Patents

Literature

36results about How to "Avoid damage and scrap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antipollution sofa leather making method

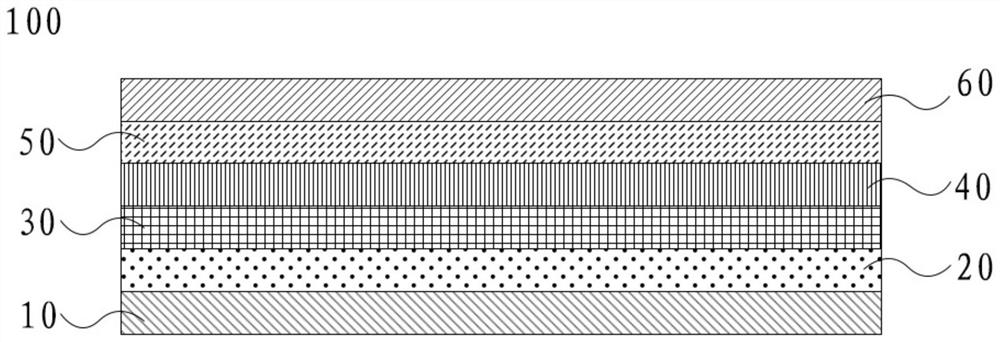

ActiveCN104141237AAvoid damageAvoid damage and scrapSynthetic resin layered productsTextiles and paperOrganic solventSurface layer

The invention discloses an antipollution sofa leather making method. The method comprises the following steps: uniformly stirring 5-10 parts of dimethyl formamide with 2-10 parts of a color paste, 10-30 parts of wood powder and 1-5 parts of a surfactant; adding 80-100 parts of wet polyurethane resin and 150-280 parts of dimethyl formamide to obtain a wet material; impregnating a base fabric, ironing, drying, coating the wet material, solidifying, foaming, washing with water, and drying to obtain a wet base; uniformly mixing 80-100 parts of a polyurethane surface layer resin with 40-70 parts of an organic solvent, 0.5-2 parts of an assistant and 5-8 parts of an environmentally friendly toner to obtain a dry material; uniformly mixing 80-100 parts of a polyurethane binding resin with 20-60 parts of the organic solvent, 0.5-2 parts of the assistant and 5-8 parts of the environmentally friendly toner to obtain a binder; coating the dry material on release paper, drying, coating the binder, pasting the wet base, drying, cooling, and separating from the release paper to obtain a semi-finished product; and carrying out surface treatment to obtain a finished product. The method effectively improves the oil stain resistance of sofa leather.

Owner:江苏协孚新材料科技有限公司

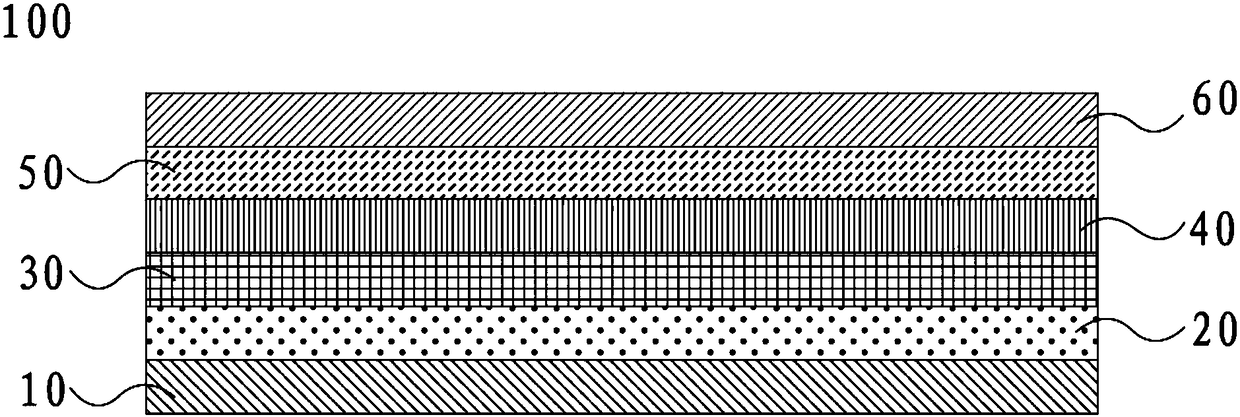

Preparation method for artificial leather

The invention discloses a preparation method for artificial leather. The preparation method includes the steps of: a) uniformly mixing 5-10 parts of dimethylformamide, 2-10 parts of color paste, 10-30 parts of wood powder, and 1-5 parts of a surfactant; b) adding 80-100 parts of wet-method polyurethane resin and 150-280 parts of dimethylformamide, and uniformly mixing the components to prepare a wet-method material; c) impregnating a base cloth, ironing and drying the base cloth, coating the base cloth with the wet-method material, solidifying and the foaming wet-method material, and water-washing and drying the base cloth to prepare a wet-method base; d) uniformly mixing 80-100 parts of polyurethane surface layer resin, 40-70 parts of an organic solvent, 0.5-2 parts of an additive and 5-8 parts of environment-friendly color powder to prepare a dry-method material; e) uniformly mixing 80-100 parts of polyurethane binding resin, 20-60 parts of an organic solvent, 0.5-2 parts of an additive and 5-8 parts of environment-friendly color powder to prepare a binding material; f) coating release paper with the dry-method material and drying the dry-method material, coating the binding material, pasting the wet-method base, and drying and cooling the material and separating a semi-product from the release paper; and g) performing surface treatment to obtain a finish product. The preparation method effectively improves anti-oil-stain performance of the artificial leather.

Owner:青岛丰泽中兴科技服务有限公司

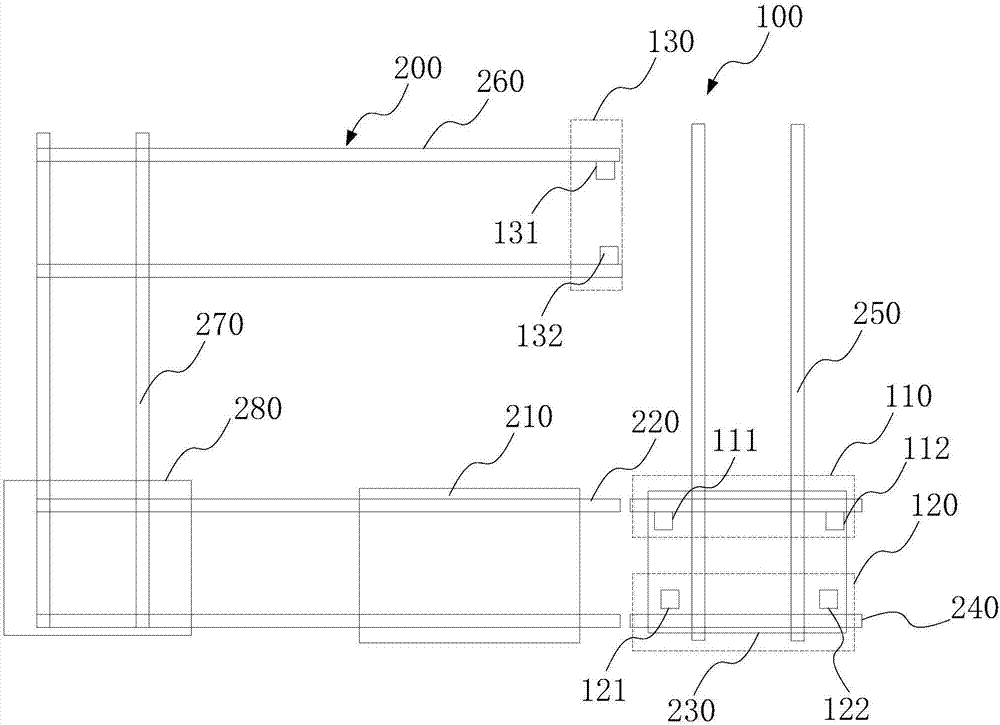

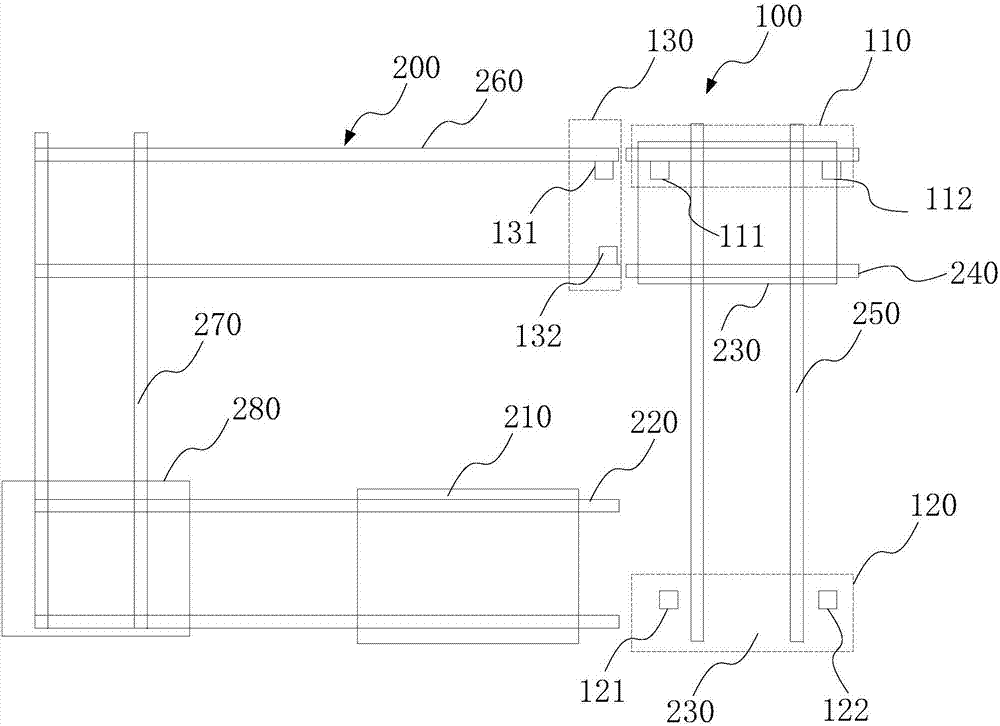

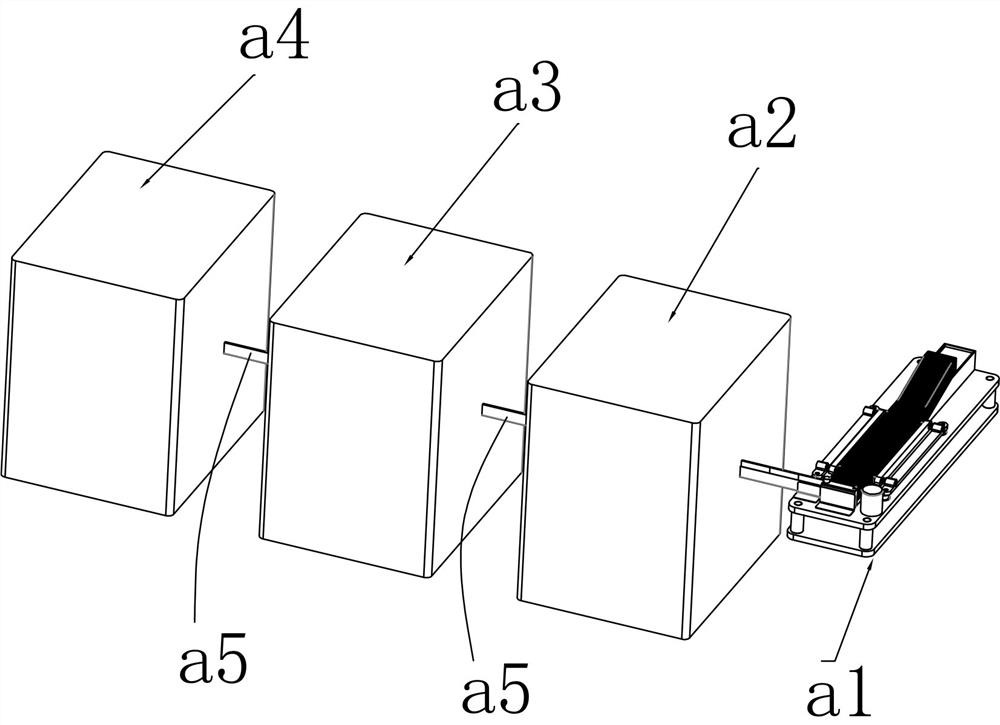

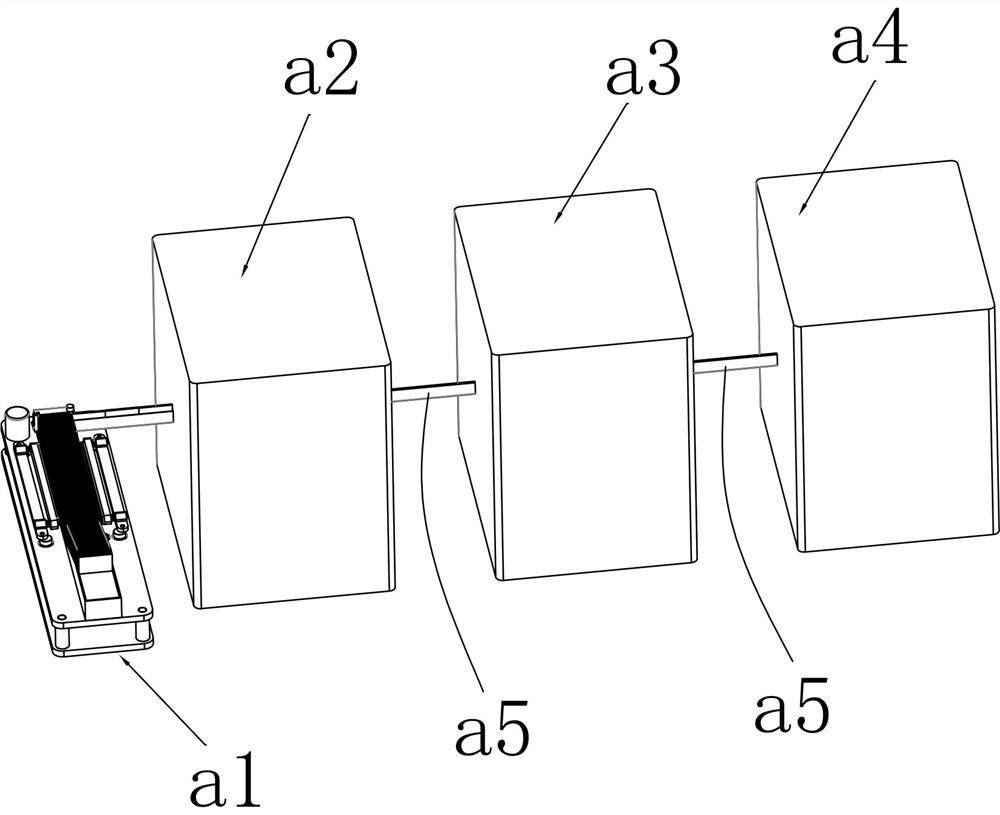

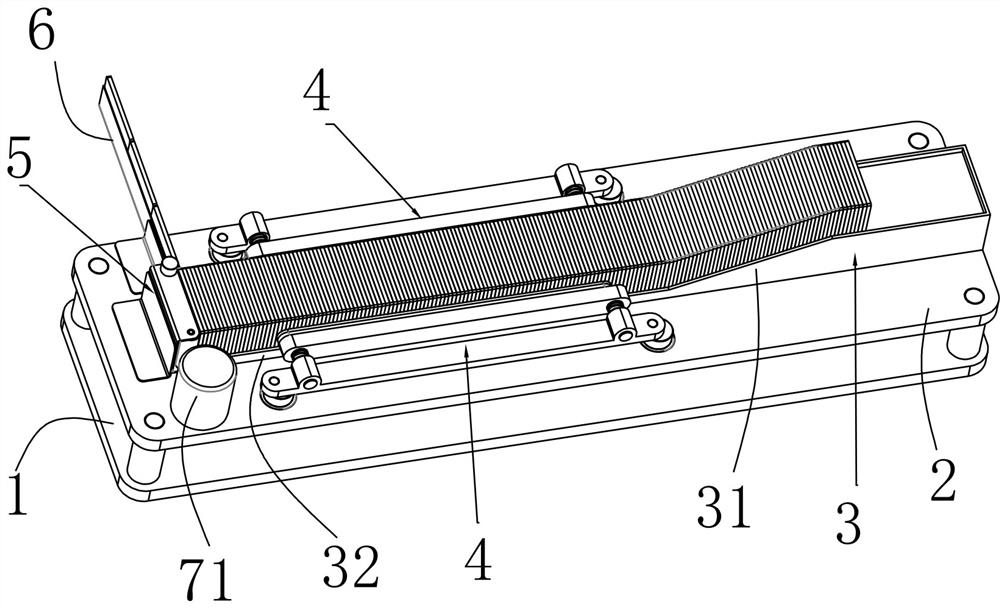

Carrier backflow device

InactiveCN107954166AAvoid damage and scrapReduce downtime lossElectrical testingControl devices for conveyorsButt jointDelayed time

The invention provides a carrier backflow device. The carrier backflow device comprises a first carrier sensing part, a transferring platform position sensor and a second carrier sensing part; the first carrier sensing part is used for detecting whether a carrier exists on a transferring platform or not, the transferring platform position sensor is used for detecting whether a transferring track is located at the position where the transferring track is butted joint with a testing track or not, and the second carrier sensing part is used for detecting whether the carrier exists on the transferring platform or not when the transferring track is moved to the place where the transferring track is butted joint with a backflow track; when the first carrier sensing part does not sense the carrier and the transferring platform position sensor senses the transferring track, the carrier is conveyed from a testing platform to the transferring platform; and when the first carrier sensing part does not sense the carrier and after the second carrier sensing part senses the carrier and when the second carrier sensing part does not sense the carrier within the preset delay time, the transferringplatform is conveyed to the position where the transferring platform is butted joint with the testing track. According to the carrier backflow device, collision between the transferring track and a board or falling of the board can be effectively avoided, the situation that the carrier is clamped, damaged and scraped is avoided, and the loss of stopping line is reduced.

Owner:INVENTEC CHONGQING

Anti-pollution sofa leather production method

ActiveCN104141237BAvoid damageAvoid damage and scrapSynthetic resin layered productsTextiles and paperSurface layerOrganic solvent

The invention discloses an antipollution sofa leather making method. The method comprises the following steps: uniformly stirring 5-10 parts of dimethyl formamide with 2-10 parts of a color paste, 10-30 parts of wood powder and 1-5 parts of a surfactant; adding 80-100 parts of wet polyurethane resin and 150-280 parts of dimethyl formamide to obtain a wet material; impregnating a base fabric, ironing, drying, coating the wet material, solidifying, foaming, washing with water, and drying to obtain a wet base; uniformly mixing 80-100 parts of a polyurethane surface layer resin with 40-70 parts of an organic solvent, 0.5-2 parts of an assistant and 5-8 parts of an environmentally friendly toner to obtain a dry material; uniformly mixing 80-100 parts of a polyurethane binding resin with 20-60 parts of the organic solvent, 0.5-2 parts of the assistant and 5-8 parts of the environmentally friendly toner to obtain a binder; coating the dry material on release paper, drying, coating the binder, pasting the wet base, drying, cooling, and separating from the release paper to obtain a semi-finished product; and carrying out surface treatment to obtain a finished product. The method effectively improves the oil stain resistance of sofa leather.

