Magnetic type welding trolley

A welding trolley and magnetic suction technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of welding trolley easy to pull, safety hazards, etc., to improve welding quality, avoid pulleys, and reduce consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

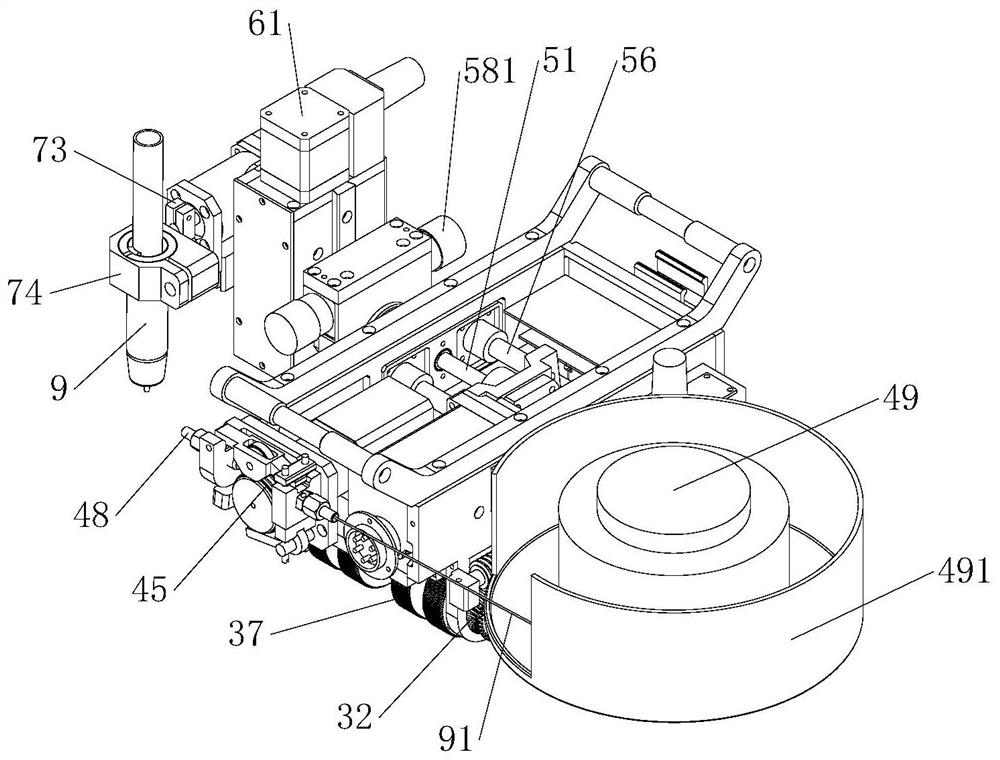

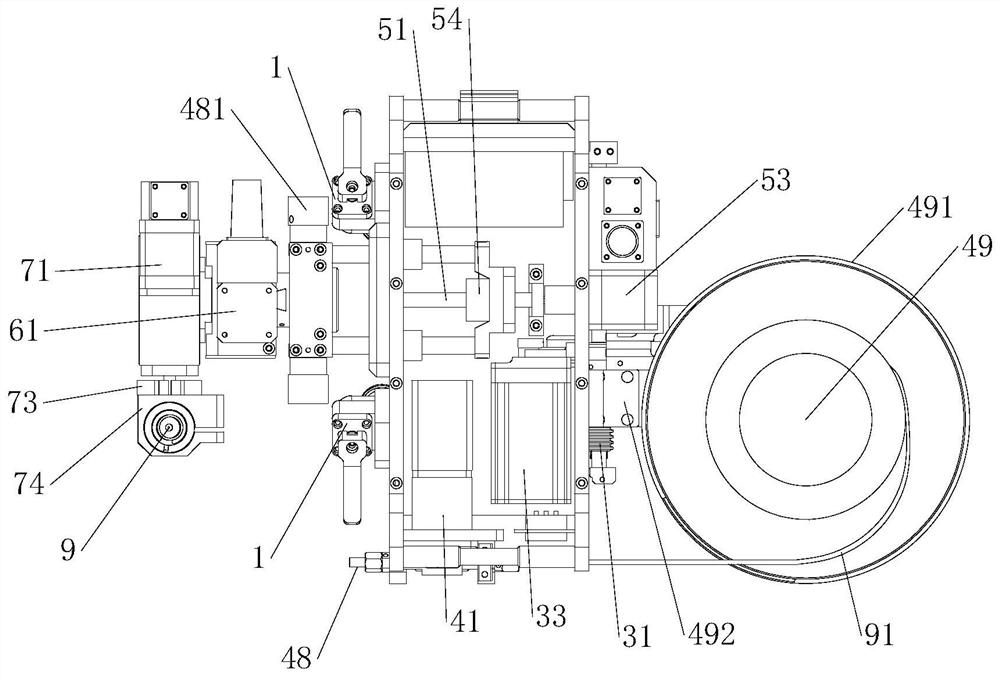

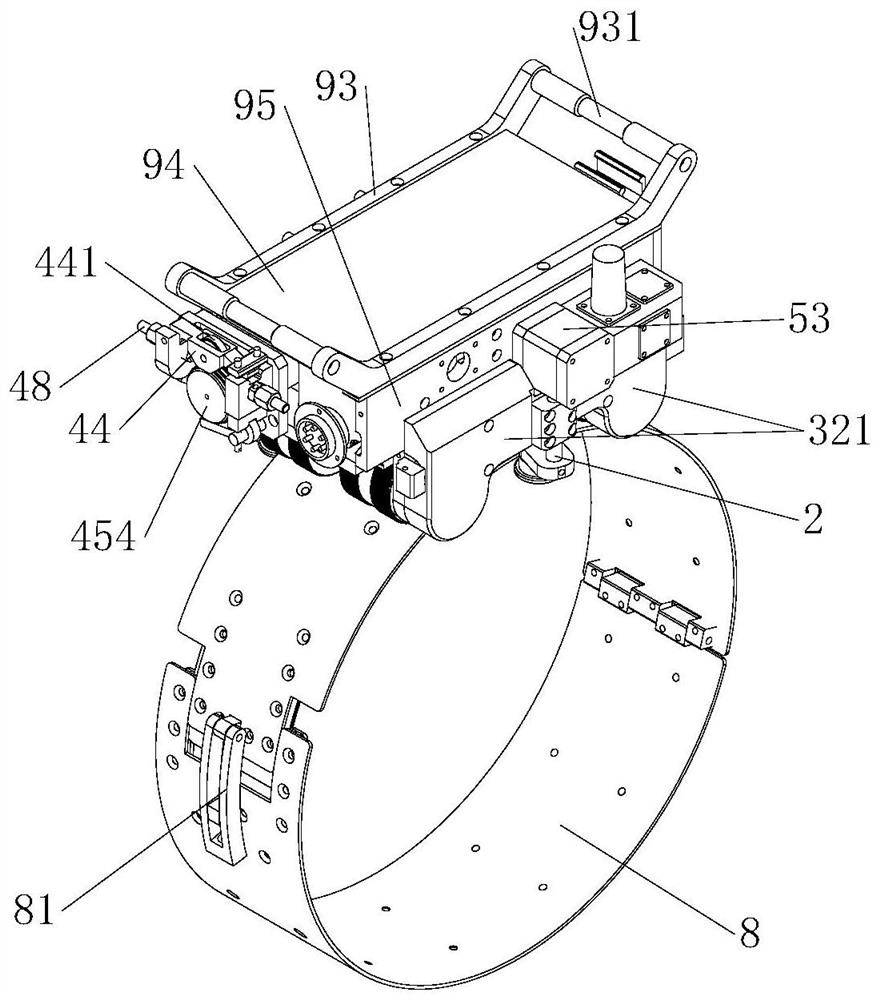

[0094] This embodiment provides a magnetic suction welding trolley, see Figure 1-6 , including trolley body, wire feeding system and welding torch position adjustment system;

[0095] The trolley body is provided with a drive system, and the drive system includes a pulley 34;

[0096] The bottom of the trolley body is provided with a magnetic wheel 37;

[0097] The drive system also includes a drive worm 31 and several drive worm gears 32, the drive worm 31 is arranged along the length direction of the trolley body, the pulley 34 is sleeved on the drive worm 31, and the drive worm 31 engages with all The driving worm gear 32 is fixedly connected to the corresponding magnetic wheel 37 .

[0098] Both the wire feeding system and the position adjustment system of the welding torch of the magnetic suction type welding trolley can adopt existing structures. The drive system uses a drive motor 33 to provide power, such as a stepper motor, which communicates with the circuit driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com