Transfer paper and its preparation method

A technology of transfer paper and transfer layer, applied in the field of packaging, can solve the problems of surface damage of transfer paper, easy mutual adhesion, and reduced production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

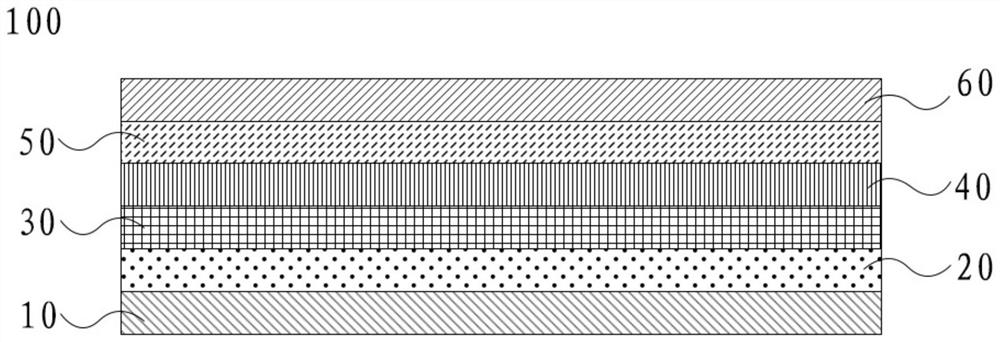

[0031] The method for preparing the above-mentioned transfer paper according to an embodiment of the present invention includes the following steps S10-S30:

[0032] S10, forming a transfer layer on the base film, performing aluminum plating on the transfer layer to form an aluminum plating layer, and forming a glue layer on the aluminum plating layer.

[0033] S20, forming a back coating on one side of the base paper, and then attaching the side of the base paper away from the back coating to the glue layer.

[0034] Specifically, the paper back-coating emulsion is prepared by weighing each component raw material according to the above-mentioned parts by mass, putting the base film into the unwinding device, coating the paper back-coating emulsion through the coating roller, and forming the back coating after drying in a three-section oven. Pass the compound roller directly without winding to make the emulsion-coated side of the uncoated paper stick to the undried glue layer,...

Embodiment 1

[0043] The raw materials were weighed according to the following parts by mass: 12.6 parts of water, 13.98 parts of acrylic emulsion, 2.1 parts of wax emulsion, 1.8 parts of γ-polyglutamic acid, 0.9 parts of sodium alginate, 0.9 parts of calcium chloride, and 1.2 parts of ketone removal additive , 0.5 parts of silk fibroin, 0.5 parts of cattail fiber, 0.3 parts of molybdenum disulfide, 0.2 parts of cellulose ether, 0.2 parts of starch ether, 0.03 parts of defoamer, 0.03 parts of preservative and 0.06 parts of leveling agent (BYK-331) share. Put water, wax emulsion, ketone-removing additives and additives into the reactor, heat the reactor to 55°C, start the stirring device at 1000rpm and stir for 0.5 hours. Then remaining raw material is dropped into reaction kettle, 800rpm continues to stir 1.5 hours, adopts 200 order filter screens to filter after cooling and obtain paper back coating emulsion.

[0044] Put the base film into the unwinding device, apply the transfer coating...

Embodiment 2

[0046] The experimental procedure of Example 2 is basically the same as that of Example 1, except that the raw materials do not include silk fibroin and cattail fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com