Owner:江苏协孚新材料科技有限公司

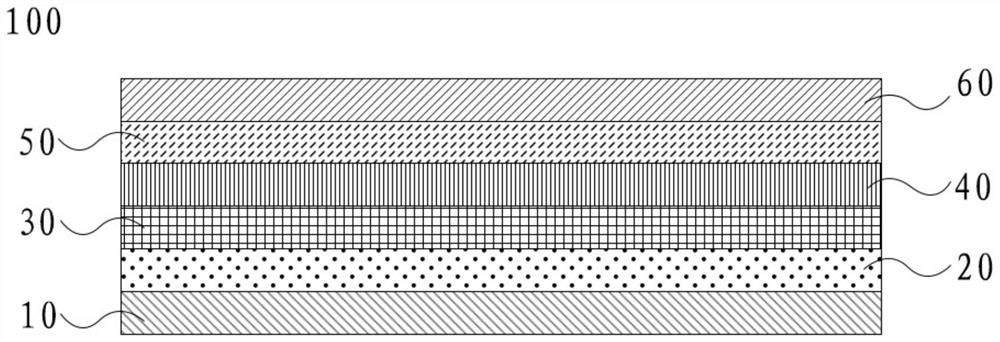

Transfer paper and preparation method thereof

ActiveCN108149514AGuaranteed StrengthPrevent penetrationNon-fibrous pulp additionFlexible coversWaxEmulsion

The invention relates to transfer paper and a preparation method thereof. The transfer paper comprises a back coating layer, a body paper layer, a glue layer, an aluminum plating layer, a transfer layer and a varnish layer, wherein the back coating layer is prepared from paper back coating emulsion; the paper back coating emulsion is mainly prepared from the following raw materials in parts by mass: 10-14 parts of water, 12-16 parts of acrylic emulsion, 1-4 parts of wax emulsion, 1-4 parts of gamma-polyglutamic acid, 0.5-1.5 parts of sodium alginate, 0.5-1 part of calcium chloride, 0.5-2 partsof ketone removal additive and 0.03-0.2 part of accessory ingredient. The transfer paper has good water retaining capacity and water absorptivity, the moisture of the body paper is prevented from permeating, meanwhile, moisture cohered to a surface in the environment is absorbed so as to eliminate a problem that the transfer paper layers are mutually adhered when being overlaid, so that the transfer paper layer can be easily separated during subsequent processing, damage scrap due to improper separation is avoided, production efficiency is effectively improved, production cost is lowered, anda market application prospect is wide.

Owner:常德市德源招商投资有限公司

Paper back coating emulsion, preparation method and application thereof

ActiveCN108004839AGuaranteed StrengthPrevent penetrationSpecial paperWater-repelling agents additionWaxEmulsion

The invention relates to paper back coating emulsion and a preparation method and application thereof. The paper back coating emulsion is mainly prepared from, by mass, 10-14 parts of water, 12-16 parts of acrylic emulsion, 1-4 parts of wax emulsion, 1-4 parts of gamma-polyglutamic acid, 0.5-1.5 parts of sodium alginate, 0.5-1 part of calcium chloride, 0.5-2 parts of ketone-removing additive and 0.03-0.2 part of auxiliary agent. The paper back coating emulsion is used for preparing a transfer paper back coating, the water retention capacity and water absorption can be improved, the moisture ofbase paper is prevented from permeating out, and the moisture condensed on the surface in the environment is absorbed, therefore the problem of mutual adhesion of transfer paper during overlapping issolved, so that the transfer paper is more easily separated during subsequent processing and use, the damage and waste caused by improper separation are avoided, the production efficiency is effectively improved, the production cost is reduced, and the market application prospect is broad.

Owner:常德市德源招商投资有限公司

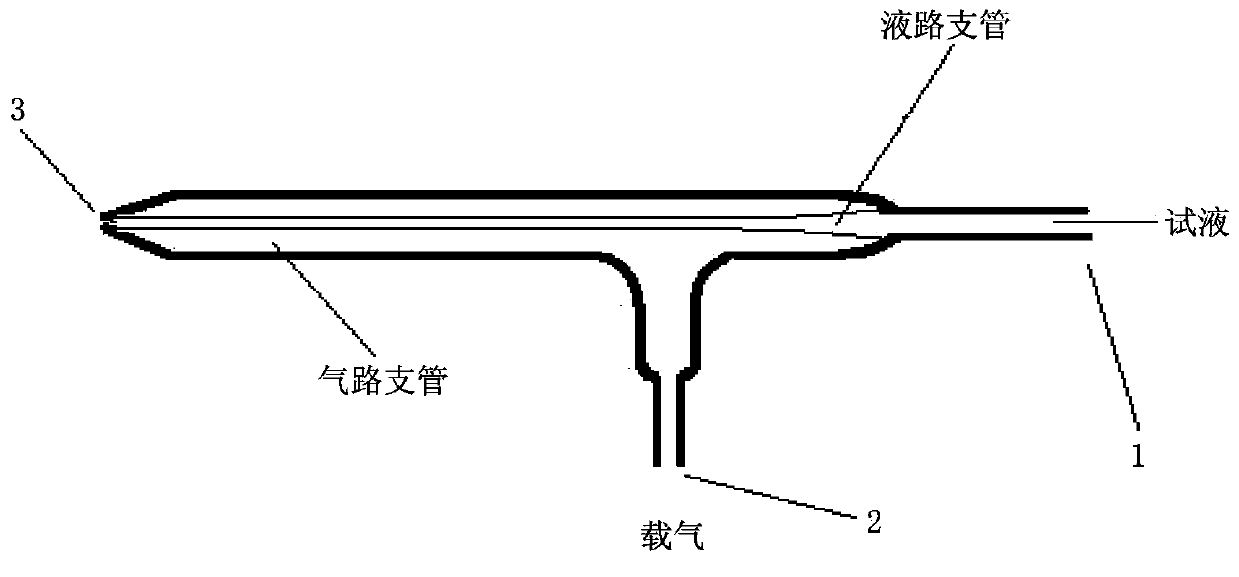

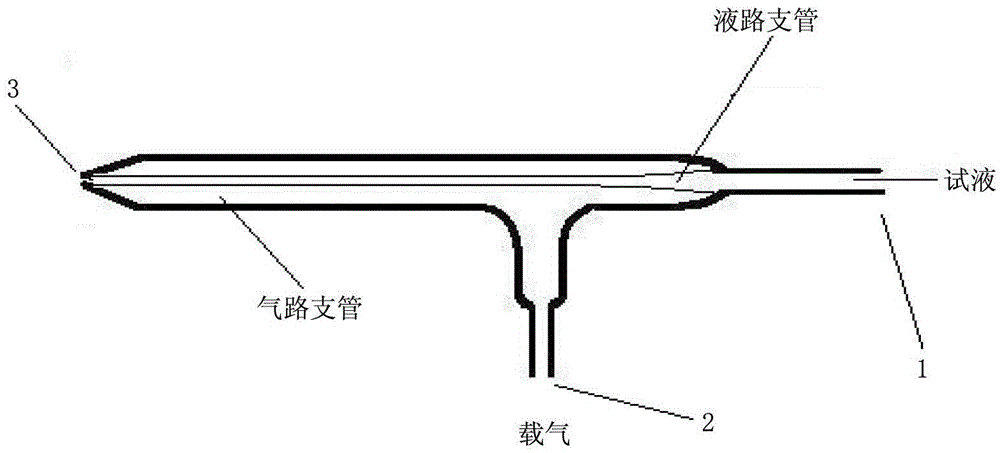

Method for cleaning gas channel branch pipe of atomizer

ActiveCN103801475AImprove atomization efficiencyAvoid damage and scrapSpraying apparatusTest performanceEngineering

The invention provides a method for cleaning a gas channel branch pipe of an atomizer. The method comprises a reverse high-pressure gas flow blowing step and / or a reverse solution pumping cleaning step, wherein the blowing step comprises the sub-steps that the gas inlet end of the gas channel branch pipe and the liquid inlet end of a liquid channel branch pipe are plugged, high-pressure gas flow is led into the atomizer through a nozzle continuously, and the gas inlet end is suddenly opened when the liquid inlet end keeps a plugged state; the cleaning step comprises the sub-steps that the nozzle is placed in cleaning solution and pumping operation is conducted on the gas inlet end, so that the gas channel branch pipe is filled with the cleaning solution, and substances to be cleaned in the gas channel branch pipe are discharged through the gas inlet end. The method further comprises the step that water is used for replacing the cleaning solution in the solution cleaning step so that rudimental cleaning solution in the gas channel branch pipe can be cleaned away. By means of the method, dirt or obstruction in the gas channel branch pipe of the atomizer can be eliminated, analysis and test performance of a device can be improved, spare part consumption can be reduced, and detection cost is reduced.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

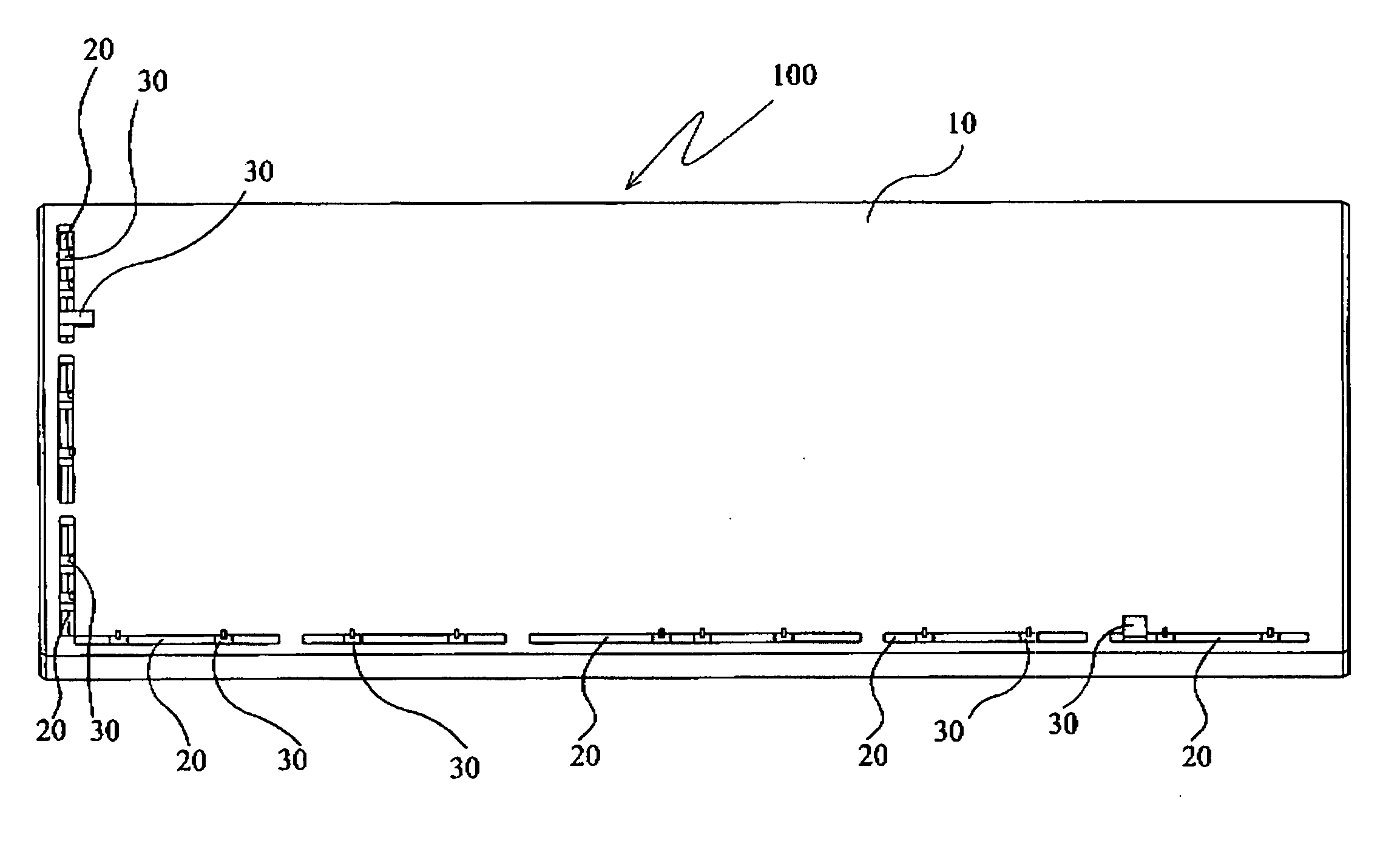

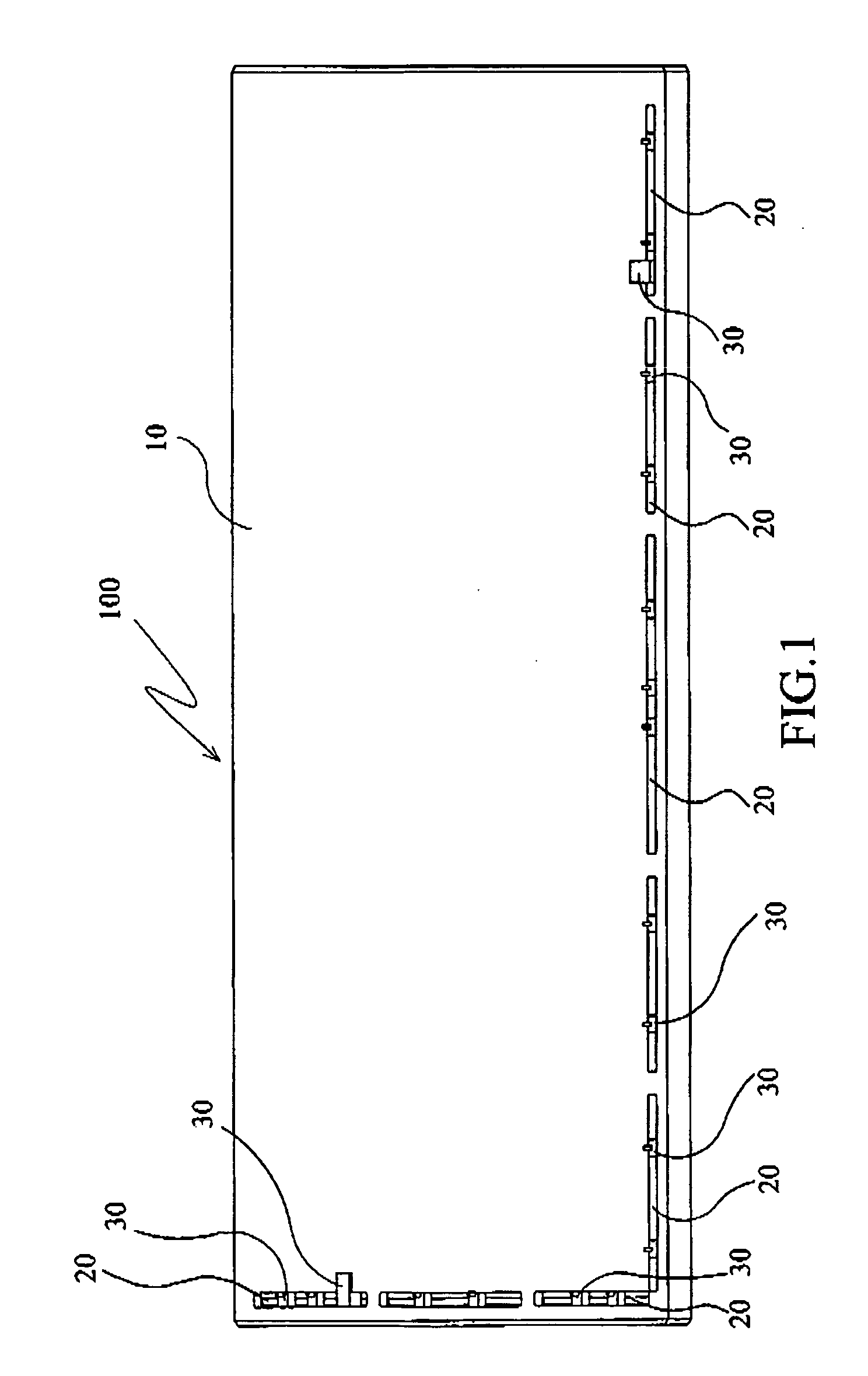

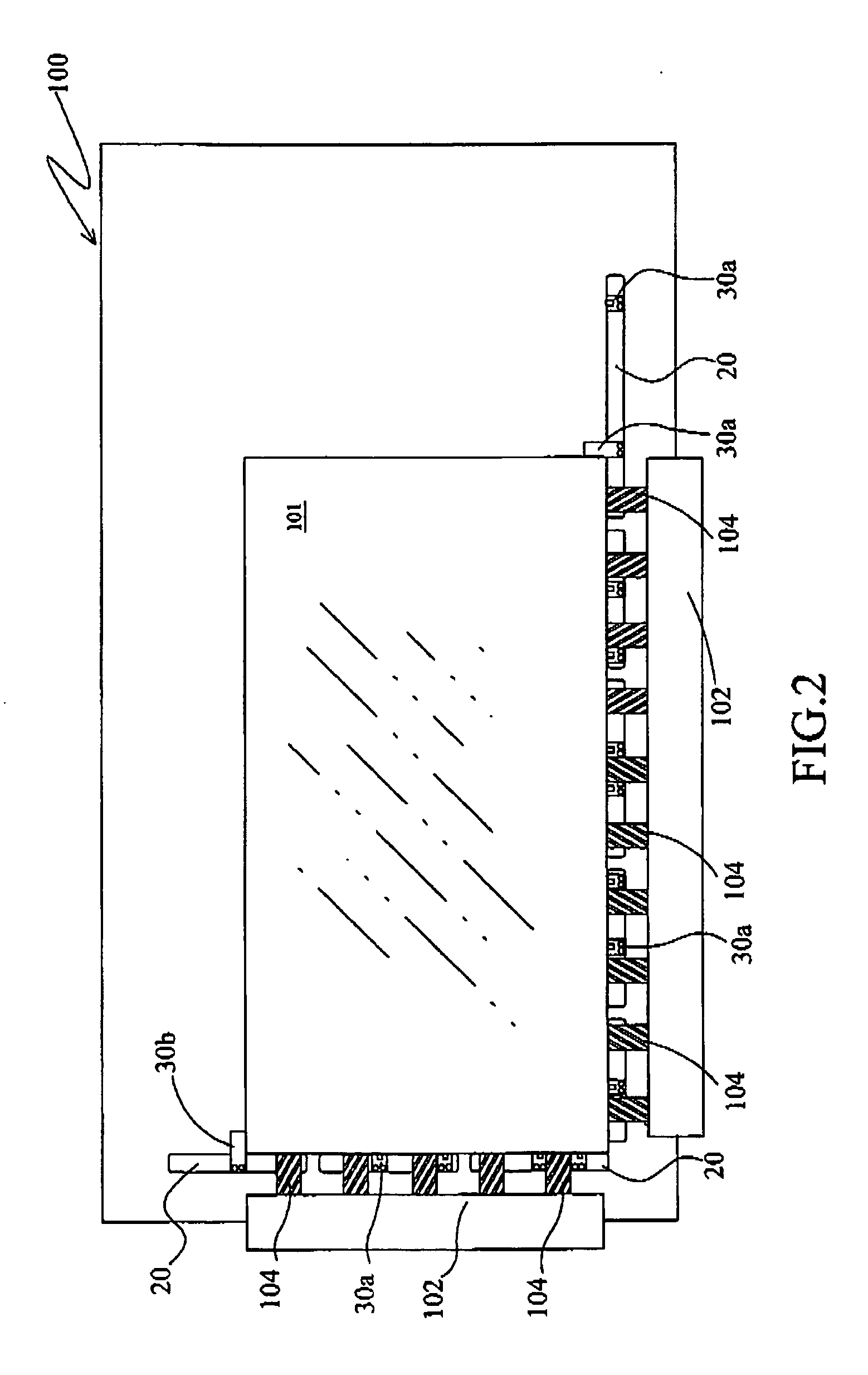

Panel positioning device

InactiveUS20070170626A1Increase stability and qualityPrevent be damageWork holdersSurface plateElectrical and Electronics engineering

