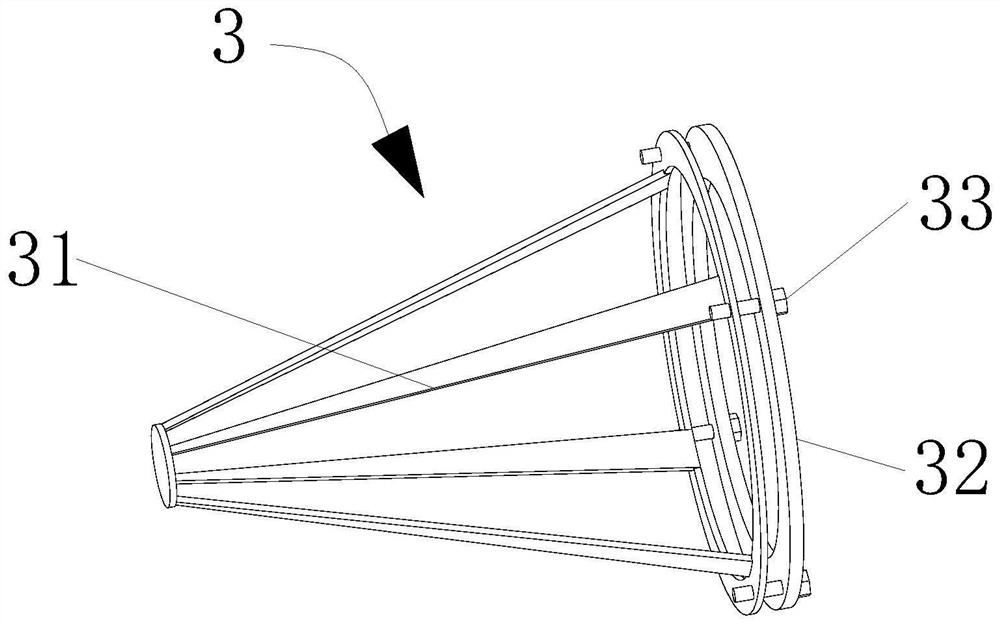

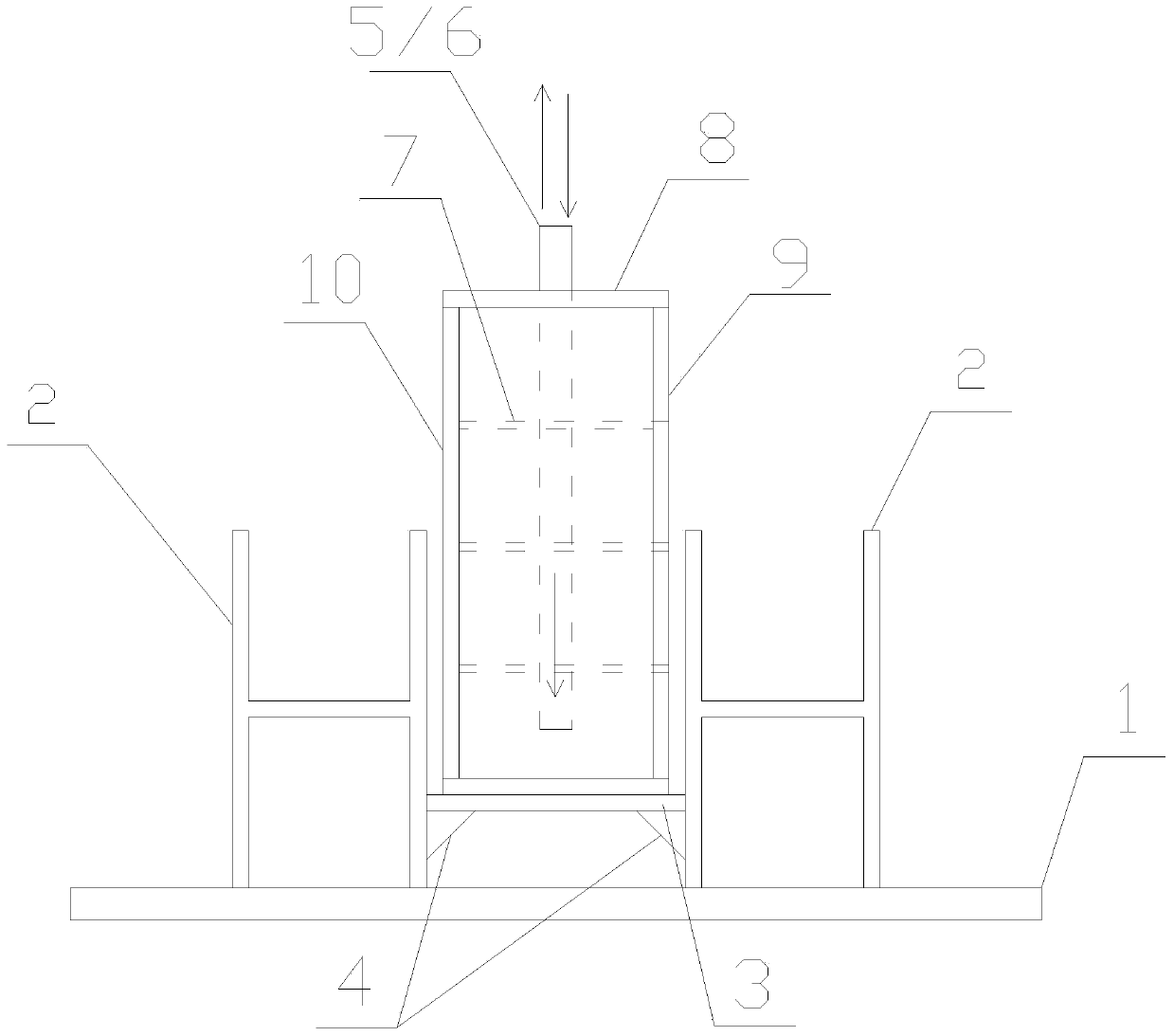

Welding device for fracture of large inclined roll shaft of ring rolling mill and repairing process of welding device

ActiveCN112935686ANovel structureCompact configurationWelding/cutting auxillary devicesAuxillary welding devicesFailure rateStructural engineering

The invention discloses a welding device for fracture of a large inclined roll shaft of a ring rolling mill. The welding device comprises a structural part fixing support, a structural part assembling and fixing tool and a heating tool, wherein the structural part fixing support is used for obliquely placing the inclined roll shaft and enabling the inclined roll shaft to freely rotate on the structural part fixing support; the structural part assembling and fixing tool is used for assembling and fixing the fractured part of the inclined roll shaft and controlling the deformation amount in the welding process; and the heating tool is used for heating the fractured part of the inclined roll shaft. A welding repairing process based on the welding device for the fracture of the large inclined roll shaft of the ring rolling mill is further disclosed. Through the implementation of the device and the process, a large amount of maintenance time can be shortened, the maintenance cost is reduced, the failure rate and shutdown loss are reduced, and a guarantee is provided for reasonable grouping production.

Owner:ANHUI MA STEEL EQUIP MAINTENANCE CO LTD

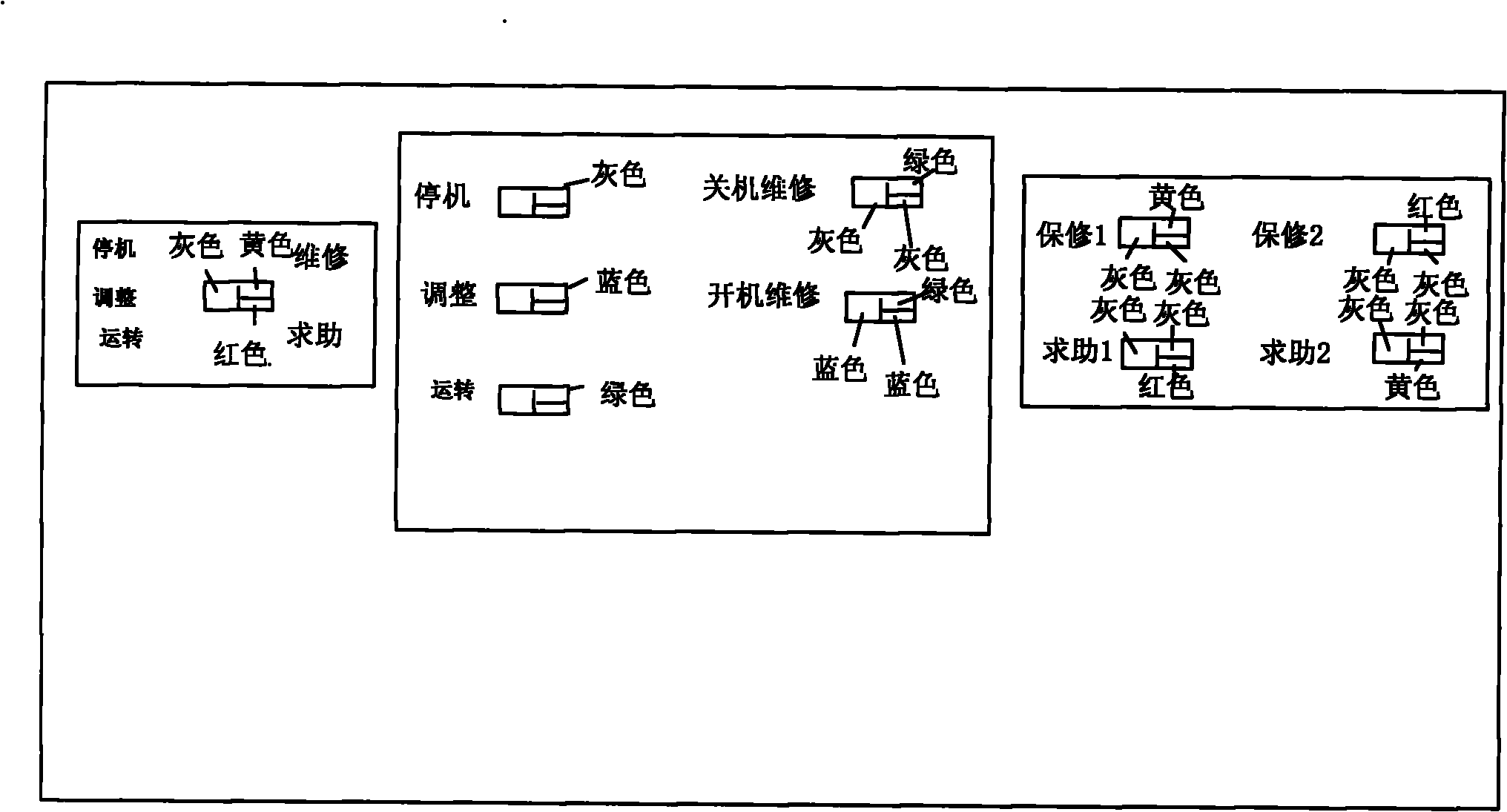

Device for displaying running state of equipment

InactiveCN101887248AIncrease productivityImprove communication efficiencyProgramme controlComputer controlLED displayData acquisition

