Transfer paper and its preparation method

A technology of transfer paper and transfer layer, applied in the field of packaging, can solve the problems of surface damage of transfer paper, electrostatic mutual adhesion, reduction of production efficiency, etc., and achieve the effect of easy separation, improvement of mutual adhesion, and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

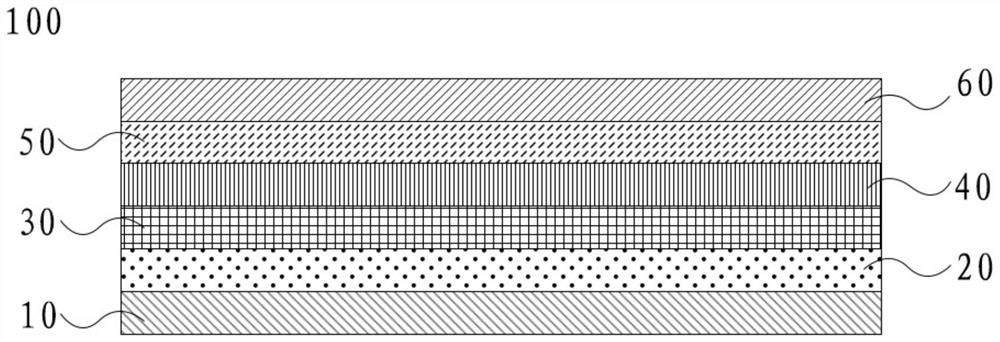

[0032] The method for preparing the above-mentioned transfer paper according to an embodiment of the present invention includes the following steps S10-S30:

[0033] S10, forming a transfer layer on the base film, performing aluminum plating on the transfer layer to form an aluminum plating layer, and forming a glue layer on the aluminum plating layer.

[0034] Specifically, the transfer coating was prepared by weighing the raw materials of each component according to the above-mentioned parts by mass, the base film was put into the unwinding device, the transfer coating was coated by the coating roller, and the transfer layer was formed after drying in a five-section oven.

[0035] Optionally, the method for preparing the above-mentioned transfer coating in one embodiment includes the following steps S11-S13:

[0036] S11. Weigh each raw material according to the parts by mass.

[0037] S12. Put the solvent, cellulose resin, polyacrylic resin and polyaniline into the reactio...

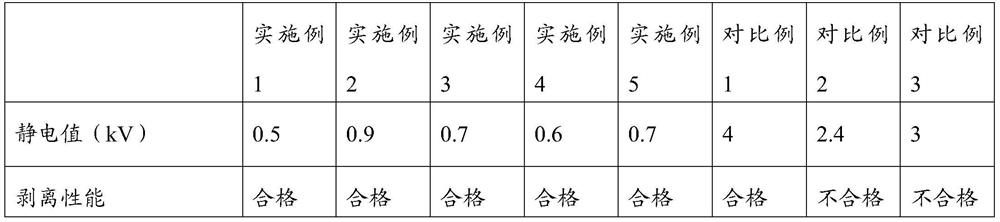

Embodiment 1

[0045] Weigh each raw material according to the following parts by mass: 10 parts of cellulose resin, 8 parts of polyacrylic resin, 6 parts of polyaniline, 0.9 part of tin tetrachloride, 3 parts of tetraacicular zinc oxide whiskers, 0.2 part of polypyrrole, 0.3 part of sodium styrene sulfonate, 0.1 part of multilayer graphene, 0.5 part of defoamer (BYK-054), 0.5 part of leveling agent, 0.5 part of wetting agent, 0.5 part of cosolvent and 60 parts of n-propyl acetate. Put n-propyl acetate, cellulose resin, polyacrylic resin and polyaniline into the reaction kettle, heat the reaction kettle to 70°C, start the stirring device at 900rpm and stir for 1.5 hours. Then put the remaining raw materials into the reaction kettle, continue stirring at 500rpm for 1.5 hours, cool to 25°C and filter through a 300-mesh filter to obtain the transfer coating.

[0046] Put the base film into the unwinding device, apply the transfer coating through the coating roller, and form the transfer layer a...

Embodiment 2

[0048] The experimental procedure of Example 2 is basically the same as that of Example 1, except that the raw material does not include tetraacicular zinc oxide whiskers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com