Owner:CHUNGHWA PICTURE TUBES LTD

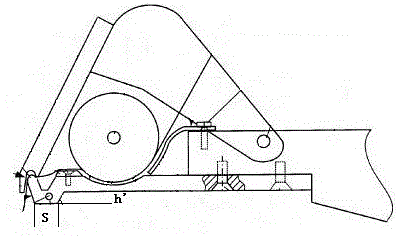

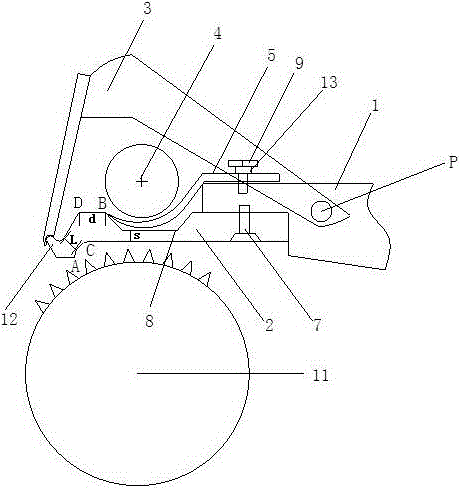

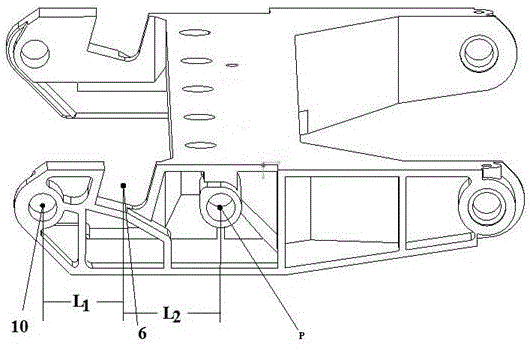

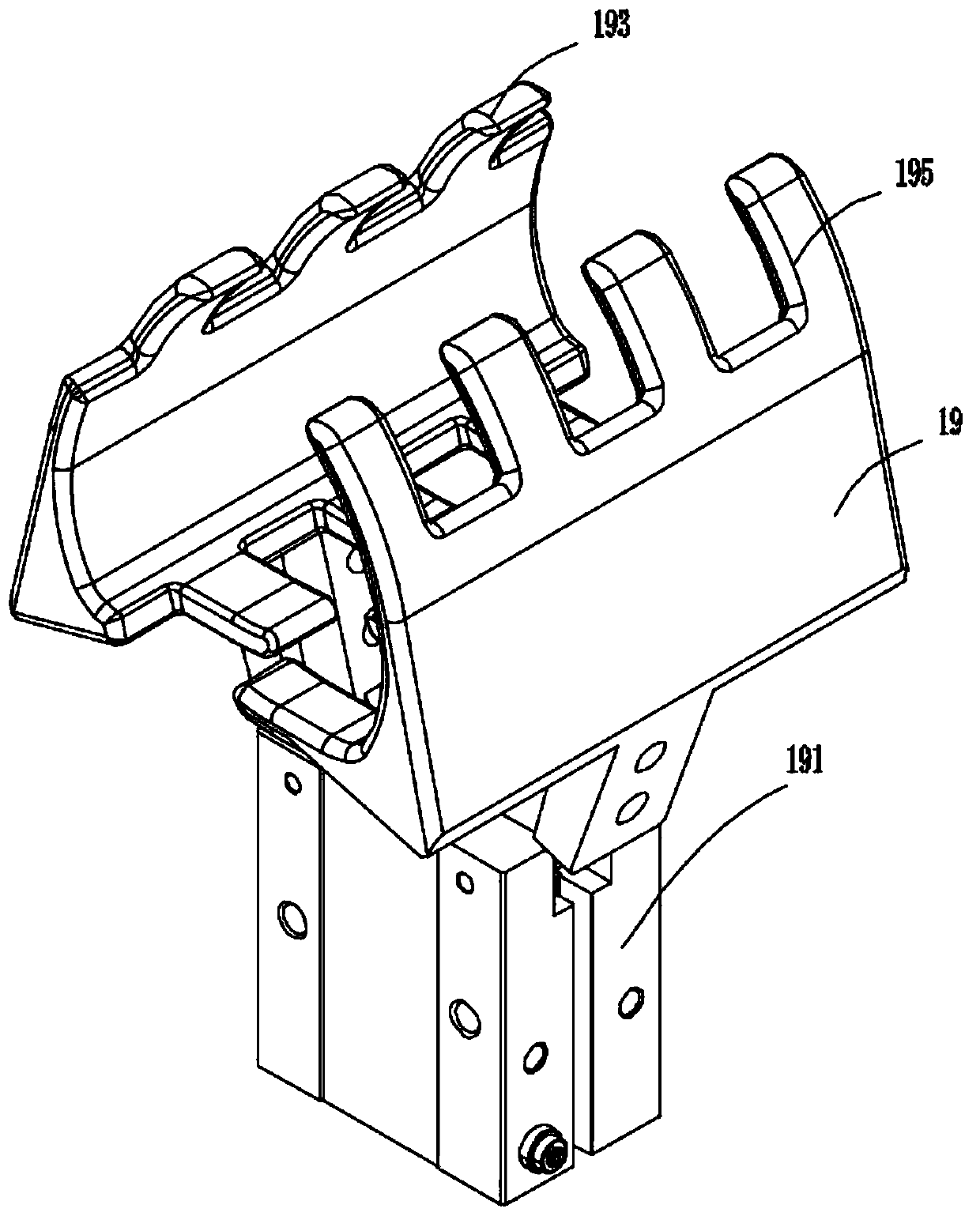

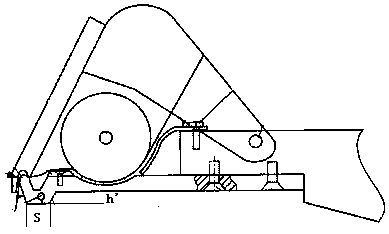

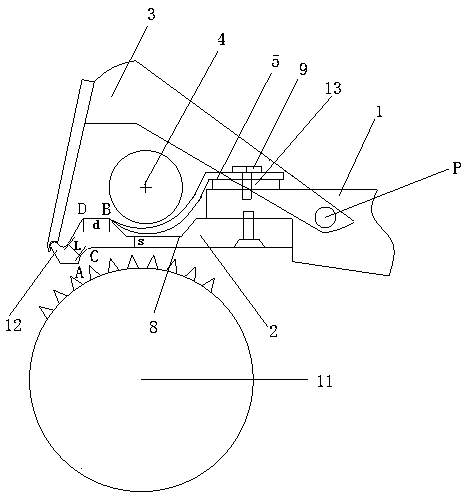

Novel combing-machine nipper mechanism

The invention discloses a novel combing-machine nipper mechanism which comprises a lower nipper seat. A lower nipper plate is fixed in front of the lower nipper seat, a trapezoidal groove is formed in the middle of the top surface of the lower nipper plate, a cotton guide plate is arranged in the trapezoidal groove, the cotton guide plate is arc-shaped on the front portion and horizontal at the tail, the tail portion of the cotton guide plate is fixed on the lower nipper plate, a feed roller is arranged above the cotton guide plate, and grooves for holding the feed roller are arranged at two ends of the lower nipper seat; the front end of the bottom surface of the lower nipper plate is provided with a plane, the rear of the plane is gradually raised through circular arc transition, and the lower nipper seat is connected with an upper nipper plate connector in a hinge joint manner. By the arrangement, a cotton feed channel can be flexibly adjusted according to thickness of a small roll, distance of the center of the front end of each nipper plate, the center of each groove and hinge point of each nipper plate can be reasonably arranged, and large quantitative of small rolls and long fibers 35mm above in length are assured to be processed smoothly through a combing machine; due to the arc-raised surface, collision against the lower nipper plate by cylinder needle teeth is avoided, compressive strength of the nipper lip of the lower nipper plate is guaranteed, the nipper plates and a cylinder of the combing machine are prevented from being damaged, and production cost is obviously reduced.

Owner:ZHONGYUAN ENGINEERING COLLEGE

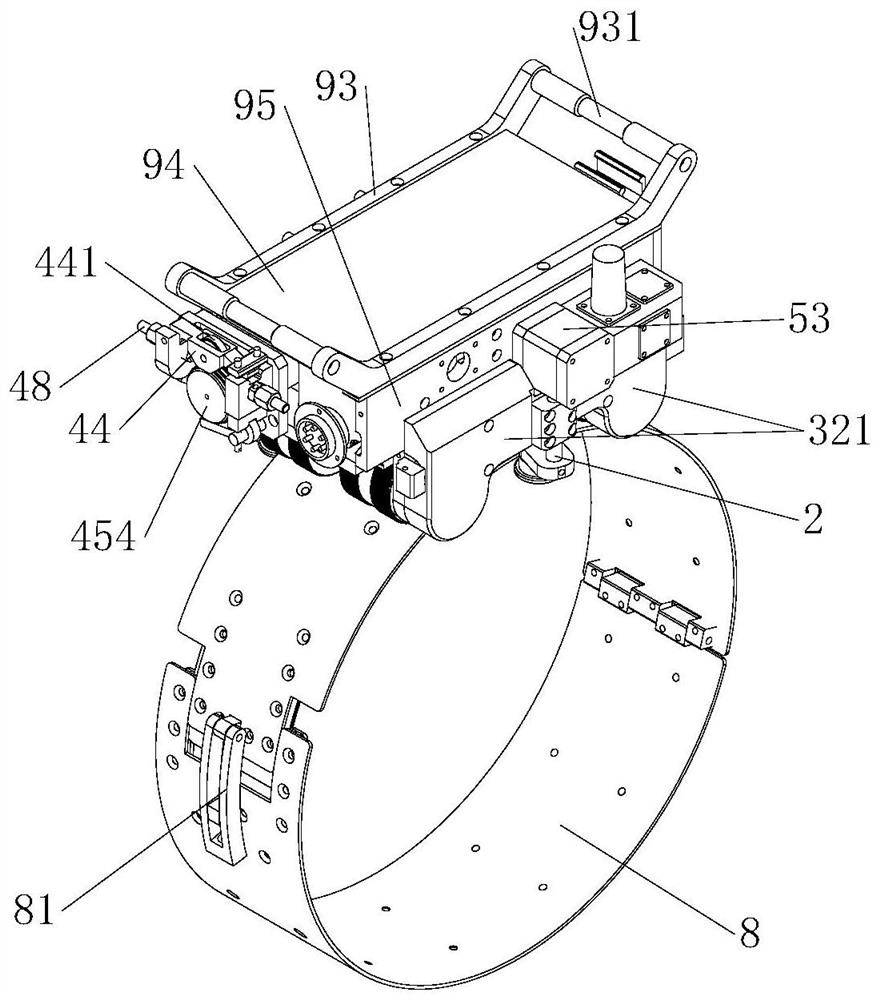

Magnetic type welding trolley

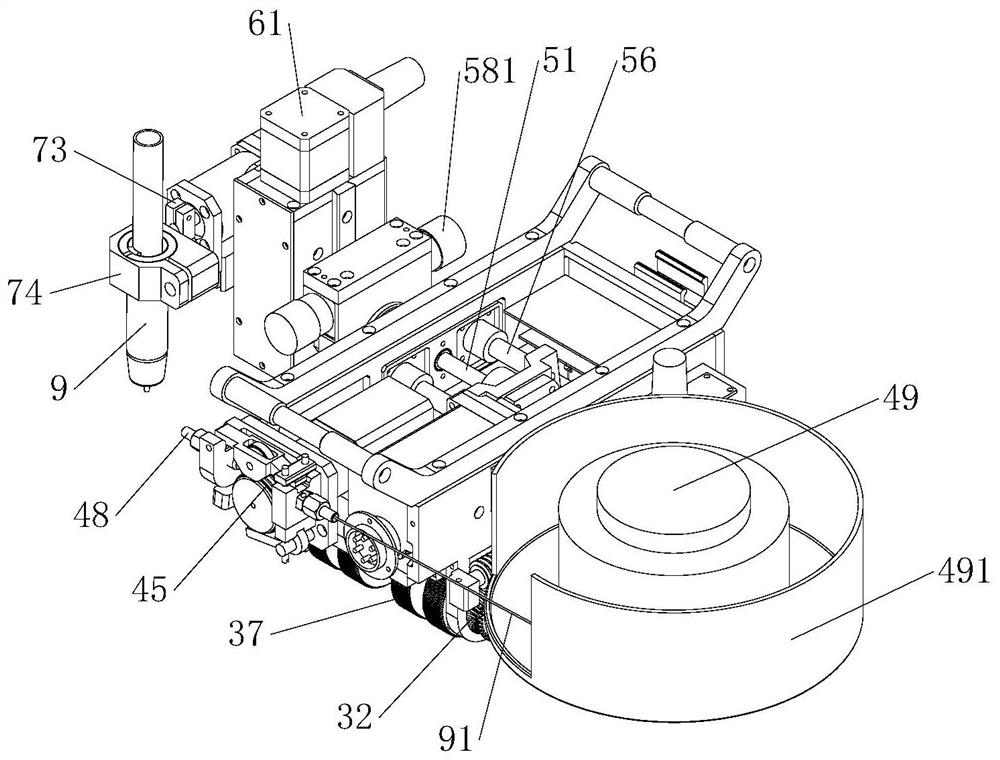

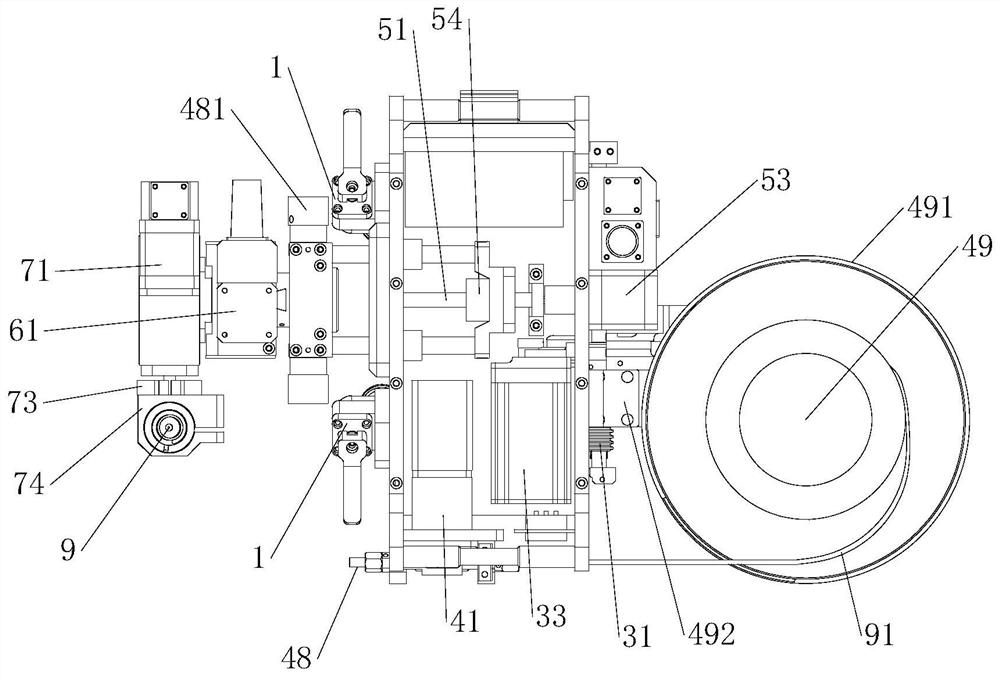

PendingCN113649743AAids in walking stabilityReduce volumeWelding/cutting auxillary devicesAuxillary welding devicesControl theoryMechanical engineering

The invention provides a magnetic type welding trolley. The magnetic type welding trolley comprises a trolley body, wherein magnetic wheels are arranged at the bottom of the trolley body; the trolley body is provided with a driving system; the driving system comprises a belt wheel, a driving worm and driving worm wheels; the driving worm is arranged along the length direction of the trolley body; the belt wheel sleeves the driving worm; the driving worm is engaged with all the driving worm wheels; and the driving worm wheels are fixedly connected with the corresponding magnetic wheels. According to the magnetic type welding trolley provided by the invention, all the driving worm wheels are driven by the same driving worm, so that the rotary frequencies of all the driving worm wheels are the same, the walking stability of the welding trolley is facilitated and an inner transmission structure of the welding trolley is easy to reduce. The rotation of the magnetic wheels needs to be driven by the worm wheels and the worm; and after the welding trolley is powered off, the worm wheels and the worm can ensure that the magnetic wheels do not rotate through self-locking, so that a phenomenon that the trolley is slipped after being powered off in a welding process is avoided and the utilization safety of the welding trolley is improved.

