Combined feeding type numerical control lathe

A CNC lathe and composite technology, applied in the field of lathes, can solve the problems of damaged and scrapped parts, increased surface temperature of tools, and unusable tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

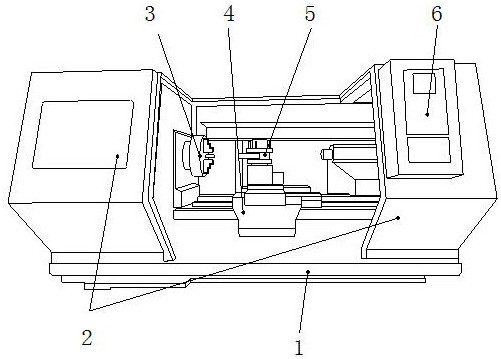

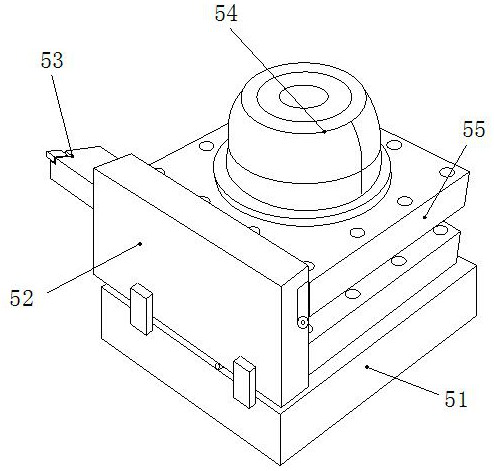

[0024] as attached figure 1 to attach Figure 5 Shown:

[0025] The invention provides a compound type CNC lathe, the structure of which includes a base 1, a movable door 2, a main shaft 3, a sliding seat 4, a tool rest 5, and a control box 6, and the upper end of the base 1 is movable with the lower end of the movable door 2. Together, the main shaft 3 is connected to the middle part of the left end of the base 1, the sliding seat 4 is slidably connected to the upper side of the middle part of the base 1, the tool holder 5 is connected to the upper end of the sliding seat 4 with bolts, and the control box 6 is connected to the outer side of the movable door 2. Welding connection, the tool holder 5 includes a bottom block 51, a clearing device 52, a cutter 53, a motor 54, and a clip 55, the bottom block 51 is connected with the upper end of the slide seat 4 by bolts, and the cleaning device 52 slides with the outside of the cutter 53 Connected, the cutter 53 is connected wit...

Embodiment 2

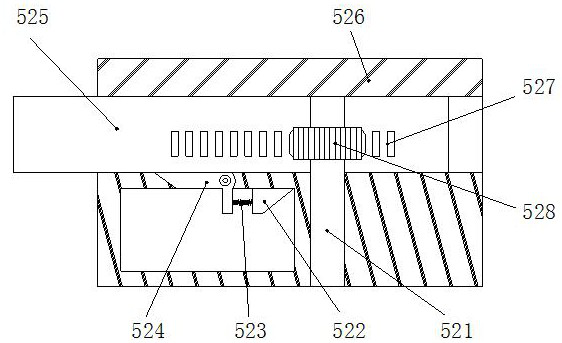

[0032] as attached Figure 6 to attach Figure 7 Shown:

[0033] Wherein, the scraper block c6 includes a support frame c61, a central axis c62, a scraper c63, and a limiting plate c64, the support frame c61 is connected to the inner shaft at the right end of the second scraper plate c5, and the central axis c62 is connected to the support frame c61 The outer side of the front is welded and connected, the scraper c63 is riveted to the right end of the support frame c61, the restricting plate c64 is axially connected to the middle of the support frame c61, the restricting plate c64 is installed obliquely, and the installation position is higher than that of the scraper c63, The limiting plate c64 can remove the molten aluminum alloy scraped off by the scraper c63, which is beneficial to improve the cleaning efficiency of the scraper c63 on the surface of the cutter 53.

[0034] Wherein, the limiting plate c64 includes a catch piece r1, a fixed shaft r2, and a contact block r3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com