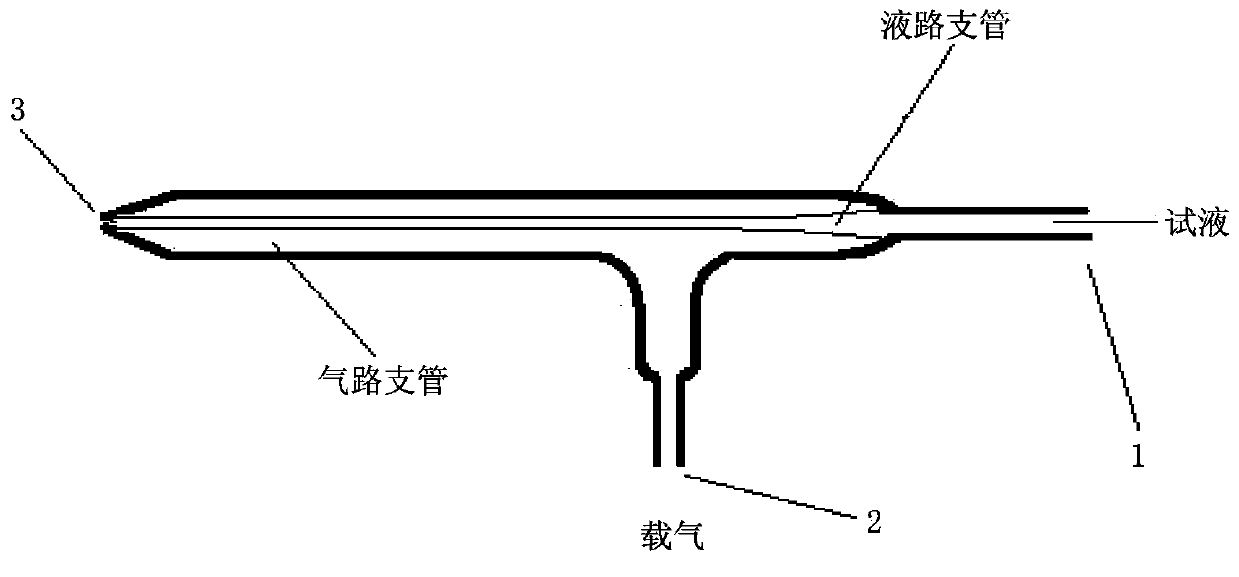

Method for cleaning gas channel branch pipe of atomizer

An atomizer and gas path technology, which is applied in the field of the gas path branch pipe of a pneumatic atomizer to achieve the effect of saving detection costs and improving atomization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0038] Clean the nebulizer that is clogged by the salt deposit of the sample solution.

[0039] Prepare a hydrochloric acid solution with a concentration of 50% by volume, that is, add 50mL of concentrated hydrochloric acid to 50mL of distilled water and mix well. With the blocked nebulizer disassembled from the instrument, follow the back pumping solution cleaning (e-g) operation steps repeatedly for 3 times to completely dissolve the blocked salt deposits in the gas branch pipe and discharge the cleaning solution, and then perform step h Clean the residual cleaning solution in the gas branch pipe with distilled water for 3 times.

example 2

[0041] Clean the nebulizer that is clogged by the salt deposit of the sample solution.

[0042] Prepare a nitric acid solution with a concentration of 55% by volume, that is, add 55mL of concentrated nitric acid to 40mL of distilled water and mix well. With the blocked nebulizer disassembled from the instrument, follow the back pumping solution cleaning (e-g) operation steps repeatedly for 5 times to completely dissolve the blocked salt deposits in the gas branch pipe and discharge the cleaning solution, and then perform step h Clean the remaining cleaning solution in the gas branch pipe with distilled water for 4 operations.

example 3

[0044] Clean nebulizers that are clogged with soluble foreign particles.

[0045] Prepare a hydrochloric acid solution with a concentration of 60% by volume, that is, add 60 mL of concentrated hydrochloric acid to 40 mL of distilled water and mix well. With the blocked nebulizer disassembled from the instrument, follow the back pumping solution cleaning (e-g) operation steps repeatedly for 5 times to completely dissolve the soluble foreign matter particles blocked in the gas branch pipe and discharge the cleaning solution, and then perform step h Clean the residual cleaning solution in the air branch pipe with distilled water 5 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com