Owner:CHENGDU F&M TECH

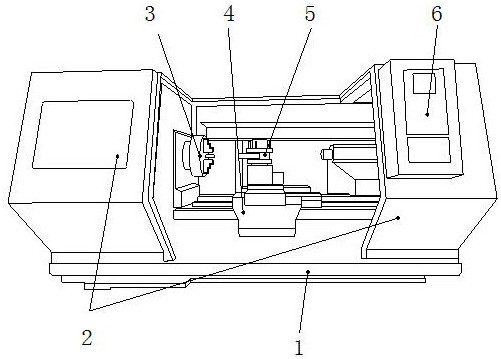

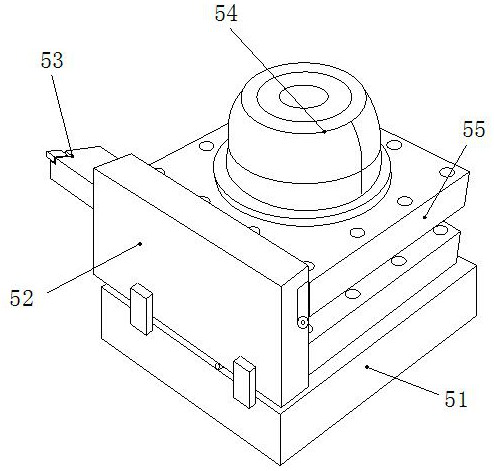

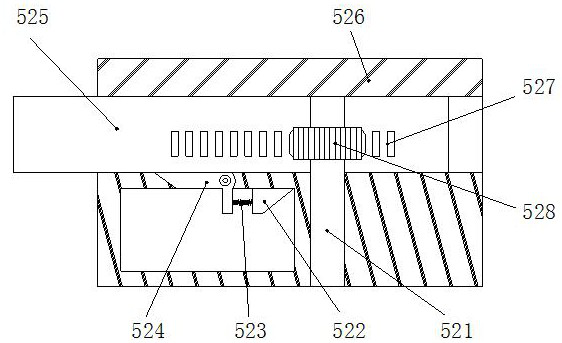

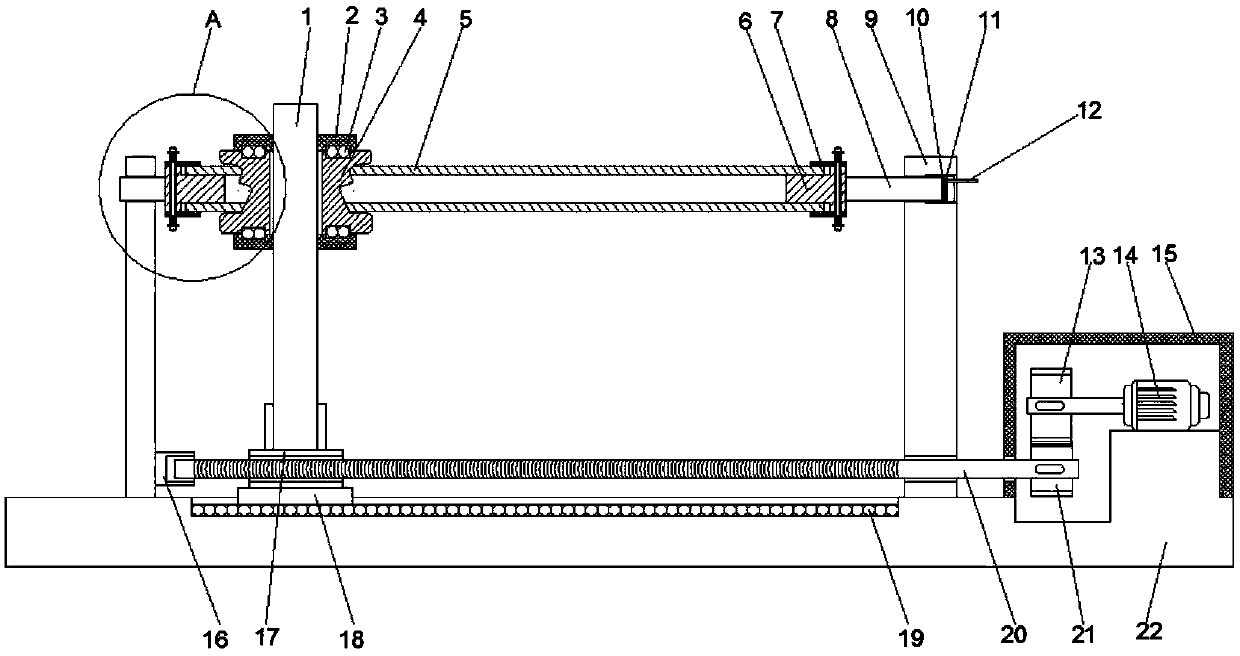

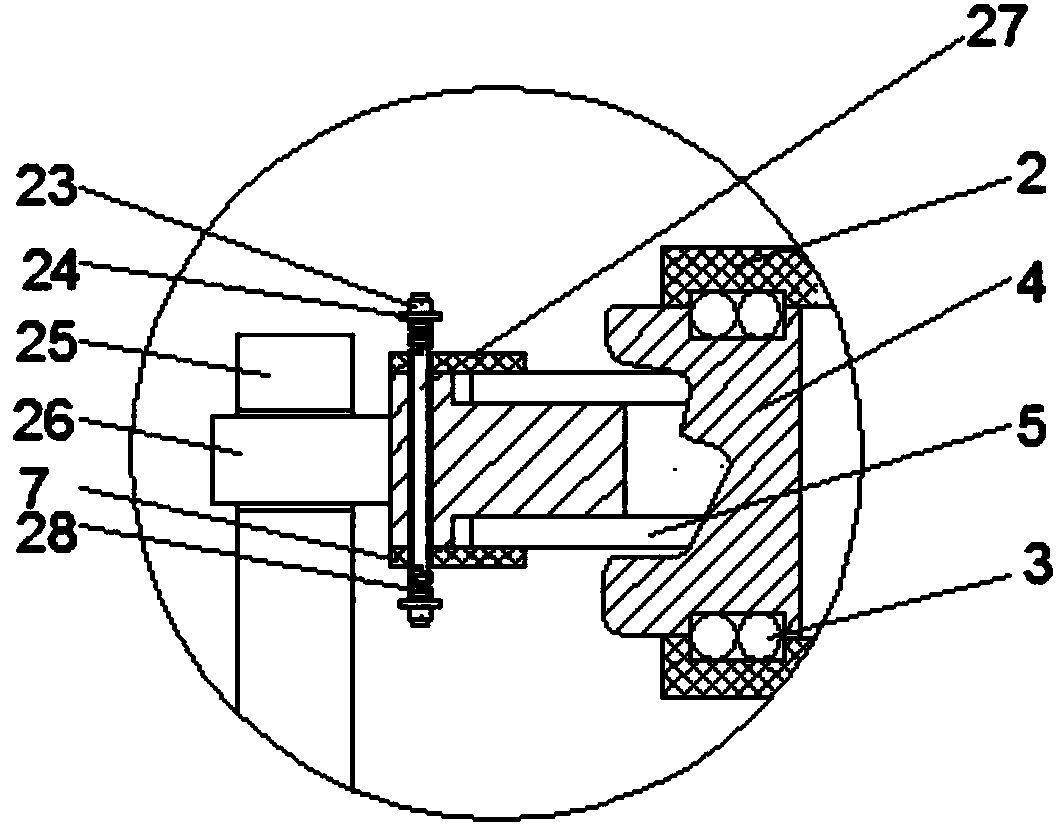

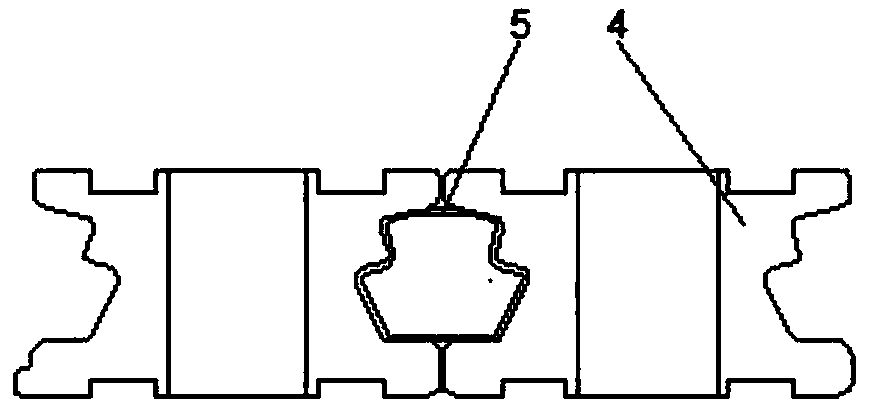

Combined feeding type numerical control lathe

InactiveCN111843592AAvoid bondingAvoid damage and scrapMaintainance and safety accessoriesNumerical controlMachine parts

The invention discloses a combined feeding type numerical control lathe. The combined feeding type numerical control lathe structurally comprises a base, a movable door, a spindle, a sliding seat, a tool rest and a control box, wherein the upper end of the base is movably clamped to the lower end of the movable door. A sliding block moves left and right, a jacking block jacks a warping plate through a spring to scrape off aluminum alloy melt cleaned off by the sliding block for storage, a scraping block cleans away the aluminum alloy melt, and the situation that aluminum alloy adheres to the outer side of a tool and makes the outer side of the tool blunt and consequently the tool cannot be used any longer is prevented. A middle shaft on the front side of a supporting frame can connect thescraping block, then, a scraper is cleaned through a limiting plate, a capturing sheet can stick the removed aluminum alloy melt on the limiting plate, a contact block can press the capturing sheet downwards under the supporting of a fixing shaft after the sliding block moves rightwards, then, the warping plate can perform scraping and collecting on the capturing sheet, and the situation that thealuminum alloy melt adheres to the tool and consequently the tool cannot be used any longer or even a machined part is damaged and scraped is prevented.

Owner:广州优易机械科技有限公司

Roll pressing manufacturing device for specially-shaped pipe

The invention discloses a roll pressing manufacturing device for a specially-shaped pipe. The roll pressing manufacturing device for the specially-shaped pipe comprises a base, wherein a first supporting column and a second supporting column are fixedly connected to the upper end of the base; a pipe component is arranged between the first supporting column and the second supporting column; guidingcolumns run through the inner parts of two ends of the pipe component; a first connecting rod is fixedly connected to one end, near the first supporting column, of the guiding column; the first connecting rod runs through the upper end of the first supporting column; a second connecting rod is fixedly connected to one end, near the second supporting column, of the guiding column; the second connecting rod runs through the second supporting column; a sliding slot is formed in the upper end of the base; a supporting plate is connected to the upper end of the sliding slot in a sliding manner; astroke plate is fixedly connected to the upper end of the supporting plate; and two symmetrically arranged mounting columns are fixedly connected to the upper end of the stroke plate. The roll pressing manufacturing device for the specially-shaped pipe is novel in structure; the roll pressing manufacturing device for the specially-shaped pipe is provided; through step-by-step analysis and roll pressing, scrapped damage during the processing of the pipe component is effectively avoided and the production cost is reduced.

Owner:合肥挺泰环保科技有限公司

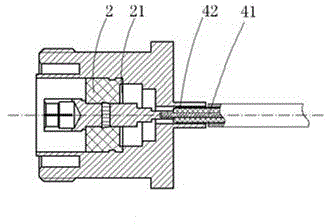

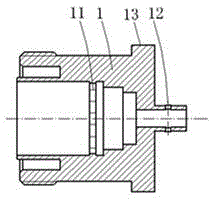

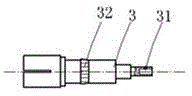

Low-intermodulation antenna stern line connector

InactiveCN104485560APrevent the bad phenomenon of sheddingAvoid damage and scrapElectrically conductive connectionsAntenna connectorsElectrical conductorHigh volume manufacturing

The invention discloses a low-intermodulation antenna stern line connector. The low-intermodulation antenna stern line connector comprises an integrated outer conductor, an insulator filled with a medium, and a central conductor; a signal transmission cavity with a coaxial structure is formed inside the outer conductor, and the tail part of the outer conductor is provided with a radio-frequency cable welding hole and a mounting flange; the insulator is formed by sintering a high-temperature resistant material and is of a dual-circle structure; the tail part of the central conductor is provided with a central welding hole required for welding a radio-frequency cable, and the central welding hole is gradual in a coaxial step manner. The low-intermodulation antenna stern line connector is simple in structure, reliable in mechanical performance, excellent in electric performance, high in assembly efficiency and high in raw material utilization rate, has low intermodulation performance and is suitable for large-batch production.

