Large-scale heat-resistant steel heating furnace door manual gas welding repair device and repair process

A technology of manual gas welding and heat-resistant steel, which is applied to measuring devices, metal processing equipment, gas flame welding equipment, etc., can solve the problem of reducing the maintenance cost, long production time and investment of the furnace door of the heat-resistant steel inlet and outlet of the ingot heating ring furnace. High cost problem, to achieve the effect of reducing maintenance cost, high work efficiency and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

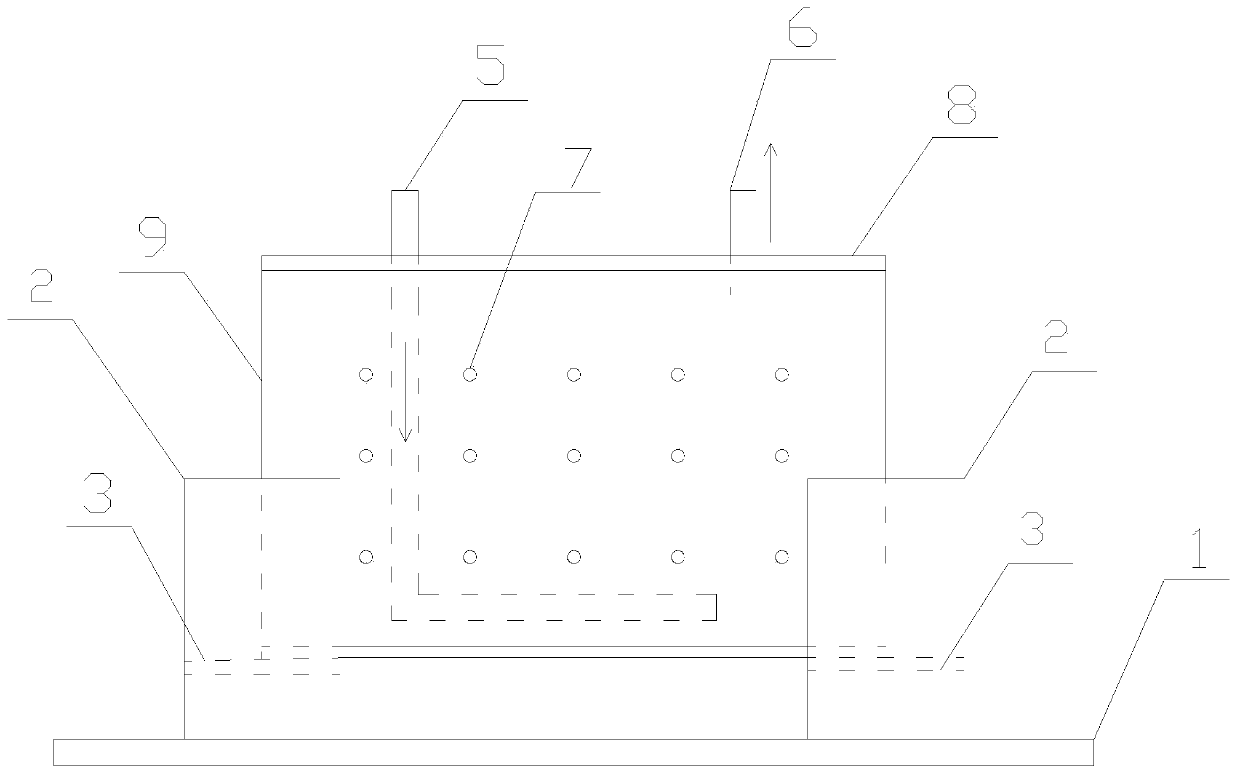

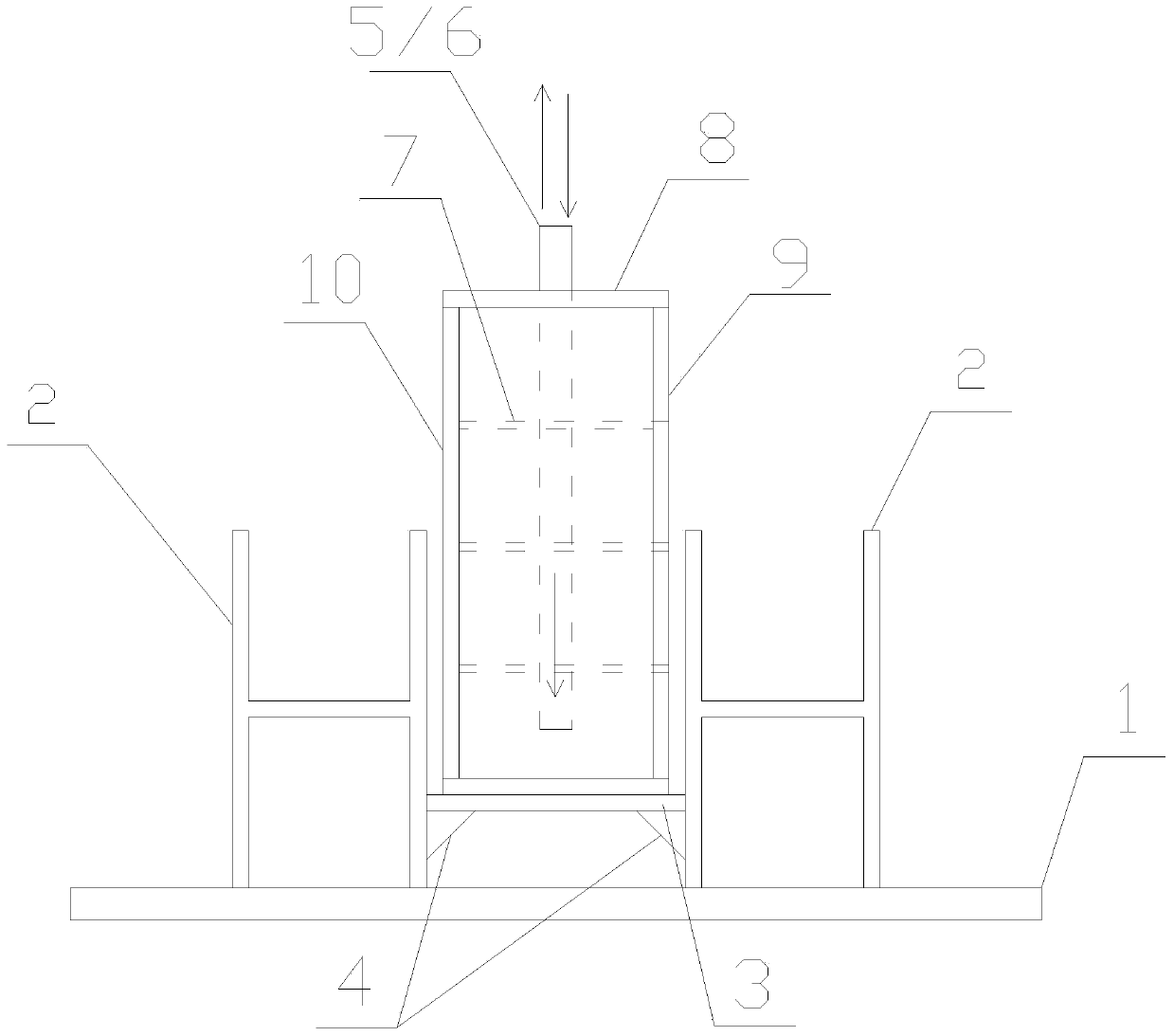

[0033] Such as figure 1 and figure 2 As shown, the present invention is a large-scale heat-resistant steel heating furnace door manual gas welding repair device, the furnace door 8 is a cuboid hollow structure, which includes a furnace door front panel 9 and a furnace door rear panel 10, and the inside is evenly arranged with A number of fixed rods 7 are characterized in that they also include a rectangular fixed bottom steel plate 1, a pressure test water inlet pipe 5 and a pressure test water outlet pipe 6; two groups of vertical H-shaped steel plates are symmetrically arranged on the left and right sides of the fixed bottom steel plate 1 The support frame 2, the horizontal H-shaped steel