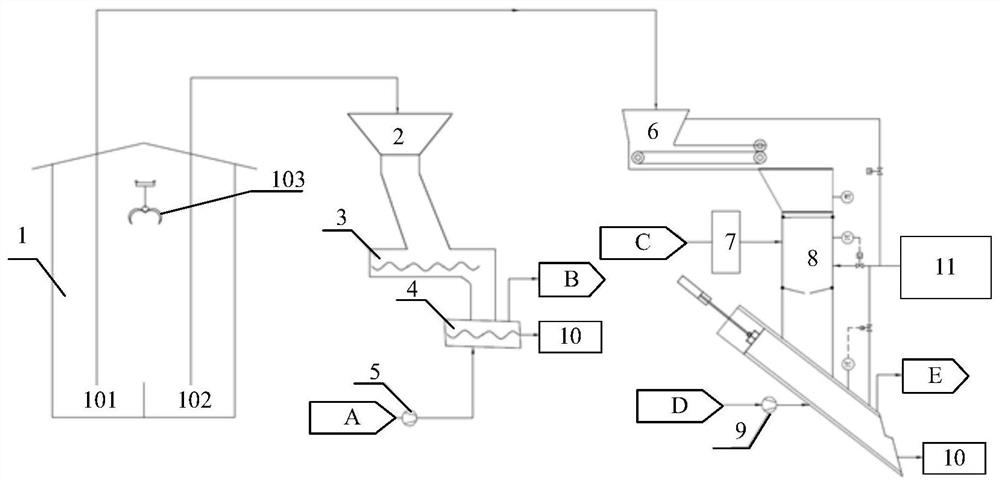

High-sulfur and high-halogen hazardous waste feed conveying system and hazardous waste incineration system

A hazardous waste and conveying system technology, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of broken bags and woven bags, shutdown and other problems, to reduce shutdown losses, improve feeding efficiency, and stabilize feeding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0063] The present invention also provides a hazardous waste incineration system, including the high-sulfur and high-halogen hazardous waste feeding and conveying system as described in the first embodiment.

[0064] Due to the high-sulfur and high-halogen hazardous waste feeding and conveying system according to the present invention, the materials that do not need to be crushed in the ton bags and woven bags are stored and transported separately from the materials that need to be crushed in the iron drums and plastic drums, avoiding tons Unnecessary crushing of sacks and woven bags causes shutdown due to entanglement of the crusher. At the same time, two sets of feeding conveying devices are used to convey the two materials separately, which can cooperate with each other to improve feeding efficiency, and can also be used as backup for each other under abnormal working conditions, reducing The shutdown loss caused by the system failure of the feed conveying system; therefore,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com