The invention relates to a device for displaying the running state of equipment. The device comprises a field data acquisition hardware system, a microprocessor and an LED display screen, wherein the field data acquisition hardware system sends state information of the equipment to the LED display screen through the microprocessor; square LED plane combined color lump lamps are distributed on the LED display screen in a matrix form; the single LED plane combined color lump lamp is divided into three color lump areas, each color lump area can display different colors, and the three color lump areas can sparkle with different frequencies; and the combined color lump lamps can perform dynamic variation according to the state of the equipment, so that one display device can display multiple kinds of state information of multiple equipment, the information transfer efficiency is improved, and remote and all workshop-level overall state monitoring is realized.

Owner:HANGZHOU C&U CONTROL SYST

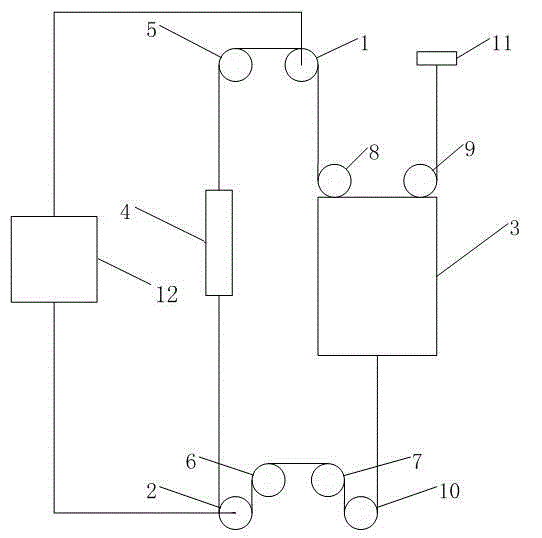

Dual-motor elevator traction system and control method thereof

InactiveCN102942098AReduce system costReduce downtime lossElevatorsBuilding liftsAutomotive engineeringTraction system

The invention relates to a dual-motor elevator traction system, which comprises two traction machines which are arranged on the top and the bottom of a well, an upper traction wheel, a lower traction wheel, a hoist rope, a car, a counterpoise, a guide wheel A, a diversion sheave A, a diversion sheave B, a car rope hitch plate and a detection control system for detecting the operation of the elevator, wherein the two traction machines are connected with the counterpoise by the hoist rope and the guide wheel A; the other end of the counterpoise is connected with the lower traction wheel; the counterpoise is arranged on the rear side of the car; one end above the car is fixed on the car hitch plate, and connected with the upper traction wheel by the diversion sheave A and the diversion sheave B, and the lower end of the car is connected with the lower traction wheel to integrally form a ring-shaped structure. The dual-motor elevator traction structure disclosed by the invention improves the reliability of elevator operation.

