A kind of release film, preparation method of flexible device, release film and flexible device

A flexible device and release film technology, applied in the manufacture of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc., can solve the problems of uneasy discharge of static charge, electrostatic breakdown damage of thin-film transistors, etc., to improve electrostatic discharge capacity, The effect of reducing the difficulty of peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

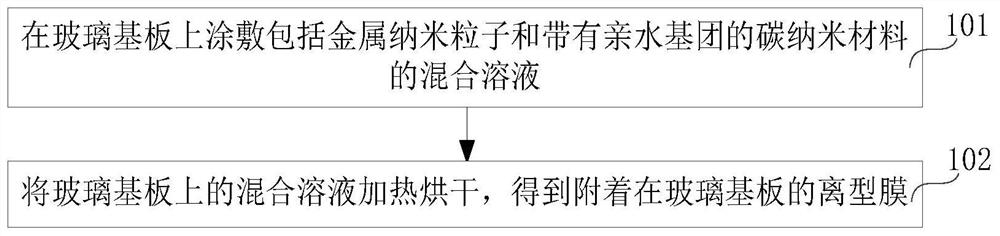

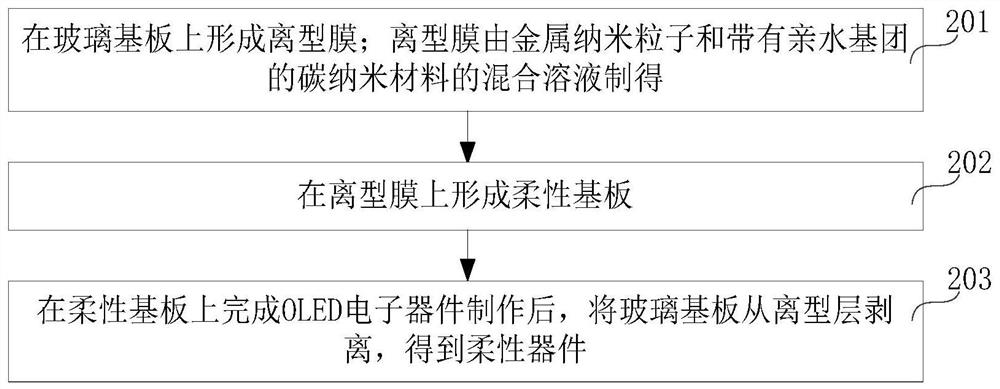

[0024] figure 1 A schematic flow chart of a method for preparing a release film provided by an embodiment of the present invention is exemplarily shown. like figure 1 Shown, this release film preparation method comprises the following steps:

[0025] Step 101: coating a mixed solution including metal nanoparticles and carbon nanomaterials with hydrophilic groups on a glass substrate;

[0026] Step 102: heating and drying the mixed solution on the glass substrate to obtain a release film attached to the glass substrate.

[0027] In the embodiment of the present invention, a mixed solution including metal nanoparticles and carbon nanomaterials with hydrophilic groups is coated on the glass substrate; the mixed solution on the glass substrate is heated and dried to obtain a release form attached to the glass substrate membrane. In this way, on the one hand, due to the weak hydrophilicity of carbon nanomaterials with hydrophilic groups, they can form chemical bonds with the hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com