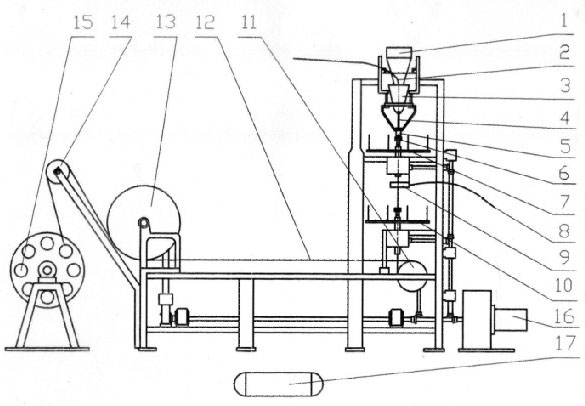

Convenient probe of detonating fuse manufacturing machine

A detonating cord making machine, a portable technology, applied in the manufacture of fuses, etc., to achieve the effect of increasing output, prolonging the cycle, and stably ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

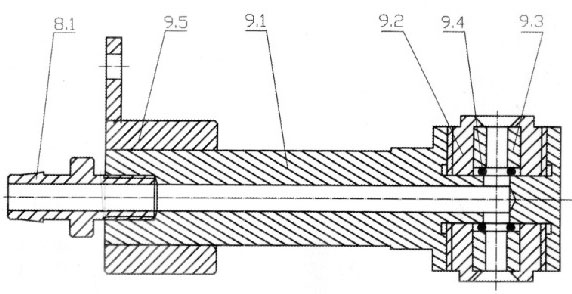

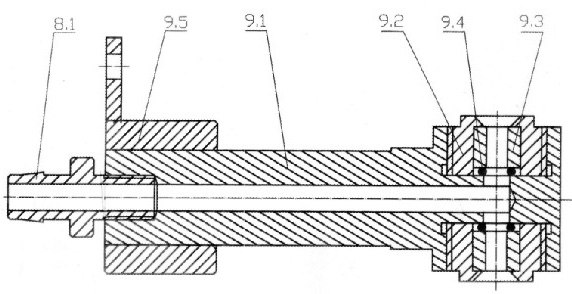

[0014] The present invention will be further described by using the accompanying drawings and examples.

[0015]When the probe 9 of a portable detonating cord making machine of the present invention is manufactured, the outer circumference of the probe main body 9.1 is first processed to form a stepped shaft, so that the outer circumference of the small shaft end is transitionally matched with the connecting inner hole of the probe bracket 9.5, and the outer circumference of the probe bracket 9.5 is transitionally fitted on the large shaft A through hole is made on the outer circumference of the probe main body 9.1 axis and perpendicular to the axis. The diameter of the through hole is 0.5-1mm in the positive deviation of the diameter of the detonating cord semi-finished product. On the outer circumference of the major shaft end of the main body 9.1, make a sunken platform threaded hole concentric with the through hole, and then at the other end of the through hole, also taking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com