Patents

Literature

182 results about "Usability inspection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Usability inspection is the name for a set of methods where an evaluator inspects a user interface. This is in contrast to usability testing where the usability of the interface is evaluated by testing it on real users. Usability inspections can generally be used early in the development process by evaluating prototypes or specifications for the system that can't be tested on users. Usability inspection methods are generally considered to be cheaper to implement than testing on users.

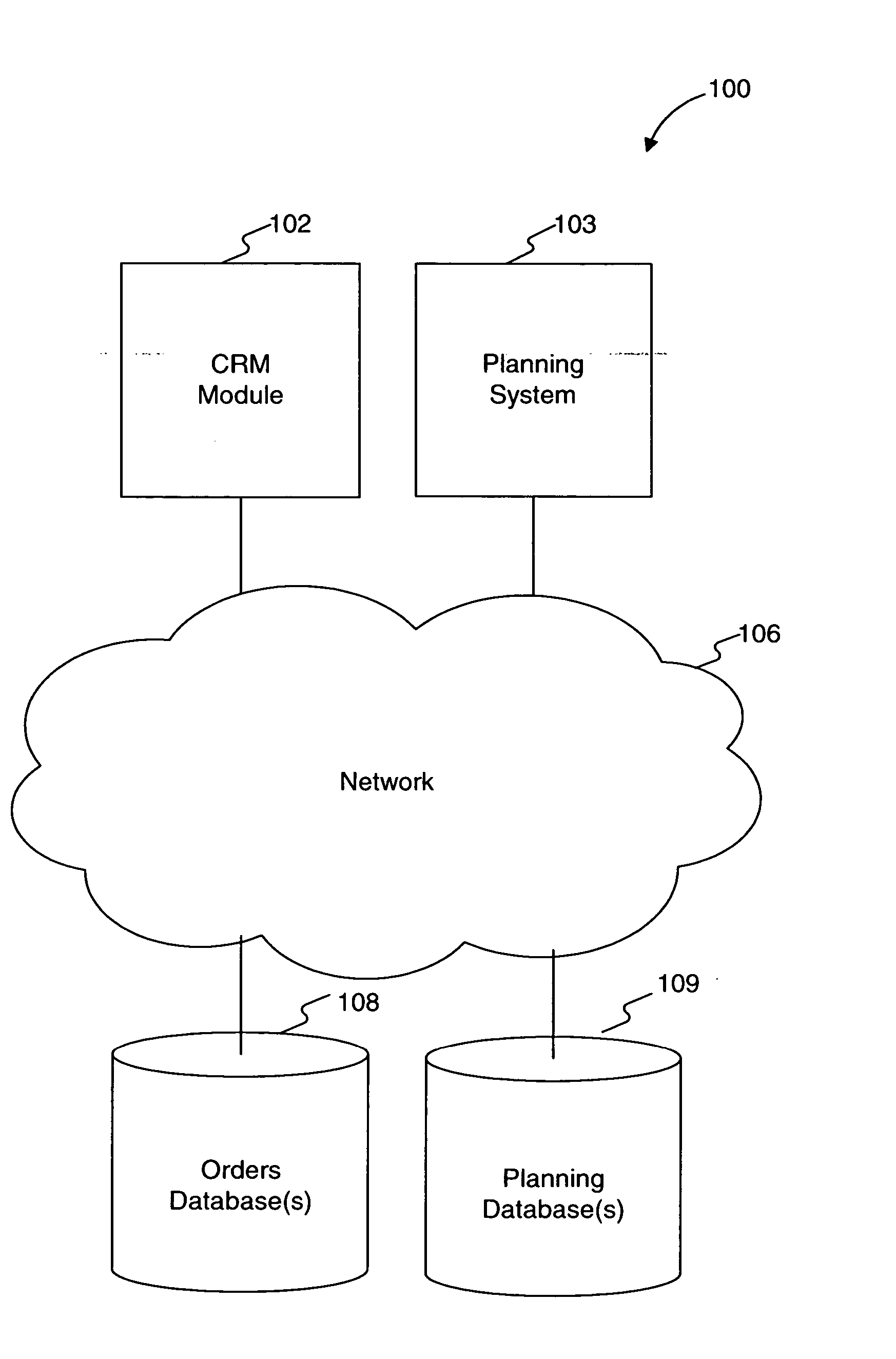

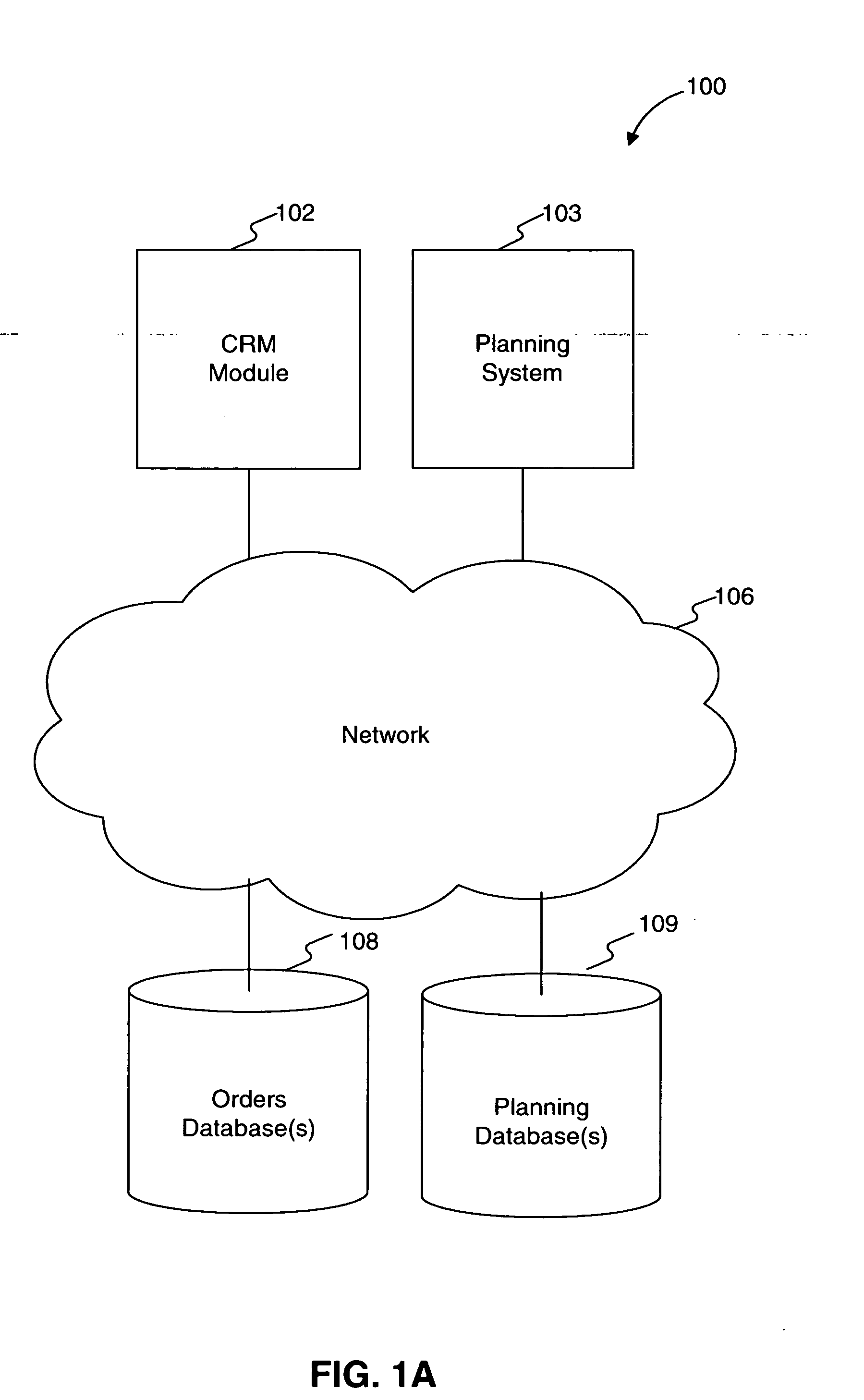

Regenerative available to promise

InactiveUS6463345B1LogisticsSpecial data processing applicationsOrder management systemWorking environment

