Twisted composite wire tension fittings for smart grid and installation method

A technology of composite wire and smart grid, which is applied in the direction of cable suspension devices, overhead lines/cable equipment, etc., can solve the problems of restricting the development of twisted composite wires, and the power tension fittings cannot fully meet the use requirements, so as to avoid scrapping damage, reduce construction difficulty, and facilitate installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

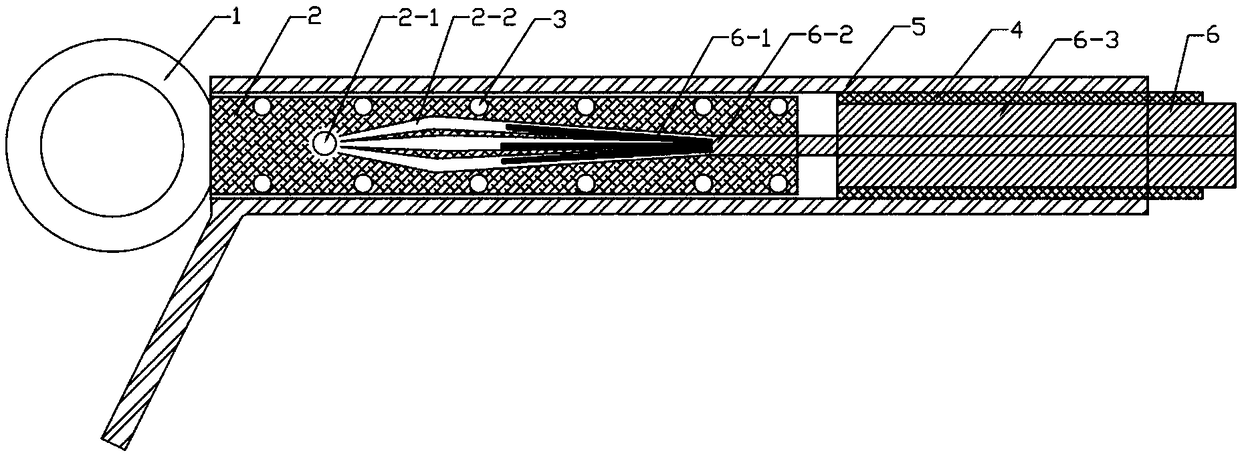

[0023] See figure 1 , the smart grid stranded composite wire tension fittings in this embodiment include steel anchor 1, tension steel pipe 2, fixing screw 3, conductor lined aluminum pipe 4 and T-shaped tension aluminum pipe 5; tension steel pipe 2 It is a hollow structure, divided into an upper steel pipe and a lower steel pipe, which are fixedly connected by fixing screws 3; the steel anchor 1 and the tensile steel pipe 2 are an integrated structure; the upper steel pipe and / or the lower steel pipe are provided with glue injection holes 2-1. The inner surface of the upper steel pipe and the lower steel pipe is provided with a plurality of grooves 2-2 with one end connected to the glue injection hole 2-1. After the upper steel pipe and the lower steel pipe are fixed by the fixing screw 3, the groove 2-2 is used as the glue injection cavity . The inner diameter of the T-shaped tensile aluminum pipe 5 is larger than the inner diameter of the tensile steel pipe 2 . Both the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com