Owner:JIANGSU UNIV

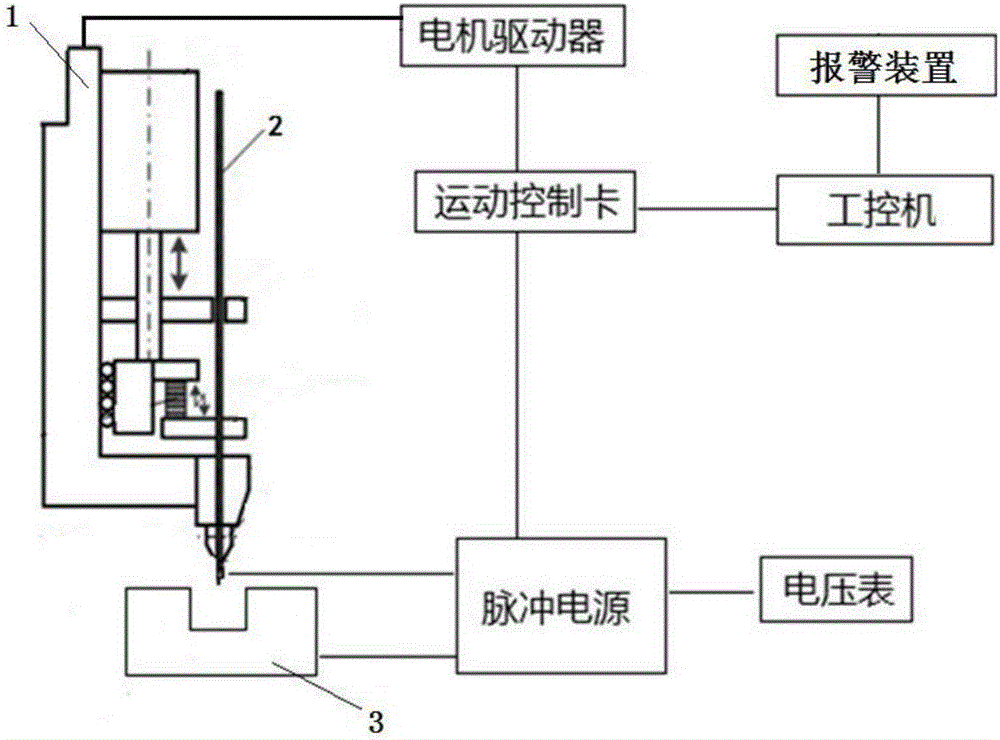

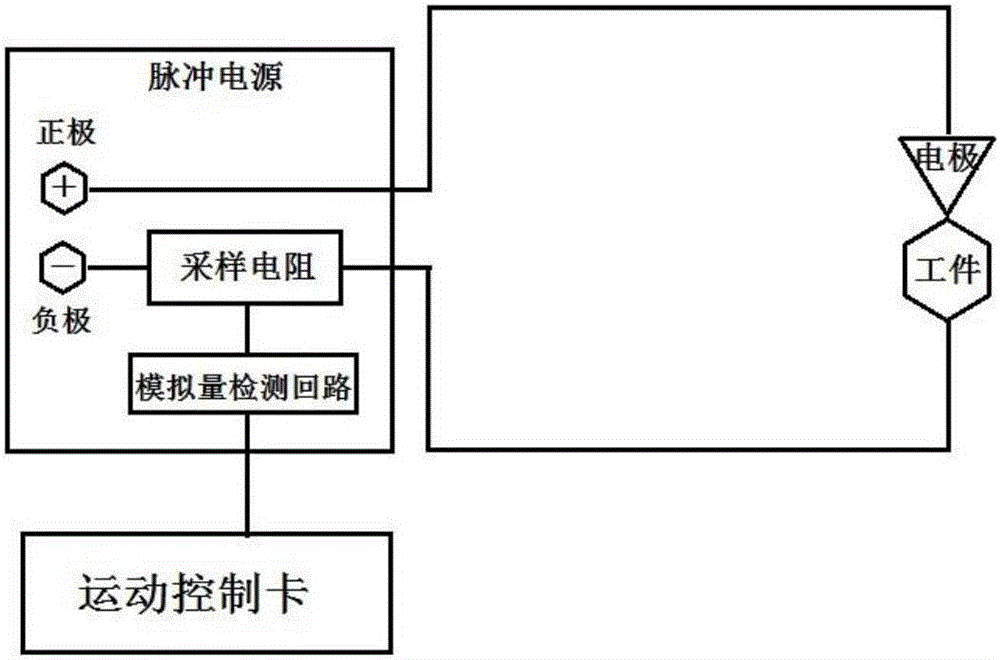

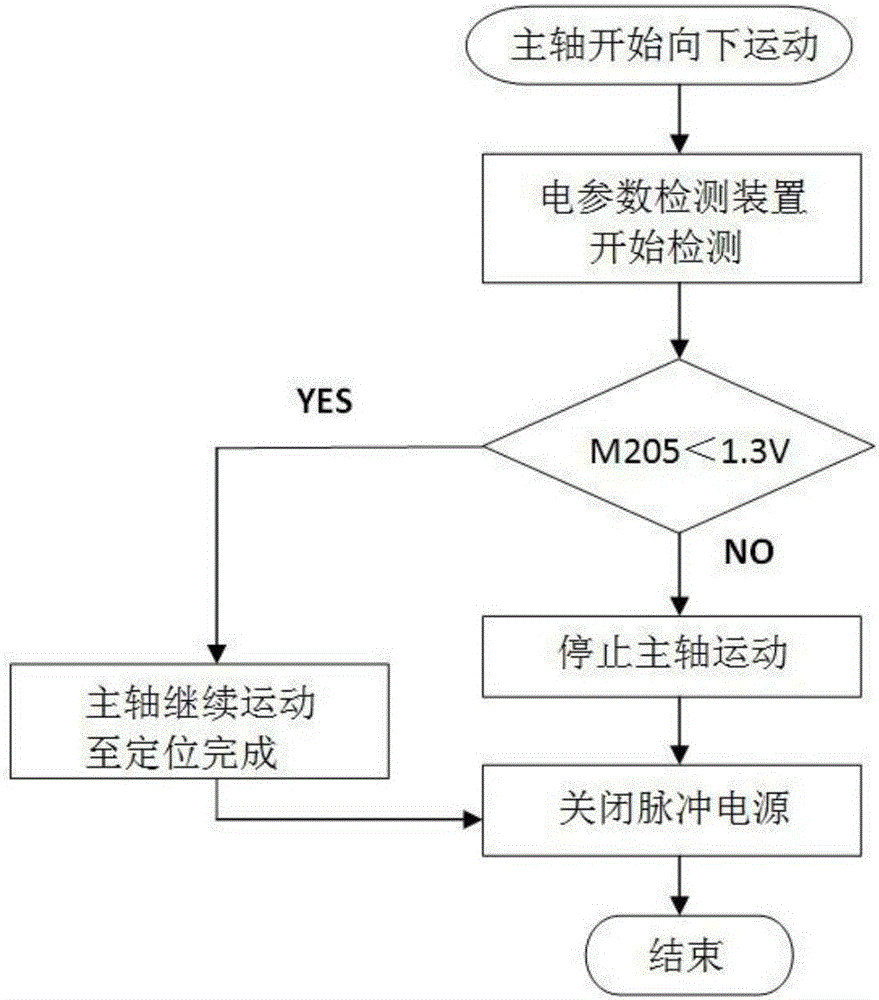

Collision-preventing protection system and method for electric spark machine tool

InactiveCN106270861AReduce precisionReduce downtime lossElectrical-based auxillary apparatusMonitoring systemPersonal computer

The invention discloses a collision-preventing protection system and a collision-preventing protection method for an electric spark machine tool. The collision-preventing protection system for the electric spark machine tool comprises a motor driver, a motion control card, a pulse power supply, a voltage meter and an industrial personal computer, wherein the industrial personal computer controls the motion control card; the motion control card is connected with the motor driver the pulse power supply respectively; the motor driver controls a main shaft to move up and down through a motor; the pulse power supply is connected with the positive electrode of an electrode wire and the negative electrode of a workpiece respectively; and the pulse power supply is connected with the external voltage meter and is used for observing the voltage condition. The collision-preventing protection system for the electric spark machine tool is a real-time monitoring system, saves shaft accessory exchange cost, shaft assembling and disassembling cost and maintenance cost, and guarantees the durable processing precision of a machine tool.