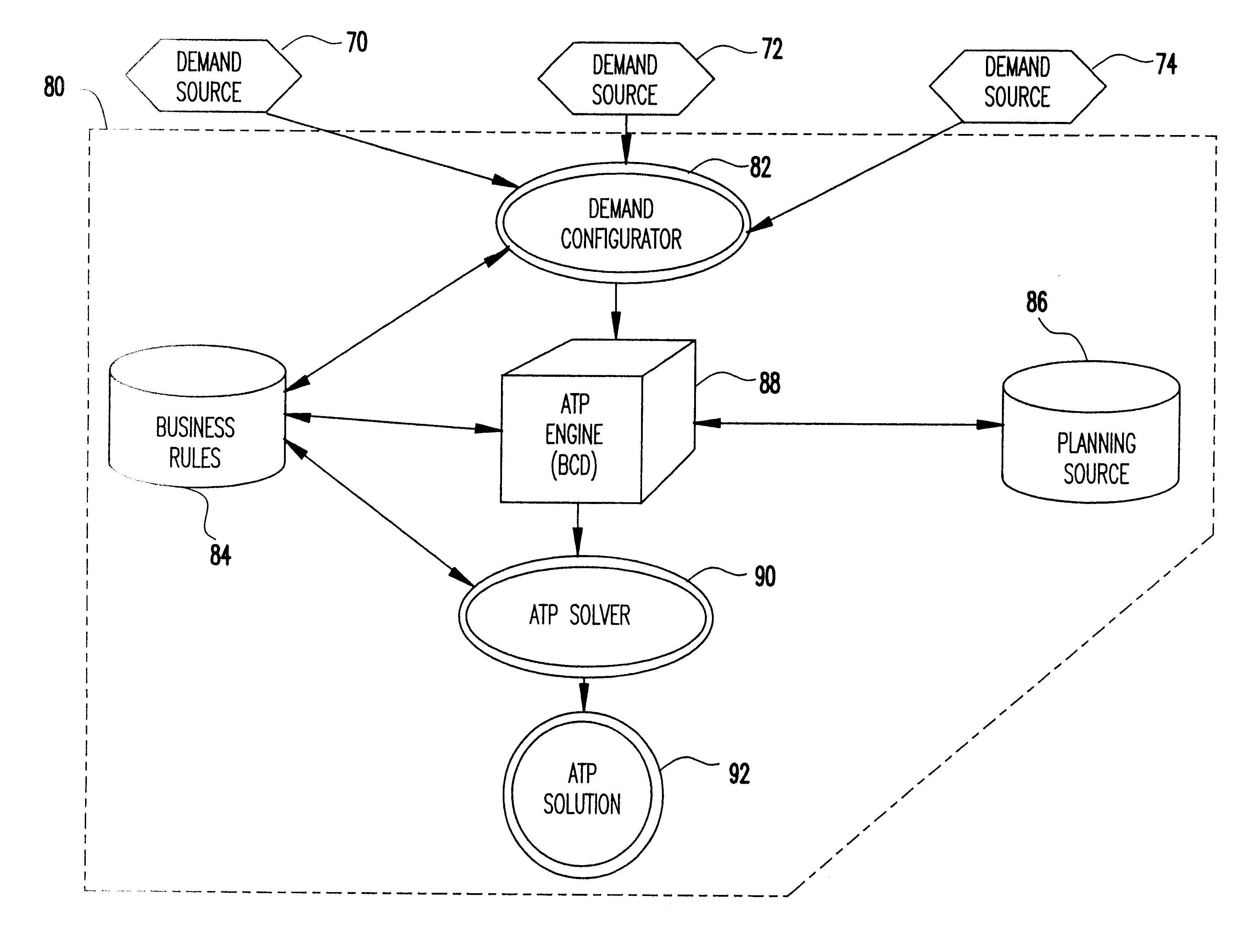

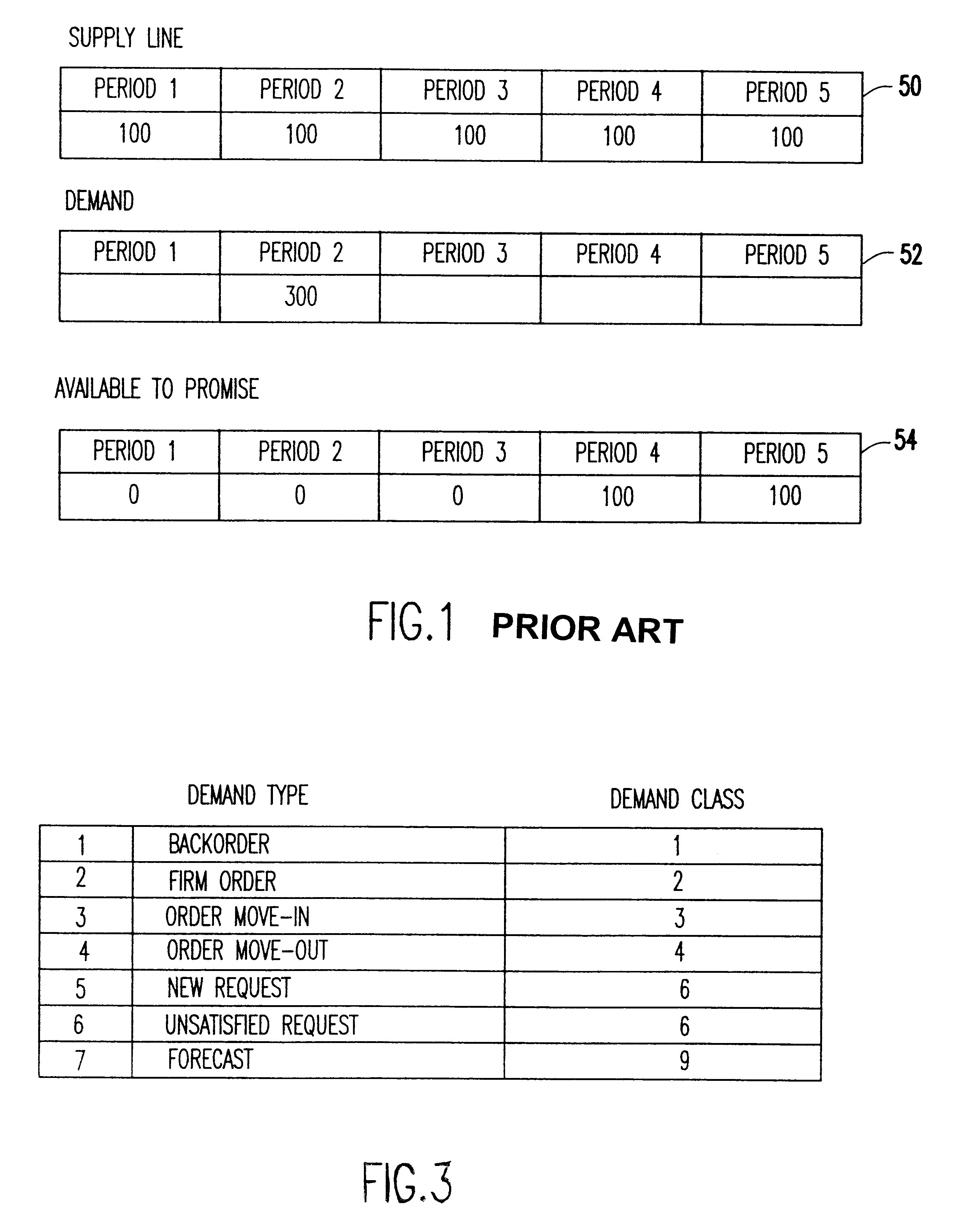

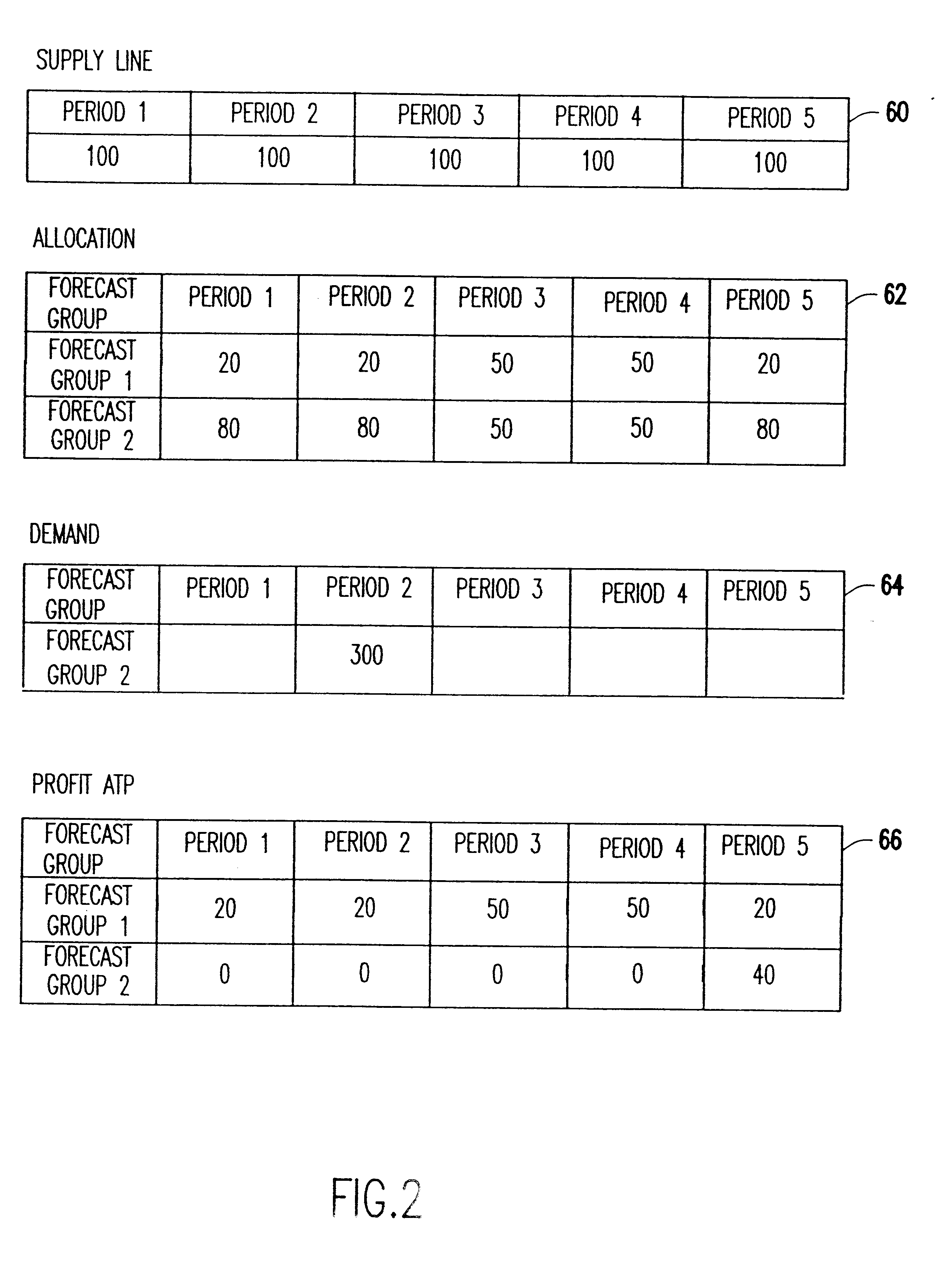

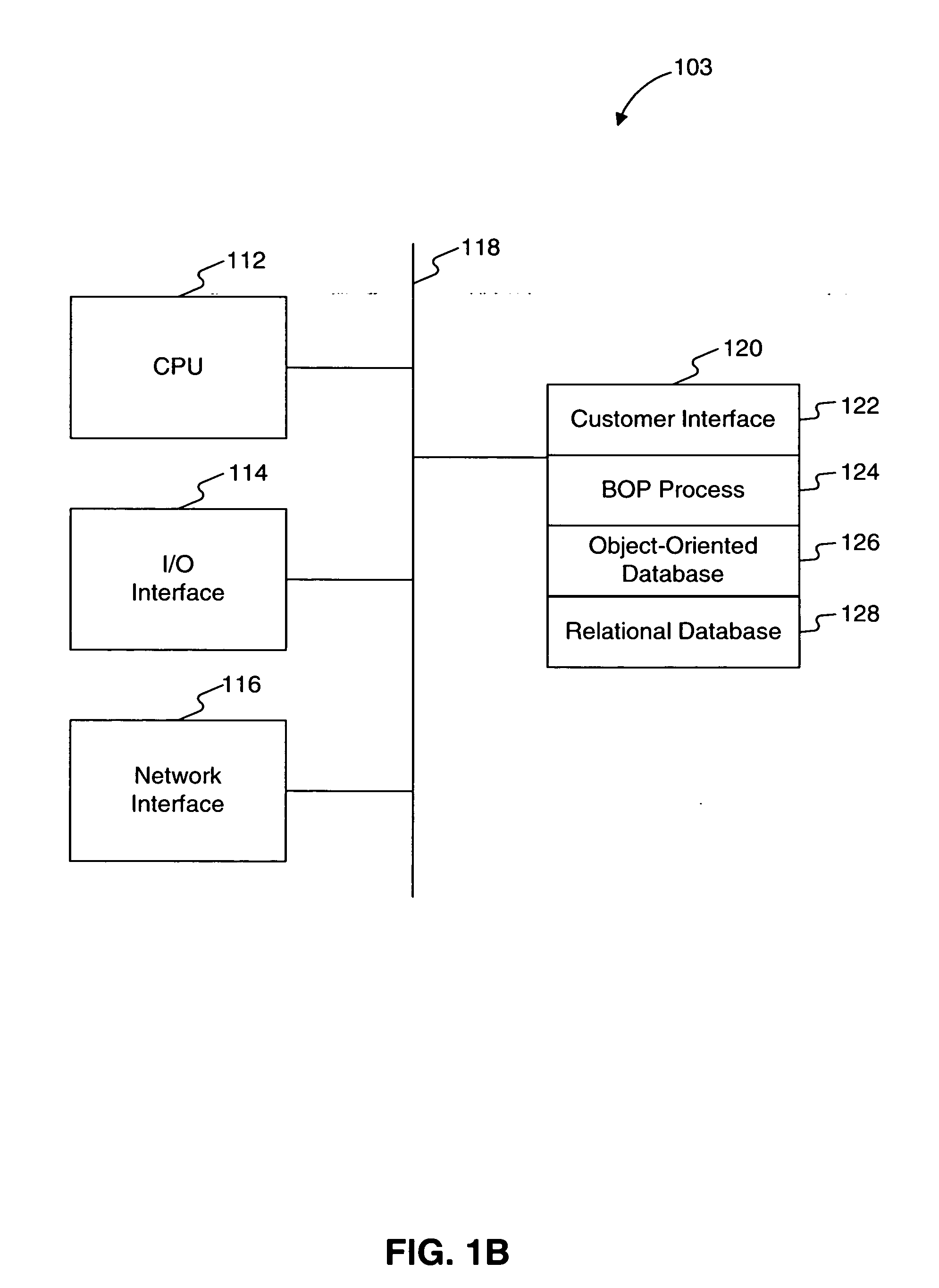

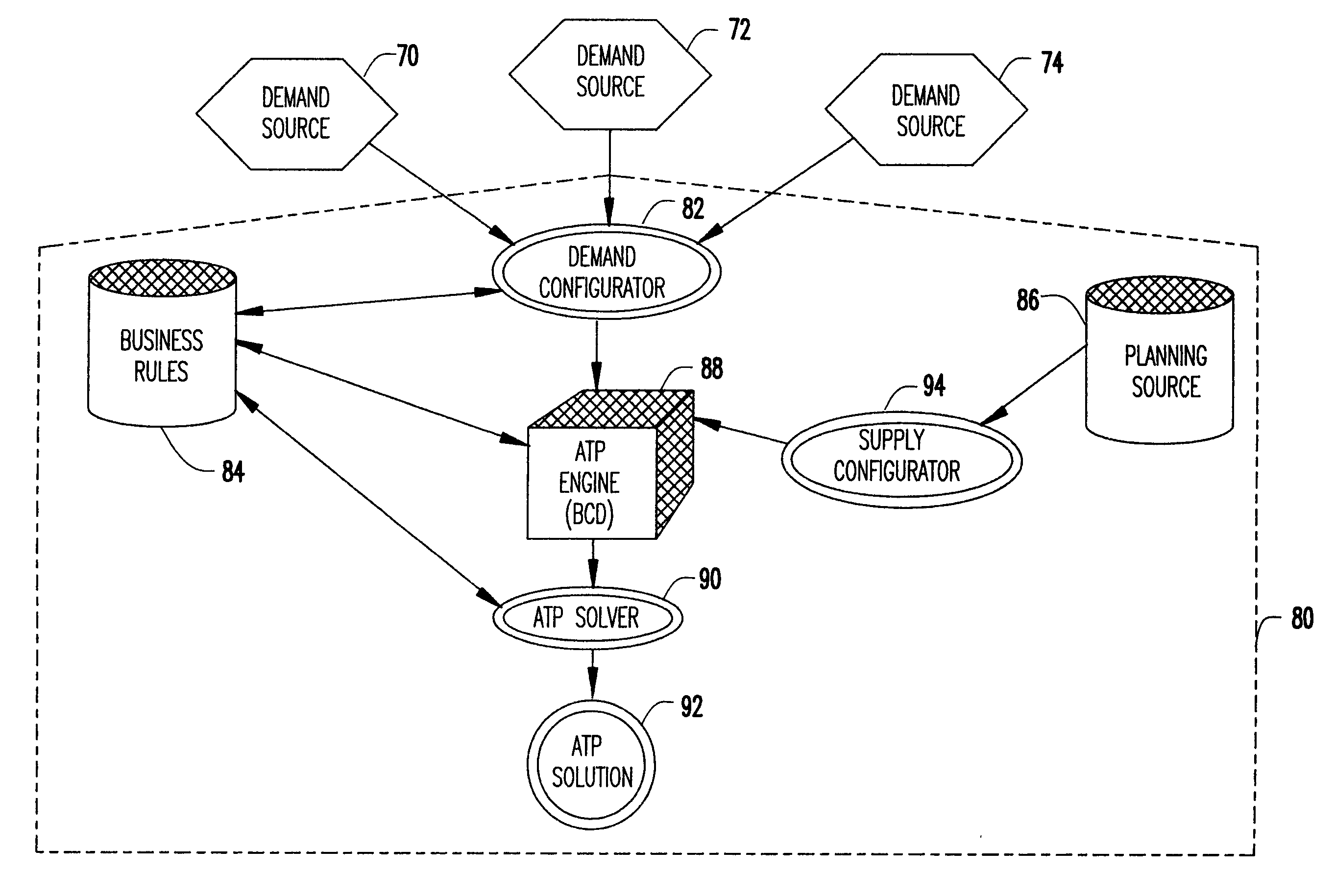

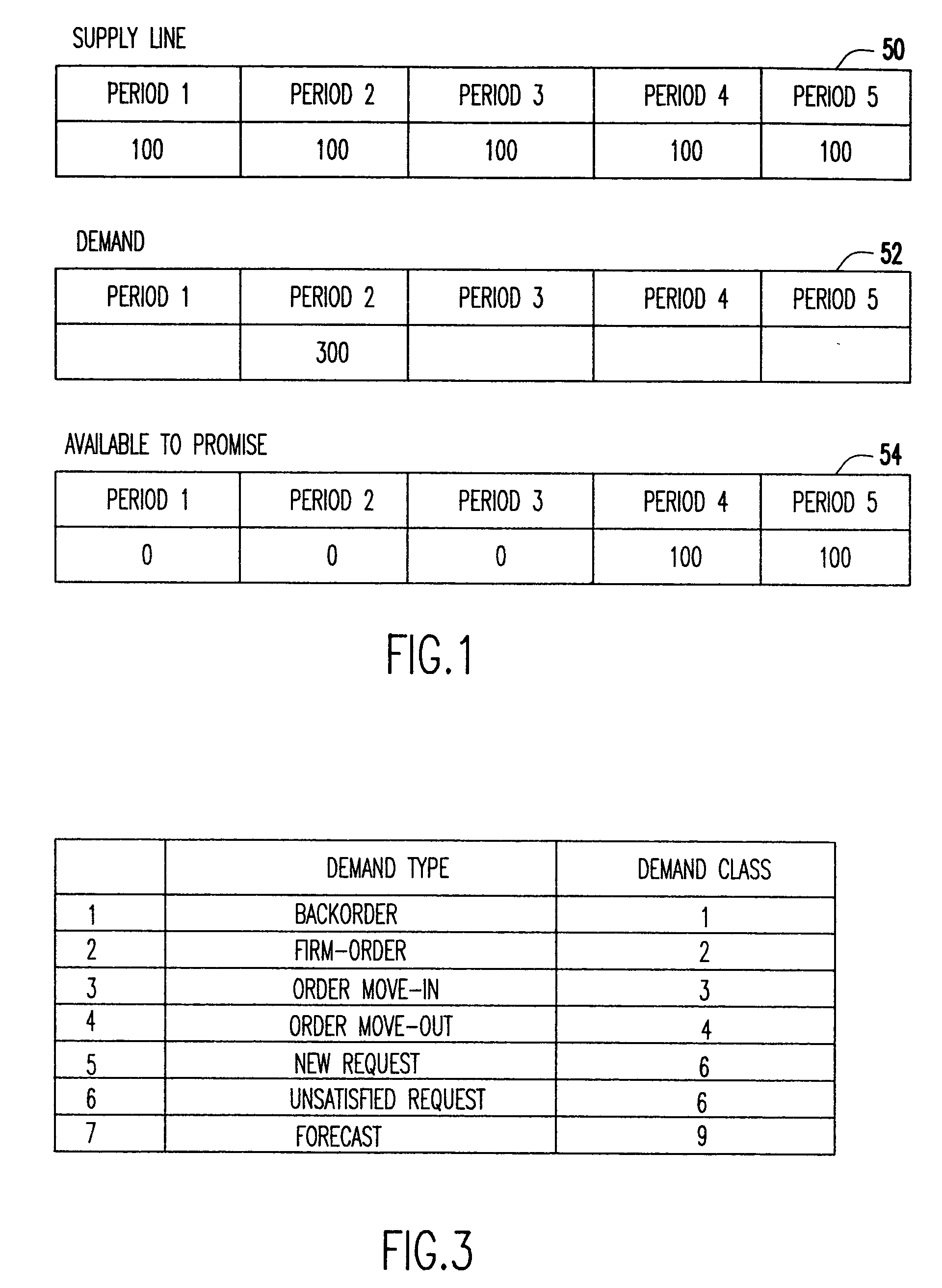

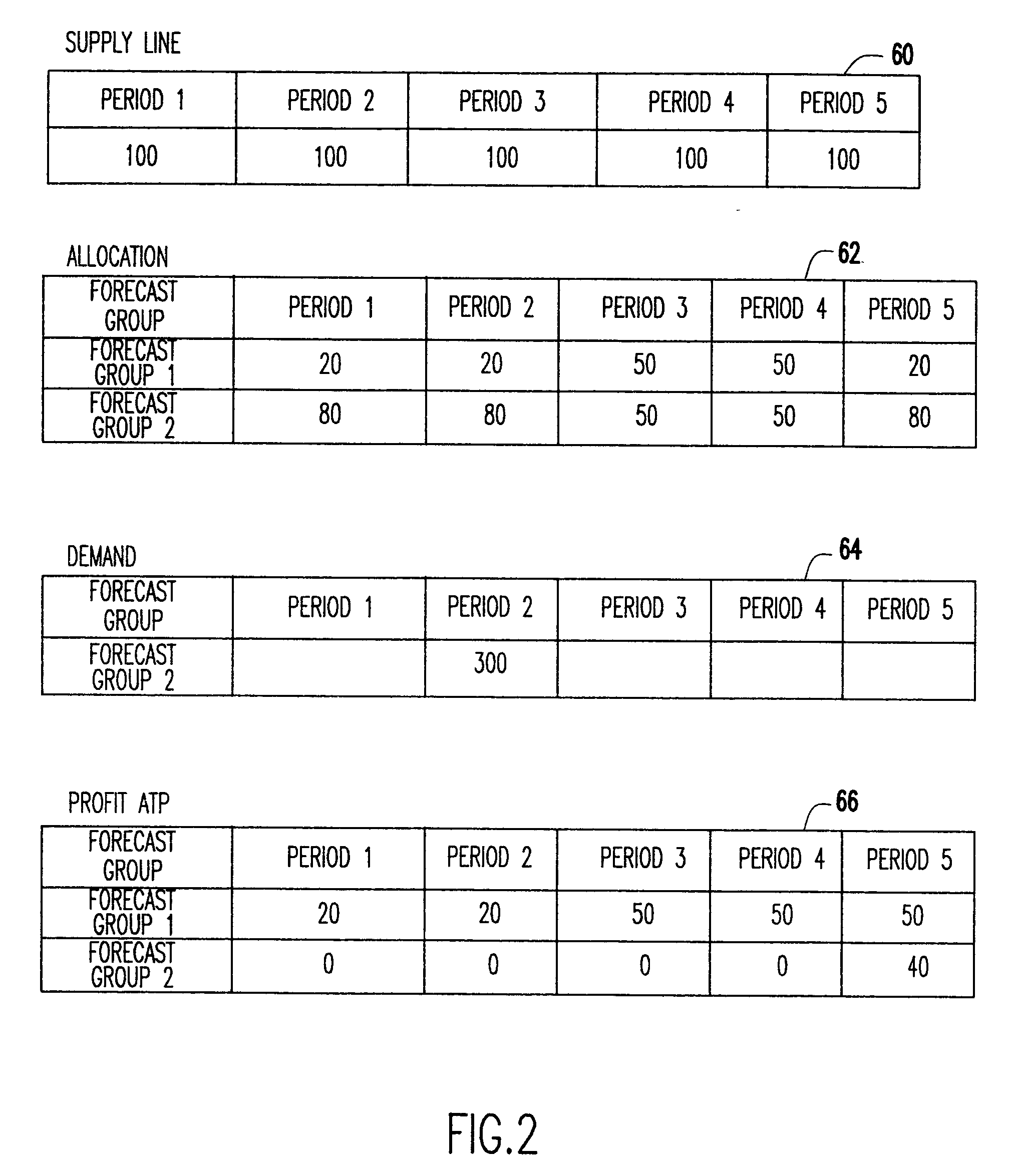

A computer implemented Availability Checking Tool enabling tool users to execute within a common work environment, from common enterprise data, and considering assets and demands across multiple order management systems and manufacturing facilities within boundaries established by manufacturing specifications and process flows and business policies. The tool receives orders from multiple demand sources or ordering systems. Tool users can easily maintain a synergistic relationship between multiple ordering systems. A demand configurator coordinates product requests based on information from the demand source according to certain rules and priorities assigned to the product requests. A material resource engine manipulates data from the demand configurator and the rules to provide material supply information. A solver manipulates the material supply information from the resource engine and the rules to provide optimized product availability information. Thus, customer business rule level definitions are supported to provide the tool users with the power to micro-manage, optimally, enterprise assets and demands.

Owner:INT BUSIESS MACHINES

Virtual check

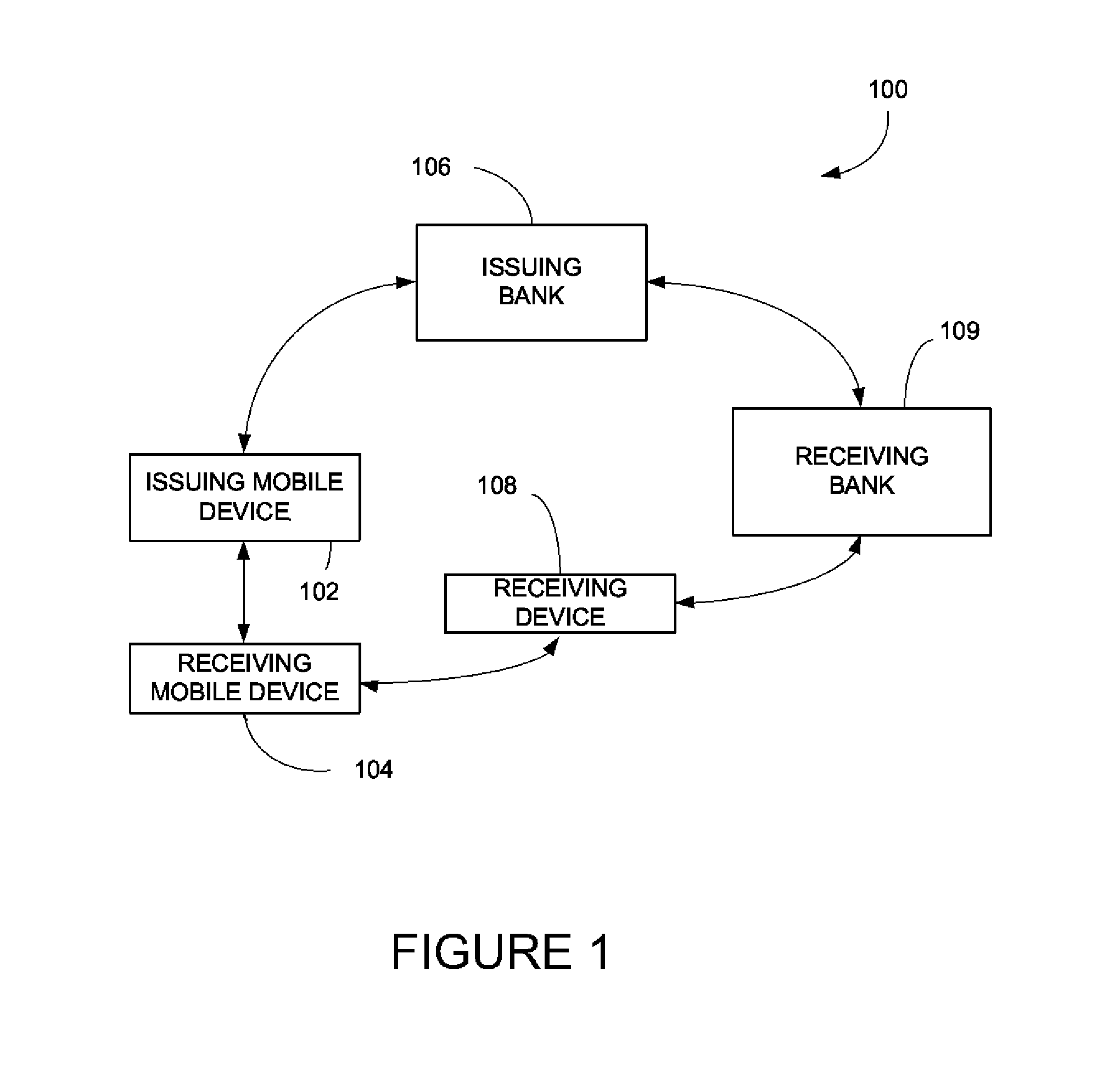

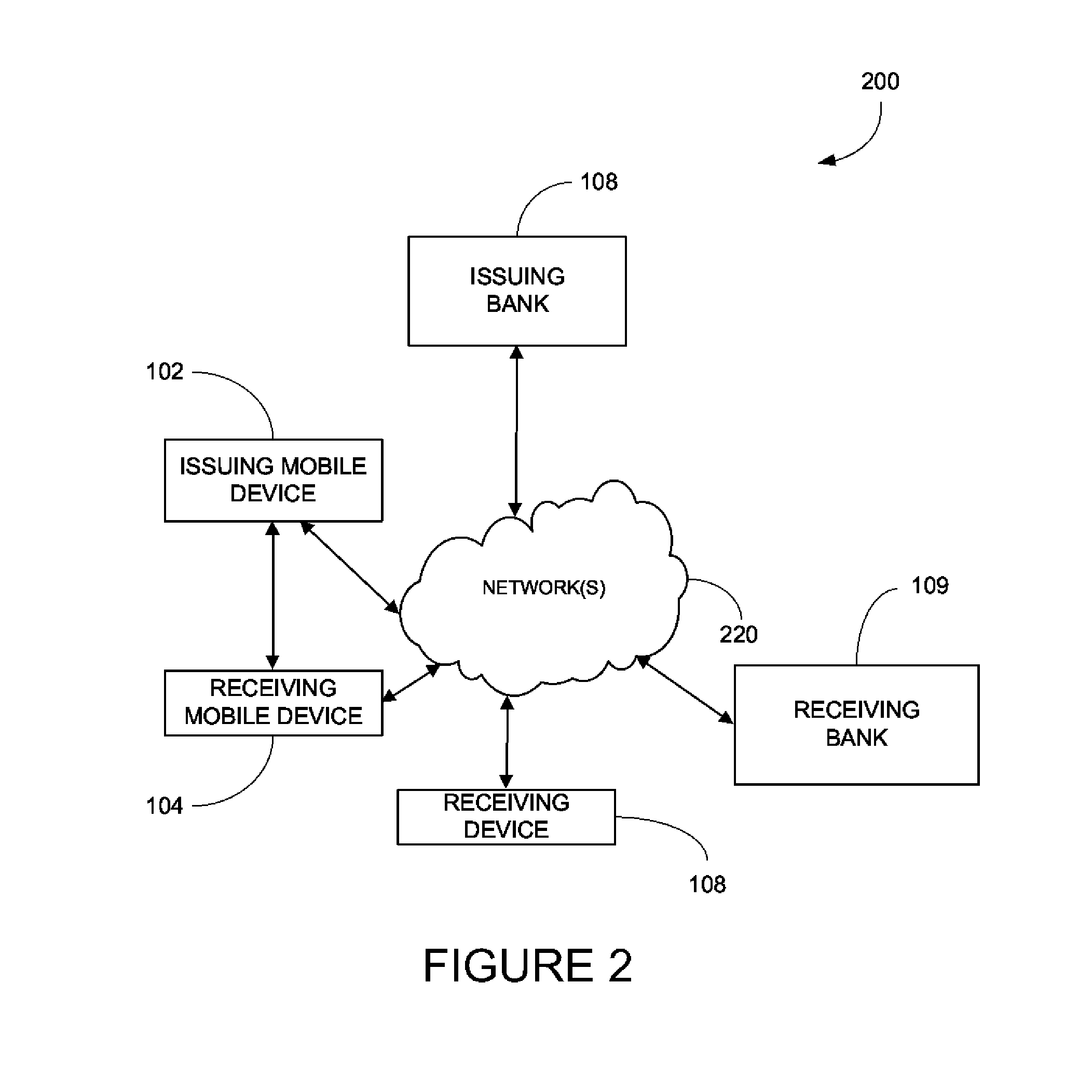

ActiveUS8332329B1Sufficient dataCryptography processingCharacter and pattern recognitionComputer hardwareS/KEY

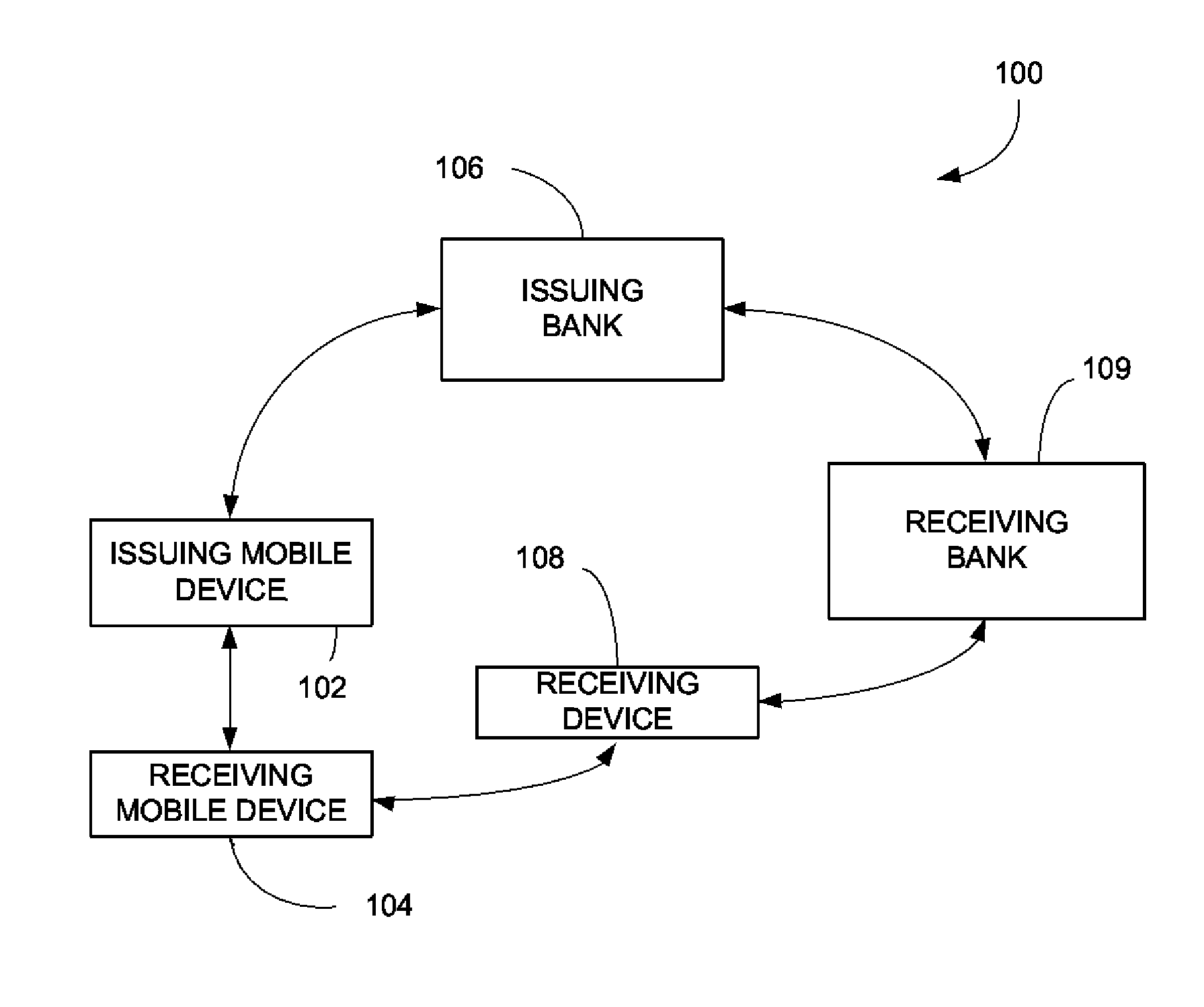

Methods and systems for virtual checking are described. A virtual check is created by a payor's device and then sent to the payee's device. The payee can be another mobile device. The virtual check has many of the same features as a regular, paper check plus additional features only available in digital form. In an example, the data can be encrypted by either the banks key or the payor's key. Further encryption can occur between the payor's device and the payee's device, which can connect on a peer-to-peer network. The check can be an image with tag data. In an example, data can be encoded into the image itself. The virtual check can include populated data that cannot be changed by the payee. In an example, the virtual check application of the payee can automatically perform a funds availability check.

