Low-intermodulation antenna stern line connector

A tail cable connector and antenna technology, which is applied in the direction of antenna connector, antenna grounding switch structure connection, connection, etc., can solve problems such as unreliable crimping, poor index stability, and difficult processing, so as to improve effective power transmission and reduce Machining error, effect of simple machining process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

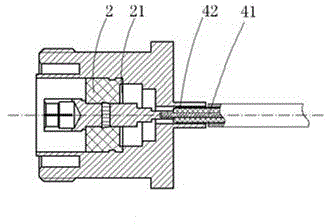

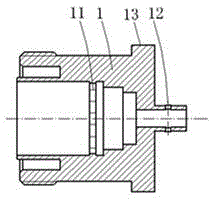

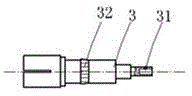

[0016] Example: Combine Figures 1A-1C , the DIN-type low-intermodulation antenna tail cable connector for matching 670-141SXE radio frequency cables in this embodiment includes: an integral outer conductor 1, an insulator 2 filled with a medium and a central conductor 3; the insulator 2 is a high temperature resistant material The sintered double-ring structure is located between the outer conductor 1 and the central conductor 3 to realize the fixing of the outer conductor and the central conductor; the tail of the central conductor 3 is provided with a central welding hole, which can realize welding with the inner conductor 41 of the radio frequency cable. The setting of the exhaust hole 31 plays a role in ensuring the welding strength, and realizes the connection between the inner conductor 41 of the radio frequency cable and the center conductor 3; Welding, the setting of the drainage hole 12 can enhance the welding strength and realize the connection between the radio fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com