Owner:安徽蓝麦通信股份有限公司

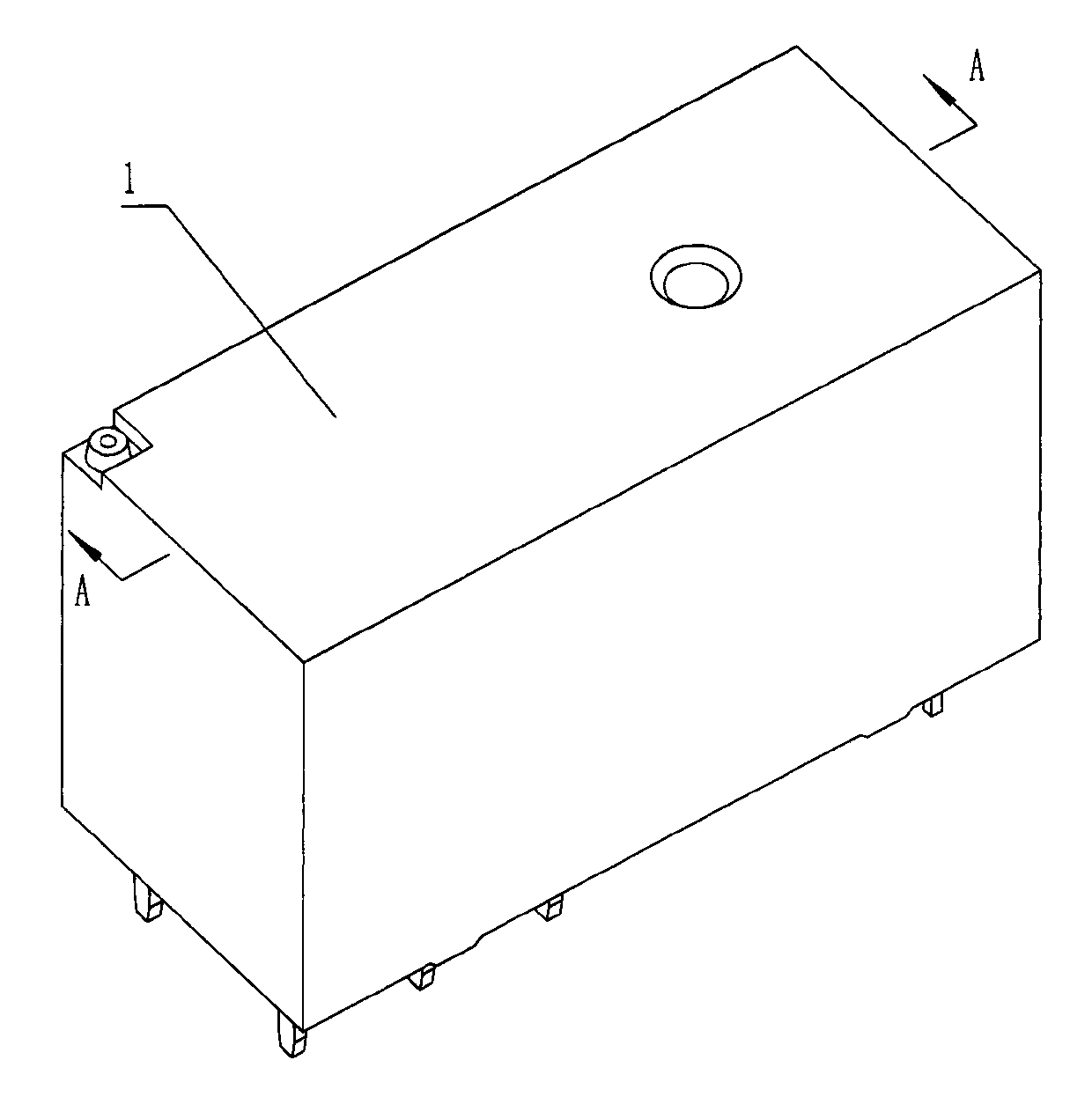

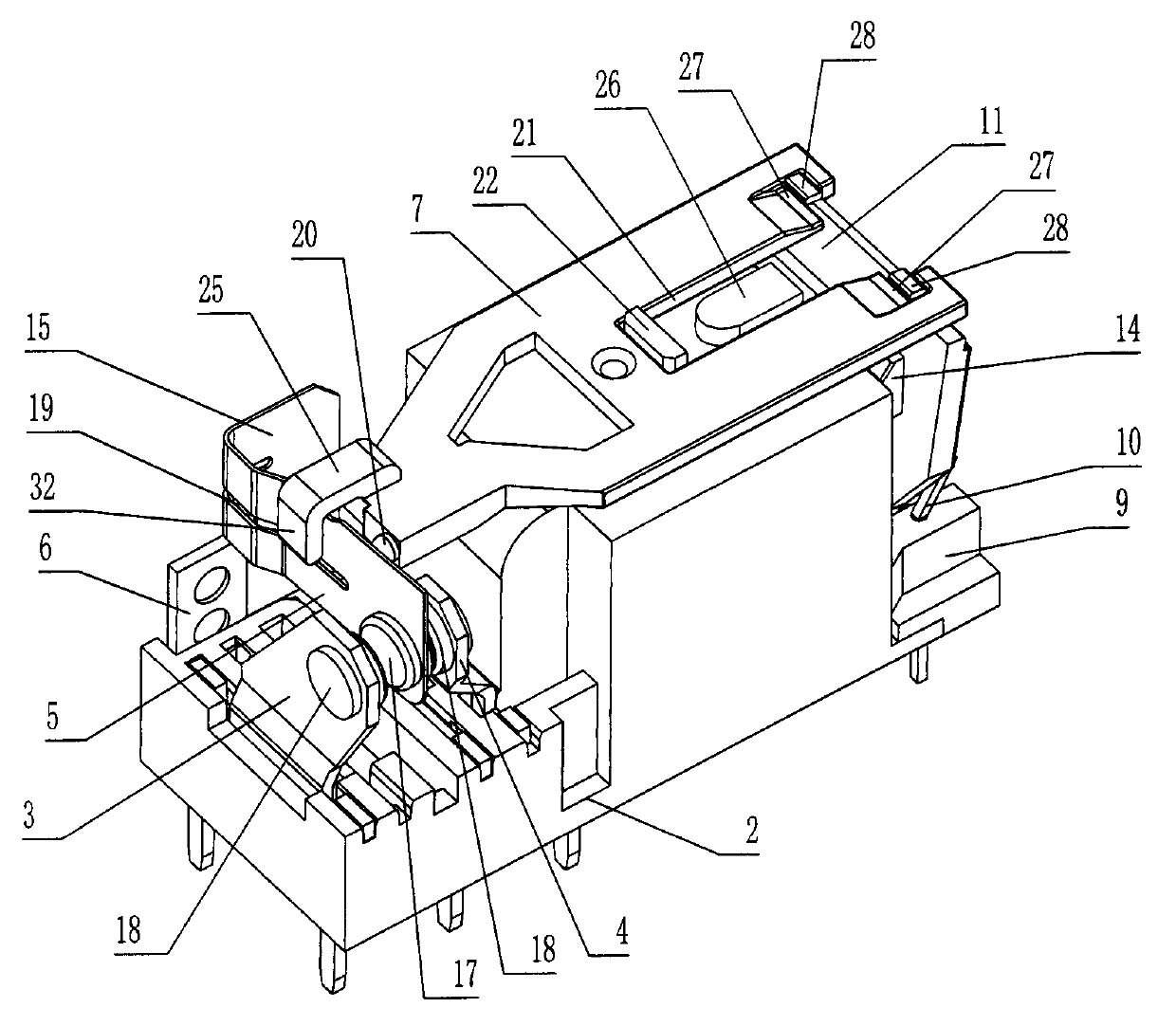

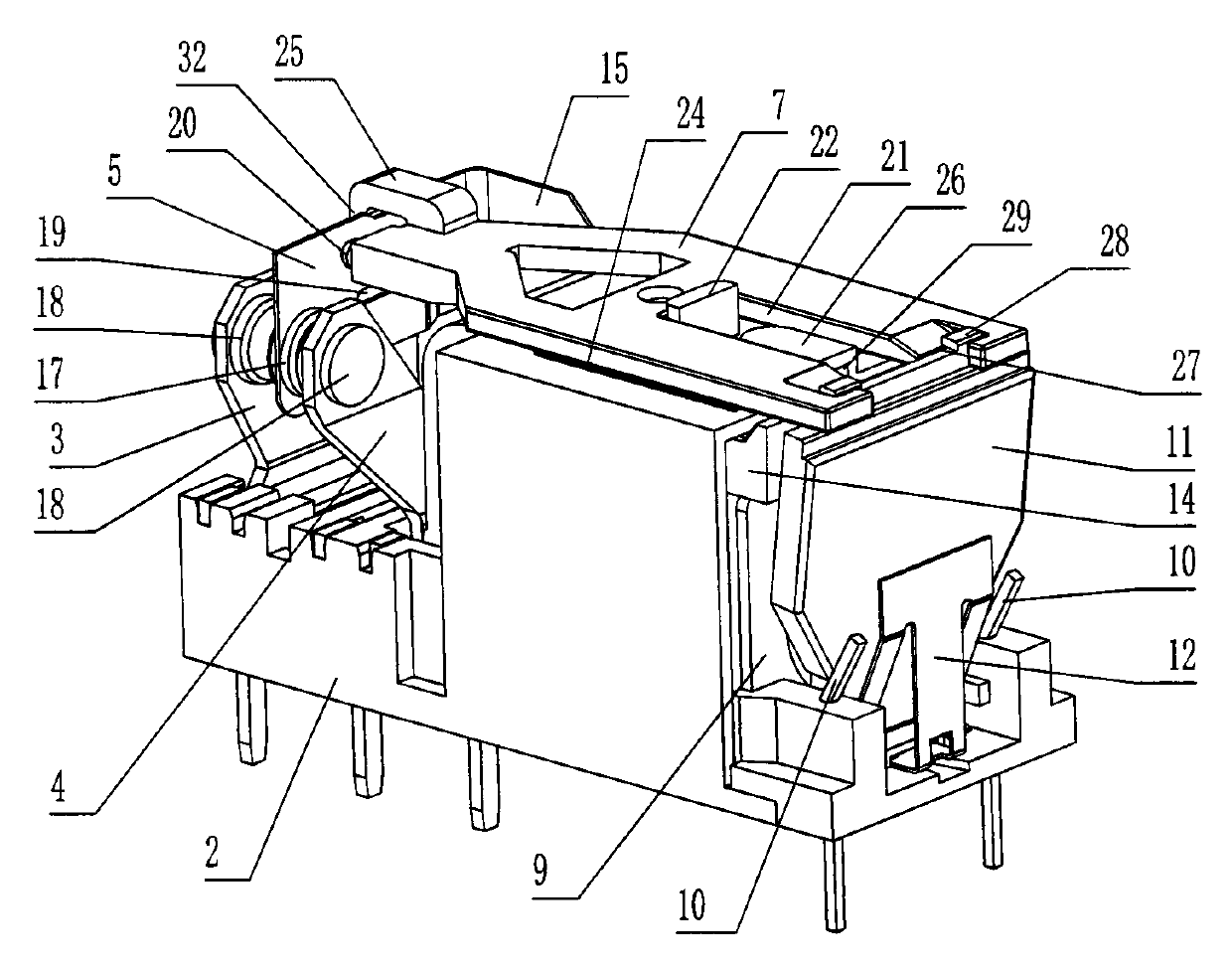

Electromagnetic relay

InactiveCN104201057AEasy to installLittle room to move up and downElectromagnetic relay detailsEngineeringMechanical engineering

The invention discloses an electromagnetic relay comprising a housing, a base, a push block, a contact portion and a magnetic circuit portion. The base is provided with a cavity. The contact portion comprises a moving spring. The push block is arranged over the outer wall of the cavity. The middle of the push block is provided with a limiting slot. A limiter block capable of sliding side to side in the limiting slot is arranged at the upper end of the outer wall of the cavity. Limiter strips in a pair are arranged at the top of an inner cavity of the housing. The limiter strips are arranged over the push block in front and rear of the limiting slot respectively. Slide strips in a pair are arranged at the lower end of the push block. The slide strips press to the upper end of the outer wall of the cavity in front and rear of the limiting slot respectively. A pull rod is arranged at the left end of the push block. The left end of the pull rod is provided with a hook; the hook crosses the moving spring through the pull rod and is arranged on the left side of the moving spring. The electromagnetic relay has the advantages that the push block is convenient to mount, the moving spring is effectively avoided being damaged and scrapped during mounting of the push block, and the electromagnetic relay can assist in resetting the moving spring.

Owner:浙江凡华电子股份有限公司

Paper back-coated emulsion and its preparation method and application

ActiveCN108004839BGuaranteed StrengthPrevent penetrationSpecial paperWater-repelling agents additionPolymer scienceEmulsion

The invention relates to paper back coating emulsion and a preparation method and application thereof. The paper back coating emulsion is mainly prepared from, by mass, 10-14 parts of water, 12-16 parts of acrylic emulsion, 1-4 parts of wax emulsion, 1-4 parts of gamma-polyglutamic acid, 0.5-1.5 parts of sodium alginate, 0.5-1 part of calcium chloride, 0.5-2 parts of ketone-removing additive and 0.03-0.2 part of auxiliary agent. The paper back coating emulsion is used for preparing a transfer paper back coating, the water retention capacity and water absorption can be improved, the moisture ofbase paper is prevented from permeating out, and the moisture condensed on the surface in the environment is absorbed, therefore the problem of mutual adhesion of transfer paper during overlapping issolved, so that the transfer paper is more easily separated during subsequent processing and use, the damage and waste caused by improper separation are avoided, the production efficiency is effectively improved, the production cost is reduced, and the market application prospect is broad.

Owner:常德洛恩全息材料科技有限公司

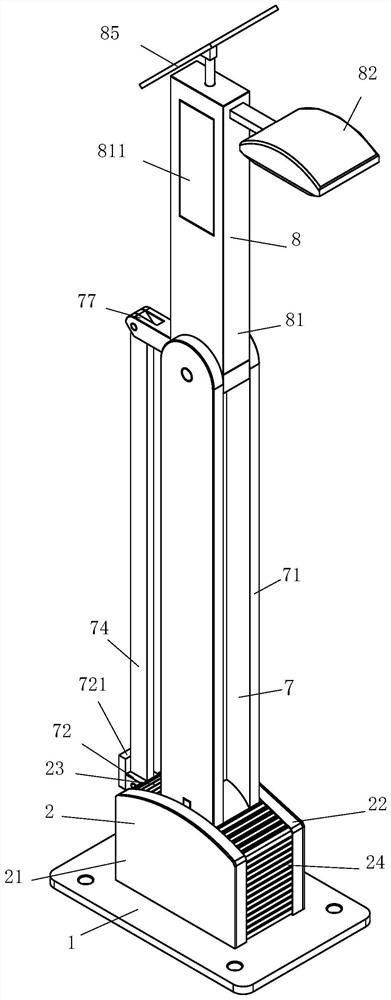

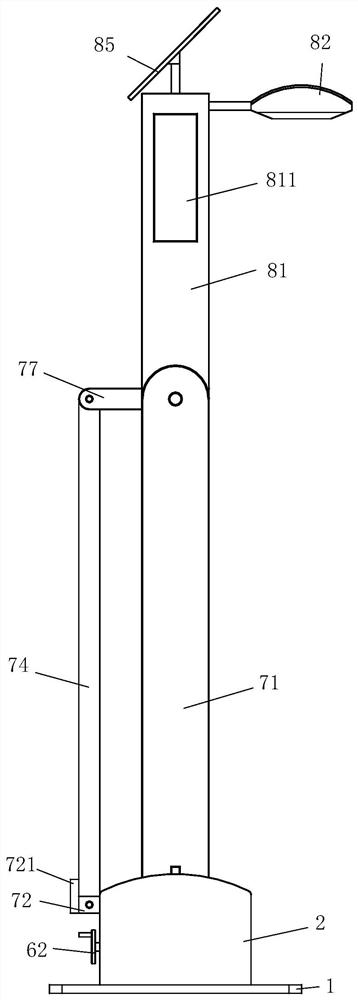

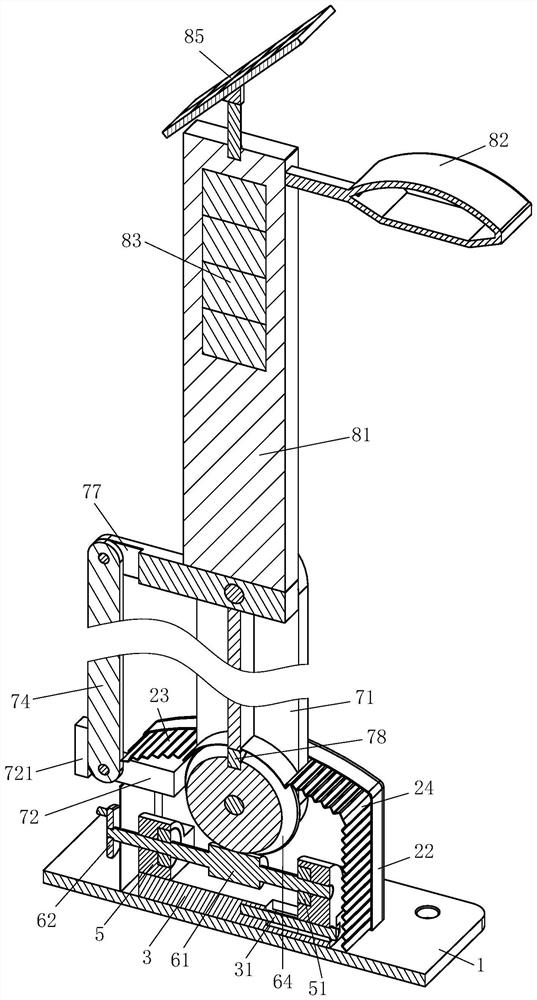

Descending type street lamp based on parallelogram structure

InactiveCN112524551AGuarantee personal safetyEasy maintenancePhotovoltaic supportsMechanical apparatusLight equipmentElectrical battery

The invention belongs to the technical field of public lighting equipment, and particularly relates to a descending type street lamp based on a parallelogram structure. The descending type street lampcomprises a bottom plate, a shell, a support base, a support plate, a support block, a power part, a rotating part and a lighting part; through joint operation of the power part, the rotating part and the lighting part, the street lamp is descended to the height facilitating maintenance of constructors; due to the fact that the street lamp is arranged on the roadside and is greatly affected by the environment, manual maintenance is frequently needed; and the lighting part at the upper end of the street lamp can be kept vertical and automatically descended to the proper height, and maintenanceof workers is facilitated, so that workers do not need to go to a high place for operation, and the danger of worker construction is greatly reduced; and a solar panel, a battery and the lamp holderare all arranged at the upper end of the street lamp, so that the energy loss of the street lamp is reduced, and street lamp lighting parts are convenient to maintain.

Owner:林明

A kind of method of cleaning the gas circuit branch pipe of atomizer

ActiveCN103801475BImprove atomization efficiencyAvoid damage and scrapSpraying apparatusTest performanceNebulizer

The invention provides a method for cleaning a gas channel branch pipe of an atomizer. The method comprises a reverse high-pressure gas flow blowing step and / or a reverse solution pumping cleaning step, wherein the blowing step comprises the sub-steps that the gas inlet end of the gas channel branch pipe and the liquid inlet end of a liquid channel branch pipe are plugged, high-pressure gas flow is led into the atomizer through a nozzle continuously, and the gas inlet end is suddenly opened when the liquid inlet end keeps a plugged state; the cleaning step comprises the sub-steps that the nozzle is placed in cleaning solution and pumping operation is conducted on the gas inlet end, so that the gas channel branch pipe is filled with the cleaning solution, and substances to be cleaned in the gas channel branch pipe are discharged through the gas inlet end. The method further comprises the step that water is used for replacing the cleaning solution in the solution cleaning step so that rudimental cleaning solution in the gas channel branch pipe can be cleaned away. By means of the method, dirt or obstruction in the gas channel branch pipe of the atomizer can be eliminated, analysis and test performance of a device can be improved, spare part consumption can be reduced, and detection cost is reduced.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

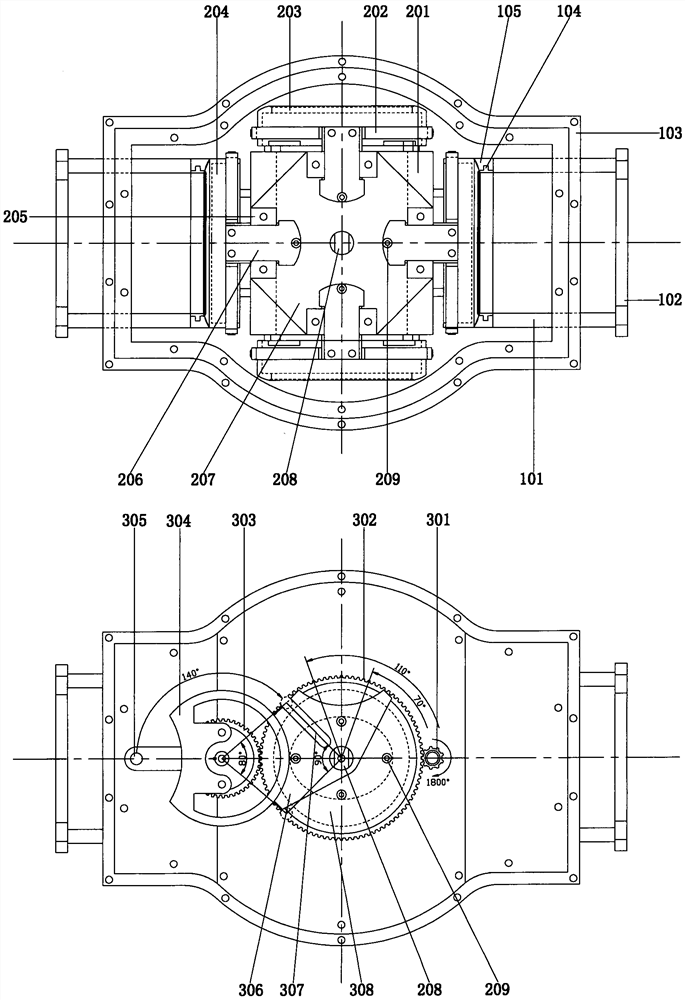

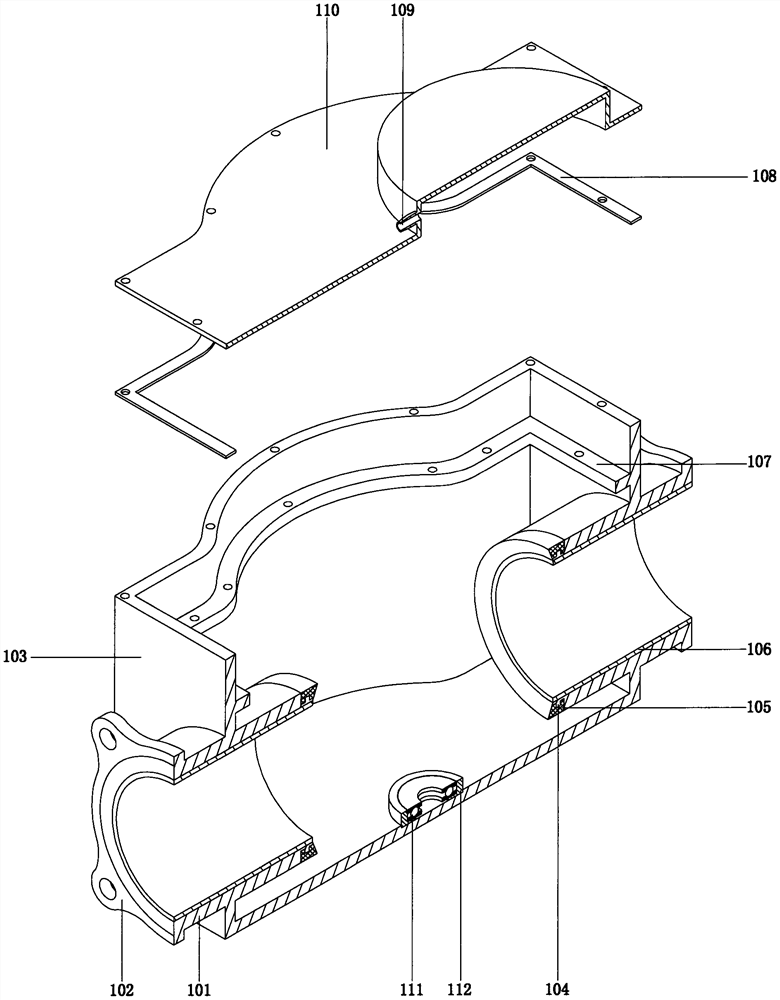

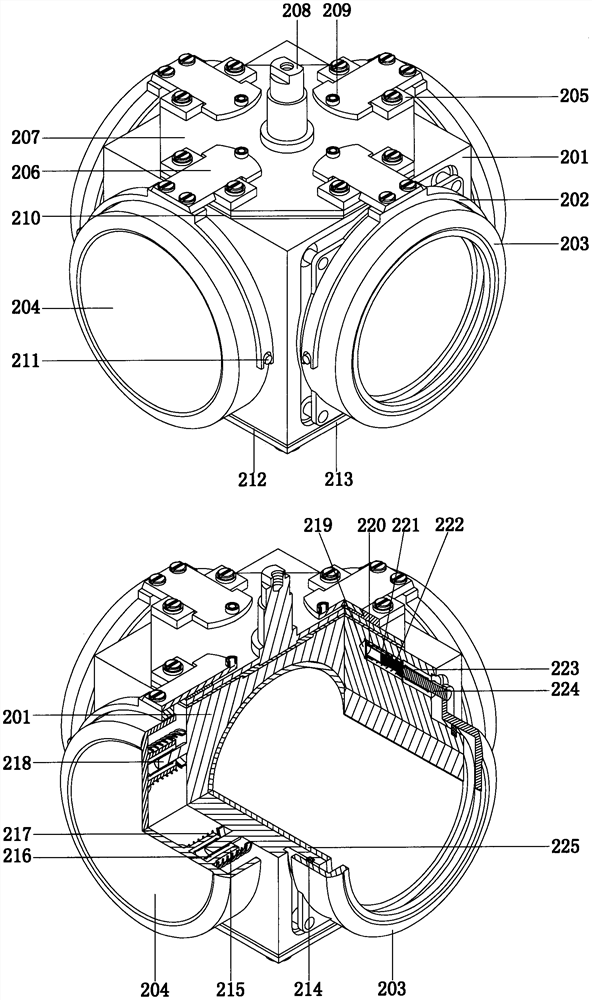

Automobile anti-theft and engine anti-water-soaking protector

PendingCN112406786AImproved and enhanced anti-theft featuresAvoid damage and scrapExhaust apparatusPedestrian/occupant safety arrangementGear wheelRotary valve

The invention relates to an automobile anti-theft and engine anti-water-soaking protection device with improved anti-theft system function, in particular to an automobile anti-theft and engine water soaking prevention protector which is composed of an inlet and outlet connecting pipe (101), a connecting flange (102), a shell (103), a silica gel sealing ring (105), a gland (110), a rotary valve mechanism body (201), a telescopic valve shifting fork (202), a normally open telescopic valve (203), a normally closed telescopic valve (204), a telescopic valve shifting fork dovetail sliding block (206), an intermediate gear (302), a driven gear (303), a 90-degree rotating disc limiting disc (304), a 90-degree rotating disc shifting fork (305), a 90-degree rotating disc (306) and a stepping motor(312). On the premise that the pipe diameter of an air inlet system and the pipe diameter of an air outlet system of an automobile are not changed, and the original structure of the automobile is notchanged, engine damage and scrapping, caused by water invasion, of the automobile are avoided, the maintenance cost for water-soaked vehicles is greatly reduced, and the anti-theft function of automobiles is improved and enhanced.