Owner:WUXI MICRO RES PRECISE MACHINERY TECH CO LTD

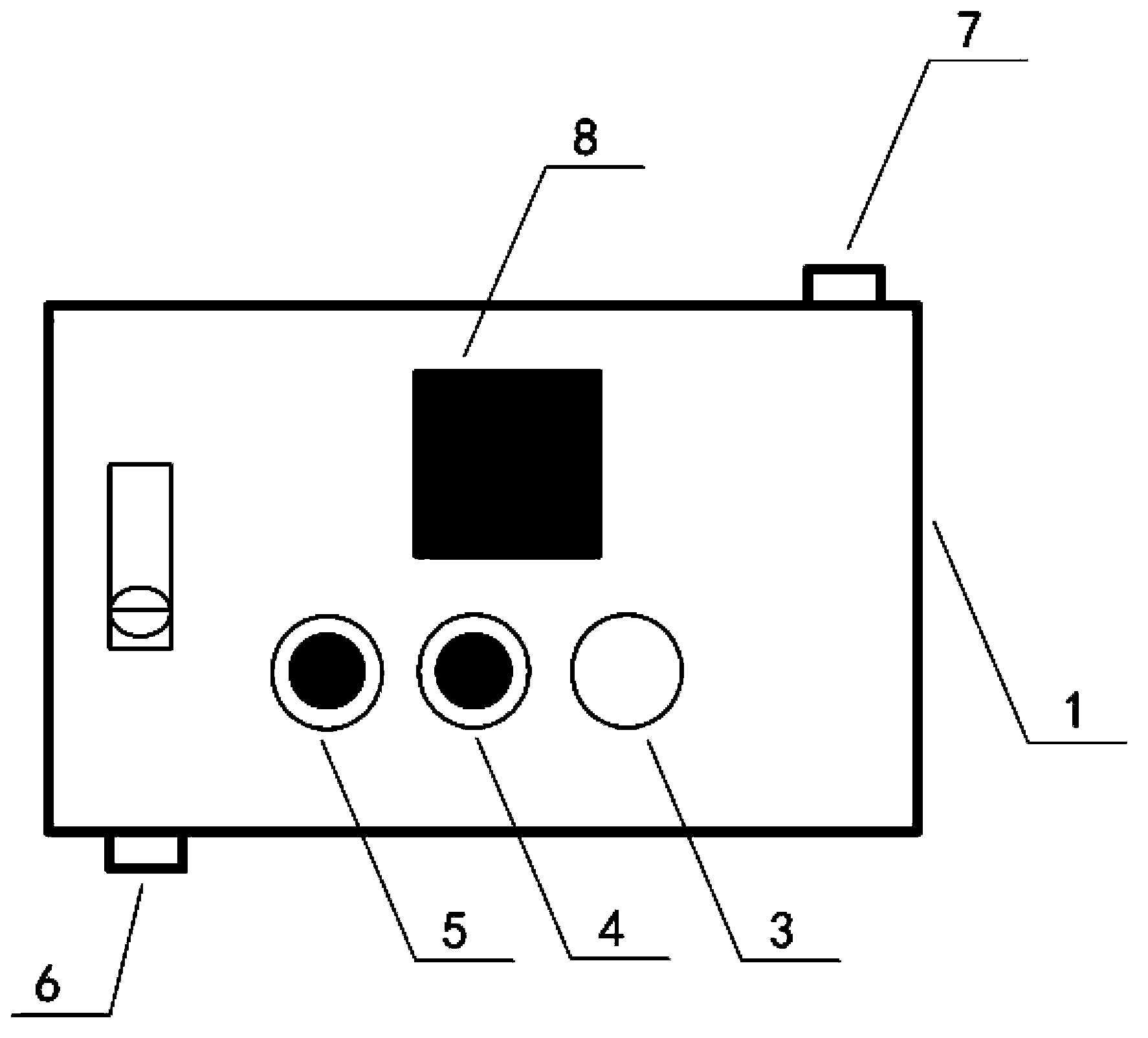

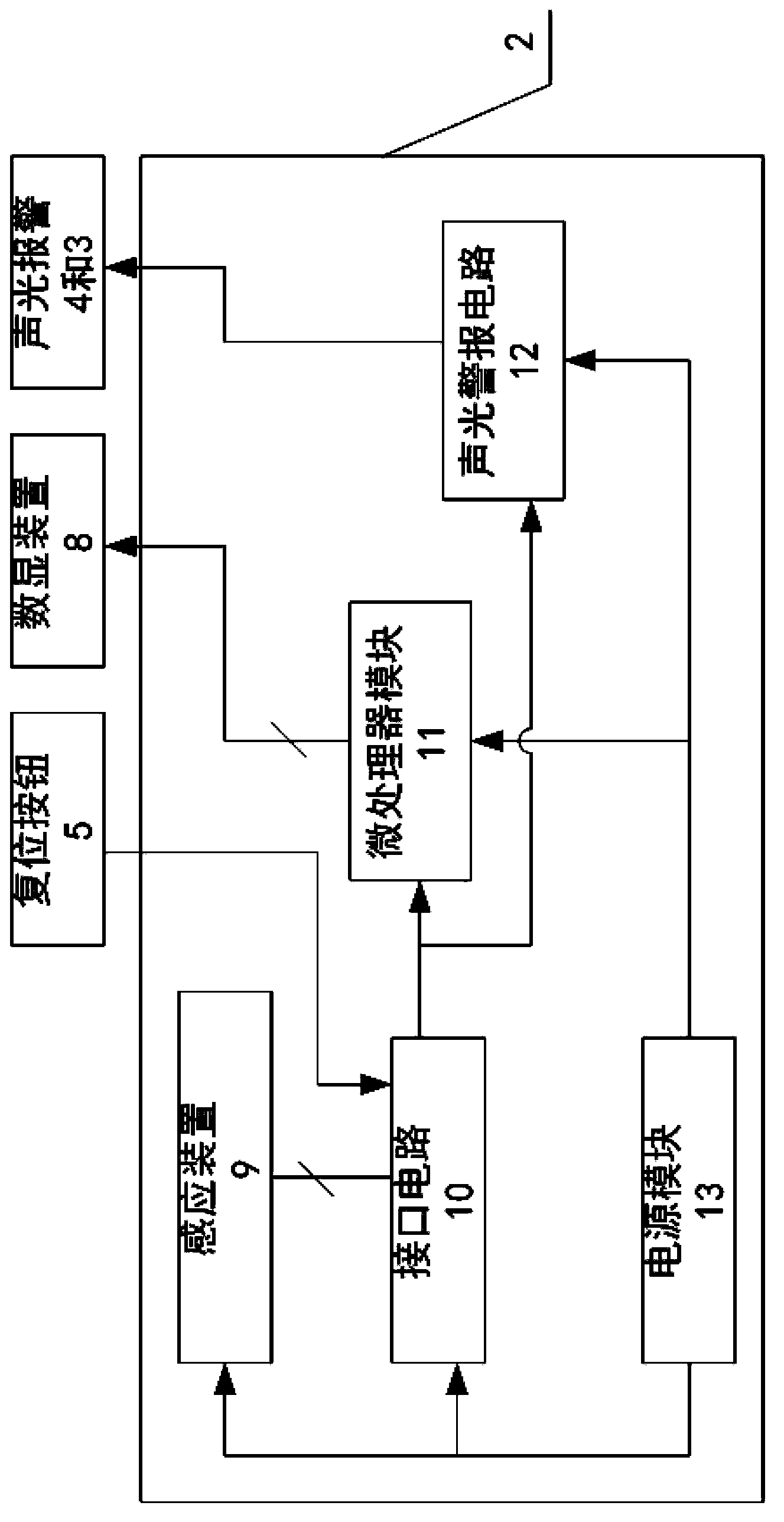

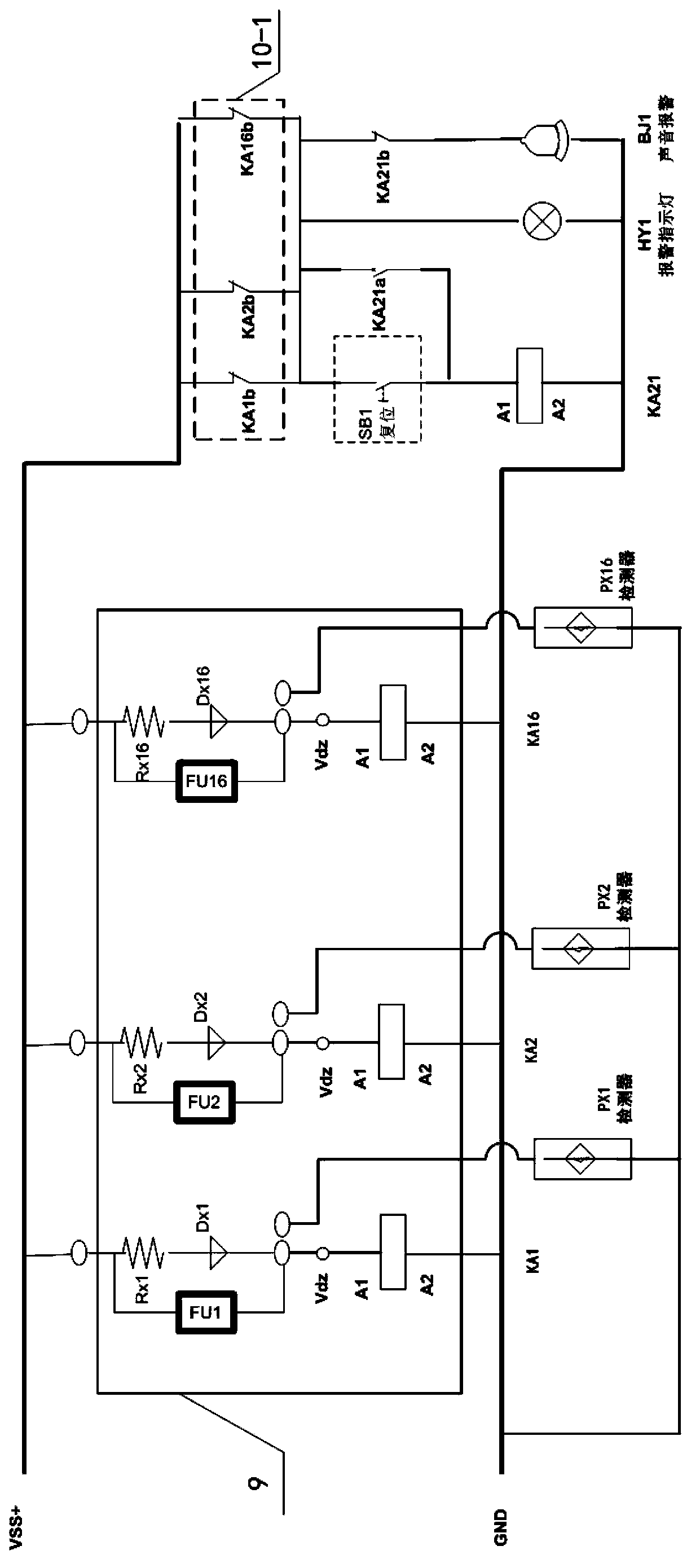

Quick positioning and digital display device of multiloop line faults and method thereof

The invention discloses a quick positioning and digital display device of multiloop line faults and a method thereof. The quick positioning and digital display device of the multiloop line faults comprises an induction device, an interface circuit, a microprocessor module and a sound-light alarming circuit. A detecting device detects the loop grounding and short-circuit states in real time, and provides a power supply for low-voltage loops; when the short-circuit and grounding faults occur, the detecting device outputs fault signals to the interface circuit; only the power supply of the fault loops is cut off; superior breakers are not cut off. The interface circuit comprises a sound-light alarming interface circuit and a digital tube display interface circuit; the fault signals are divided into normally closed contact signals and normally open contact signals, which are respectively accessed in the sound-light alarming interface circuit and the digital tube display interface circuit. The digital tube display interface circuit is connected with the input end of the microprocessor module; the output end of the microprocessor module outputs fault display characters. The sound-light alarming interface circuit is connected with the sound-light alarming circuit; the sound-light alarming circuit outputs sound and light alarms.

Owner:BAOSTEEL STAINLESS STEEL

Process for preparing superfine high-activity metakaolin by utilizing vertical high-pressure mill

InactiveCN102060302ALow investment costReduce production investment costsAluminium silicatesChemical industryGranularityKaolin clay

The invention relates to a process for preparing superfine high-activity metakaolin by utilizing a vertical high-pressure mill, which is characterized by comprising the following steps of: firstly, crushing crude ore of metakaolin into 325+ / -30 meshes, grinding the crushed crude ore by the vertical high-pressure mill to obtain a superfine high-activity metakaolin powdery material with a particle size of 2-2.5mum, then conveying the superfine metakaolin to a rotary kiln feeding system by a fan, adding the superfine metakaolin into a rotary kiln by an automatic feeding machine, then carrying out high-temperature calcining on the superfine metakaolin in the rotary kiln with the temperature of 600-900 DEG C and the calcining time of 1-4 h, and preparing a superfine metakaolin product. The process has the advantages that the production cost is greatly reduced, the occupied area is only 50% of that of a ball mill system, the production efficiency is high, the energy is saved, the environment is protected, the granularity of a product is fine and uniform, the particle size of the product is 2.1-3.0mum, the minimum particle size can be controlled to be 2mum, and the uniformity is over 90%.

Owner:INNER MONGOLIA TIANZHIJIAO KAOLIN CO LTD

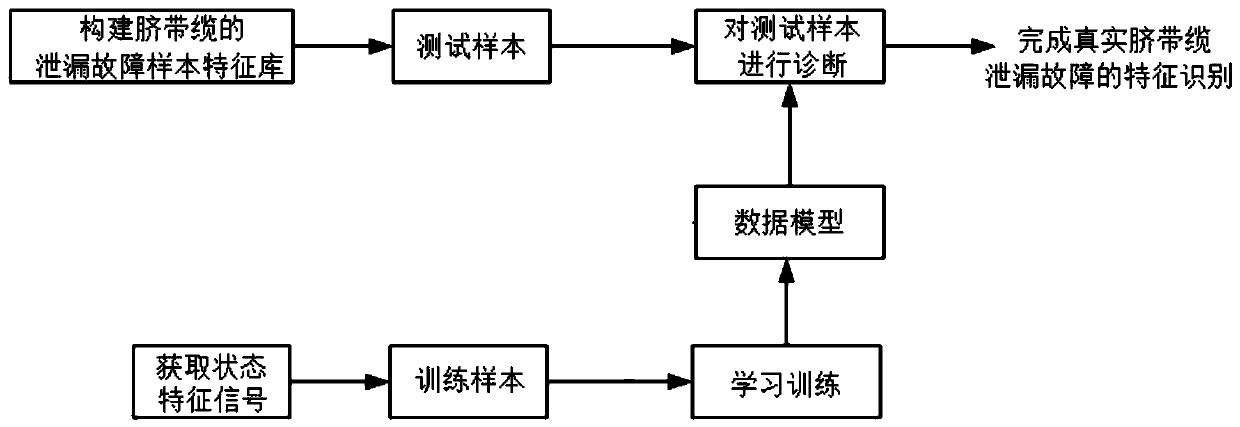

Feature recognition method for umbilical cable leakage fault

ActiveCN110275084AAccurate identificationImprove recognition accuracyFault location by conductor typesEngineeringFeature recognition

he invention relates to a feature recognition method for a umbilical cable leakage fault, characterized by comprising the following steps of: 1) acquiring the state feature signal of an offshore platform underwater production system according to the hydraulic pressure of a umbilical cable and the state feature signal of a chemical agent pipeline monitored by a sensor during the operation of the umbilical cable; 2) according to the state feature signal of the offshore platform underwater production system, obtaining the operating state features of the umbilical cable; 3) based on a umbilical cable leakage simulation model, constructing a umbilical cable leakage fault sample feature database and using the same as a training sample; 4) studying and training the training sample to construct a data model of the training sample; 5) diagnosing the operating state features of the umbilical cable according to the data model of the training sample to obtain a diagnostic network describing a mapping relationship between feature variables and the leakage fault so as to realize the feature recognition of the umbilical cable leakage fault. The feature recognition method can be widely applied in the field of umbilical cable leakage fault diagnosis.