Owner:USAA

Systems and methods for automated parallelization of back-order processing

ActiveUS20070094098A1Facilitate automated parallelizationPayment architectureResourcesOrder processingUsability inspection

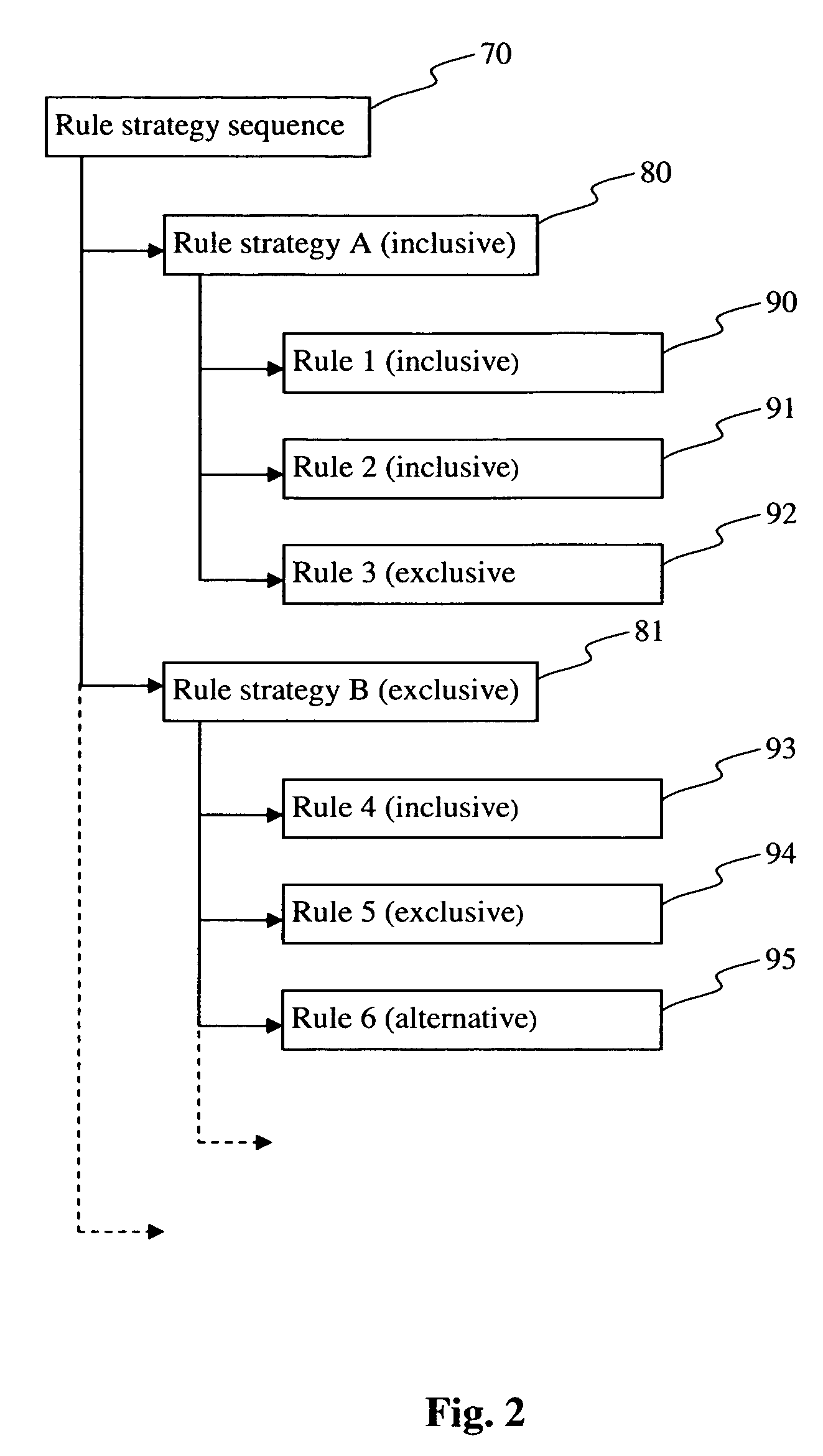

Systems, methods, and computer-readable media provide mechanisms to determine the availability of one or more order items within a supply chain environment. In one embodiment, the method may comprise defining a profile to be associated with an availability check, wherein the availability check consists of a filter process, a sort process, a prepare process, a check process, and an update process, electronically building one or more processing packages for the one or more order items based on the defined profile, and executing the availability check using the profile and one or more processing packages.

Owner:SAP AG

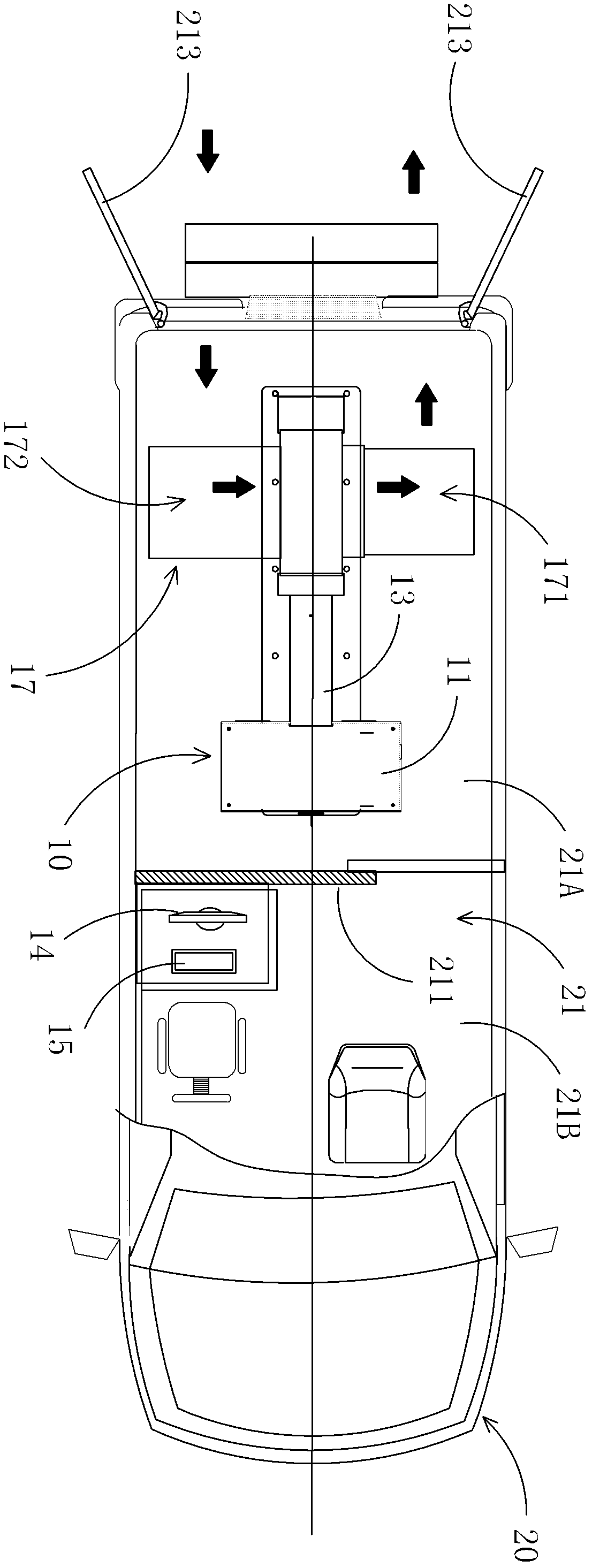

Submarine cable detection underwater robot and operating method

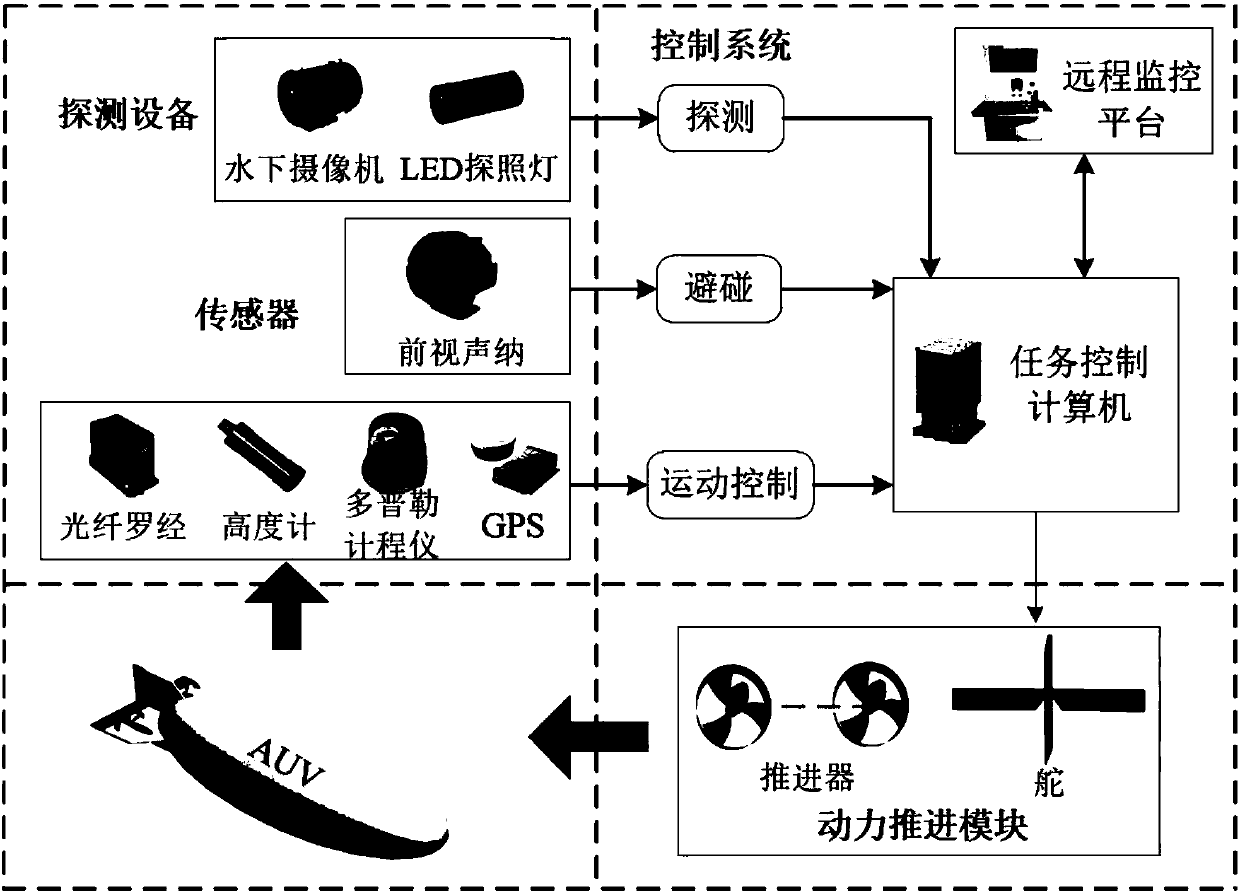

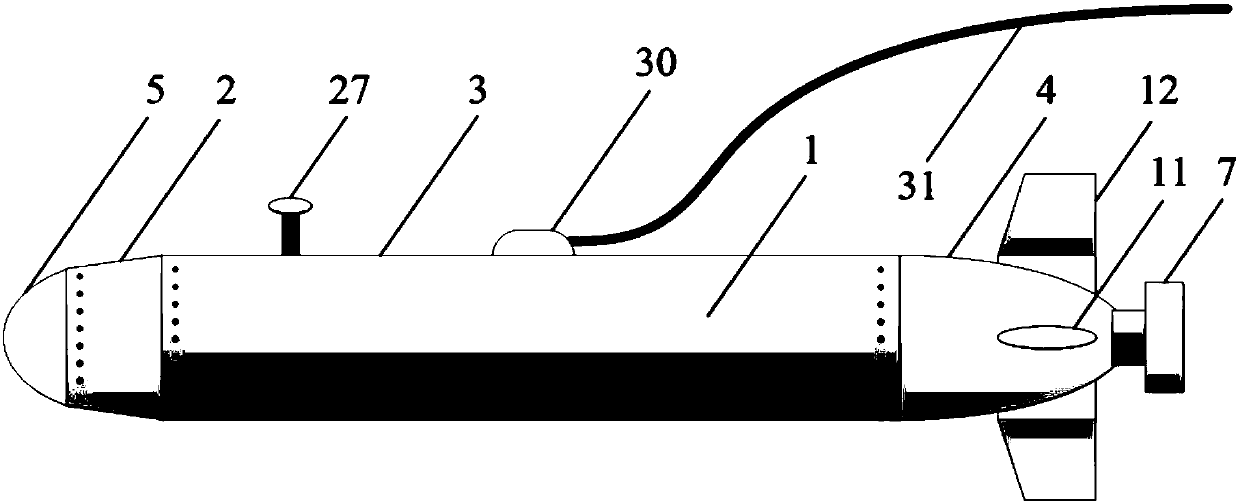

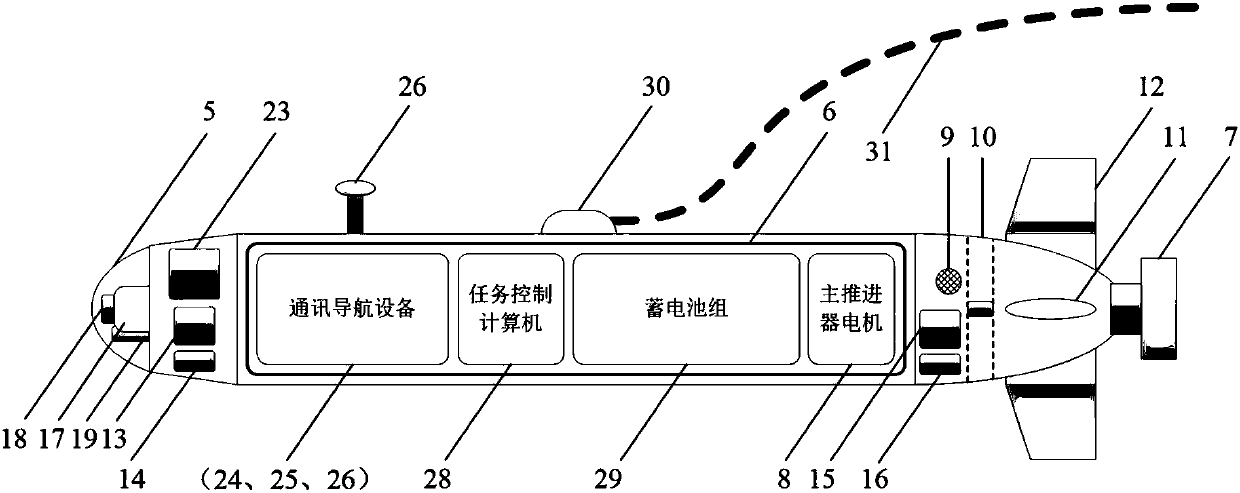

InactiveCN108045530AUpload in real timeHas the function of reliefUnderwater vesselsUnderwater equipmentOcean bottomUsability inspection

The invention discloses a submarine cable detection underwater robot and an operating method. Mutual switching of a ROV mode and an AUV mode can be achieved by means of a cable security interface, thecapabilities of autonomous navigation, long-distance control and accurate detection are achieved, and the submarine cable detection underwater robot is used for construction exploration, daily routing inspection and failure detection of a submarine cable project. Construction exploration can be conducted on landform of a submarine cable route before the submarine cable project starts, daily inspection is conducted on burying and operation conditions of submarine cables which are put into operation already, and on-site close observation is conducted on the submarine cables being subjected to breaking down or cracking accidents.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +2

Systems and methods for transporting ordered products

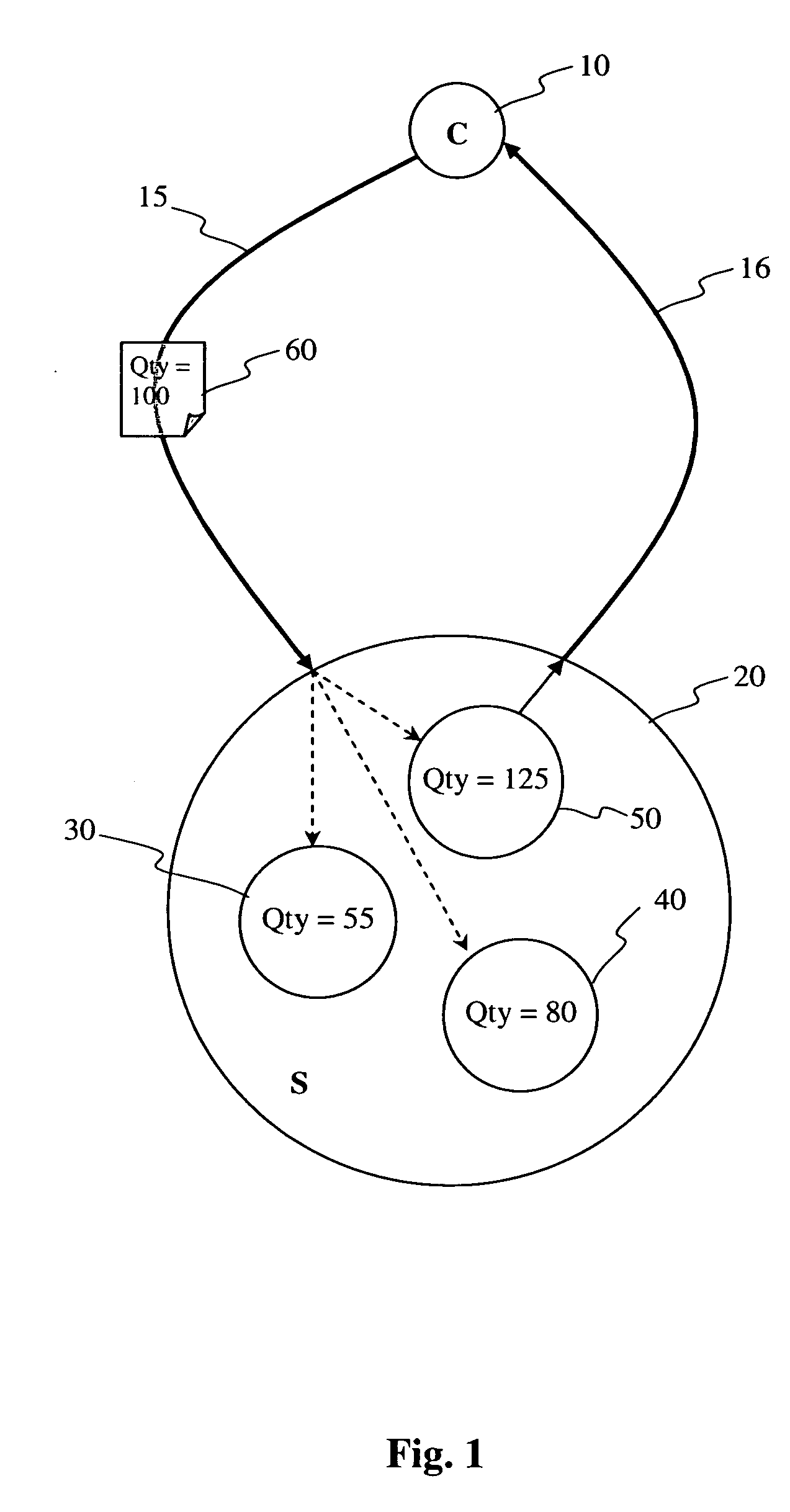

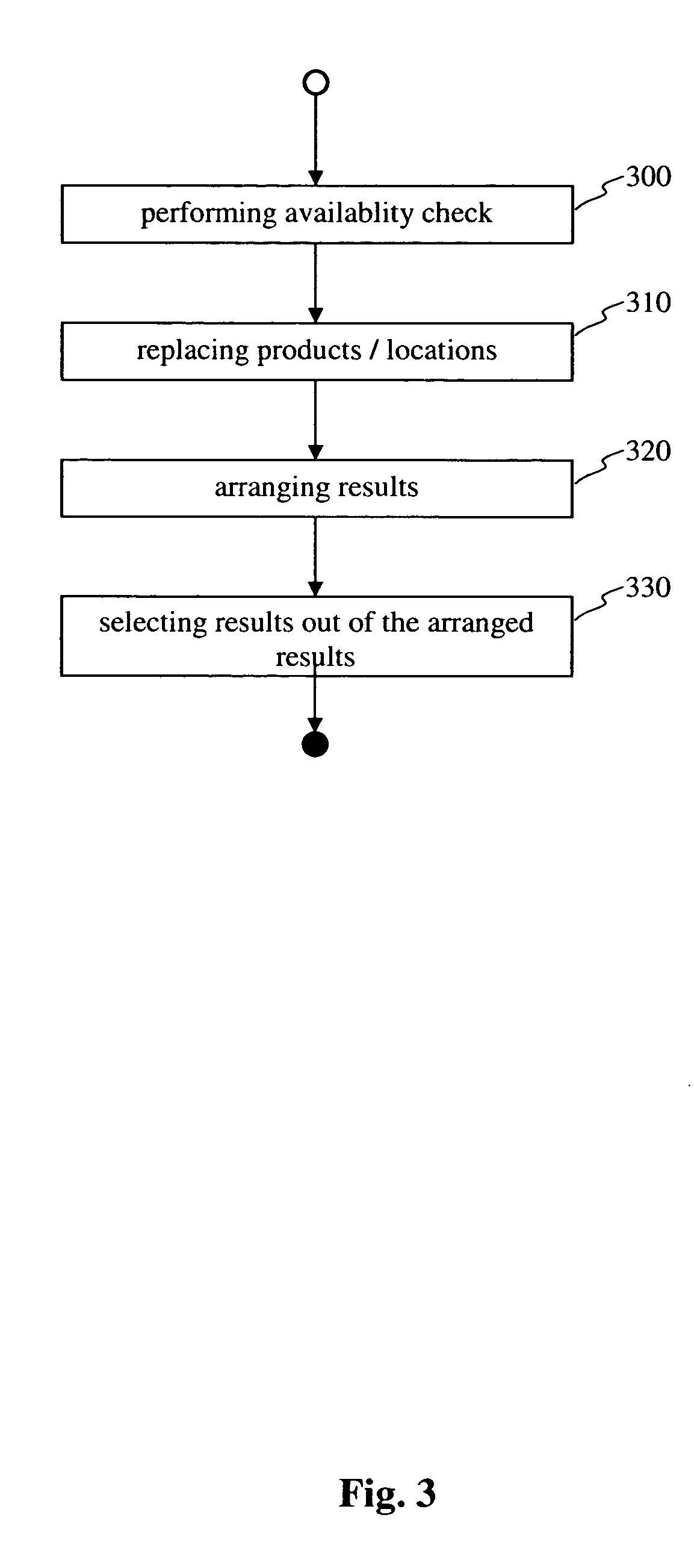

Systems and methods are provided for processing a customer order specifying products and required quantities. In one implementation, a computer-implemented method performs a plurality of availability checks for the specified products with at least one location. Each availability check creates a result that comprises one or more products, locations, and available quantities. The method includes replacing the products and corresponding locations if a sum of available quantities within each of the results does not correspond to a required quantity of the specified products. The results may be arranged according to product and location. Further, the method may include selecting a plurality of results from the arranged results, wherein at least one of a number of different locations and a number of different products within the plurality of results is predetermined.