Owner:李凤桐

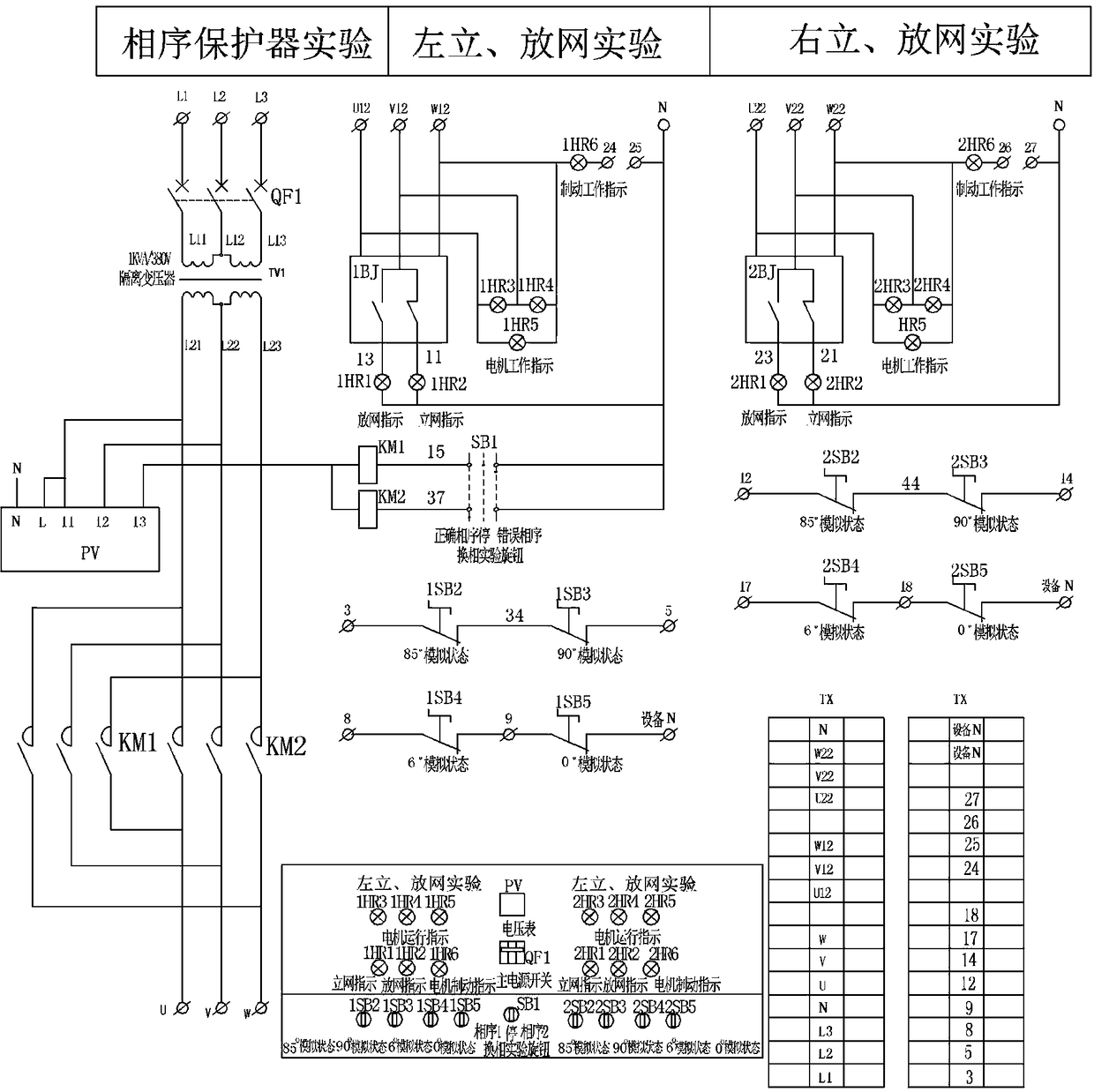

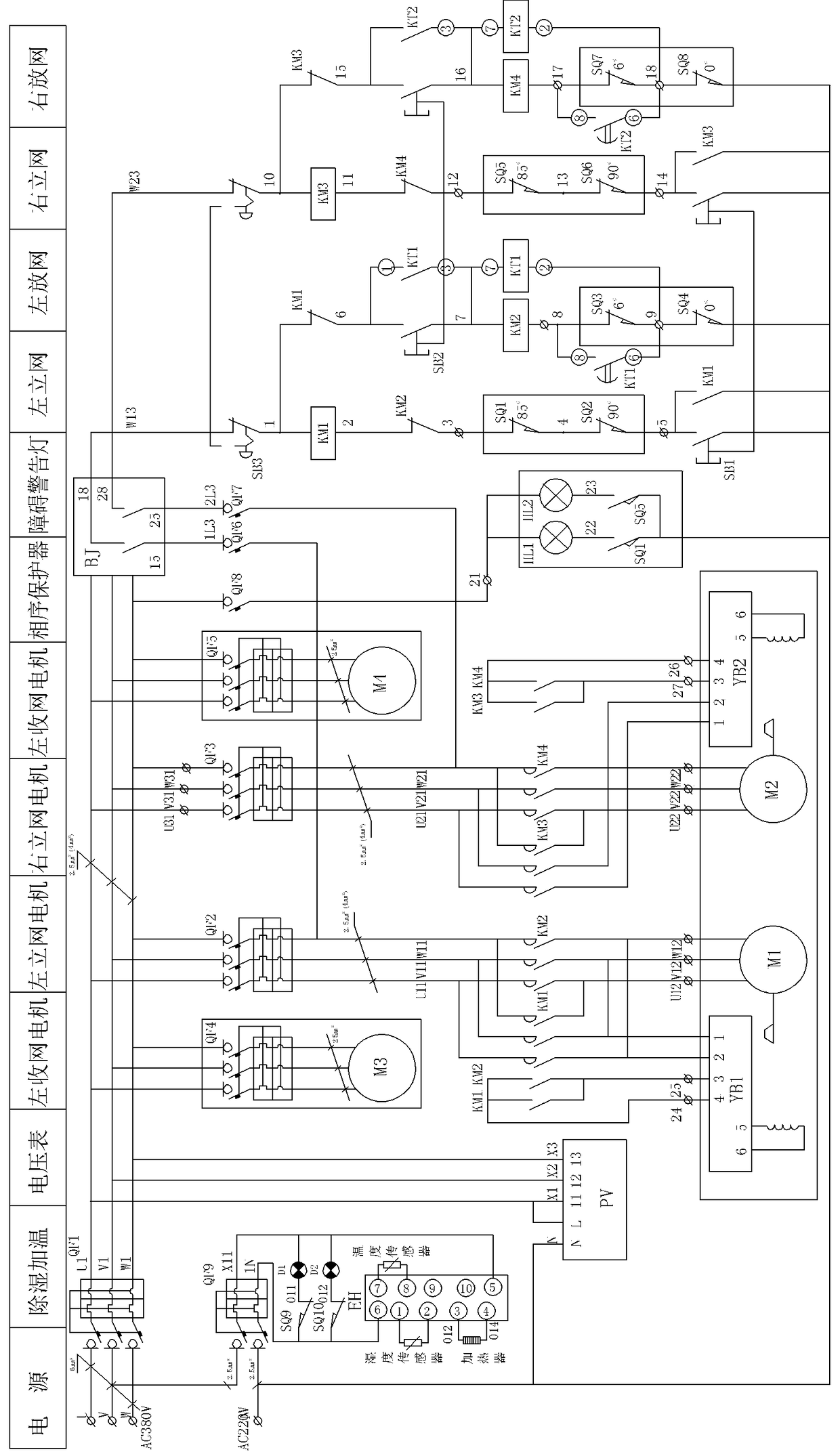

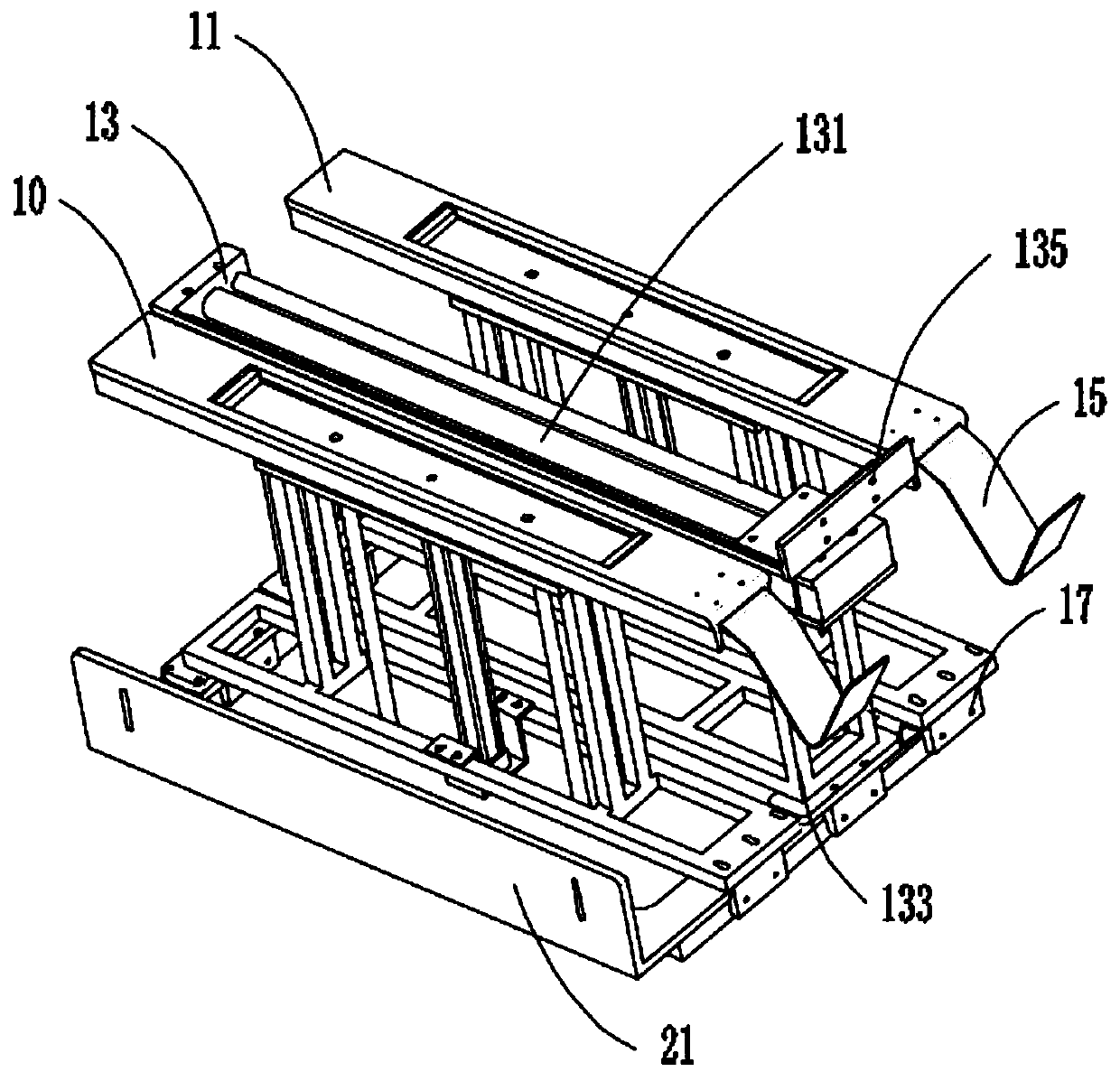

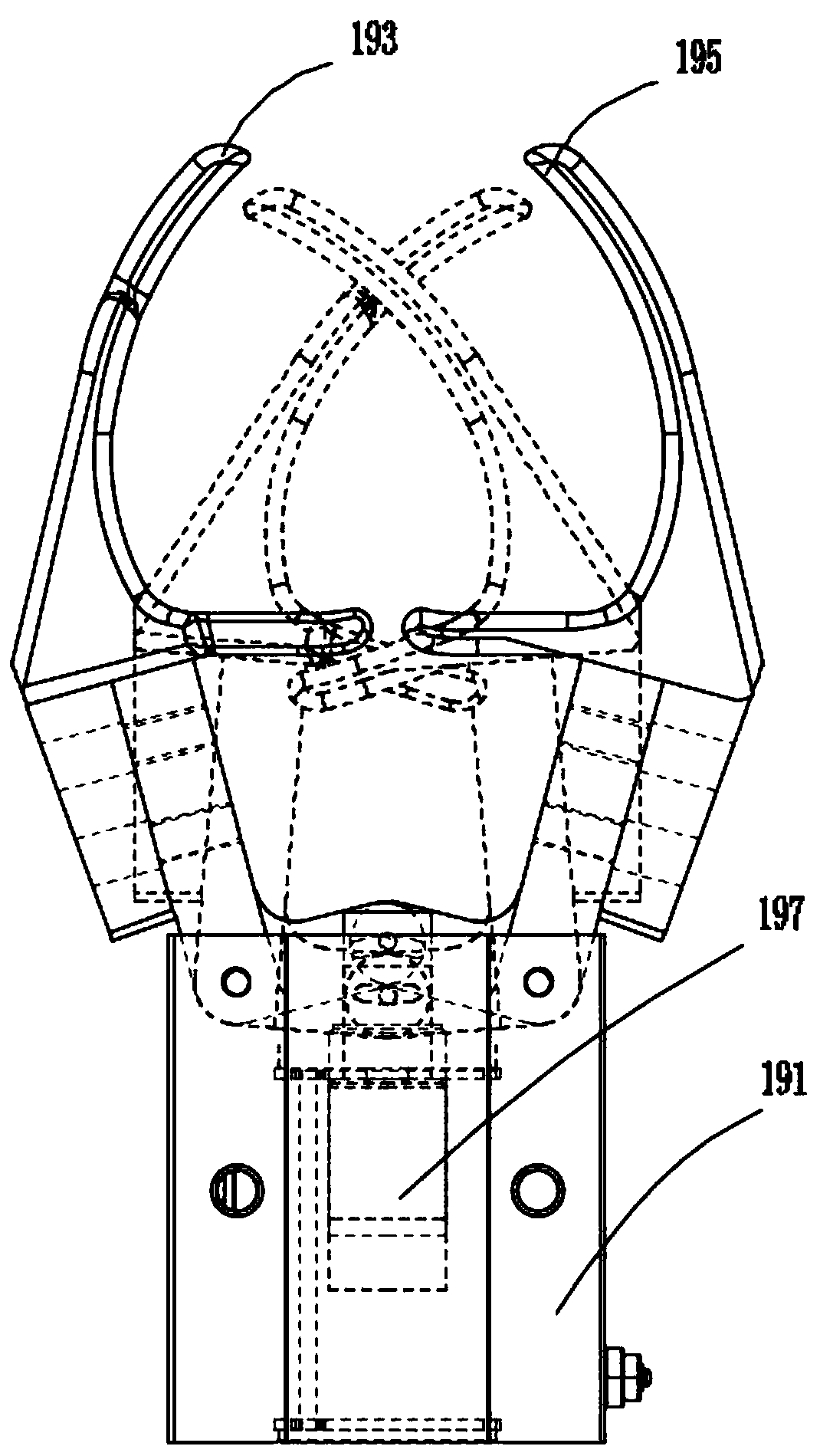

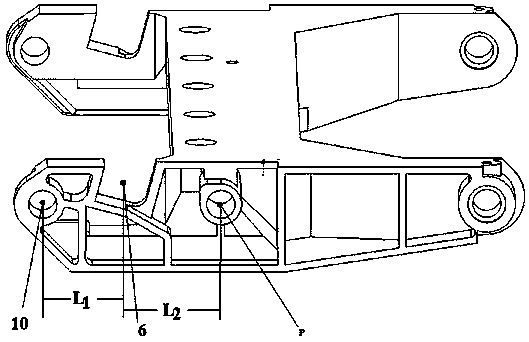

Electric control box test connection circuit

The invention discloses an electric cabinet test connection circuit, belongs to the technical field of a test circuit and especially relates to an electric cabinet test connection circuit which is advantaged in high work efficiency and convenient operation. The electric cabinet test connection circuit comprises an electric cabinet test circuit and an electric cabinet circuit of airplane blocking equipment, and is mainly structurally characterized in that the electric cabinet test circuit comprises L1, L2, L3 and N terminal connected with a power source, U, V, W and N terminals which are connected with main switches U, V, W and N of the electric cabinet circuit of the airplane blocking equipment, U12, V12 and W12 terminals which are connected with left control motor terminals U12, V12 and W12 of the electric cabinet circuit of the airplane blocking equipment, 24 and 25 terminals which are connected with externally-led motor internal solenoid valves of the electric cabinet circuit of the airplane blocking equipment, and 3, 5, 8, 9 and equipment N terminals which are connected with externally-led limiting switch terminals 3, 5, 8, 9 and equipment N of the electric cabinet circuit of the airplane blocking equipment.

Owner:辽宁东鹰航空装备科技股份有限公司

Automatic material receiving system

PendingCN110723524AAvoid damage and scrapAchieve staff reduction and increase efficiencyConveyorsStacking articlesMechanical engineeringPhysics

The invention provides an automatic material receiving system which comprises at least two material receiving mechanisms and a pushing mechanism. Each material receiving mechanism comprises a materialreceiving feeding plate and a material receiving movable plate, wherein the material receiving movable plate can move in a direction vertical to the surface of the material receiving feeding plate and penetrates through the material receiving feeding plate, and the material receiving movable plate receives fallen materials at the position, higher than the upper surface of the material receiving feeding plate, of the upper surface of the material receiving movable plate and drives the received fallen materials to move downwards so as to place the fallen materials on the material receiving feeding plate. The pushing mechanism is used for pushing the fallen materials on the material receiving feeding plates. The automatic material receiving system not only can effectively prevent the fallenmaterials from falling off and scrapping, but also can improve labor efficiency and realize labor reduction and efficiency improvement.