Owner:CHINA NAT OFFSHORE OIL CORP +2

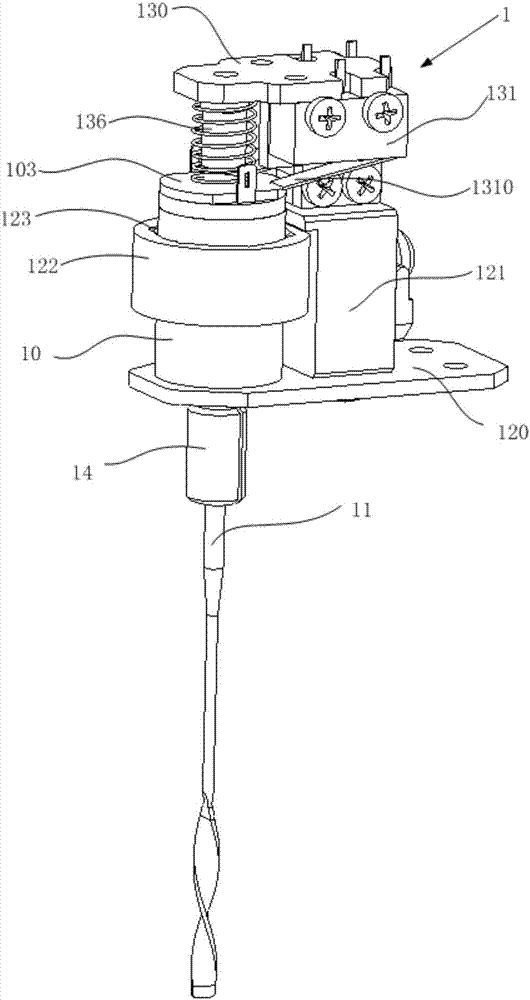

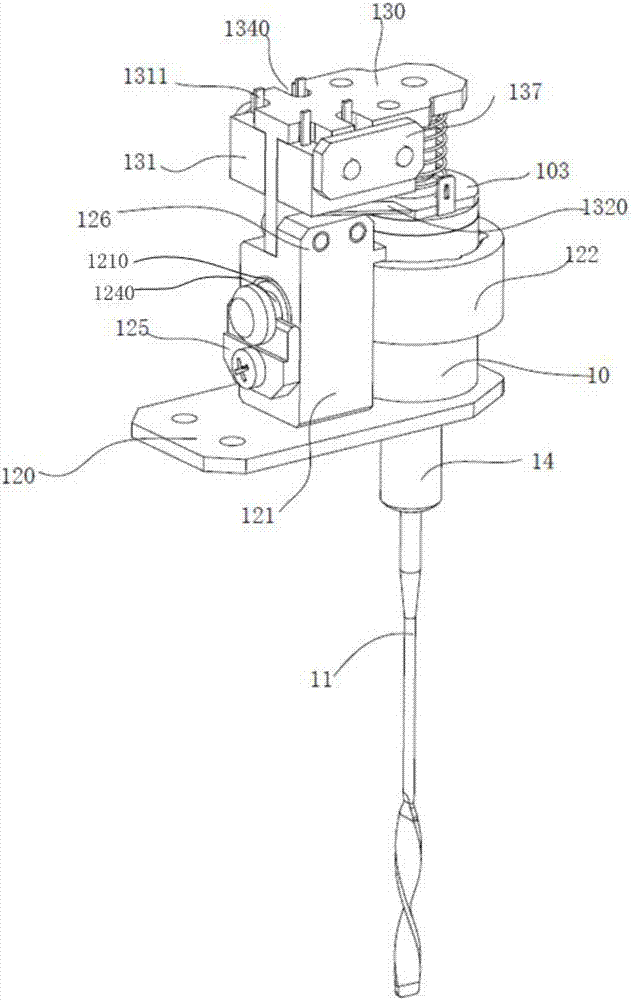

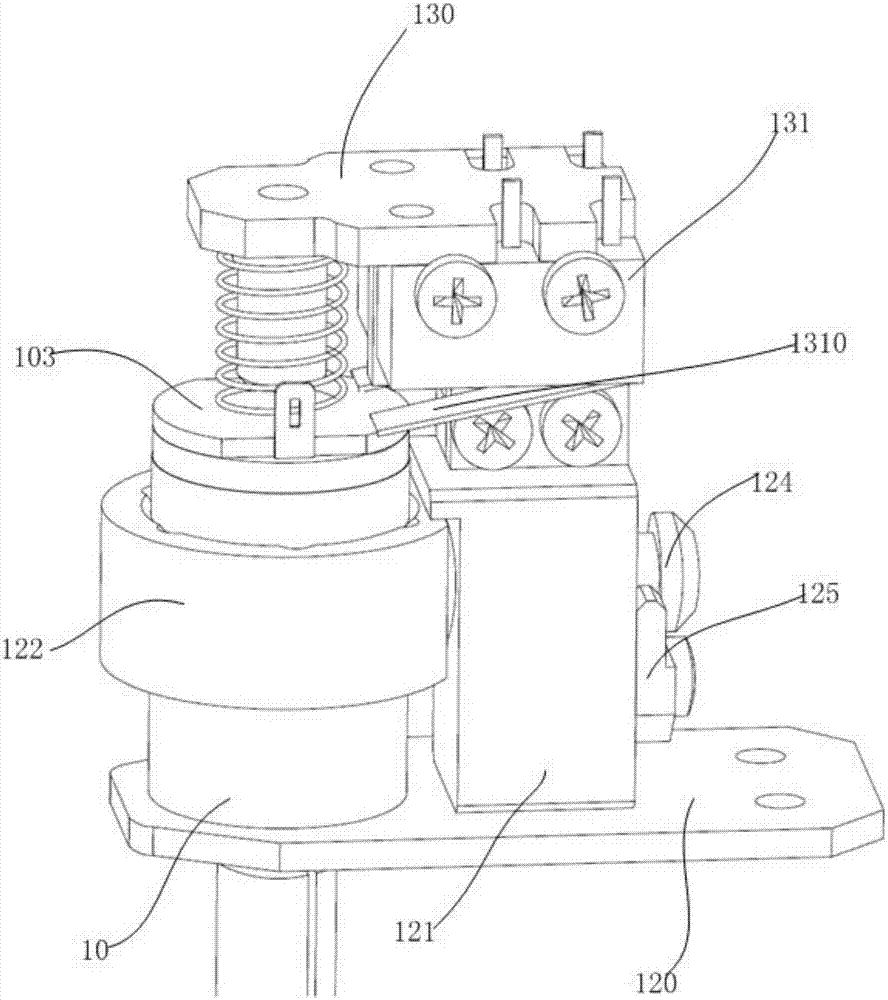

In-vitro diagnosis equipment and stirring paddle anti-collision device of in-vitro diagnosis equipment

ActiveCN107328635AReduce downtime lossReduce instrument maintenance costsRotary stirring mixersTransportation and packagingMotor shaftElectricity

The invention provides in-vitro diagnosis equipment and a stirring paddle anti-collision device of the in-vitro diagnosis equipment. The equipment comprises the stirring paddle anti-collision device, a driving device and a control system, wherein the driving device and the control system are electrically connected with the stirring paddle anti-collision device. The stirring paddle anti-collision device comprises a motor, a stirring paddle, a motor mounting assembly and an anti-collision sensing assembly, wherein the motor is arranged on the motor mounting assembly in a sliding mode, the anti-collision sensing assembly is assembled on the motor mounting assembly, the motor is provided with a first end face abutting against the mounting assembly and a second end face abutting against the anti-collision sensing assembly, and a clamping part for connecting a motor shaft and the stirring paddle is arranged between the motor shaft and the stirring paddle. When the stirring paddle anti-collision device is prevented from descending, rotating and swinging along with the driving device, the stirring paddle pushes the motor to rebound along the mounting assembly and trigger the anti-collision sensing assembly to output a signal to the control system, the equipment stops moving or reversely moves back to a safe position according to program setting, the stirring paddle is prevented from being damaged, and then the shutdown loss and the instrument maintenance cost are reduced.