Owner:SAP AG

Systems, methods, and articles of manufacture for performing product availability check

ActiveUS20060036516A1Overcome excessive storage spaceSave storage spaceHand manipulated computer devicesDigital data processing detailsData setData element

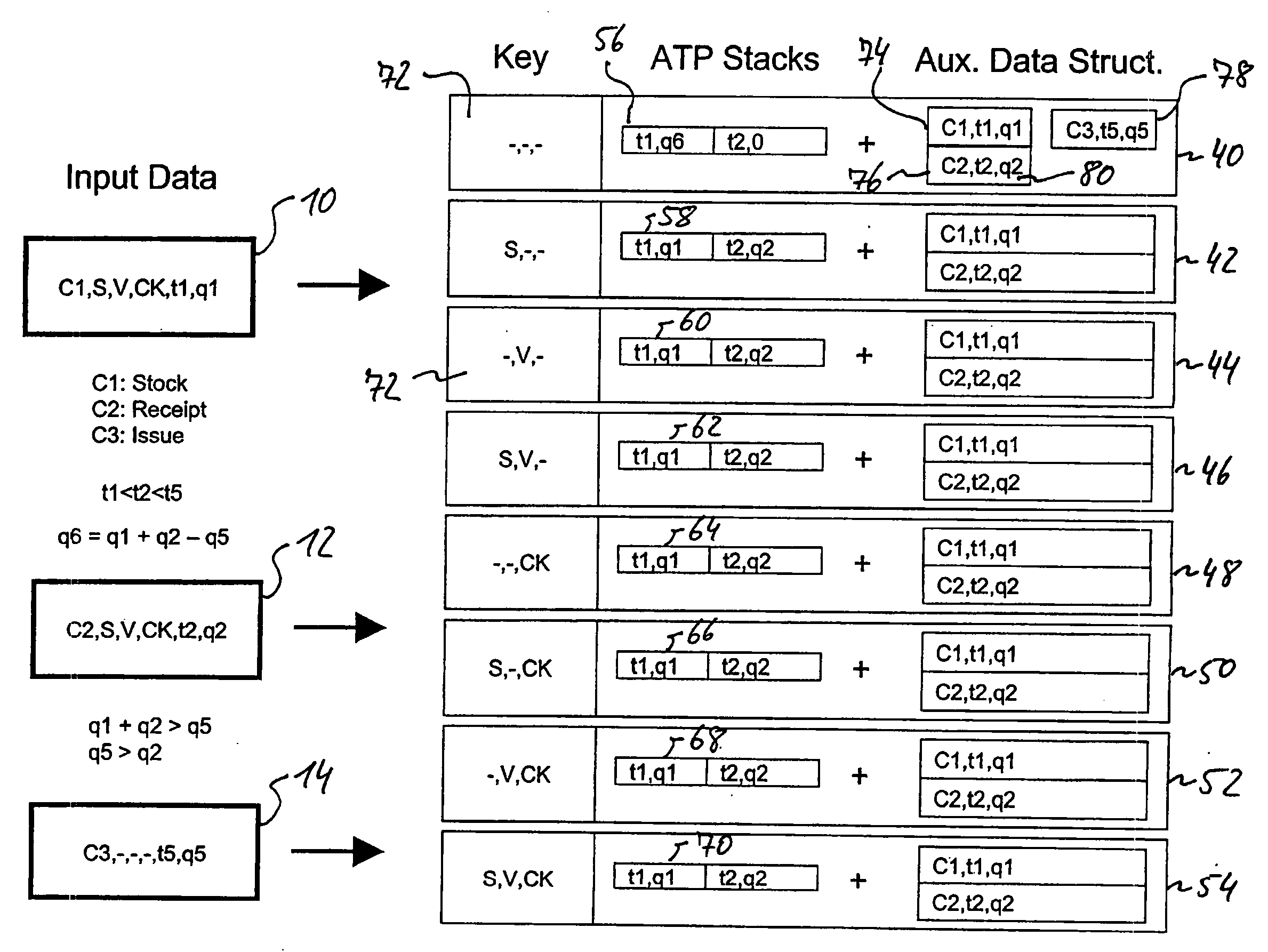

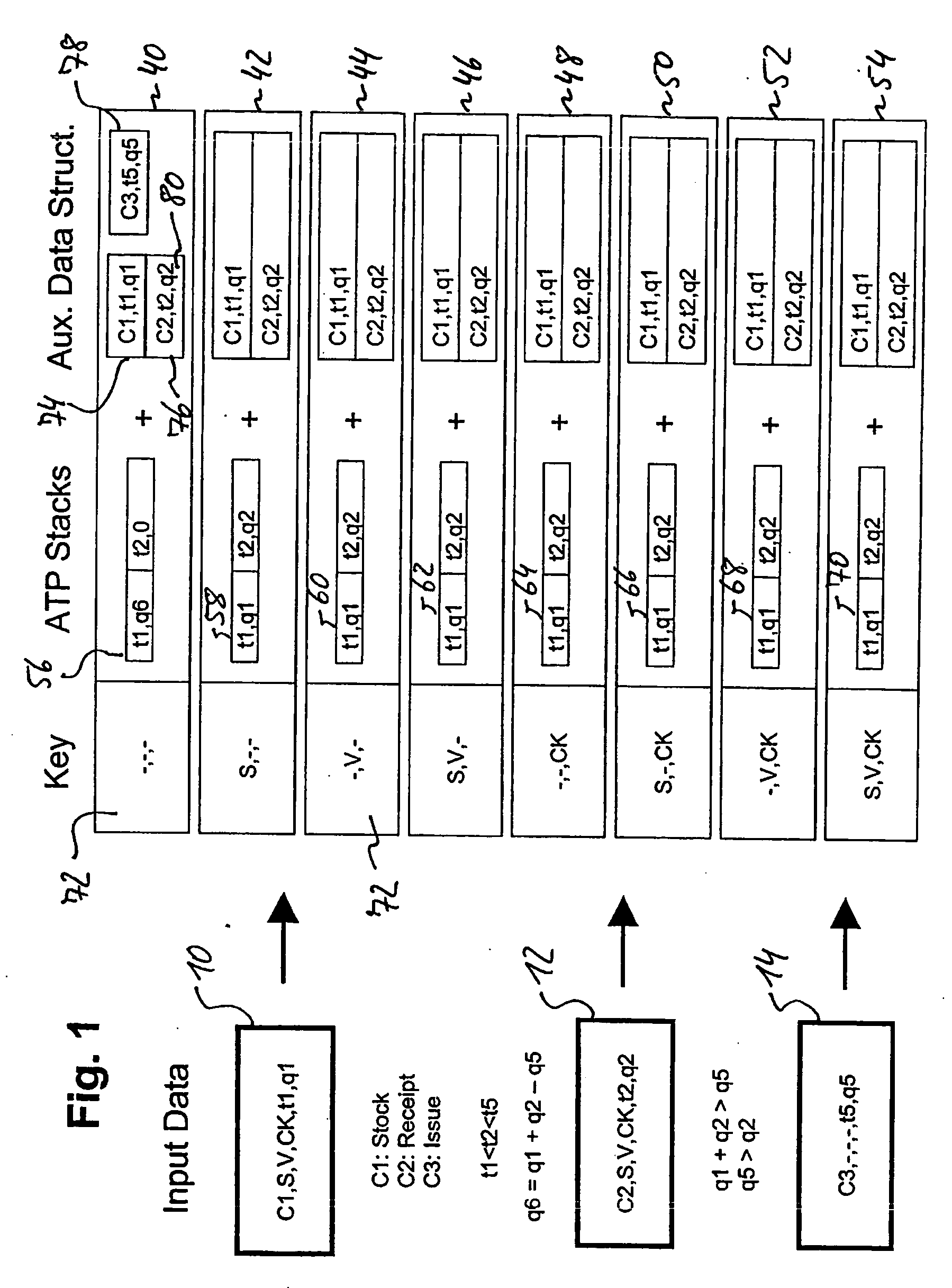

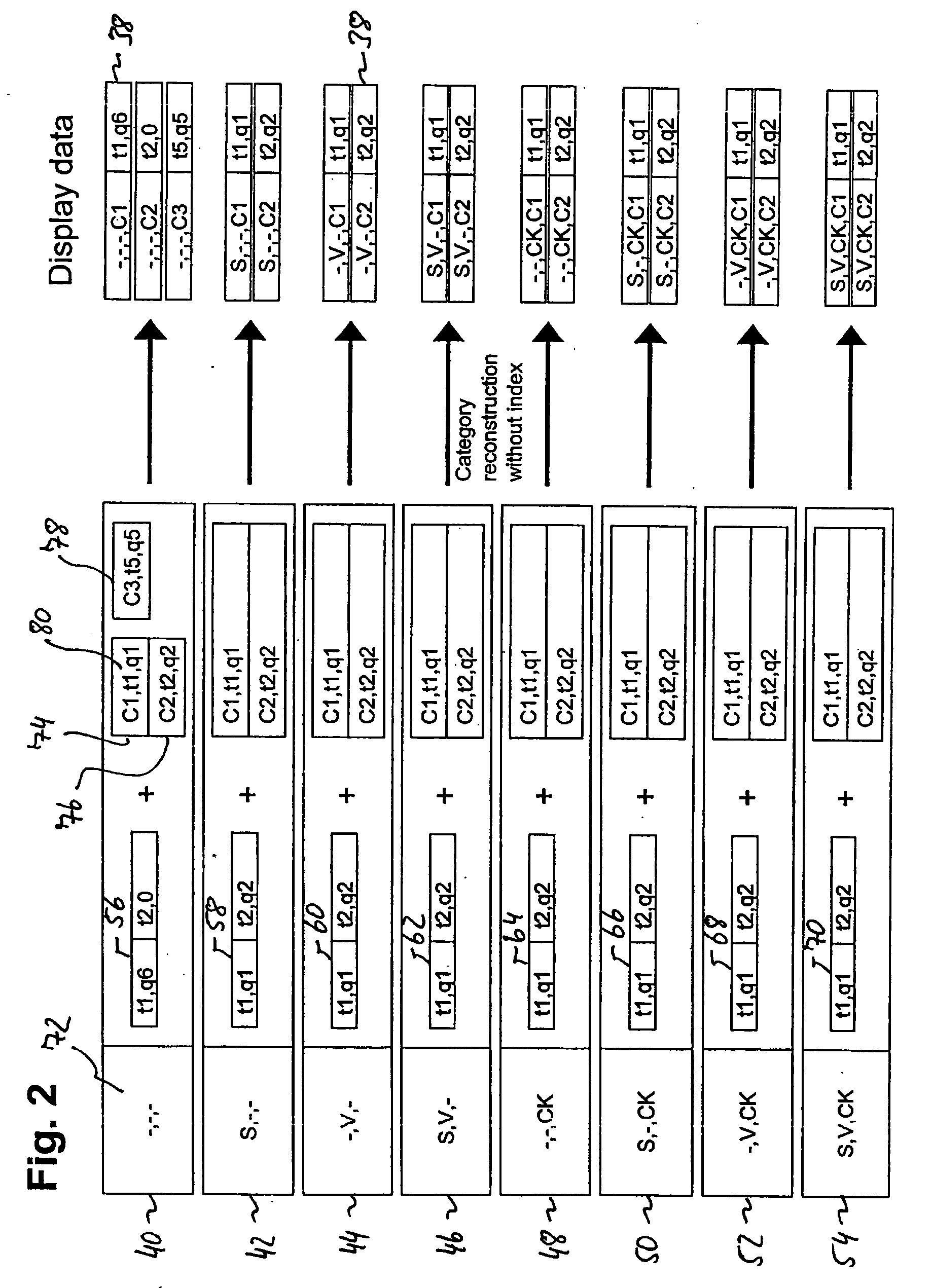

A computer-implemented method of performing a product availability check comprises the step of receiving information on a plurality of first electronic data sets, each of which includes a first key and a product quantity in relation to a single point of time or time period. The first key includes a primary key element and a plurality of secondary key elements representative of product-related conditions each. The method further comprises the step of deriving, based on the information on the first data sets, information on one or more second electronic data sets, each of which includes a second key and product quantities in relation to a series of points of time or time periods. The second key is formed exclusively of the secondary key elements. Based on the information on the one or more second data sets, result information on the availability of one or more products in dependence of time and the primary and secondary key elements is then derived. According to the invention, the information on the one or more second data sets is generated to further include in each second data set one or more auxiliary data structures, each auxiliary data structure including one or more auxiliary data elements, each auxiliary data element including the primary key element, product quantity and point of time or time period as included in a respective first data set that contributes to the time-dependent product quantities in the corresponding second data set.

Owner:SAP AG

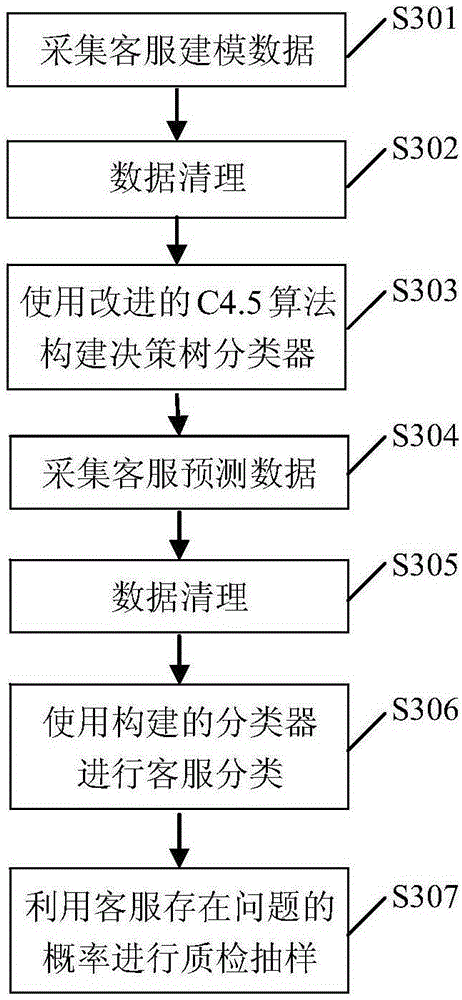

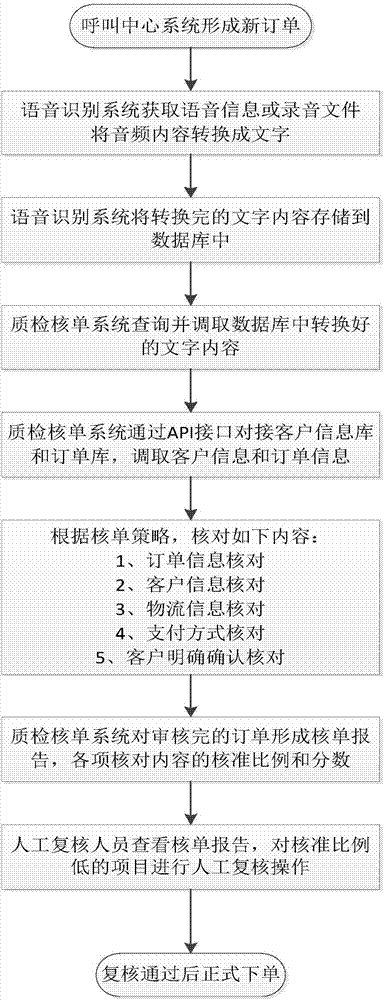

Quality inspection treatment method and system

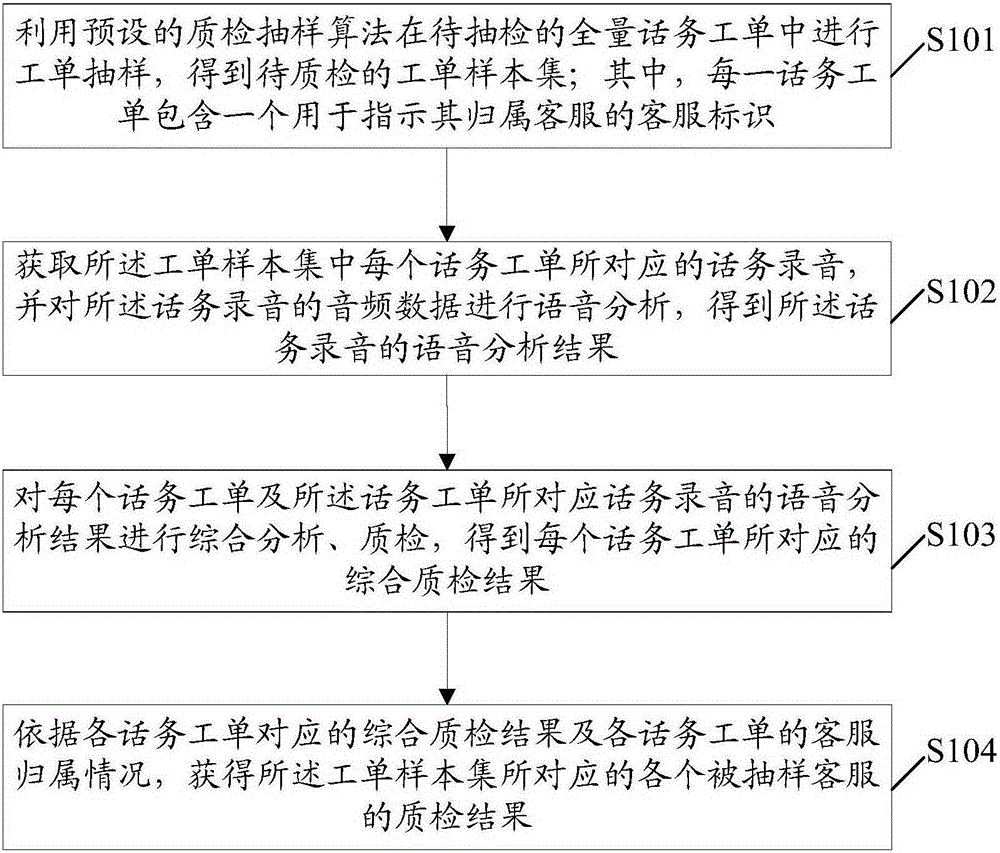

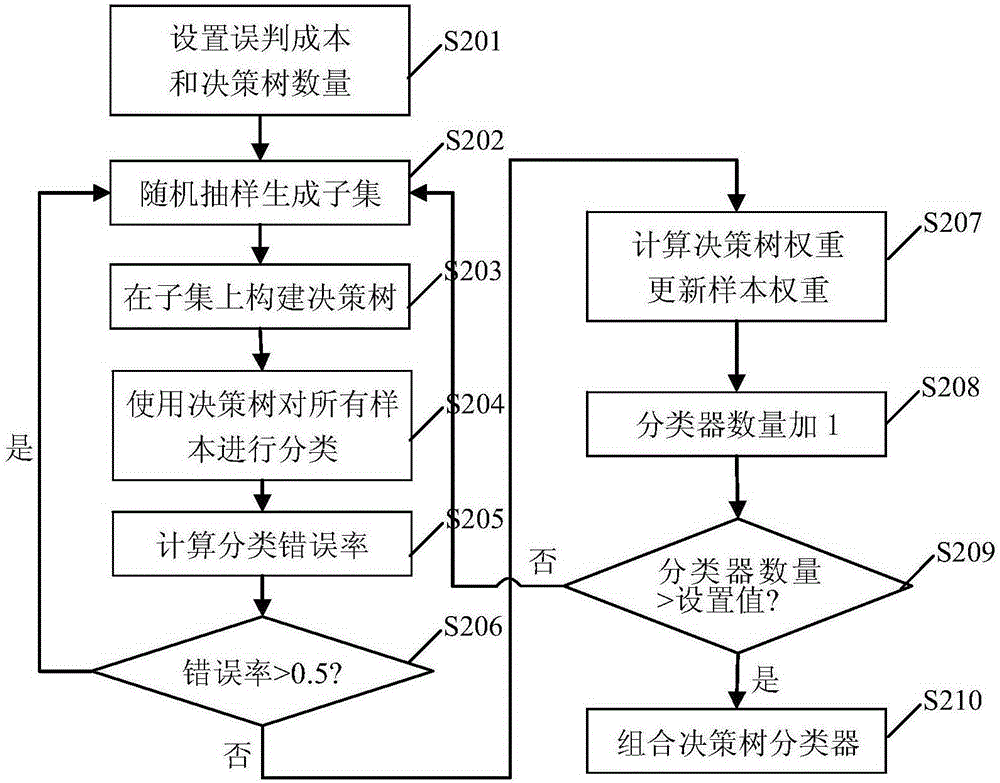

ActiveCN105184315AFully automatedOvercome resourcesCharacter and pattern recognitionResourcesVisual inspectionVoice analysis

The present application provides a quality inspection treatment method and a system. After the work order sampling process, all traffic orders to be subjected to quality inspection are obtained. After that, the data of a recorded audio file corresponding to each traffic order is subjected to voice analysis. Meanwhile, the comprehensive analysis and the quality inspection for each traffic order and the voice analysis result of the corresponding recorded audio file are conducted, so that a comprehensive quality inspection result is obtained. Finally, according to the comprehensive quality inspection result of each traffic order and the customer service ownership condition of the traffic order, the quality inspection result of each sampled customer service corresponding to the traffic order can be obtained. In this way, the quality inspection process for the customer service is automatically realized. Therefore, the problems that the existing manual quality inspection manner is large in occupancy of human resources, poor in quality inspection efficiency and not objective in quality inspection result in the prior art can be solved.

