Process for testing quality of presswork

A printed matter and process technology, applied in the process field that can improve the efficiency of printed matter quality inspection, can solve the problems of insufficient special defect detection ability, affecting the accuracy of quality inspection, bad shape, size, spacing, etc., to achieve simple structure and reduce detection cost , the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described below in conjunction with the accompanying drawings.

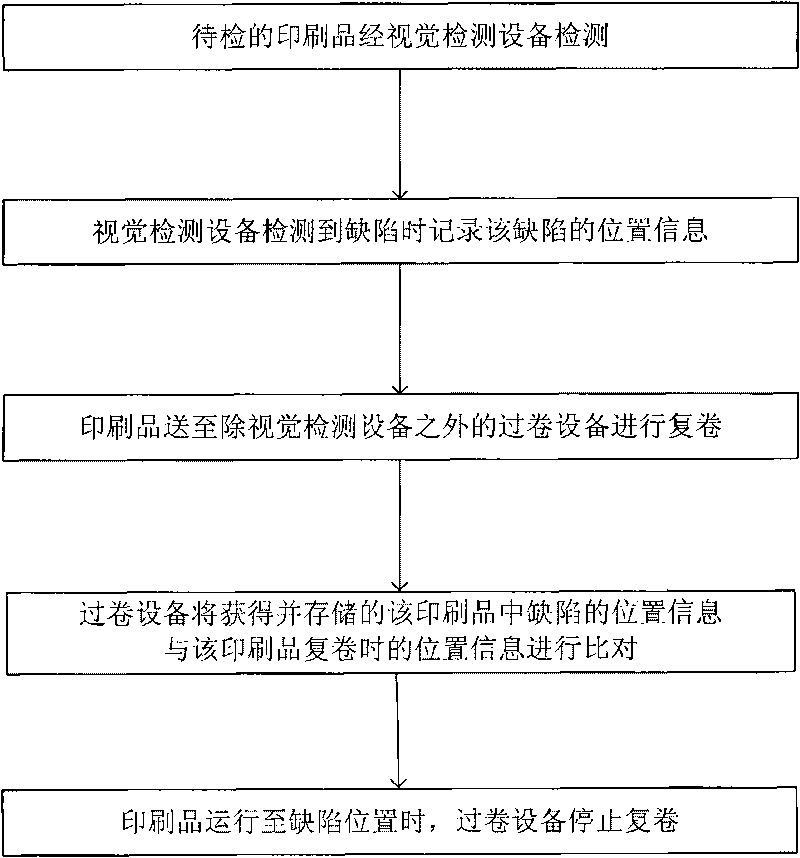

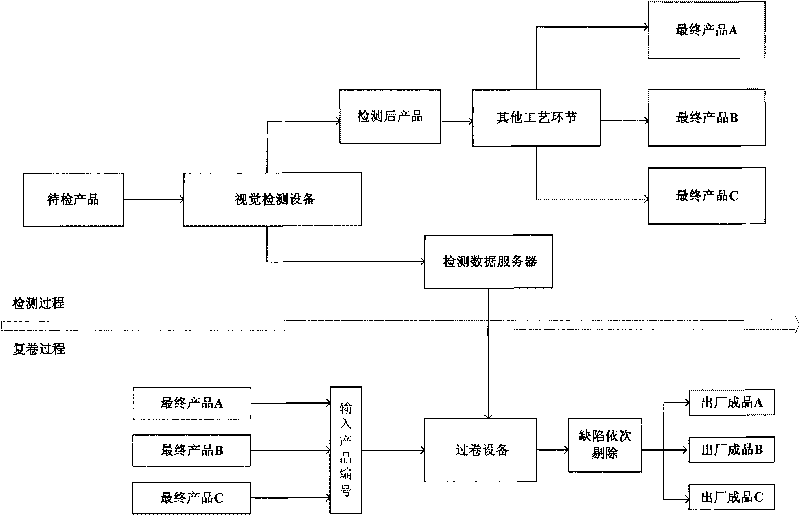

[0036] figure 1 It is a flow chart of the print quality detection process of the present invention, comprising the following steps:

[0037] A. The printed matter to be inspected is inspected by visual inspection equipment;

[0038] B. When the visual inspection equipment detects a defect, record the position information of the defect in the printed matter;

[0039] B', the visual inspection equipment uploads the positional information of the defect in the recorded printed matter to the inspection data server;

[0040] C. Send the printed matter to an overwinding device other than the visual inspection equipment for rewinding, and the overwinding device downloads and stores the position information of the defect in the printed matter from the detection data server described in step B';

[0041] D. The overwinding device compares the stored position information of the defect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com