Owner:东软威特曼生物科技(沈阳)有限公司

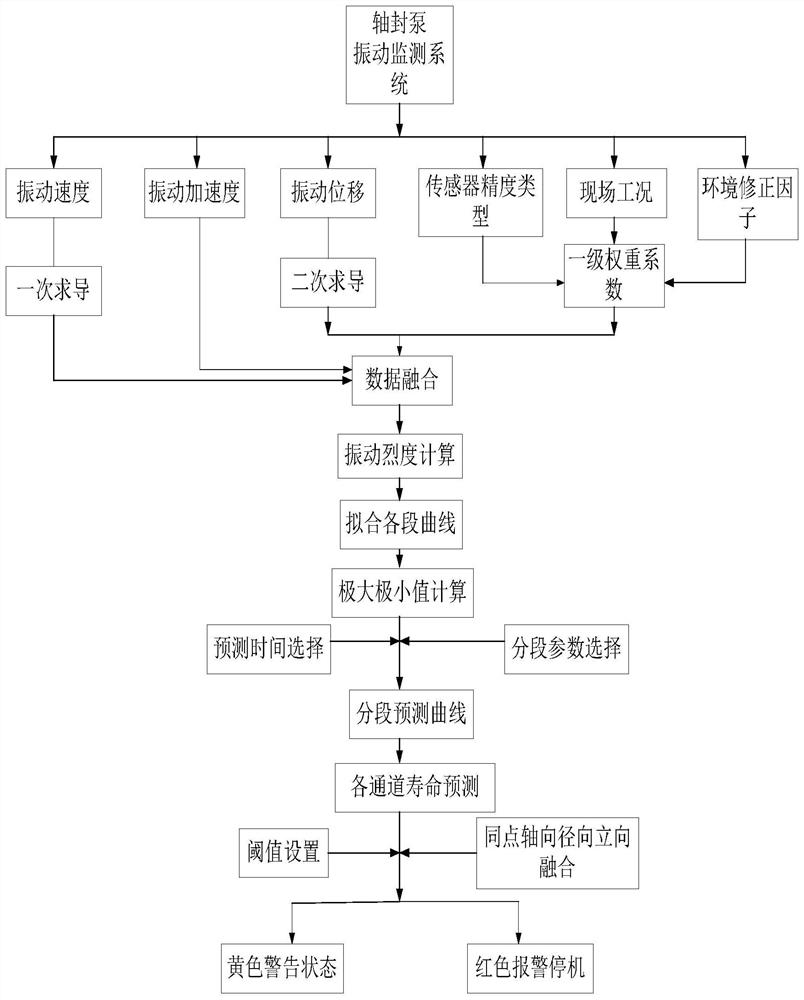

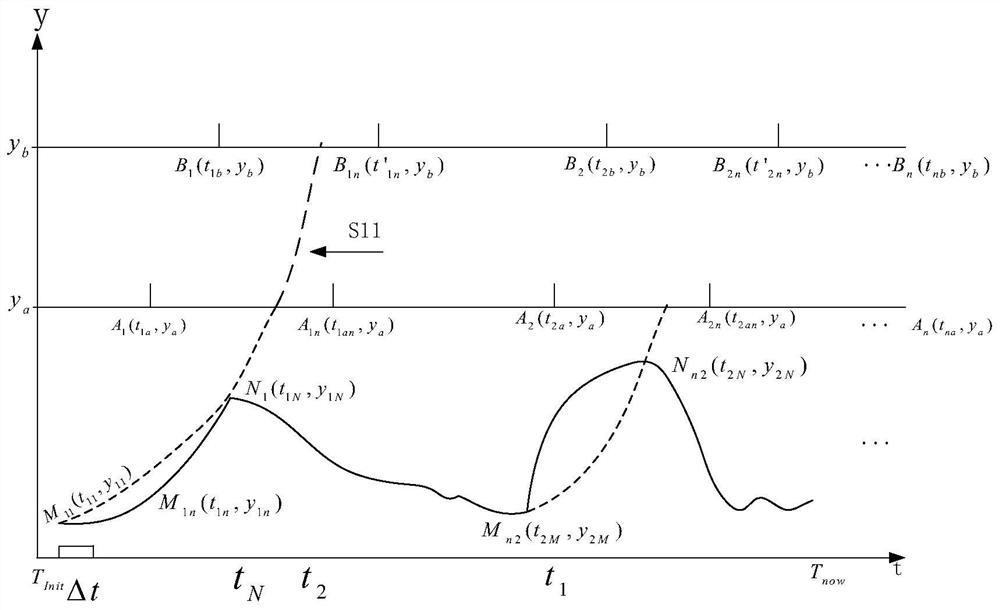

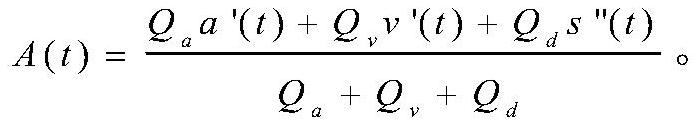

Fault moment prediction method for vibration monitoring of reactor shaft seal pump

ActiveCN113074122AImprove securityImprove economyMeasurement devicesNuclear energy generationComputational physicsVibration acceleration

The invention discloses a fault moment prediction method for vibration monitoring of a reactor shaft seal pump. The fault moment prediction method for vibration monitoring of the reactor shaft seal pump is characterized by comprising the following steps of: 1, obtaining monitoring data of the reactor shaft seal pump, wherein the monitoring data are vibration acceleration a (t), vibration velocity v (t) and vibration displacement s (t), and t is less than or equal to Tnow and greater than or equal to TInit; 2, determining a first-level acceleration weight coefficient Qa, a first-level speed weight coefficient Qv and a first-level displacement weight coefficient Qd; 3, carrying out fusion processing to obtain fused vibration A (t); 4, carrying out mathematical fitting processing on the vibration intensity V (t) to obtain a fitting curve; 5, screening out an effective curve segment used for predicting a fault moment from the fitting curve; 6, performing high-order nonlinear function fitting processing on the effective curve segment to obtain a corresponding prediction curve; and 7, calculating an intersection point of the prediction curve and a vibration intensity threshold line, and marking a moment corresponding to the intersection point as a prediction fault moment.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Convenient probe of detonating fuse manufacturing machine

InactiveCN102675013AImprove detection accuracyExtended service lifeFuse manufactureEngineeringWasher

a convenient probe of a detonating fuse manufacturing machine relates to an automatic explosive interruption or shortage detection probe of the detonating fuse manufacturing machine, adopts a separated structure instead of an integral structure and comprises a probe main body, a probe clamp pipe sleeve, a probe clamp pipe, sealing washers and a probe support, wherein a through hole passing through and perpendicular to the axial lead of the probe and countersunk threaded holes concentric with the two ends of the through hole are formed in the outer circumference of the probe main body; the probe clamp pipe sleeve and the sealing washers are mounted in the countersunk threaded holes; and the probe clamp pipe is made of high-hardness wear-resistant material. The convenient probe has the advantages that the service life of the probe is prolonged, the detection accuracy is improved, the product quality is stabilized and guaranteed, the replacement cycle of the probe is prolonged, the loss in downtime is reduced, and the yield is increased; and when the abrasion of the probe reaches the set value, all that is needed to do is conveniently and fast replace the probe clamp pipe by unscrewing the probe clamp pipe sleeve rather than disassemble and replace the whole probe, so as to save material cost and cost of unit production time and achieve remarkable comprehensive economic benefits. The convenient probe can be popularized in and applied to all detonating fuse manufacturers.

Owner:HUBEI SHUAILI CHEM

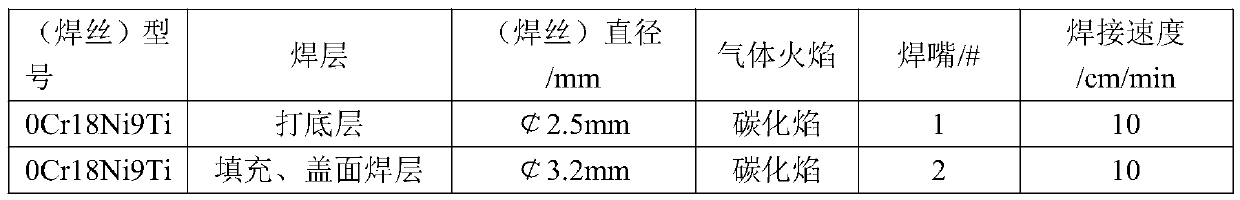

Large-scale heat-resistant steel heating furnace door manual gas welding repair device and repair process

PendingCN111360363AReduce downtime lossImprove welding qualityMeasurement of fluid loss/gain rateGas flame welding apparatusIngotHeating furnace

The invention discloses a large-scale heat-resistant steel heating furnace door manual gas welding repair device. A furnace door is of a cuboid hollow structure and comprises a furnace door front panel and a furnace door rear panel. A plurality of fixed rods are uniformly arranged inside the furnace door front panel and the furnace door rear panel. The large-scale heat-resistant steel heating furnace door manual gas welding repair device further comprises a rectangular fixed bottom steel plate, a pressure test water inlet pipe and a pressure test water outlet pipe. A plurality of sets of vertical H-steel supporting frames are arranged on the fixed bottom steel plate in bilateral symmetry. A transverse H-steel supporting frame with the height less than the vertical H-steel supporting framesis arranged between each set of the vertical H-steel supporting frames. The pressure test water inlet pipe and the pressure test water outlet pipe are arranged on the two sides of the interior of thefurnace door correspondingly. The pipe heads of one ends of the pressure test water inlet pipe and the pressure test water outlet pipe face upwards. The large-scale heat-resistant steel heating furnace door manual gas welding repair device is safe and easy to operate, stable in welding quality, low in investment cost and high in working efficiency, meets the actual demands on site, greatly reduces the maintenance cost, reduces shutdown loss during the process of heating an annular furnace and provides a guarantee for reasonable assembly production of various specifications of wheels and ringparts and heating steel ingots.