Owner:BEIJING CHINA POWER INFORMATION TECH +3

Synchronization access technology of transforming web page

InactiveCN101539932AReduce processingAvoid repeated conversionsTransmissionSpecial data processing applicationsAccess methodUsability

The invention relates to a synchronization access method of a transforming web page, which is as follows: a transformation engine transforms a WEB page returned by a network server according to the access request of a user into a WAP web page; the transformed web page is returned to the user and cached; after the request of the user accessing the web page is received again, firstly, usability check is carried out on the cached and transformed web page; if the cached and transformed web page can be used, the transformed web page is directly returned to the user; if the cached and transformed web page can not be used, the access request of the user is transmitted into a corresponding network server; the web page returned by the network server is transformed and returned to the user; the new transformed web page is cached again to replace the former caching web page in a buffer. In a fitting time period, only primary transformation on the same WEB page can meet the access requirements of the same web page, thus speeding up processing speed, saving processing time and increasing treating capability.

Owner:HUAWEI TECH CO LTD

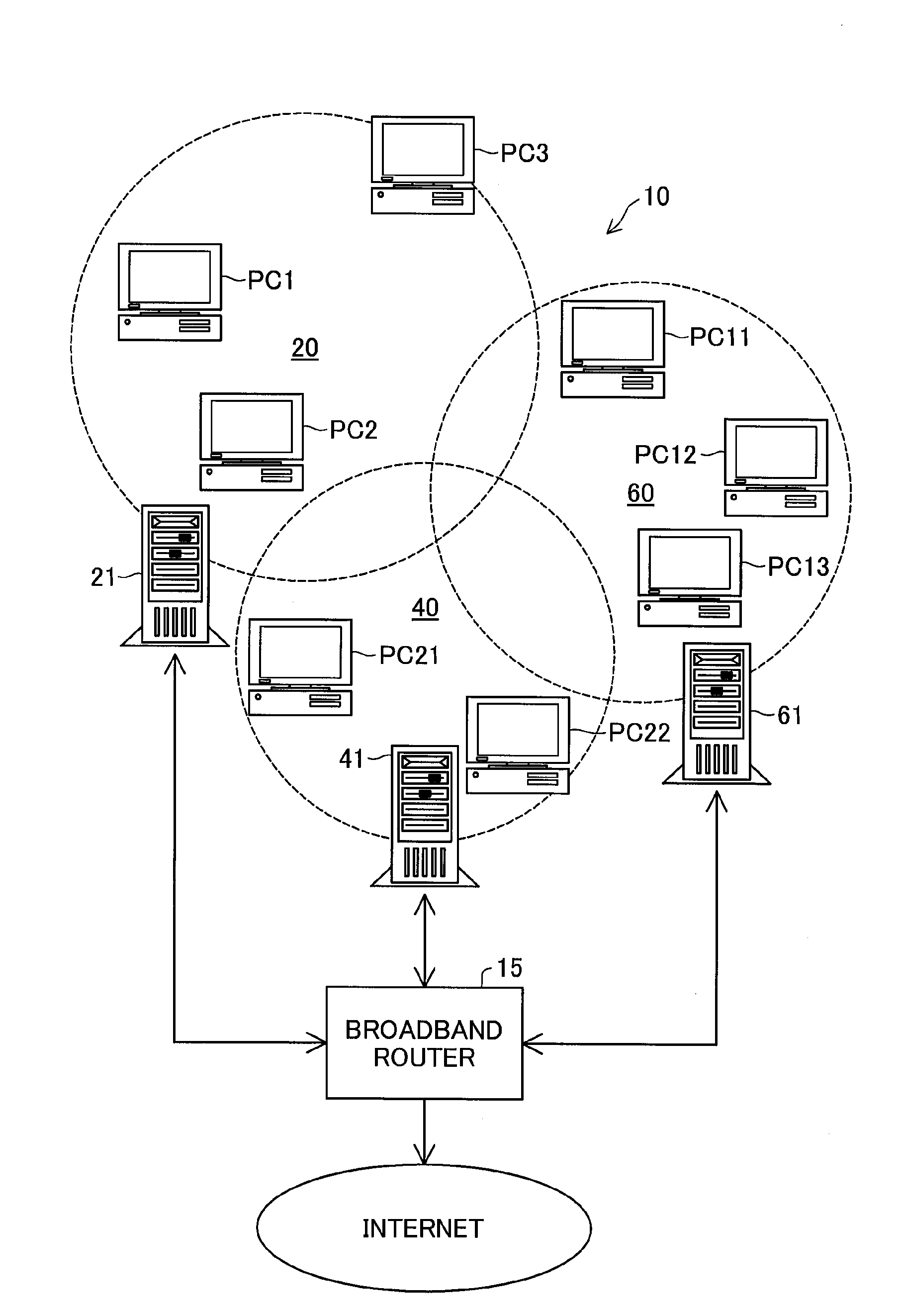

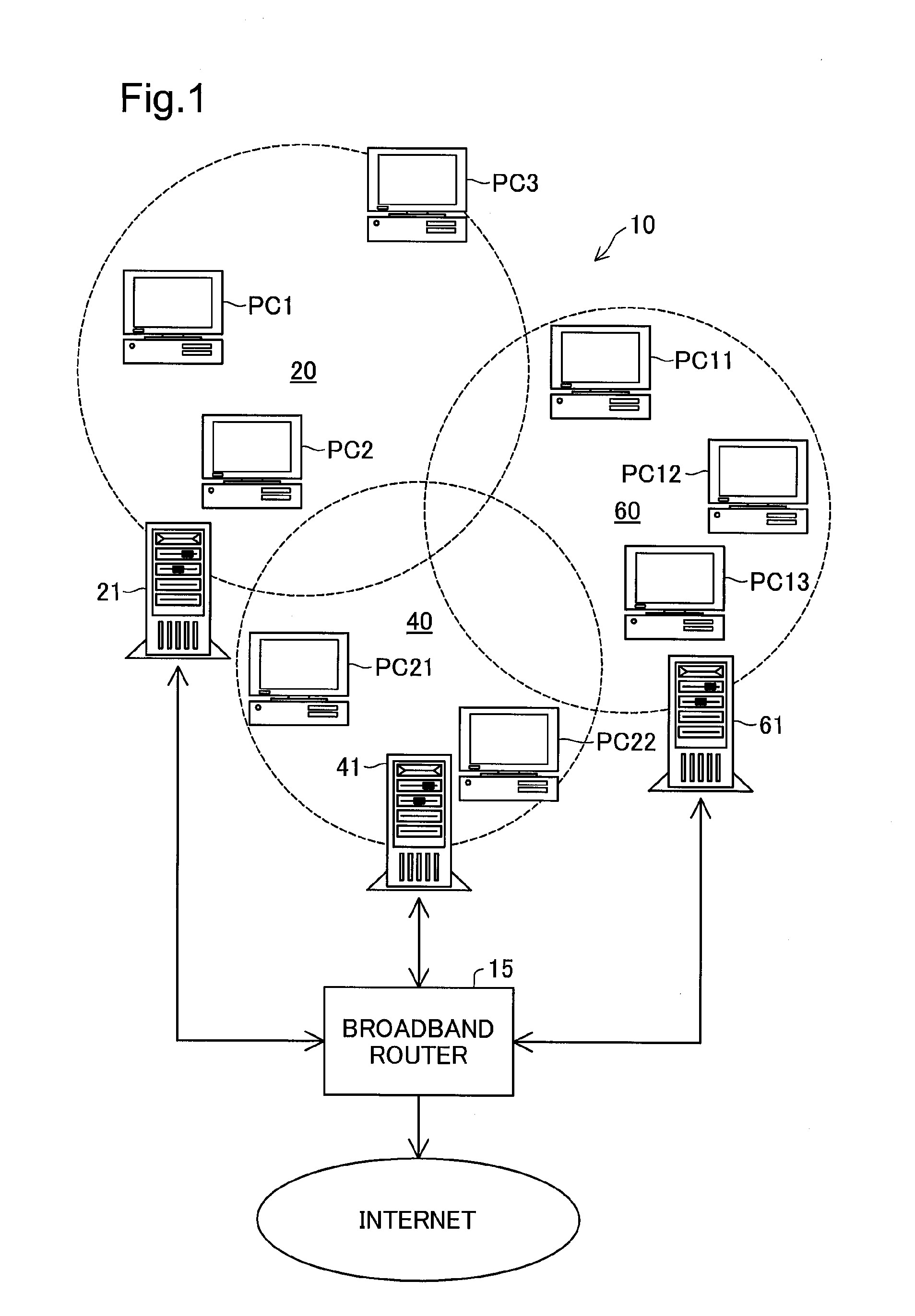

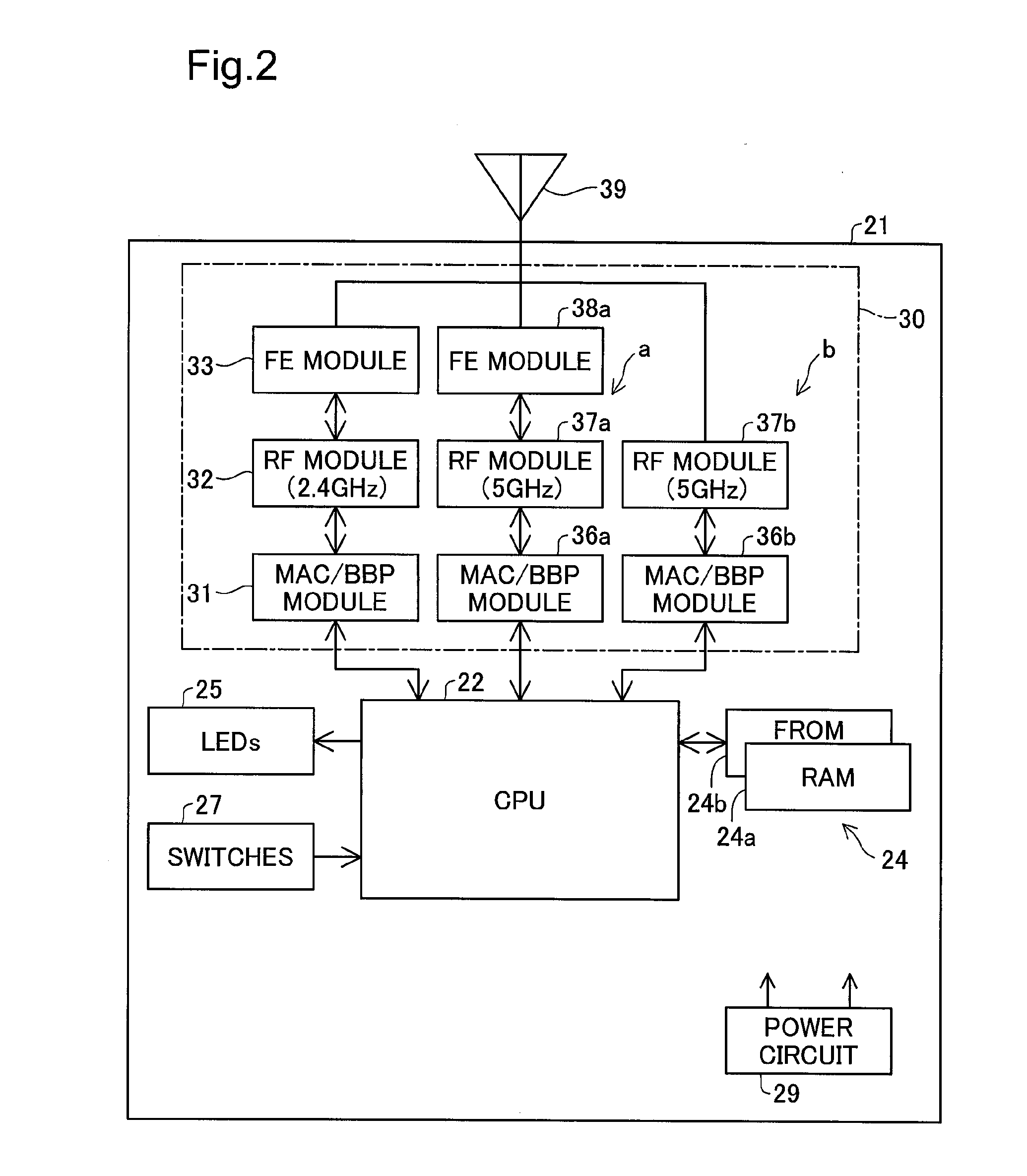

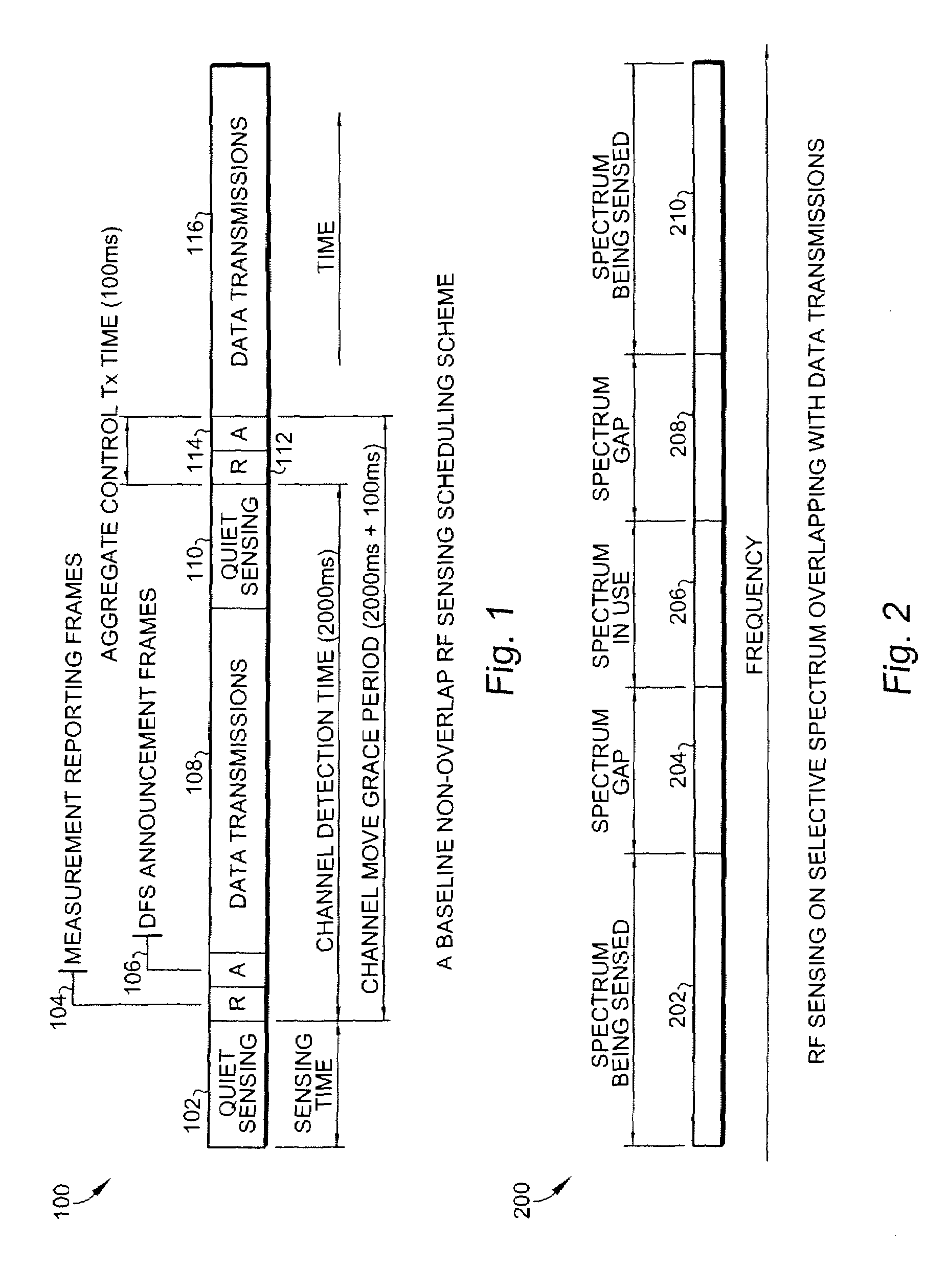

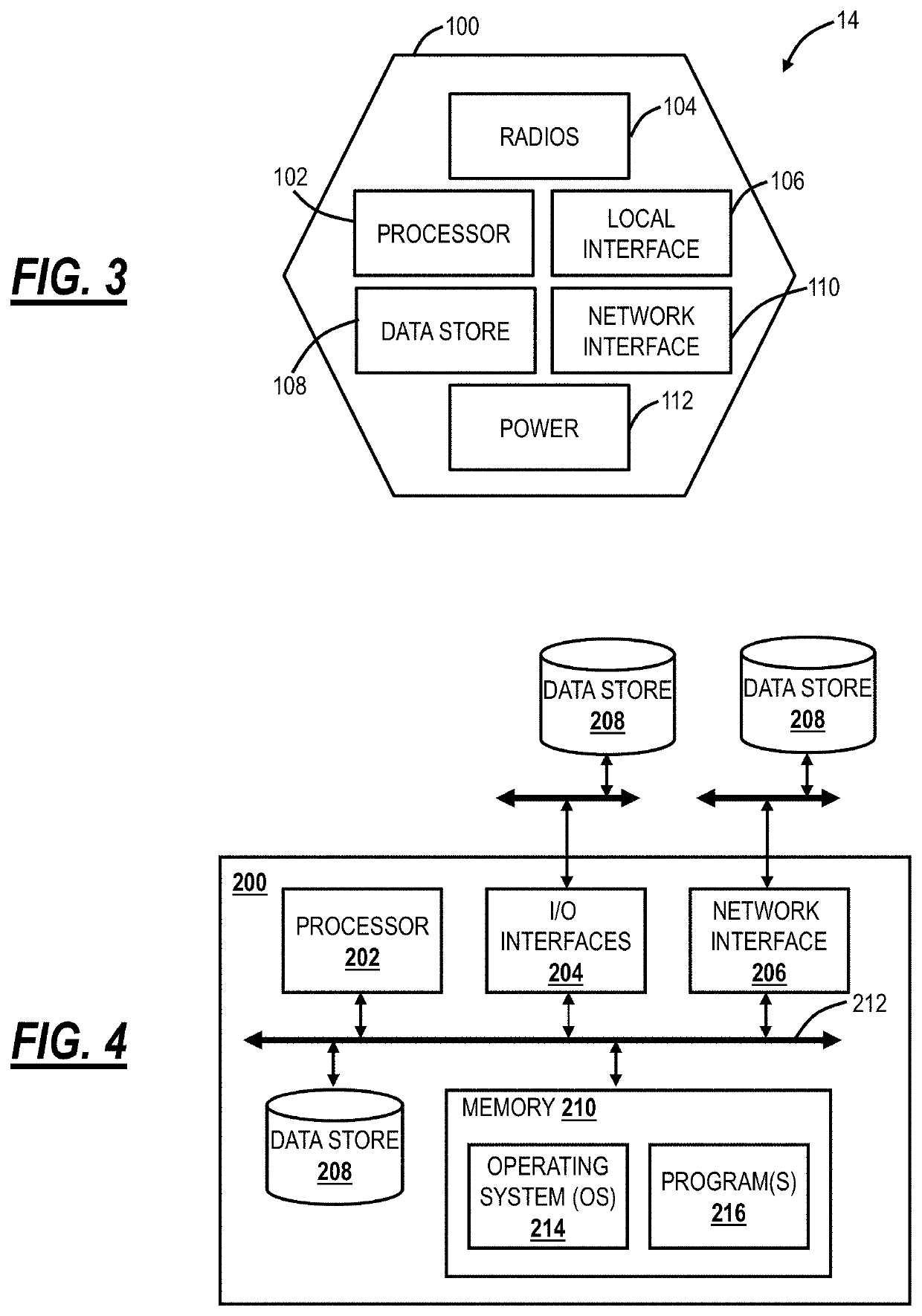

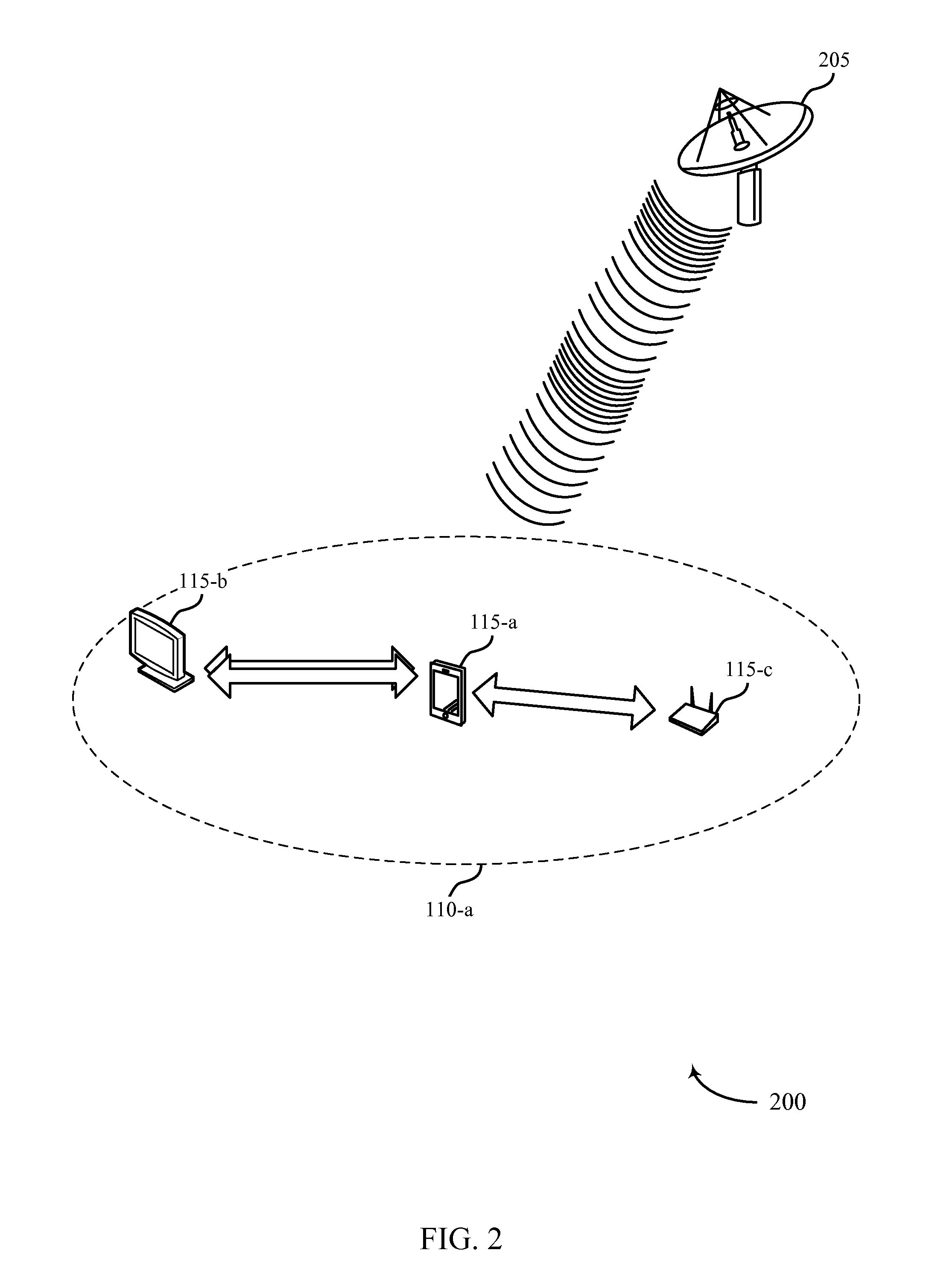

Wireless communication device, wireless communication system, and wireless communication method

ActiveUS20100302966A1Reduce distractionsAvoid disturbanceWave based measurement systemsError preventionWeather radarCommunications system

An access point establishing a wireless LAN is constructed to have a monitor system ‘b’ for monitoring an available channel for communication, in addition to a communication system ‘a’. In the event of detection of radar / radio signals, the access point changes a communication channel used for wireless communication from a current active channel to the monitored channel. Each terminal belonging to the wireless LAN recognizes and follows this channel change by detection of a beacon broadcasted by the access point. In the case of non-detection of radar / radio signals for one minute at the monitored channel, the wireless communication is reestablished immediately at the monitored channel recognized as a CAC (channel availability check)-finished channel. This series of processing is also applicable to inter-access point communication, for example, communication in a WDS (wireless distribution system) mode. This arrangement desirably prevents the potential interruption of wireless communication in a 5 GHz frequency band for a significant period, in the event of detection of radar / radio signals, for example, a weather radar.

