Recheck platform and quality inspection system of prints

A print and platform technology, applied to the re-inspection platform and the system field of print quality inspection using this platform, can solve problems such as time-consuming, existing problems, and insufficient special defect detection capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described below in conjunction with the accompanying drawings.

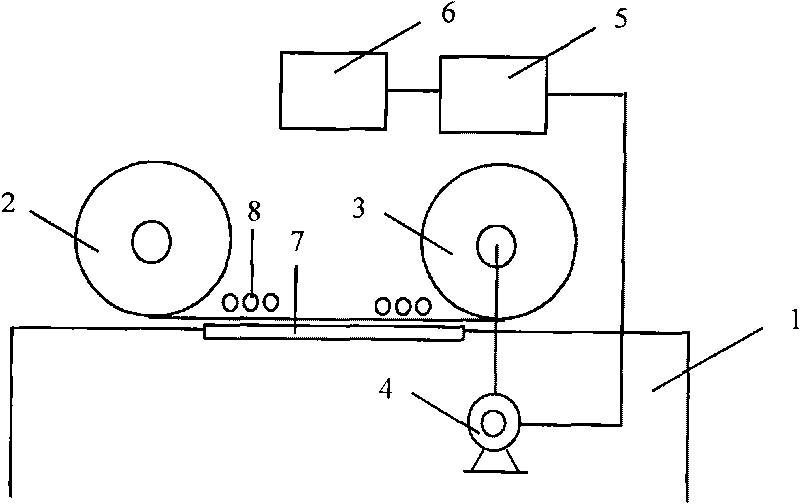

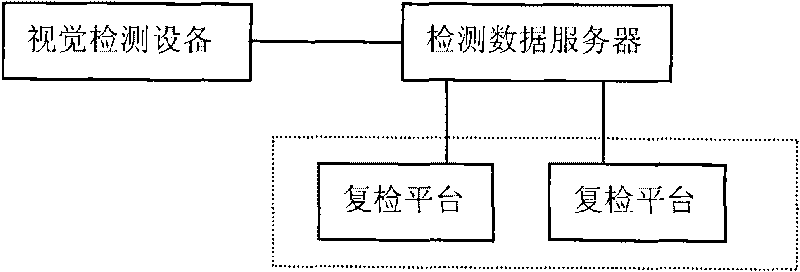

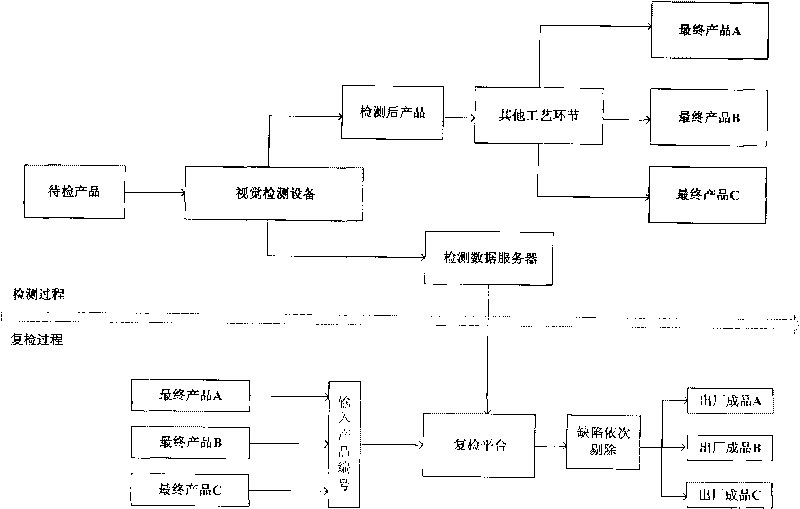

[0032] figure 1 It is a structural block diagram of the re-examination platform of the present invention. The re-inspection platform of the present invention is used for re-inspection of defects in the quality inspection of printed matter, including a frame 1, a workbench 7, an unwinding wheel 2, a rewinding wheel 3, a position detection device, a power device 4 and a microcontroller 5, The unwinding wheel 2 and the winding wheel 3 are both arranged on the frame 1, the unwinding wheel 2 transports the printed matter to the winding wheel 3 to rewind the printed matter, and the workbench 7 is set between the unwinding wheel 2 and the winding wheel 3 for rewinding. Below the printed matter of the roll, the winding wheel 3 is connected to the power unit 4, and the microcontroller 5 stores the position information of the defect of the printed matter and compares it with the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com