Owner:ANHUI MA STEEL EQUIP MAINTENANCE CO LTD

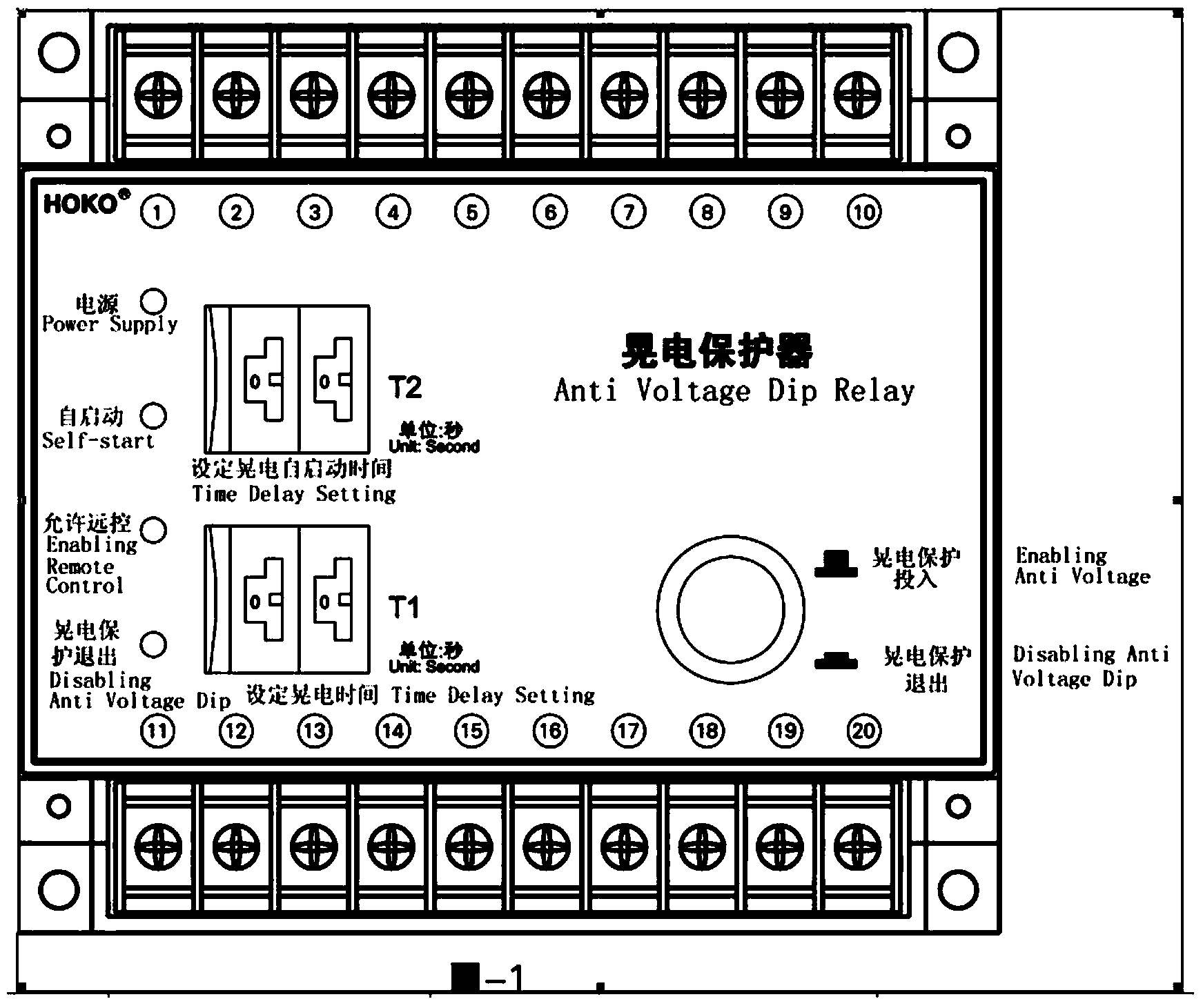

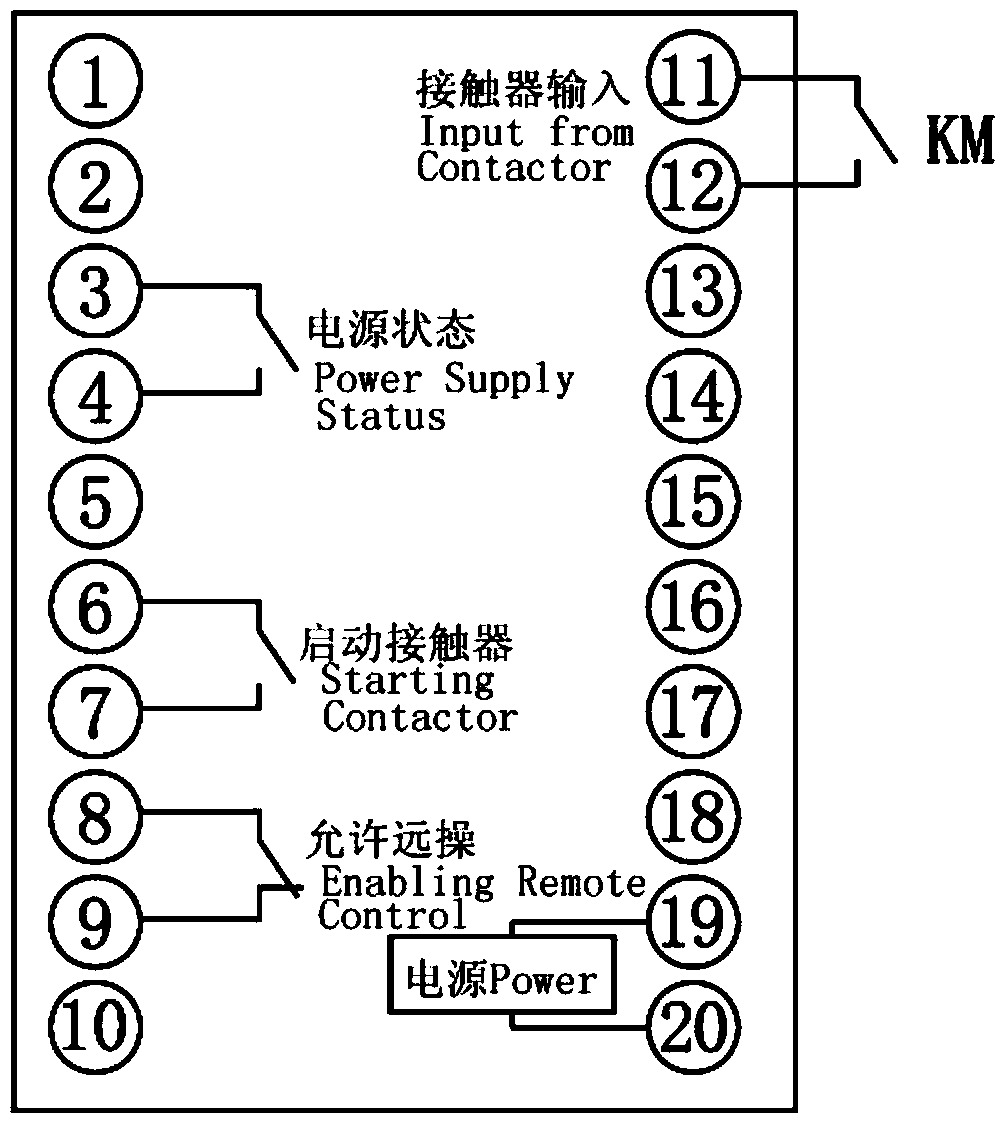

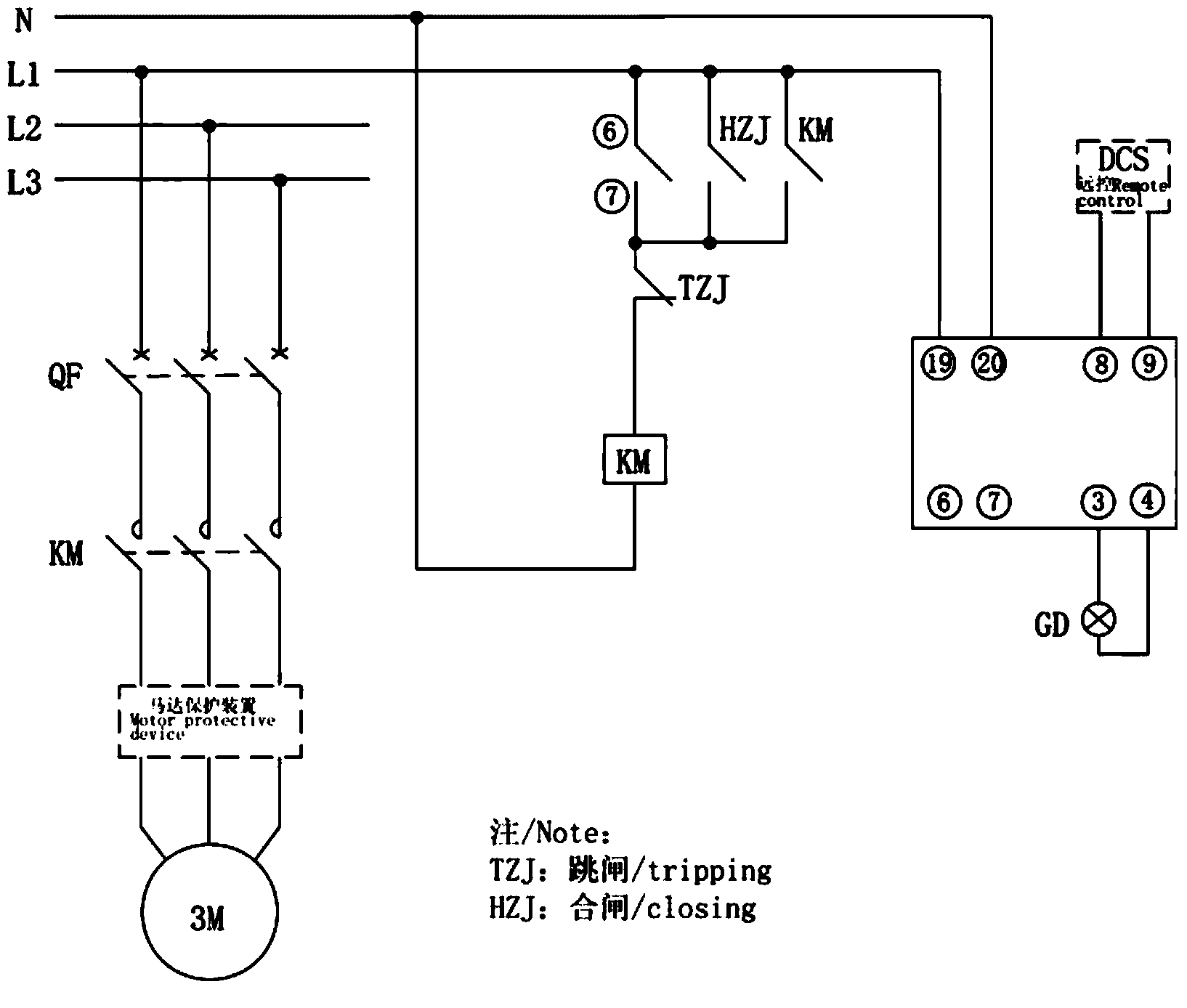

Wiring circuit of interference electricity protector

InactiveCN103560489AEnsure safetyAvoid startingEmergency protective circuit arrangementsProcess systemsElectricity

The invention relates to a wiring circuit of an interference electricity protector. The wiring circuit comprises the interference electricity protector and a power supply state input interface, two power supply interfaces of the interference electricity protector are connected with the end N and the end L1 of an alternating current power supply respectively, a remote control interface of the interference electricity protector is connected with a remote controller, the interference electricity protector is switched off in the starting process of interference electricity self-starting delay, and is switched on in other time frames. When the input voltage of a power supply interface is larger than 80% of a nominal voltage, the power supply state input interface is closed, and is opened normally otherwise. The safety of a power supply and distribution network is effectively guaranteed, power distribution inlet wire breaker tripping caused by the starting of a motor group is avoided, and according to the requirements of a production process, a motor is started fast by itself, the work condition of a process system before interference electricity is restored, a normal production operation procedure is guaranteed, and shut losses caused by the interference electricity are greatly reduced. The interference electricity protector is provided with a contact switch specially matched with a DCS in a remote control mode, the remote control operation is automatically blocked in the self-starting process, and remote control error group starting is avoided.