Owner:BUFFALO CORP LTD

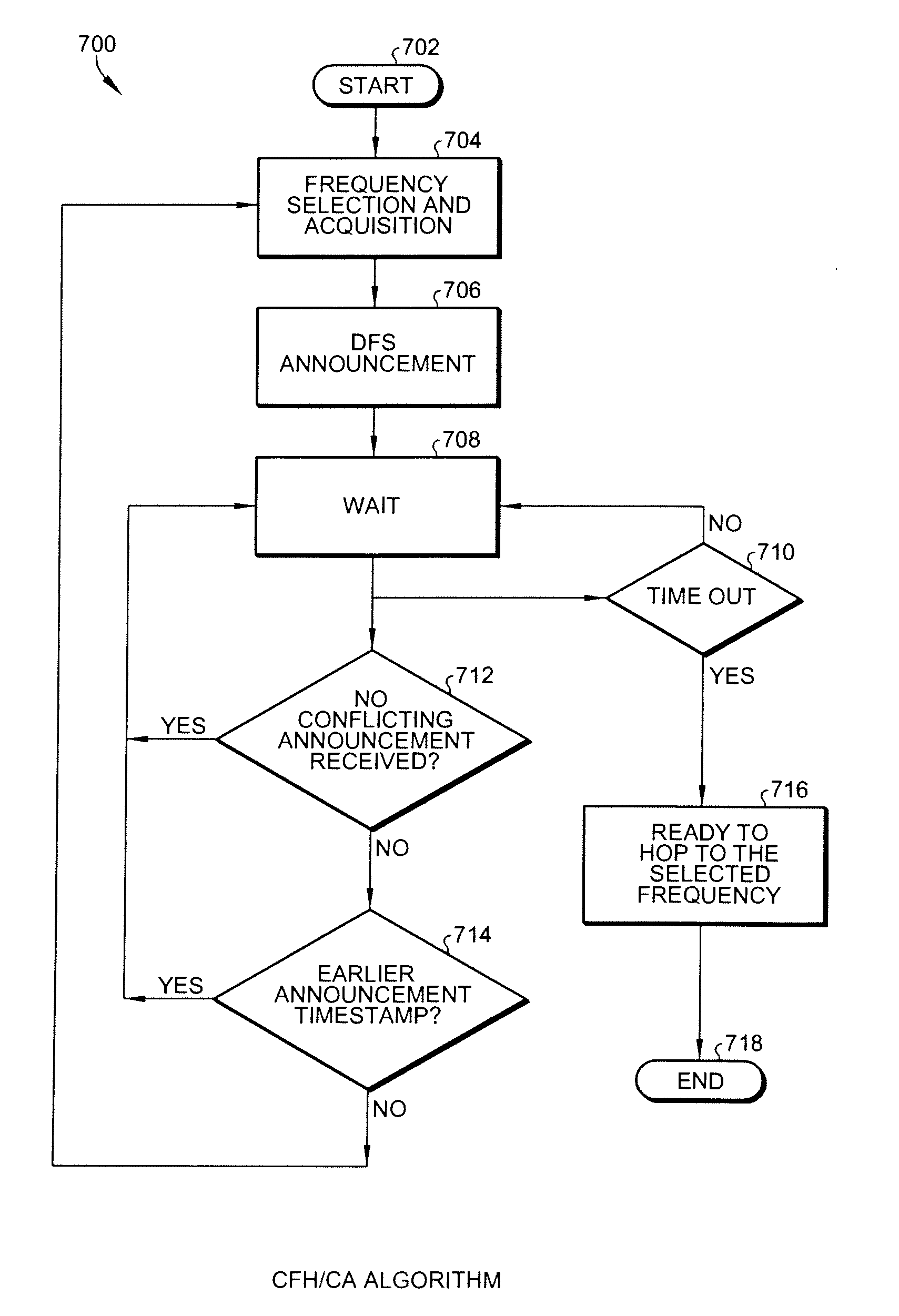

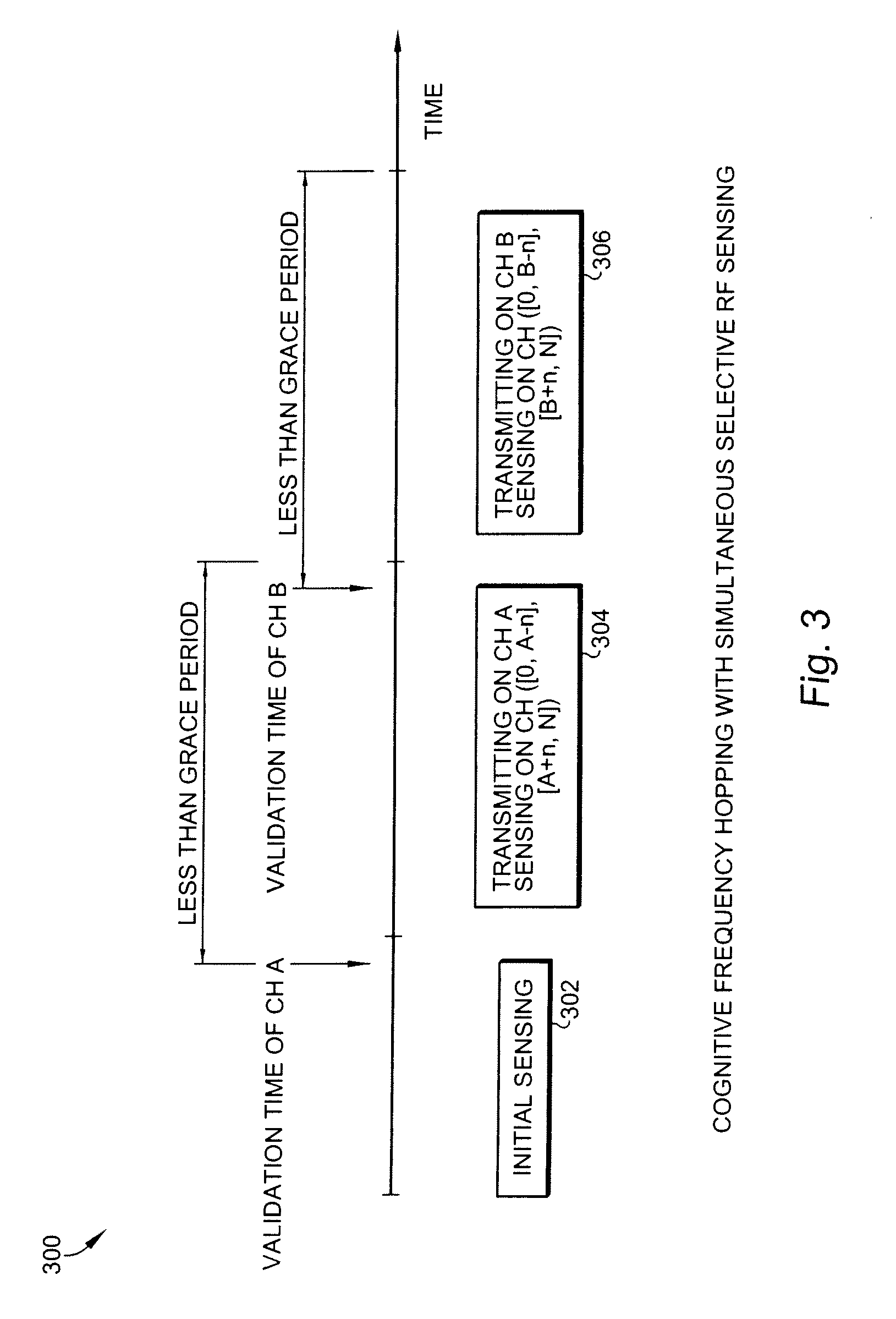

Zero delay frequency switching with dynamic frequency hopping for cognitive radio based dynamic spectrum access network systems

ActiveUS20080089389A1DelayWireless commuication servicesTransmissionAccess networkFrequency spectrum

This invention relates to cognitive radio based wireless communications of dynamic spectrum access networks, and in particular to a method of addressing zero-delay frequency switching for cognitive dynamic frequency hopping. The method combines regular (periodic) channel maintenance with dynamic frequency hopping over a cluster of vacated channels that are initially setup such that the switching delays for channel setup and channel availability check are eliminated.

Owner:STMICROELECTRONICS SRL

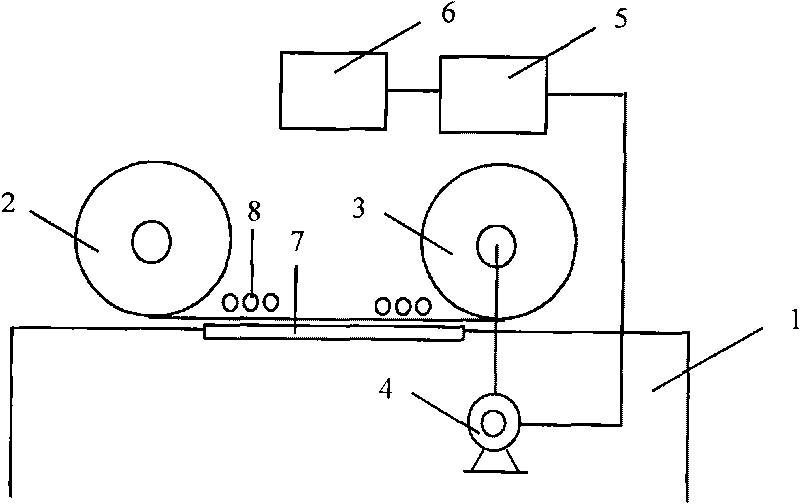

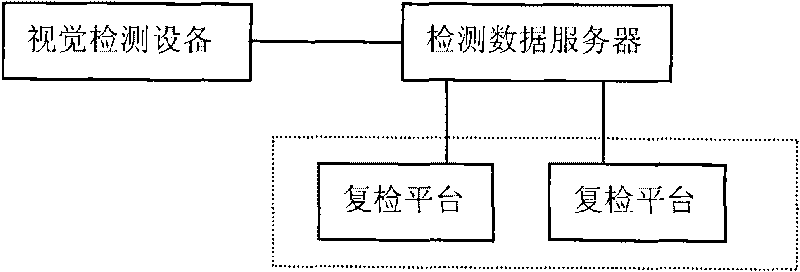

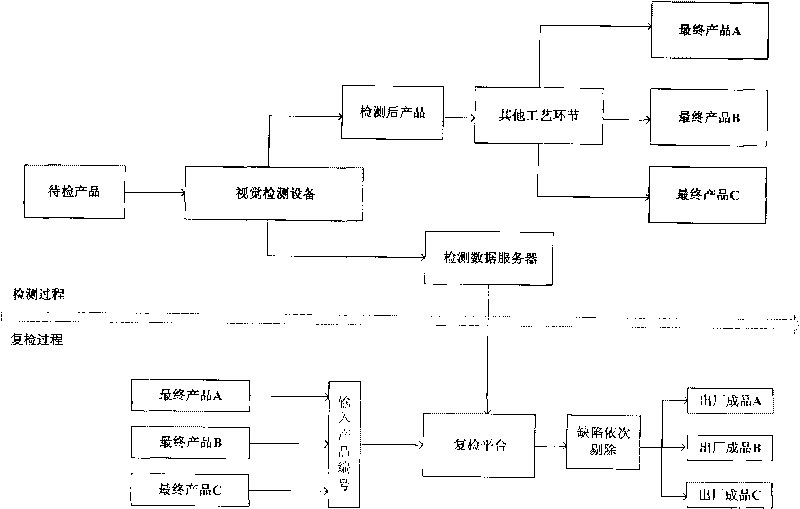

Recheck platform and quality inspection system of prints

InactiveCN101738396AReduce the burden onEasy to operateOptically investigating flaws/contaminationMicrocontrollerLocation detection

The invention discloses a recheck platform which is used for rechecking defects in quality inspection of prints and comprises a rack, a working table, an unwinding wheel, a winding wheel, a position detection device, a power device and a microcontroller, wherein, the unwinding wheel and the winding wheel are arranged on the rack; the unwinding wheel transmits the prints to the winding wheel to rewind the prints; the winding wheel is connected with a power device; the position detection device detects the position to which the prints are transmitted and is connected with the microcontroller; the microcontroller stores the position information of defects of the prints and compares with the information of the position when the prints are transmitted to control the power device. The recheck platform can lighten the burden of visual sense detection device, thus the visual sense detection device is only responsible for detection, reconstructs the detection process, separates the process links such as time consuming stopping rejection and label supplementing and the like from the detection process, lowers cost and improves the efficiency of quality detection. The invention also relates to a system adopting the platform to detect the quality of prints.

Owner:BEIJING LUSTER LIGHTTECH

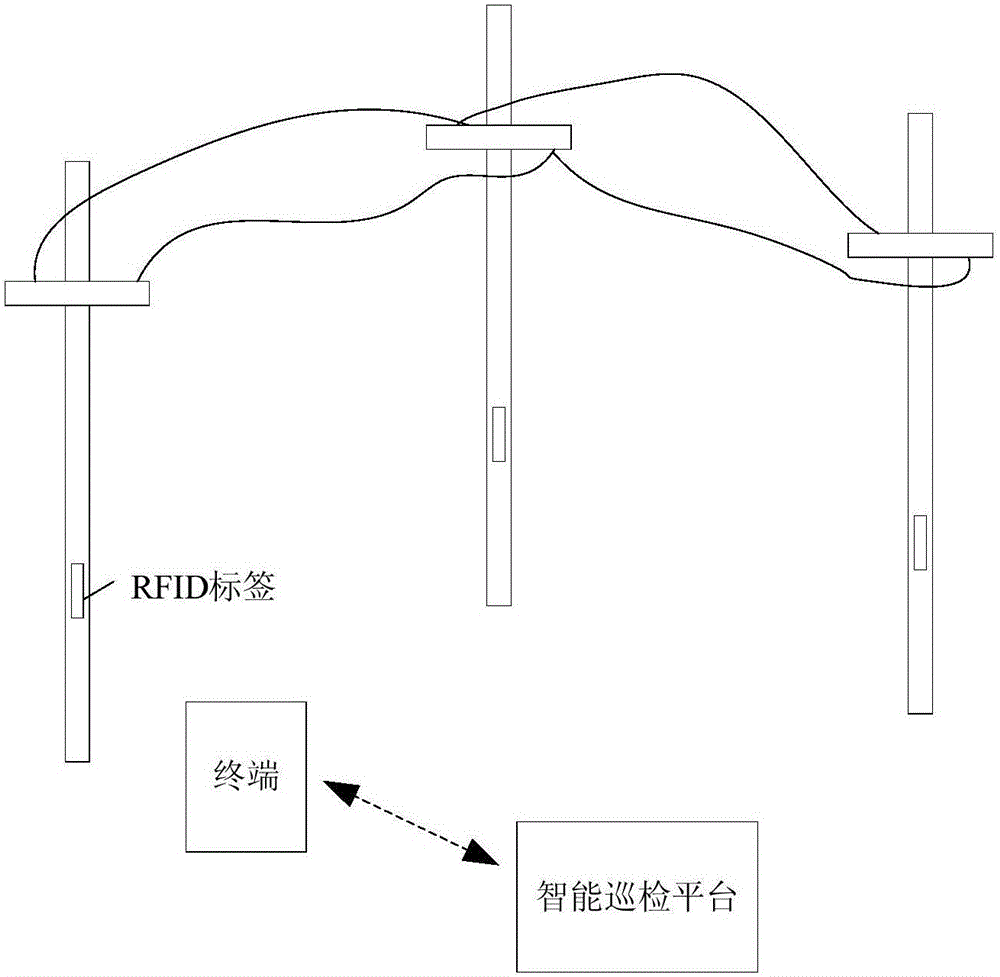

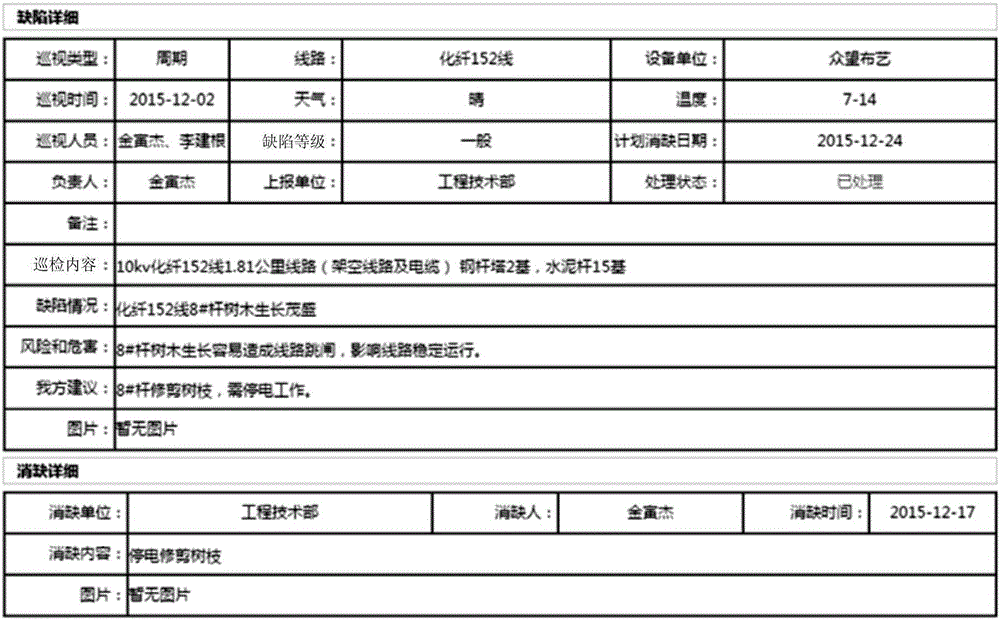

Intelligent inspection system

InactiveCN105825556AInspection quality reachedTimely processingChecking time patrolsCo-operative working arrangementsProgram planningSystem configuration

The invention provides an intelligent inspection system, including a terminal, an intelligent inspection platform and an RFID tag; an intelligent inspection application is installed on the terminal, and the intelligent inspection platform can communicate with the terminal in real time through a wireless network; the RFID tag is set at the inspection point , Form a binding relationship with the inspection point; through the terminal scanning and the RFID tag bound to the inspection point, the inspection work can be quantified. The intelligent inspection platform includes four modules: basic ledger module, defect management module, inspection plan module, and system configuration module; the intelligent inspection application includes four modules: inspection task module, defect management upload module, Defect record module and information management module; managers arrange inspection plans on the Web side, and inspection personnel use handheld terminals to conduct on-site inspections according to the inspection plan, scan the RFID tags on the tower to obtain information and check the basic ledger data, if any defects are found Record defects, and managers can directly view defect records through the web.