support frame 3 with a height lower than the height of the vertical H-shaped steel support frame 2 is arranged between each group of vertical H-shaped steel support frames 2, and the distance between two sets of vertical H-shaped steel support frames 2 Less than the length of the bottom o...

Embodiment 2

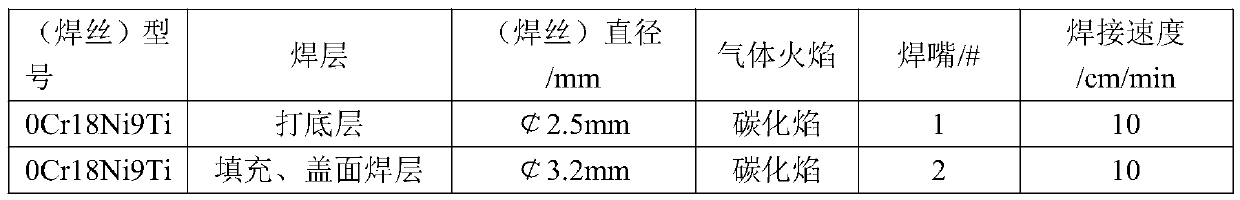

[0037] The present invention is a large-scale heat-resistant steel heating furnace door manual gas welding repair process. After the furnace door 8 is used for a long time, water leakage trachoma will appear on the furnace door front panel 9 and the furnace door rear panel 10. This embodiment The leakage trachoma on the furnace door front panel 9 and the furnace door rear panel 10 is repaired by using the large-scale heat-resistant steel heating furnace door manual gas welding repair device described in Example 1. The specific steps are:

[0038] Step 1. Fabrication of the manual gas welding repair device; determining the specifications of the fixed bottom steel plate 1, the vertical H-shaped steel support frame 2 and the horizontal H-shaped steel support frame 3 in the manual gas welding repair device according to the specifications of the furnace door 8, and cutting and manufacturing, Then each group of vertical H-shaped steel support frames 2 is set out and sorted on the fix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com