Owner:GUANGZHOU HOKO ELECTRIC

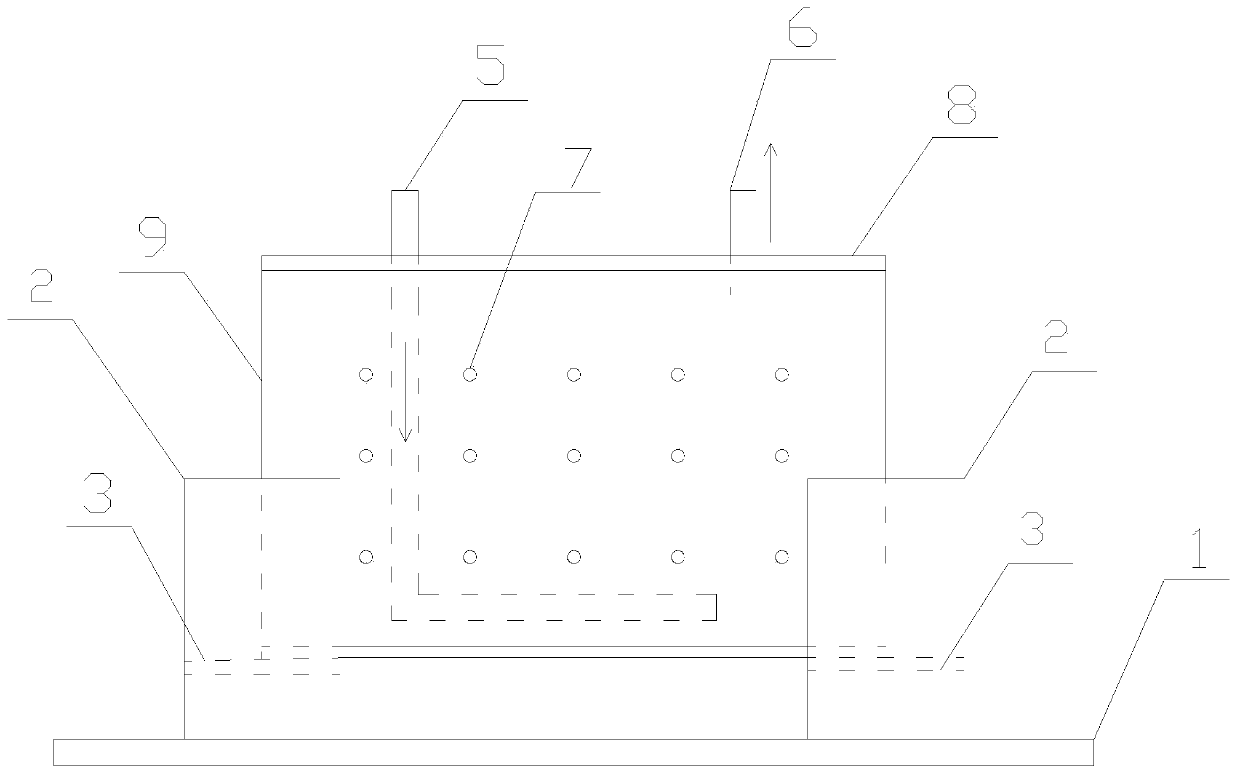

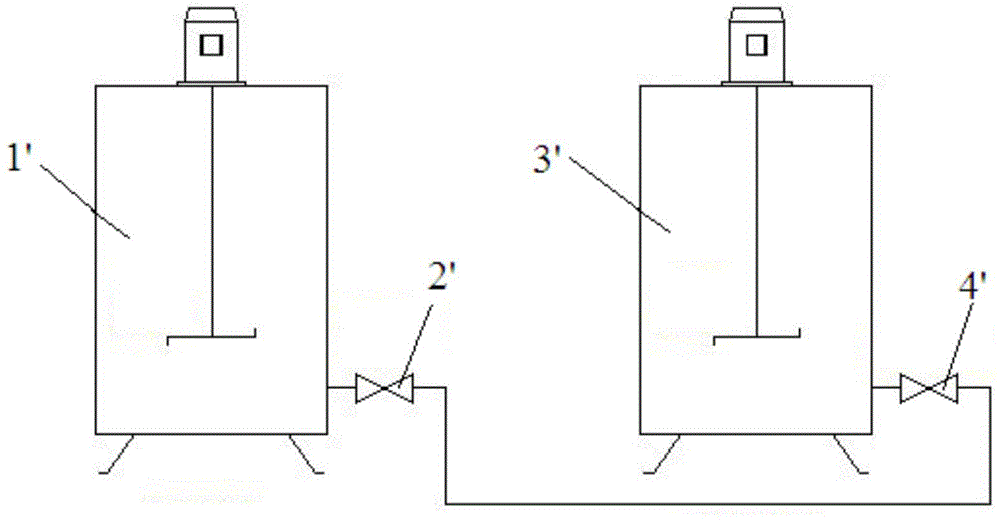

Medicinal liquid delivery system for wet towel dispenser

InactiveCN104549006AIncrease production capacityImprove effective utilizationRotary stirring mixersMixer accessoriesLiquid wasteInlet valve

The invention relates to a medicinal liquid delivery system for a wet towel dispenser. The system comprises a medicinal liquid proportioning device, at least two wet towel dispenser medicinal liquid storage devices and a PLC, wherein the wet towel dispenser medicinal liquid storage devices are connected with the medicinal liquid proportioning device; the PLC is connected with the medicinal liquid proportioning device and the wet towel dispenser medicinal liquid storage devices respectively; each wet towel dispenser medicinal liquid storage device comprises a medicinal liquid barrel, a stirring component, an automatic water inlet valve, a liquid level meter and an audible and visual alarm; each medicinal liquid barrel is connected with the medicinal liquid proportioning device by virtue of the respective automatic water inlet valve; the stirring components, the liquid level meters and the audible and visual alarms are arranged on the medicinal liquid barrels, and are respectively connected with the PLC; the liquid level liquid is used for collecting the liquid level state of medicinal liquid in real time; the PLC is used for opening / closing the automatic water inlet valves according to the liquid level state, and controlling the audible and visual alarms according to the liquid level state. Compared with the prior art, the medicinal liquid delivery system has the advantages of improving the production efficiency, reducing labor intensity, reducing medicinal liquid waste and the like.

Owner:上海东冠纸业有限公司

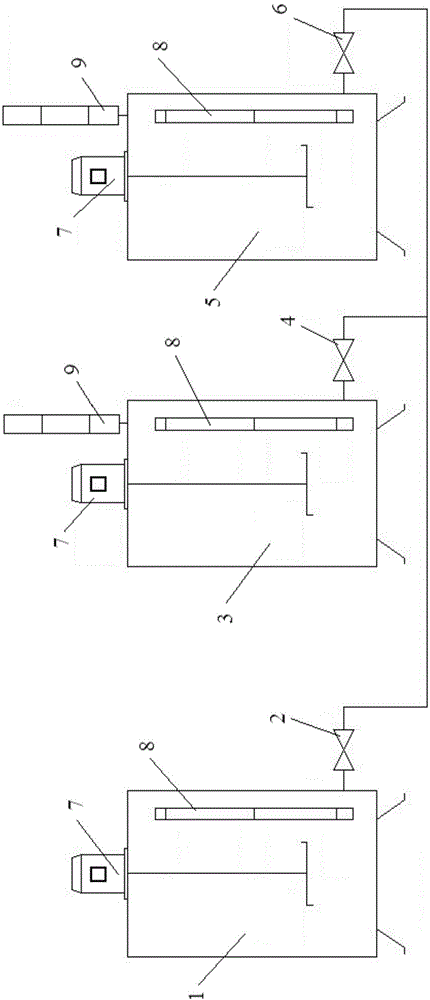

High-sulfur and high-halogen hazardous waste feed conveying system and hazardous waste incineration system

PendingCN111981486AAvoid downtimeAvoid burning open unstable situationsIncinerator apparatusHalogenEngineering

The invention discloses a high-sulfur and high-halogen hazardous waste feed conveying system and a hazardous waste incineration system. The high-sulfur and high-halogen hazardous waste feed conveyingsystem comprises: a crushing apparatus for crushing a material required to be crushed to form a crushed material; a pit comprising a bulk material area and a crushed material area, the bulk material area being used for storing a material not required to be crushed, and the crushed material area being used for storing the crushed material; a first feed conveying apparatus for conveying the materialnot required to be crushed to an incineration furnace; and a second feed conveying apparatus for conveying the crushed material to the incineration furnace. According to the invention, the stop caused by winding of a crusher by means of unnecessary crushing of a tonnage package and a woven bag is prevented; moreover, two materials are respectively conveyed by using two sets of feed conveying apparatuses; and the two feed conveying apparatus can be cooperated to improve the feed efficiency, and can also be standby for each other under the working condition of abnormalities, so that the stop loss is reduced.

Owner:光大绿色环保管理(深圳)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com