Owner:GREE ELECTRIC APPLIANCES WUHAN +1

Transfer paper and its preparation method

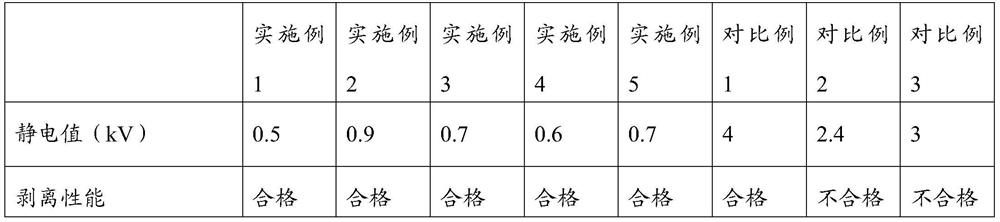

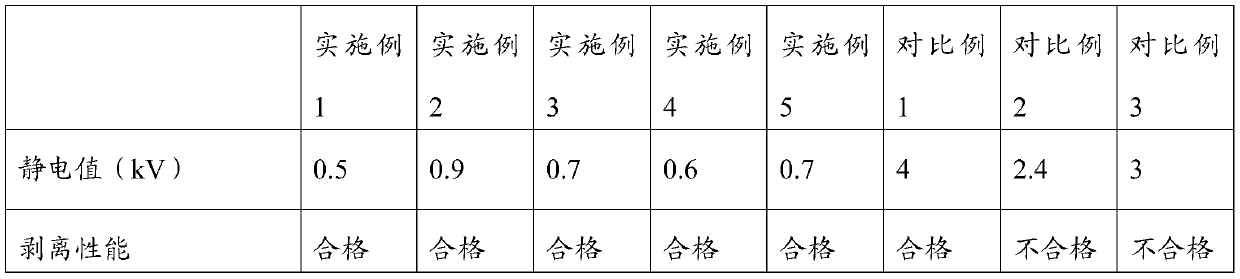

ActiveCN108149513BImprove electrostatic discharge abilityReduce accumulationNon-fibrous pulp additionFlexible coversCelluloseAdhesive glue

The invention relates to transfer paper and a preparation method thereof. The transfer paper comprises a back coating layer, a body paper layer, a glue layer, an aluminum plating layer, a transfer layer and a varnish layer, wherein the transfer layer is prepared from a transfer coating; the transfer coating is mainly prepared from the following raw materials in parts by mass: 8-12 parts of cellulose resin, 6-10 parts of polyacrylic acid resin, 5-8 parts of polyaniline, 0.2-1.5 parts of stannic chloride, 0.5-4 parts of auxiliary agent and 55-65 parts of solvent. The transfer paper disclosed bythe invention has good anti-static electricity capacity, static electricity is unlikely to be accumulated on the transfer paper so as to eliminate a problem that the transfer paper layers are mutuallyadhered due to static electricity when being overlaid, so that the transfer paper layer can be easily separated during processing, paper damage scrap due to improper separation is avoided, productionefficiency is effectively improved, production cost is lowered, and a market application prospect is wide.

Owner:湖南裕同印刷包装有限公司

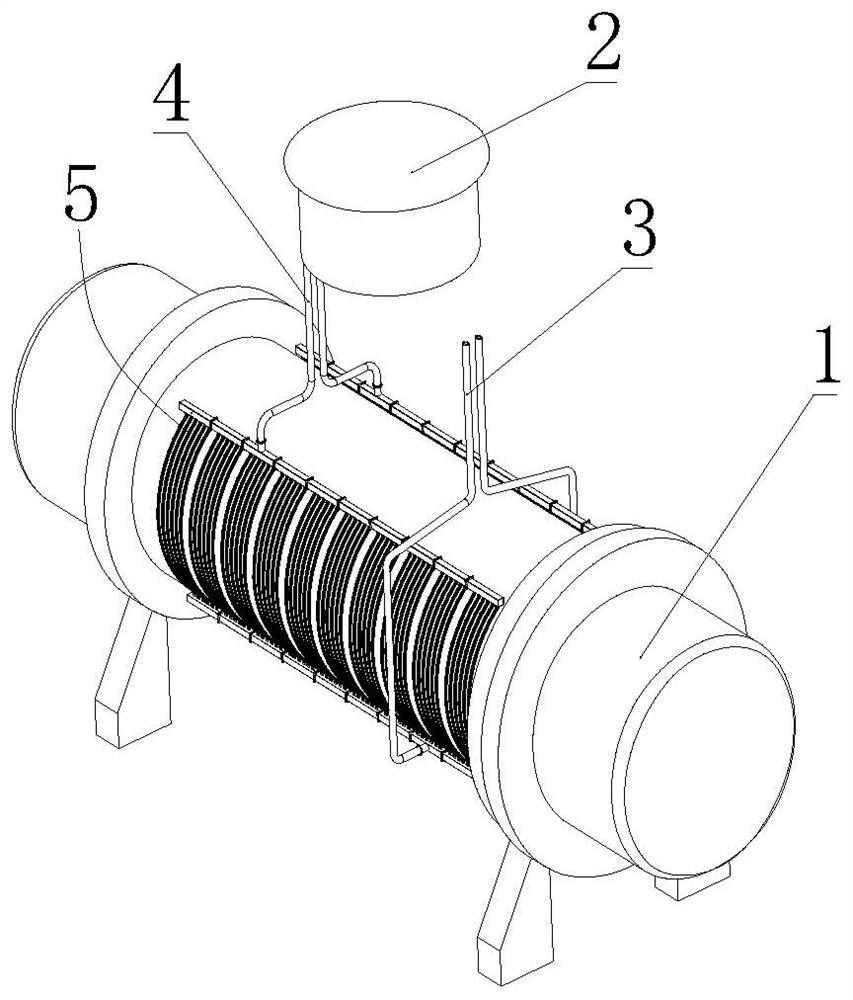

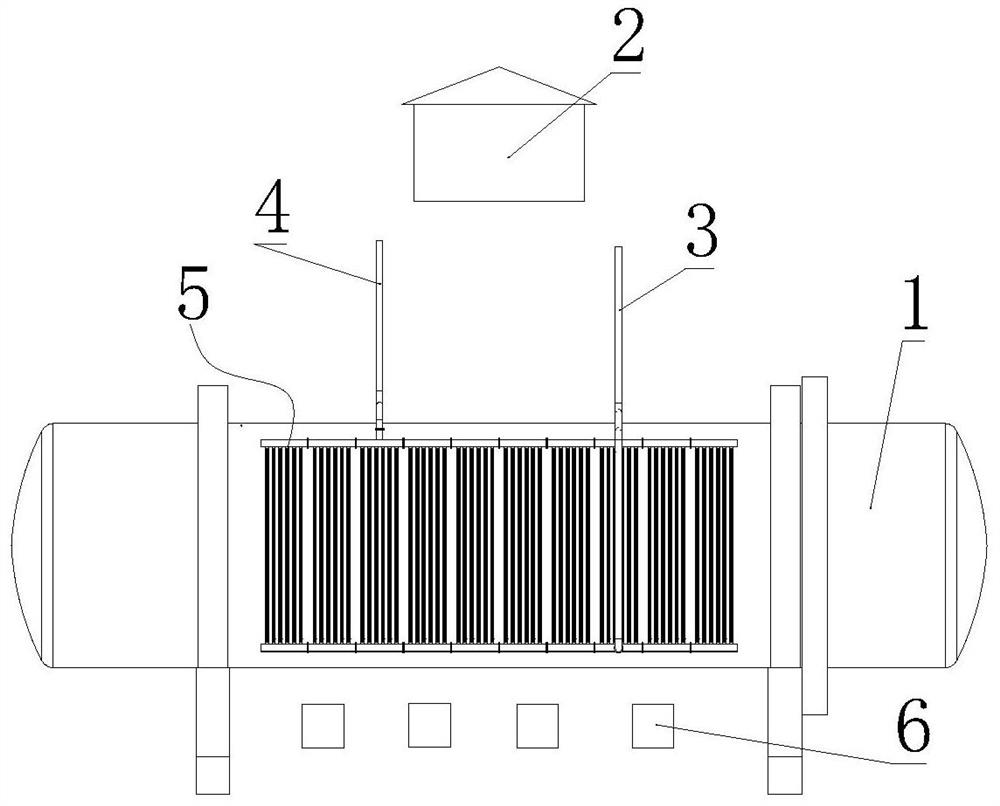

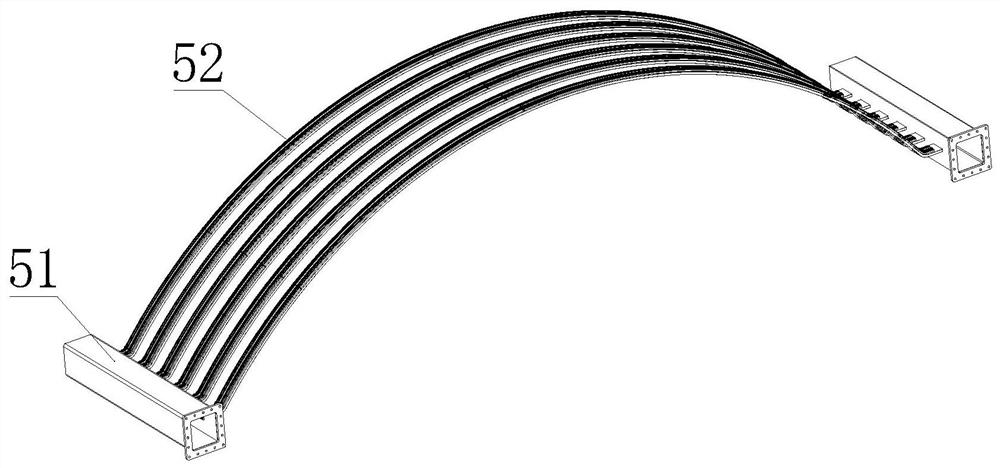

Constant temperature assembly with furnace body

PendingCN113945094AIncrease contact areaImprove cooling effectFurnace cooling arrangementsFurnace coolingWater pipeEngineering

The invention is suitable for the technical field of radiators, and provides a constant temperature assembly with a furnace body. The constant temperature assembly with the furnace body comprises the furnace body, the two sides of the outer wall of the furnace body are symmetrically provided with heat dissipation assemblies in a covered mode, the upper portions of the two heat dissipation assemblies are both connected with first water pipes, the lower portions of the two heat dissipation assemblies are both connected with second water pipes, each heat dissipation assembly comprises a plurality of heat dissipation units, each heat dissipation unit comprises two water guide pipes and a plurality of heat dissipation plates fixedly connected between the two water guide pipes, each heat dissipation plate comprises an arc-shaped heat dissipation part attached to the outer wall of the furnace body and a connecting part connected with the water guide pipes, a plurality of fins are arranged on one side, away from the furnace body, of each heat dissipation part, and a plurality of first water channels with W-shaped cross sections are arranged in the heat dissipation plates. Therefore, according to the constant temperature assembly with the furnace body, the contact areas between the heat dissipation plates and water and the contact areas between the heat dissipation plates and air can be enlarged at the same time, the heat dissipation effect is improved to the maximum extent, cooling can be carried out on the outer wall of the furnace body, and deformation, damage and scrapping of the furnace body caused by overheating of the outer wall of the furnace body are prevented.

Owner:WEIFANG HUALONG RADIATOR

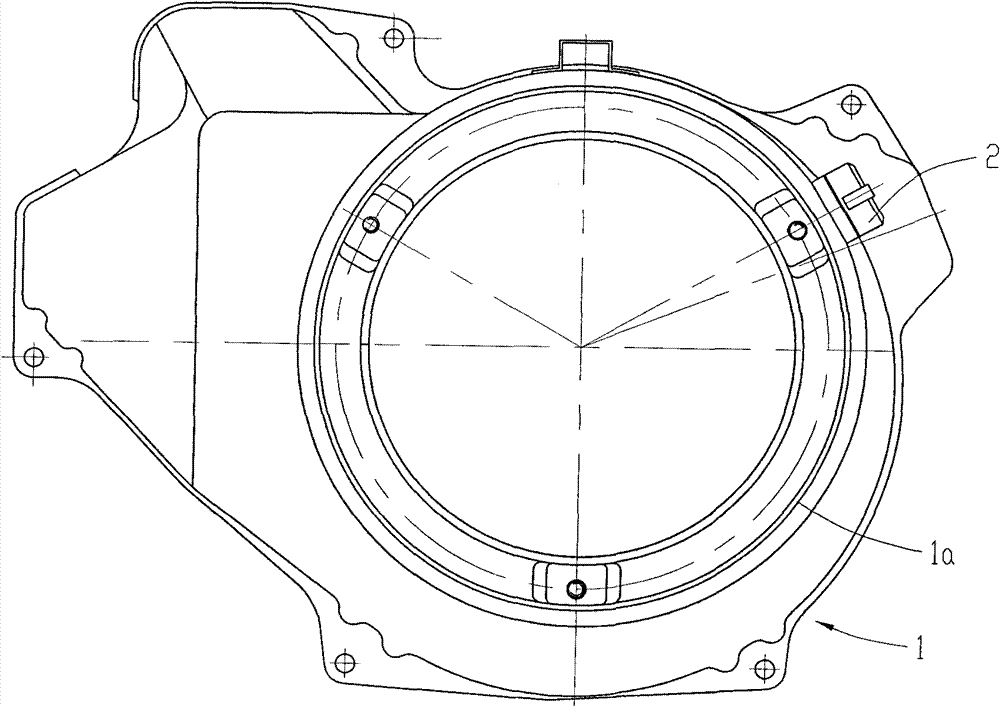

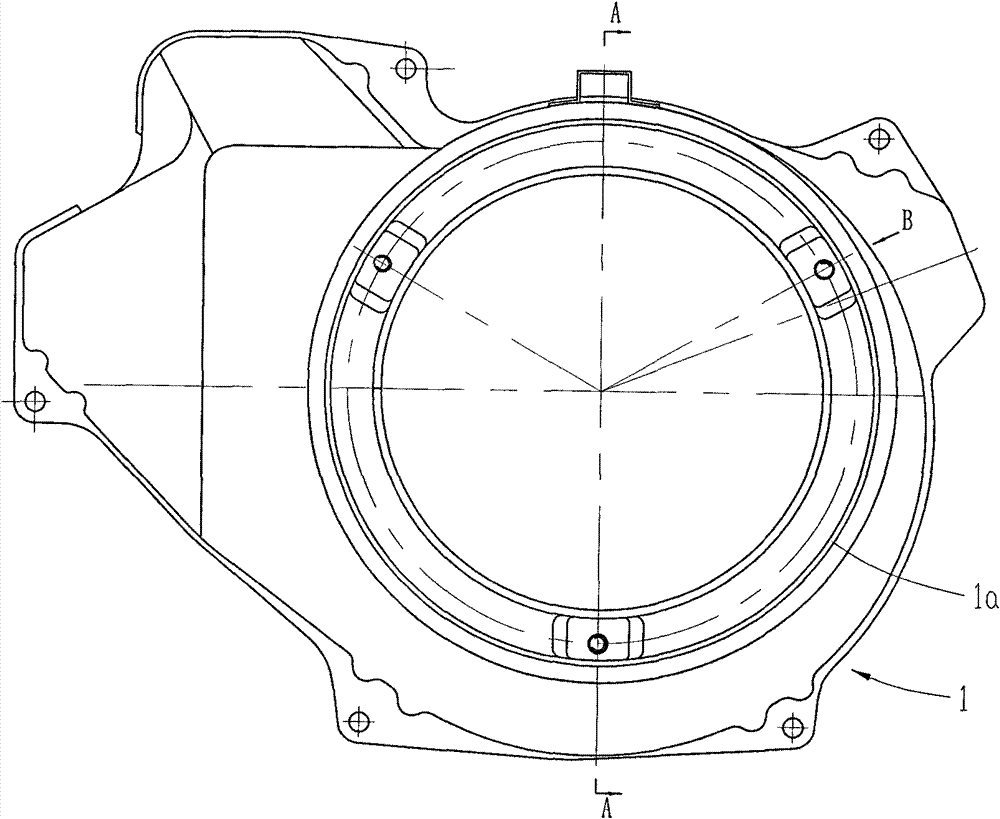

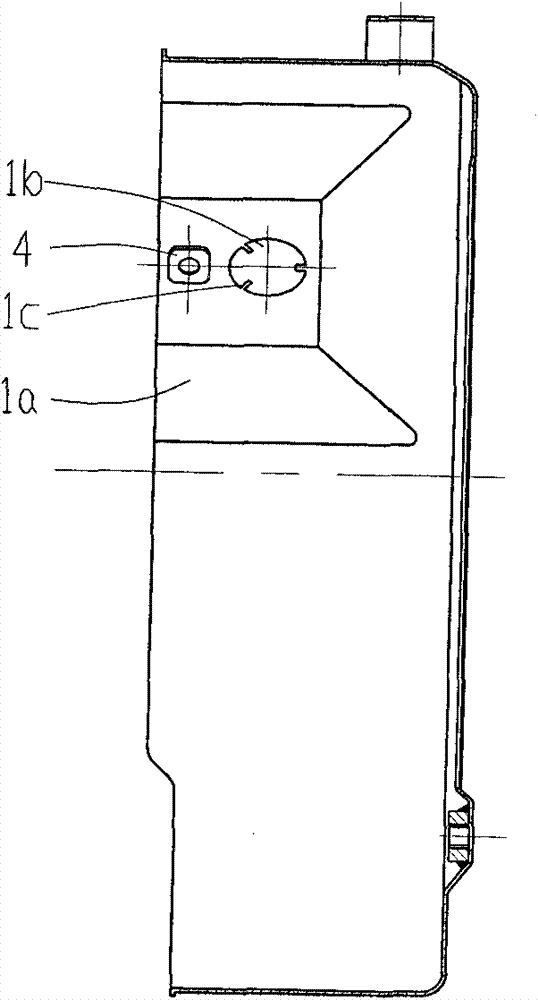

Combination of fan cover assembly and extinguishing switch

InactiveCN101798963AReduce the difficulty of assemblyEasy to assemble and disassembleEngine controllersMachines/enginesEngineeringLight hole

The invention relates to a combination of a fan cover assembly and an extinguishing switch. A positioning hole for inserting the extinguishing switch is arranged on a cover shell of the fan cover assembly, a round lug boss is arranged at the lower part of the extinguishing switch which is provided with a supporting ear in the middle, the positioning hole on the cover shell is a light hole and is provided with a limit protruding sheet on the hole wall, an assembly hole is arranged beside the positioning hole, the round lug boss of the extinguishing switch is inserted in and tightly matched with the positioning hole of the cover shell, an opening arranged on the round lug boss and the limit protruding sheet on the hole wall of the positioning hole are clamped, the supporting ear of the extinguishing switch is provided with a via hole, and a screw penetrates through the via hole arranged on the supporting ear and the assembly hole on the cover shell and locked by a nut. The invention has simple structure and easy processing and manufacture, effectively lowers the assembly difficulty of the extinguishing switch, greatly improves the assembly efficiency and prevents the extinguishing switch and the fan cover assembly from being damaged and discarded in the disassembly process while ensuring the extinguishing switch is convenient to disassemble and the extinguishing switch is firmly mounted.

Owner:力帆科技(集团)股份有限公司

Transfer coating and preparation method thereof

ActiveCN108059883BImprove electrostatic discharge abilityAvoid damage and scrapElectrically-conductive paintsCelluloseProcess engineering

The invention relates to a transfer coating and a preparation method thereof. The transfer coating is mainly prepared from the raw materials in parts by mass: 8 to 12 parts of cellulsic resin, 6 to 10parts of polyacrylic resin, 5 to 8 parts of polyaniline, 0.2 to 1.5 parts of stannic chloride, 0.5 to 4 parts of auxiliary agents and 55 to 65 parts of a solvent. The transfer coating provided by theinvention is used for preparing a transfer layer of transfer paper and can reduce accumulation of static electricity on the transfer paper, so that the problem that the transfer paper adheres to eachother because of static electricity when the transfer paper is stacked is solved; therefore, the transfer paper is easier to separate in a processing process, and meanwhile, paper surface damage andscrap caused by improper separation are also avoided; the production efficiency is effectively improved; the production cost is reduced; the market application prospect is broad.