Owner:HANGZHOU KAIDA ELECTRIC POWER CONSTR

Single level bill of material available to promise

A computer implemented Availability Checking Tool wherein tool users work within a common work environment, from common enterprise data, and considering assets and demands across multiple order management systems and manufacturing facilities within boundaries established by manufacturing specifications, process flows and business policies. Tool users can easily maintain a synergistic relationship between orders from multiple demand sources or ordering systems. A demand configurator receives demand information from each demand source and coordinates product requests in accordance with customer request rules and priorities. A supply configurator receives manufacturing and planning data from a planning source and manipulates the received manufacturing and planning data to create new supply data. A material resource engine provides material supply information from the new supply data, the received demand information following product supply rules and priorities. A solver for optimizes product availability information in response to the material supply information, product supply rules and priorities. Thus, customer business rule level

Owner:IBM CORP

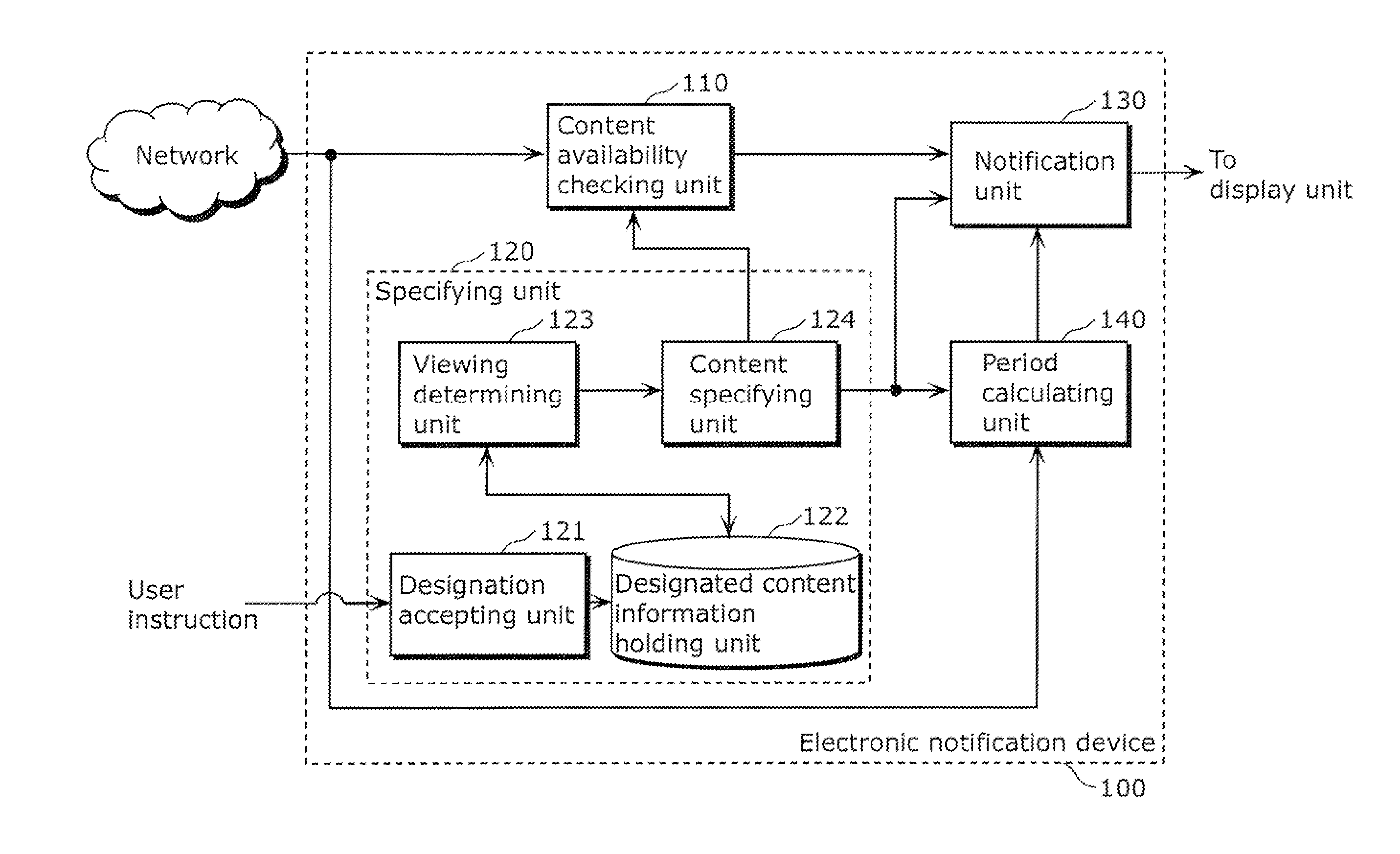

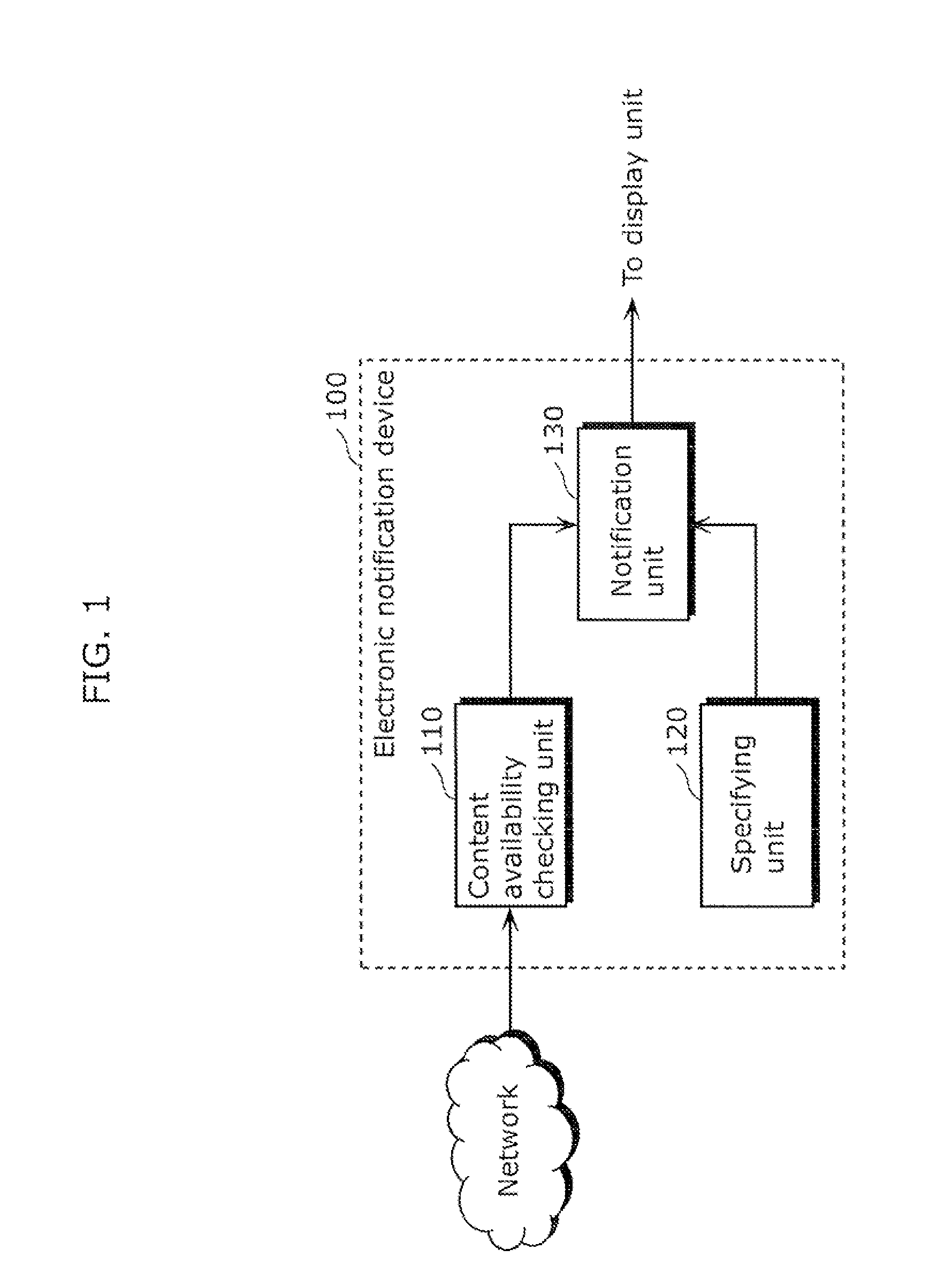

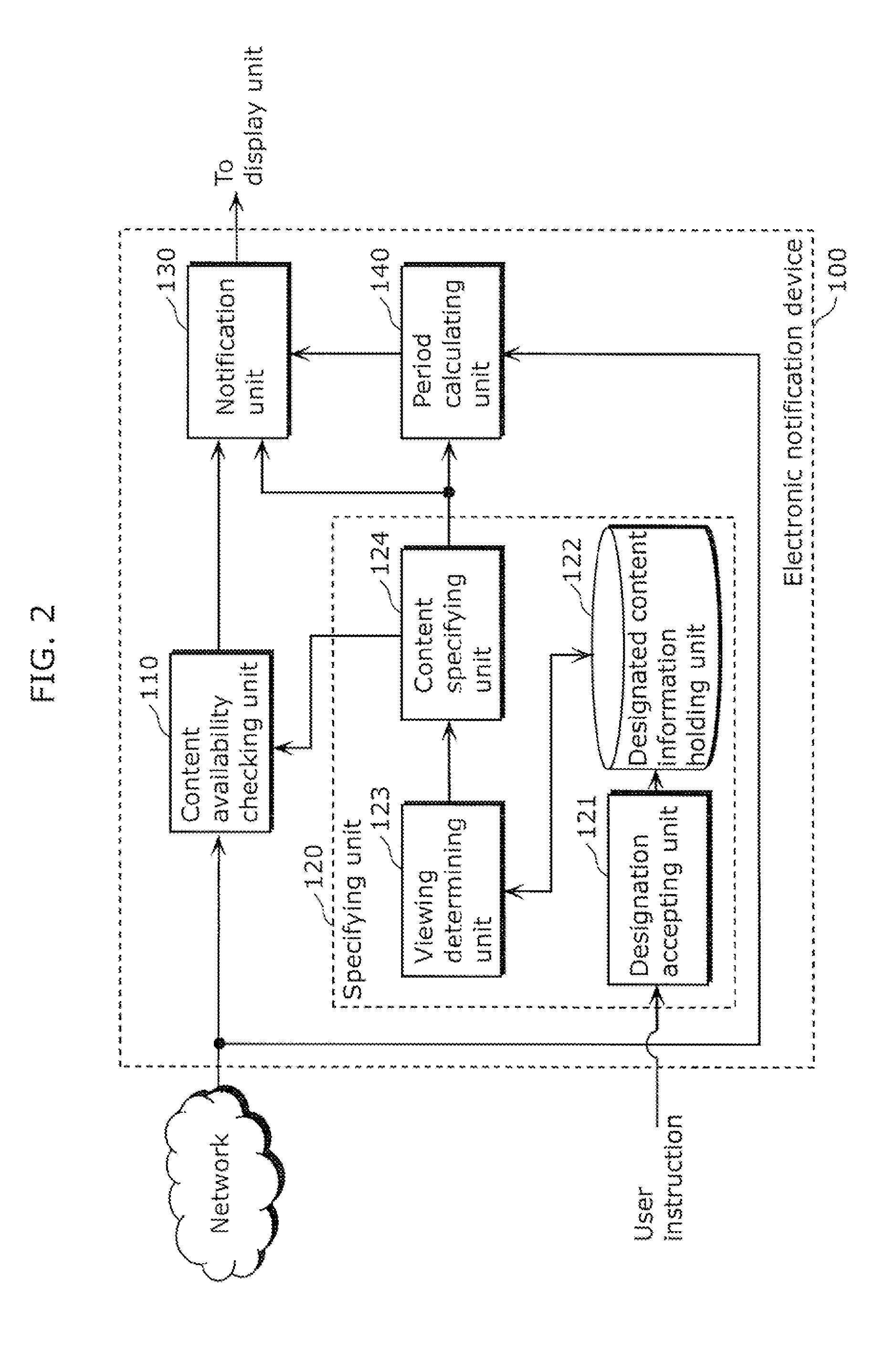

Electronic notification device and electronic notification method

InactiveUS20120030050A1Television system detailsColor television detailsUsability inspectionWorld Wide Web

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

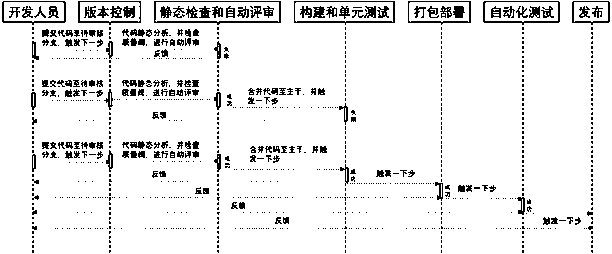

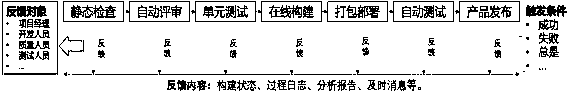

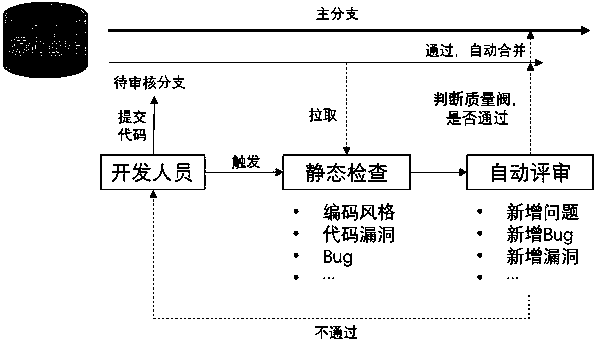

An automatic software system quality inspection and rapid iteration method

InactiveCN109684215AImplement QAFast iterationSoftware testing/debuggingSoftware systemContinuous feedback

The invention discloses an automatic software system quality inspection and rapid iteration method which comprises the following steps: firstly, a developer submits a code to a branch to be audited, and when a monitoring server detects that the branch has code change, a static analysis task is triggered to carry out code automatic review; After the code passes the review, the automatic branches are merged to the trunk and unit testing and online compiling tasks are triggered; When the unit test and the online compiling have no problem, packaging and deploying are carried out, and meanwhile anautomatic system software test is started; And finally, the tested software product is published. According to the method, the automation level of software research and development is improved; The complexity of manual review is reduced; An automatic test framework of multiple languages is established, the manual participation cost is reduced, and manpower resources are saved; A continuous feedback mechanism of each stage of software system research and development is established, problems occur, feedback is conducted in time, and engineering software quality control is achieved.

Owner:中国科学院电子学研究所苏州研究院

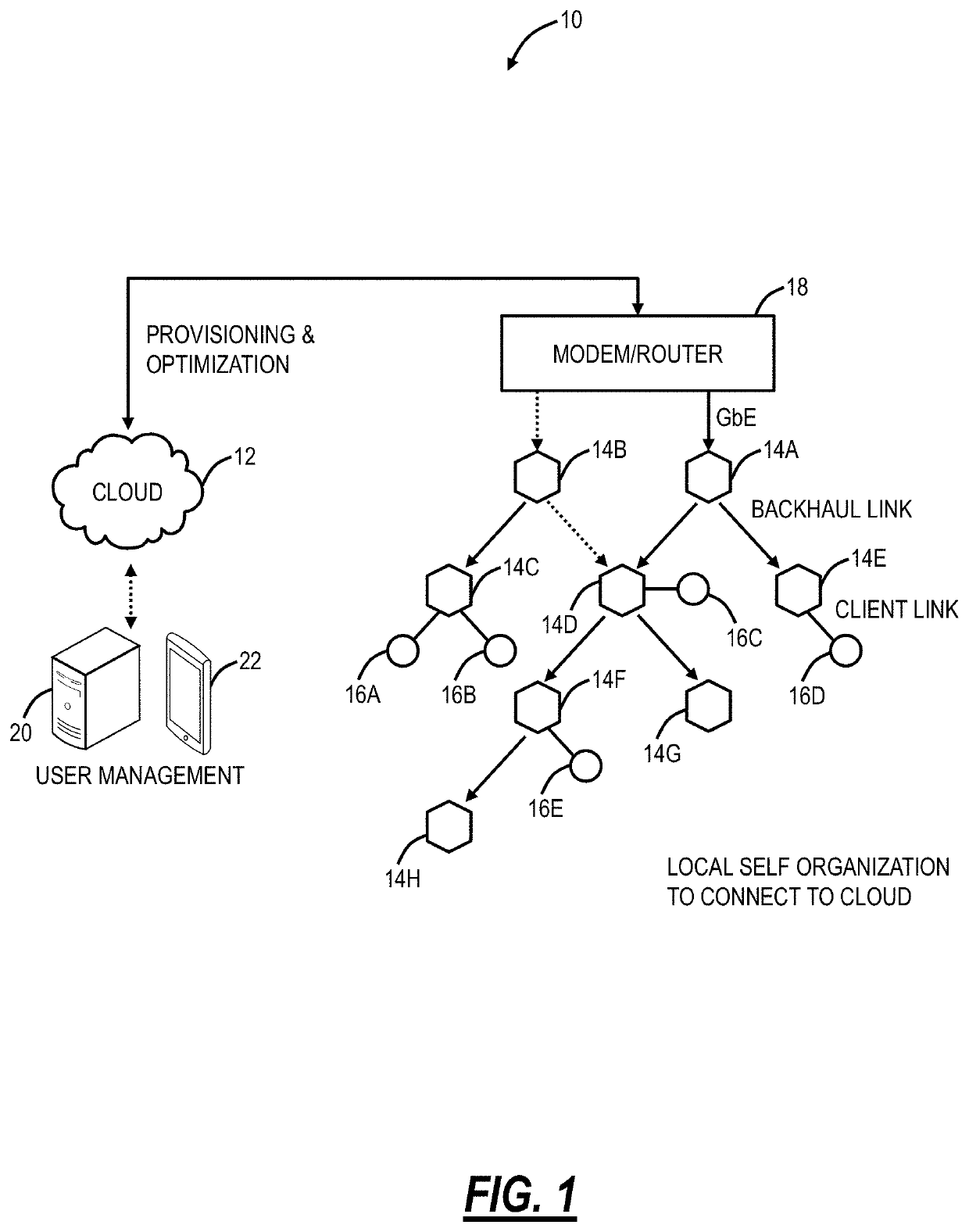

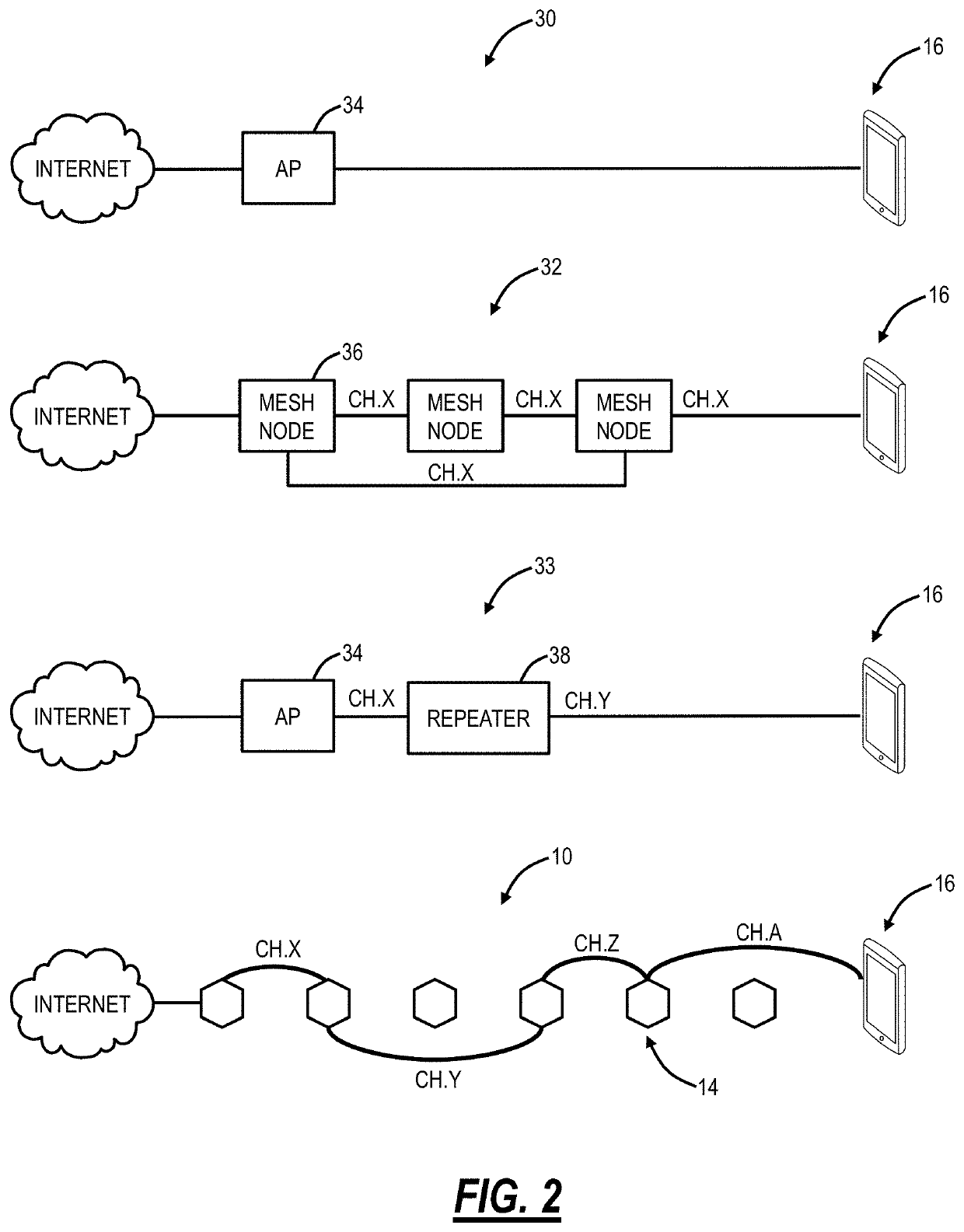

Dynamic frequency selection in distributed Wi-Fi networks

A Wi-Fi system includes a plurality of access points each configured to operate on a plurality of channels including Dynamic Frequency Selection (DFS) frequency channels and non-DFS frequency channels; and at least one access point of the plurality of access points is connected to a controller, wherein the controller is configured to coordinate usage of the plurality of channels between the plurality of access points including usage of the DFS frequency channels pursuant to predetermined DFS rules. One or more access points of the plurality of access points are configured to perform DFS measurements for a Channel Availability Check (CAC) and the DFS measurements are provided to the controller.