Owner:常德洛恩全息材料科技有限公司

A new type of combing machine nipper mechanism

The invention discloses a novel combing-machine nipper mechanism which comprises a lower nipper seat. A lower nipper plate is fixed in front of the lower nipper seat, a trapezoidal groove is formed in the middle of the top surface of the lower nipper plate, a cotton guide plate is arranged in the trapezoidal groove, the cotton guide plate is arc-shaped on the front portion and horizontal at the tail, the tail portion of the cotton guide plate is fixed on the lower nipper plate, a feed roller is arranged above the cotton guide plate, and grooves for holding the feed roller are arranged at two ends of the lower nipper seat; the front end of the bottom surface of the lower nipper plate is provided with a plane, the rear of the plane is gradually raised through circular arc transition, and the lower nipper seat is connected with an upper nipper plate connector in a hinge joint manner. By the arrangement, a cotton feed channel can be flexibly adjusted according to thickness of a small roll, distance of the center of the front end of each nipper plate, the center of each groove and hinge point of each nipper plate can be reasonably arranged, and large quantitative of small rolls and long fibers 35mm above in length are assured to be processed smoothly through a combing machine; due to the arc-raised surface, collision against the lower nipper plate by cylinder needle teeth is avoided, compressive strength of the nipper lip of the lower nipper plate is guaranteed, the nipper plates and a cylinder of the combing machine are prevented from being damaged, and production cost is obviously reduced.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Combination of fan cover assembly and extinguishing switch

InactiveCN101798963BReduce the difficulty of assemblyEasy to assemble and disassembleEngine controllersMachines/enginesEngineeringLight hole

The invention relates to a combination of a fan cover assembly and an extinguishing switch. A positioning hole for inserting the extinguishing switch is arranged on a cover shell of the fan cover assembly, a round lug boss is arranged at the lower part of the extinguishing switch which is provided with a supporting ear in the middle, the positioning hole on the cover shell is a light hole and is provided with a limit protruding sheet on the hole wall, an assembly hole is arranged beside the positioning hole, the round lug boss of the extinguishing switch is inserted in and tightly matched with the positioning hole of the cover shell, an opening arranged on the round lug boss and the limit protruding sheet on the hole wall of the positioning hole are clamped, the supporting ear of the extinguishing switch is provided with a via hole, and a screw penetrates through the via hole arranged on the supporting ear and the assembly hole on the cover shell and locked by a nut. The invention hassimple structure and easy processing and manufacture, effectively lowers the assembly difficulty of the extinguishing switch, greatly improves the assembly efficiency and prevents the extinguishing switch and the fan cover assembly from being damaged and discarded in the disassembly process while ensuring the extinguishing switch is convenient to disassemble and the extinguishing switch is firmlymounted.

Owner:力帆科技(集团)股份有限公司

Transfer paper and its preparation method

ActiveCN108149514BGuaranteed StrengthPrevent penetrationNon-fibrous pulp additionFlexible coversPolymer scienceEmulsion

The invention relates to transfer paper and a preparation method thereof. The transfer paper comprises a back coating layer, a body paper layer, a glue layer, an aluminum plating layer, a transfer layer and a varnish layer, wherein the back coating layer is prepared from paper back coating emulsion; the paper back coating emulsion is mainly prepared from the following raw materials in parts by mass: 10-14 parts of water, 12-16 parts of acrylic emulsion, 1-4 parts of wax emulsion, 1-4 parts of gamma-polyglutamic acid, 0.5-1.5 parts of sodium alginate, 0.5-1 part of calcium chloride, 0.5-2 partsof ketone removal additive and 0.03-0.2 part of accessory ingredient. The transfer paper has good water retaining capacity and water absorptivity, the moisture of the body paper is prevented from permeating, meanwhile, moisture cohered to a surface in the environment is absorbed so as to eliminate a problem that the transfer paper layers are mutually adhered when being overlaid, so that the transfer paper layer can be easily separated during subsequent processing, damage scrap due to improper separation is avoided, production efficiency is effectively improved, production cost is lowered, anda market application prospect is wide.

Owner:常德洛恩全息材料科技有限公司

Buffer type stepping neodymium-iron-boron thin magnetic sheet feeding robot production line

InactiveCN112405222AImprove work efficiencyAvoid damage and scrapGrinding drivesGrinding machinesProduction lineElectric machinery

The invention discloses a buffer type stepping neodymium iron boron thin magnetic sheet feeding robot production line. The buffer type stepping neodymium iron boron thin magnetic sheet feeding robot production line comprises a magnetic sheet buffer feeding device, a grinding device, a chamfering device and a polishing device; the magnetic sheet buffer feeding device comprises a bottom plate, a topplate, a stacking rail, two buffer material moving mechanisms, a friction feeding mechanism, a discharging groove and a material moving driving mechanism; the stacking rail is provided with an inclined part and a linear part; the buffer material moving mechanisms are distributed at the two sides of the linear part; each buffer material moving mechanism comprises two eccentric shafts, a transverseconnecting rod, a longitudinal sliding support, a buffer sliding plate and a protective contact layer; each transverse connecting rod movably sleeves every two eccentric shafts; each longitudinal sliding support is elastically connected to the corresponding transverse connecting rod in a sliding manner; each buffer sliding plate is elastically connected to the corresponding longitudinal sliding support in a sliding manner; and the friction feeding mechanism comprises a first support, a feeding support, a feeding motor, a feeding friction belt and a rolling shaft. According to the buffer typestepping neodymium iron boron thin magnetic sheet feeding robot production line, magnetic sheets are effectively prevented from being damaged due to excessive external impact, and meanwhile, the working efficiency and the production efficiency of feeding are improved.

Owner:米核(南京)电子科技有限公司

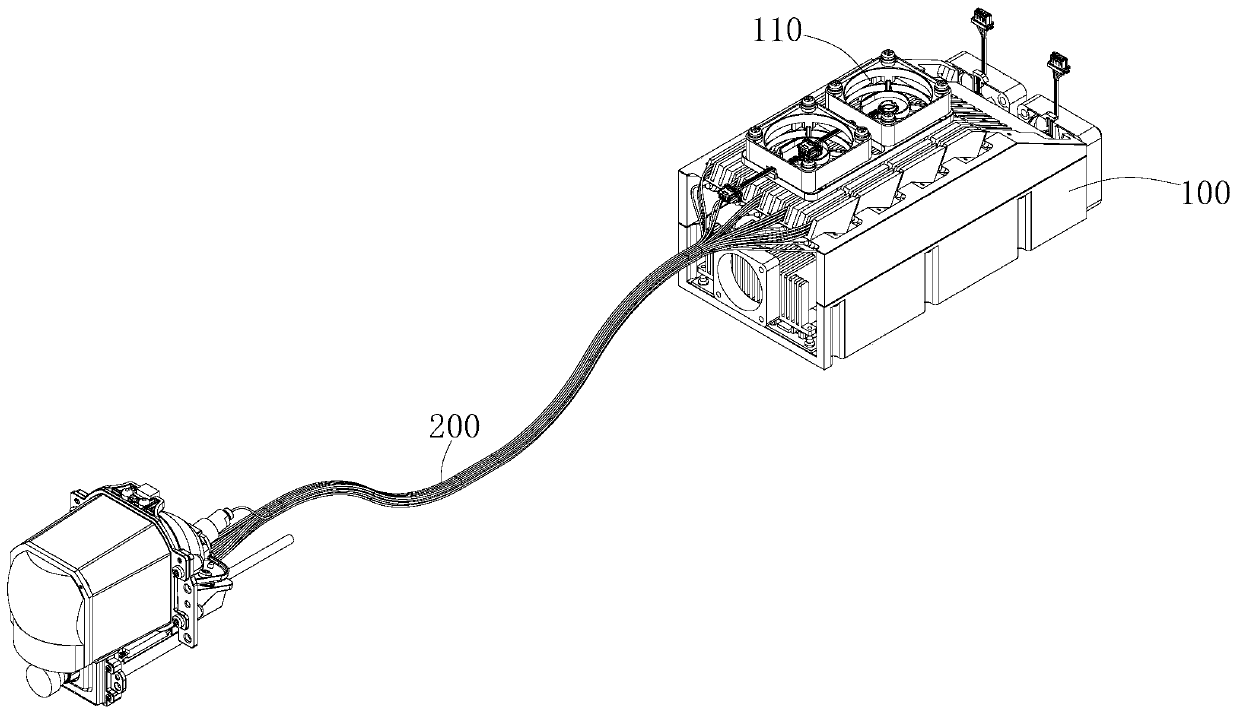

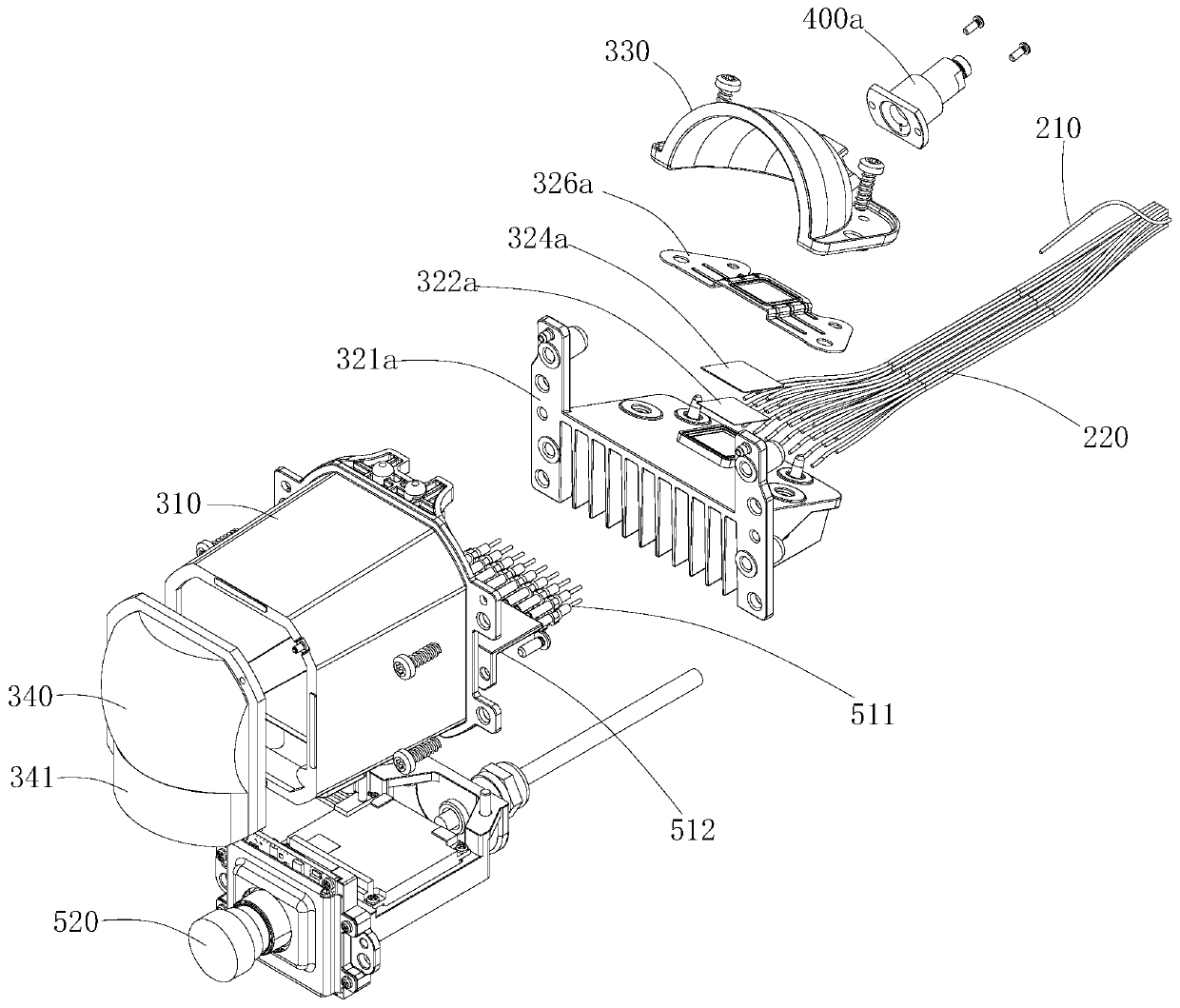

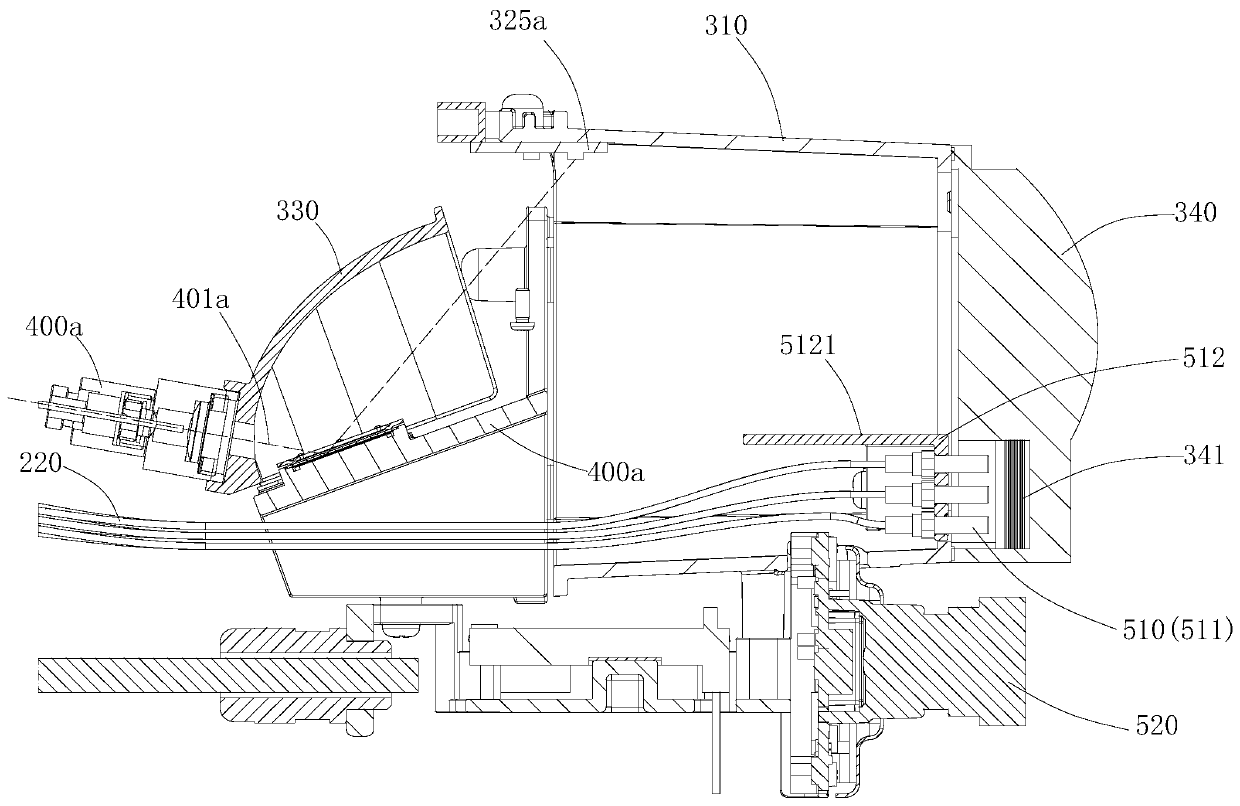

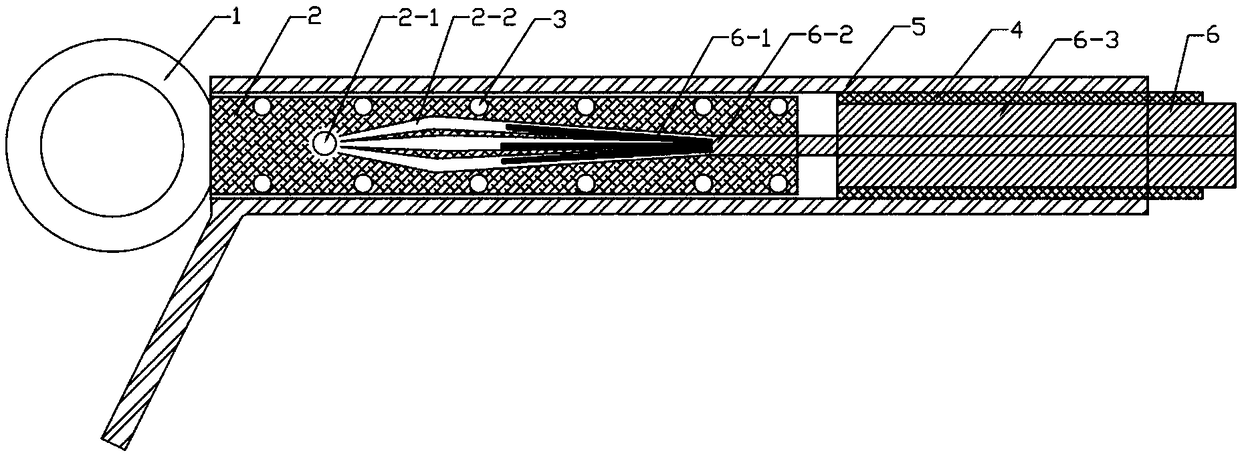

Lighting detection module

PendingCN111076140AExtended service lifeEasy to installVehicle headlampsElectrical apparatusPhysicsLight detection

The invention relates to an illumination detection module, and the module comprises a light source assembly which is used for emitting illumination light and detection light; a light transmission part, one end of the light transmission part being connected with the light source assembly, and the light transmission part being used for transmitting the illumination light and the detection light; anillumination assembly, connected with the other end of the light transmission part and used for receiving the illumination light transmitted by the light transmission part to provide illumination; anda light detection and measurement assembly, connected with the other end of the light transmission part and used for outwards emitting the detection light transmitted by the light transmission part so as to detect position parameters of surrounding objects. As the light source assembly with large heat productivity is independent of the lighting assembly and the light detection and measurement assembly, and the light detection and measurement assembly is small in size and can be integrated with the lighting assembly to be arranged at a vehicle lamp mounting position, the detection angle and range can be expanded. The connecting mode of the lighting assembly, the optical detection and measurement assembly and the light source assembly is simple, a large number of connecting wire harnesses do not need to be arranged, the structure is simple, and later maintenance and overhaul are facilitated.

Owner:HASCO VISION TECHNOLOGY CO LTD

Twisted composite wire tension fittings for smart grid and installation method

ActiveCN106410717BThere will be no damage to the wireAvoid damage and scrapSuspension arrangements for electric cablesApparatus for overhead lines/cablesElectrical conductorSmart grid

The present invention discloses a stranded composite conductor tension metal fitting for a smart power network and an installation method thereof. The fitting comprises a steel anchor, a tension steel tube, a retaining screw, a conductor lining aluminum tube and a T-shaped tension aluminum tube. The tension steel tube is a hollow structure and is divided into an upper steel tube and a lower steel tube which are fixedly connected with each other through the retaining screw; the steel anchor and the tension steel tube are an integrated structure; and the upper steel tube and / or the lower steel tube are provided with resin injection holes. The steel anchor and the tension steel tube are combined into one body without the screw thread and the phenomenon that the screw threads are broken when the steel anchor is installed, and therefore, it is avoided that the metal fitting is scraped and damaged and there is no any damaging for the composite cores.

Owner:FAR EAST CABLE +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com