Owner:PLUME DESIGN INC

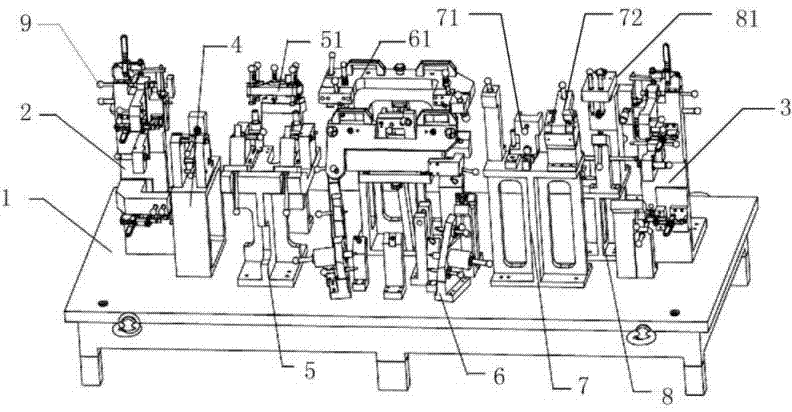

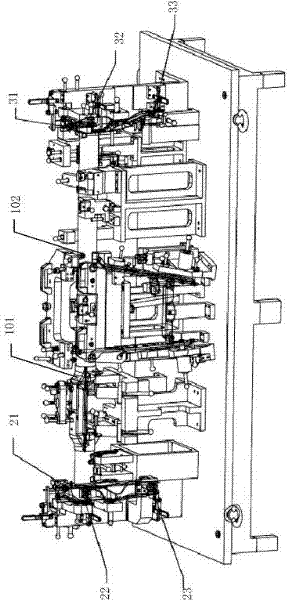

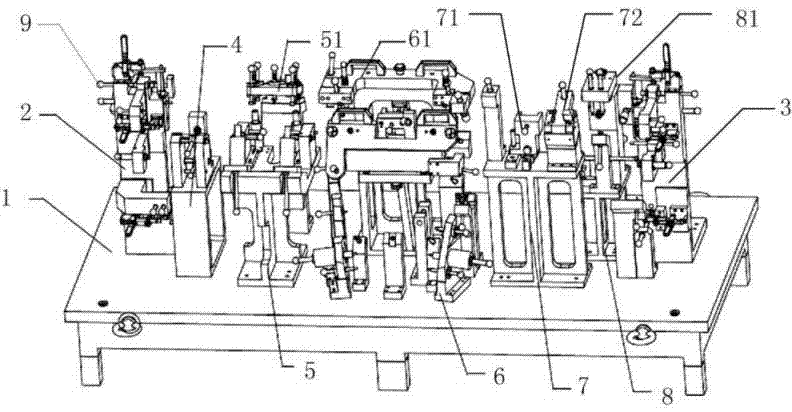

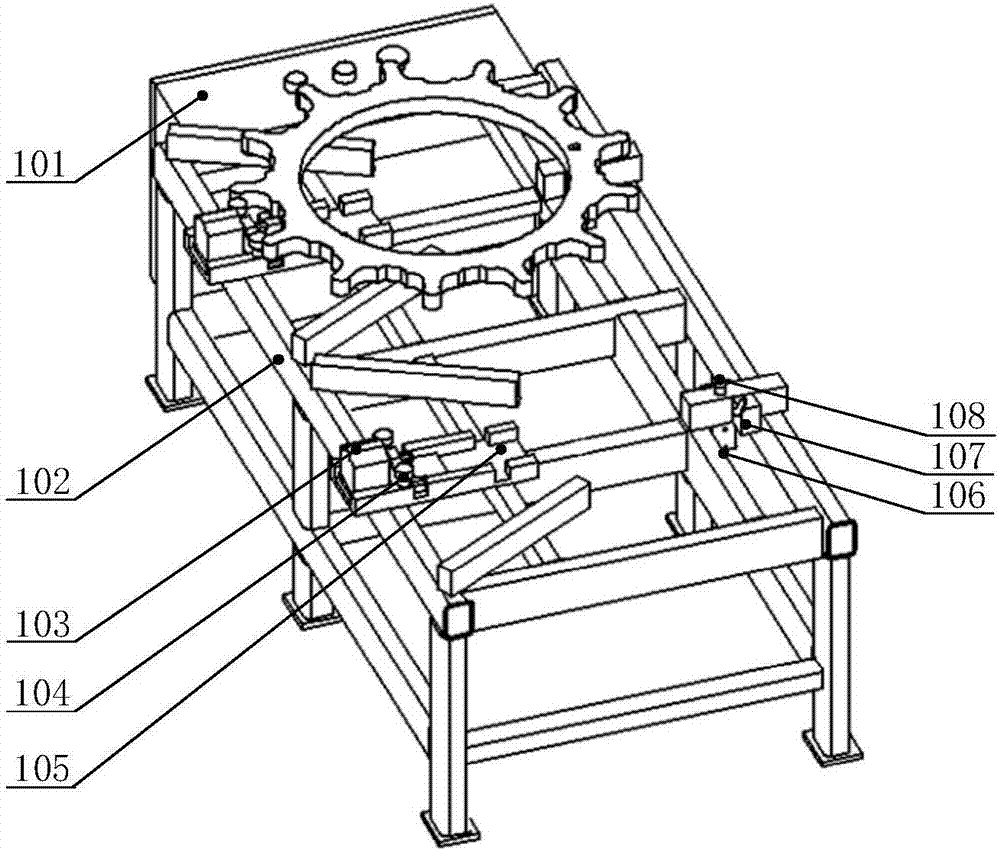

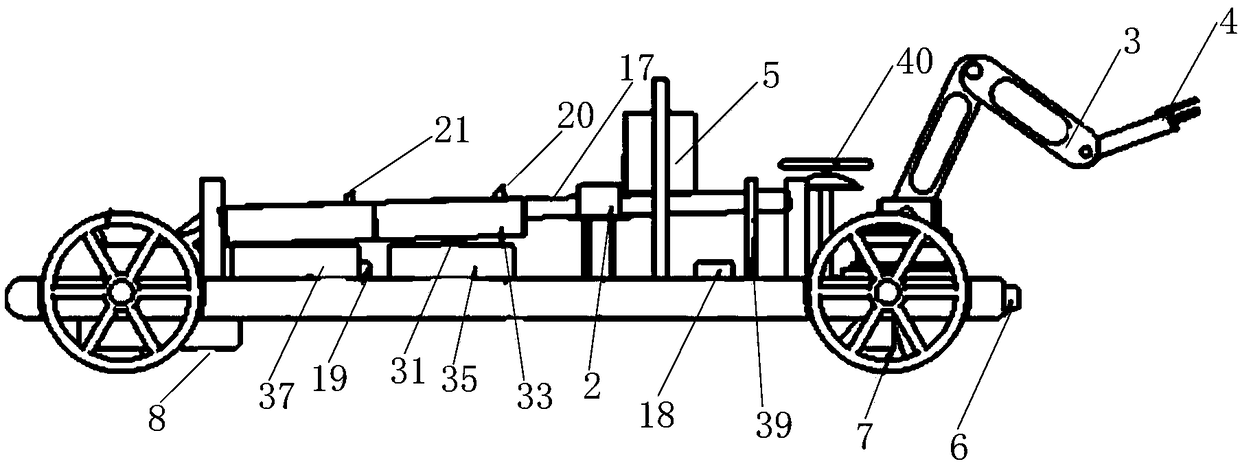

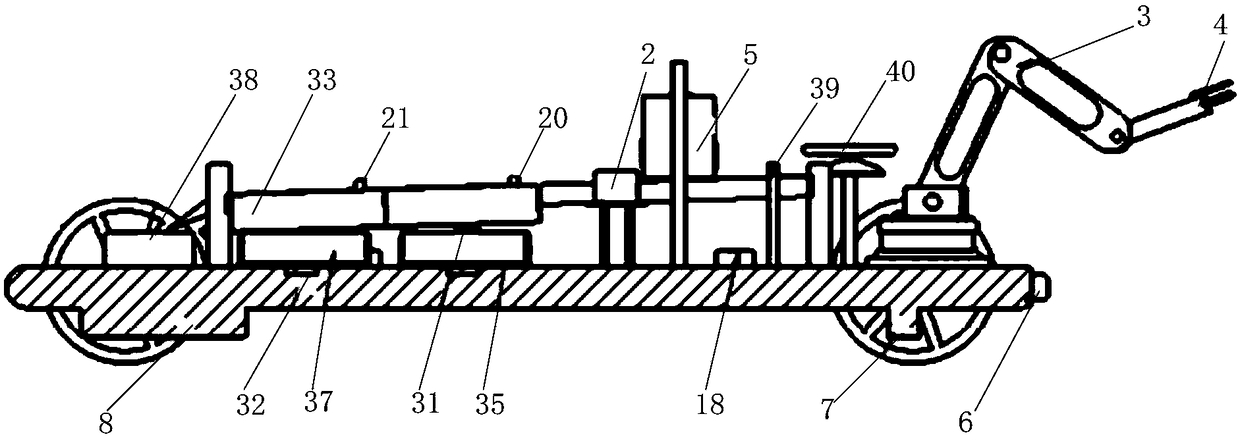

Inspection tool for automobile instrument panel support

InactiveCN102419144ASimple structureLow costMechanical diameter measurementsDashboardVisual inspection

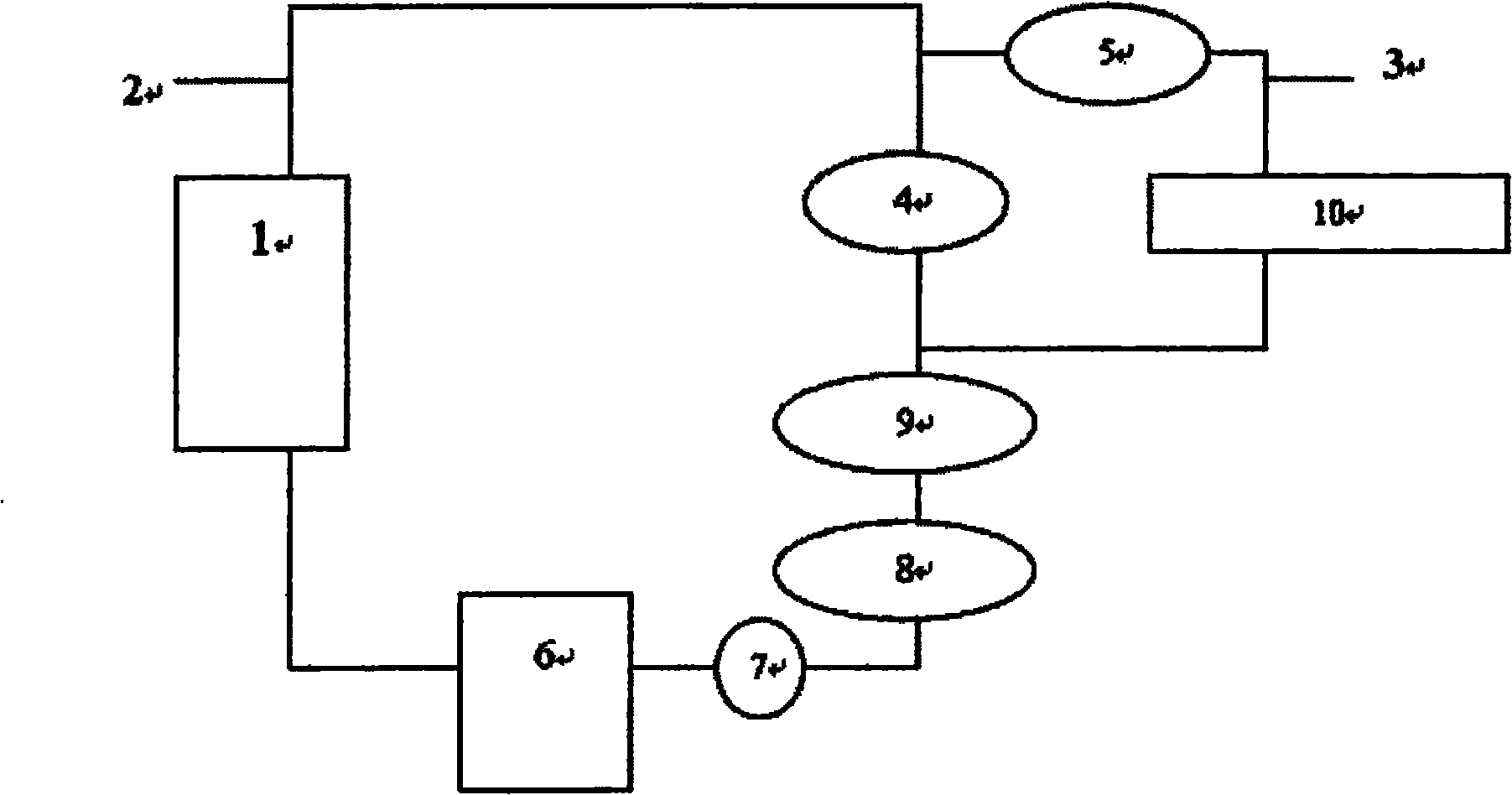

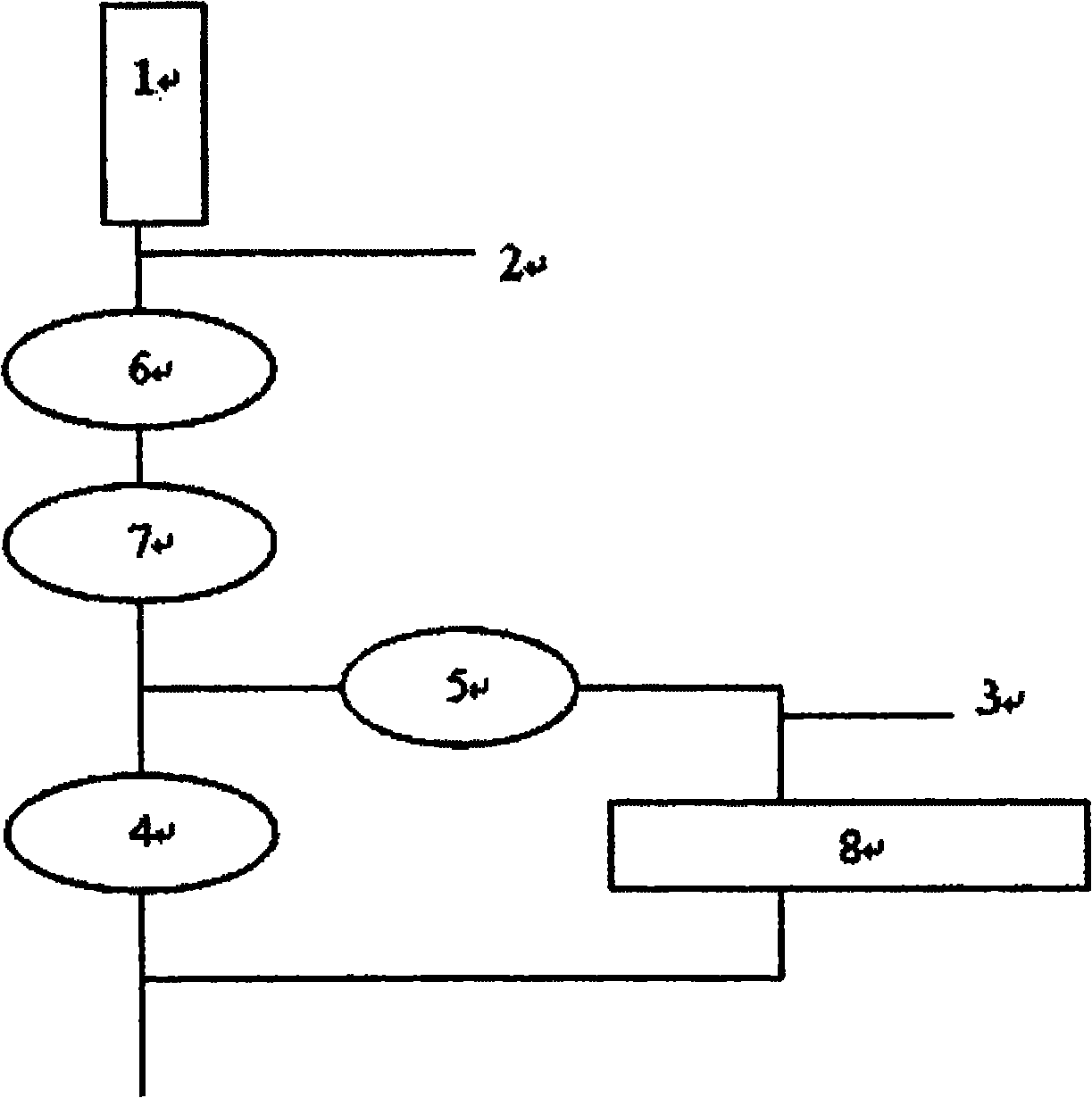

The invention discloses an inspection tool for an automobile instrument panel support, which is used for quality inspection of a to-be-detected automobile instrument panel support (101), wherein a plurality of installing holes (102) are arranged in the automobile instrument panel support (101), the automobile instrument panel support (101) comprises a base (1), a left end rack (2) and a right end rack (3) which are symmetrically arranged are fixed on the base (1), the position of the base (1), which is between the left end rack (2) and the right end rack (3), is sequentially provided with five supporting vertical racks: a first supporting vertical rack (4), a second supporting vertical rack (5), a third supporting vertical rack (6), a fourth supporting vertical rack (7) and a fifth supporting vertical rack (8), and the positions of the supporting racks correspond to the structure of the automobile instrument panel support (101). According to the inspection tool, the inspection speed and accuracy are improved, the operation is convenient and quick, the inspection efficiency and accuracy are high, the design requirements and the production quality requirements of a product are met, the structure is simple, and the cost is low.

Owner:奇昊汽车系统(苏州)有限公司

Quality inspection and control system for medicinal compositions

ActiveCN102038757AImprove product qualityThe production process is stable and controllableComponent separationAntipyreticAutomatic controlControl system

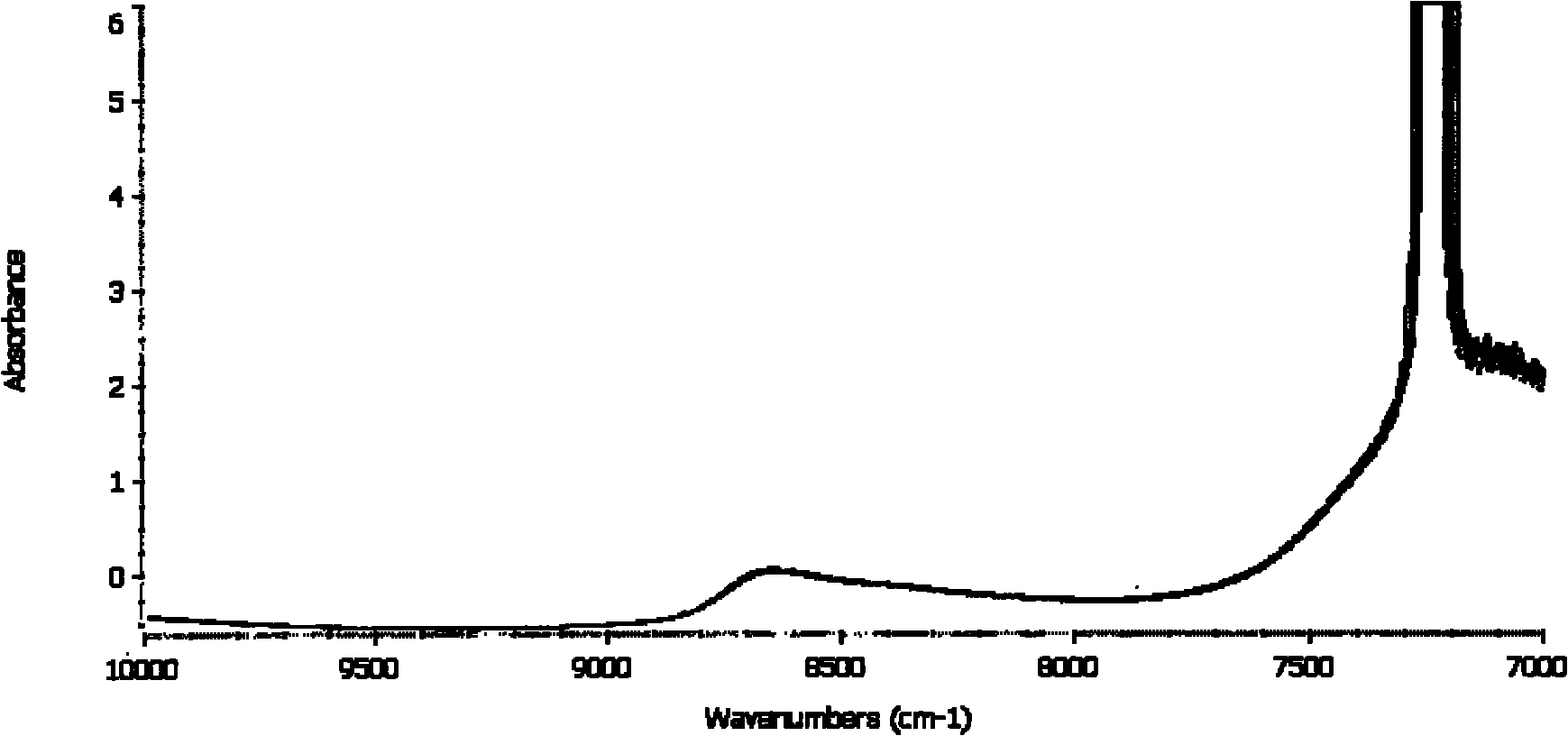

The invention discloses a quality inspection and control system for use in production process of medicinal compositions. Based on an advanced, reliable, practical and demonstrative principle, the design and application study on the online quality control systems of the units in a production process are carried out to realize the automatic control over the production process of traditional Chinese medicines. The bottleneck problems that the lack of online quality control methods and means in production process of the traditional Chinese medicine products makes it difficult to guarantee the quality of the traditional Chinese medicine products and the uniformity of the traditional Chinese medicine products is low, which influence the internationalization and modernization of the traditional Chinese medicines, are solved, and the system has a demonstration effect on the automation and modernization of traditional Chinese medicine.

Owner:TONG REN TANG TECH CO LTD +1

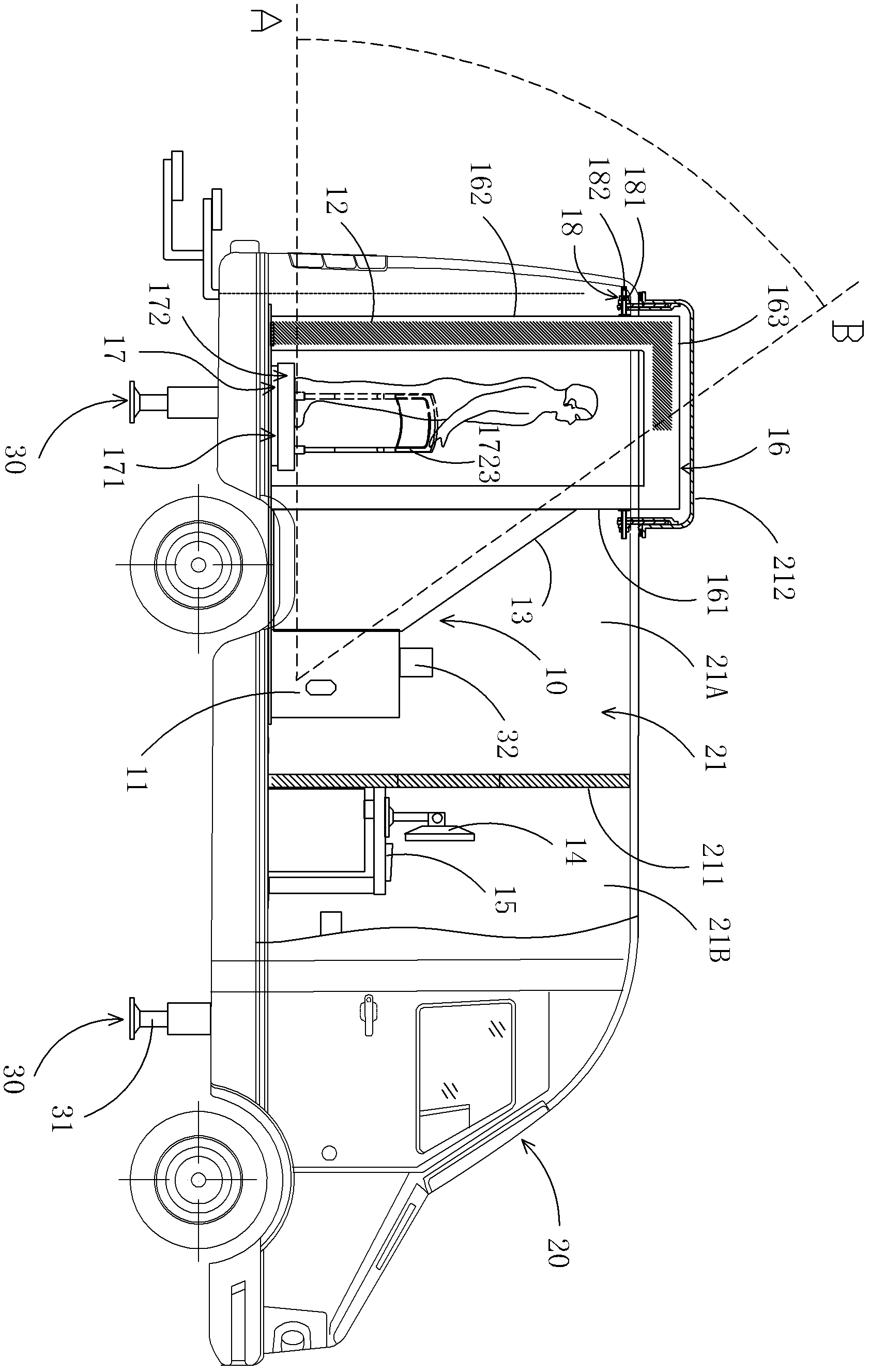

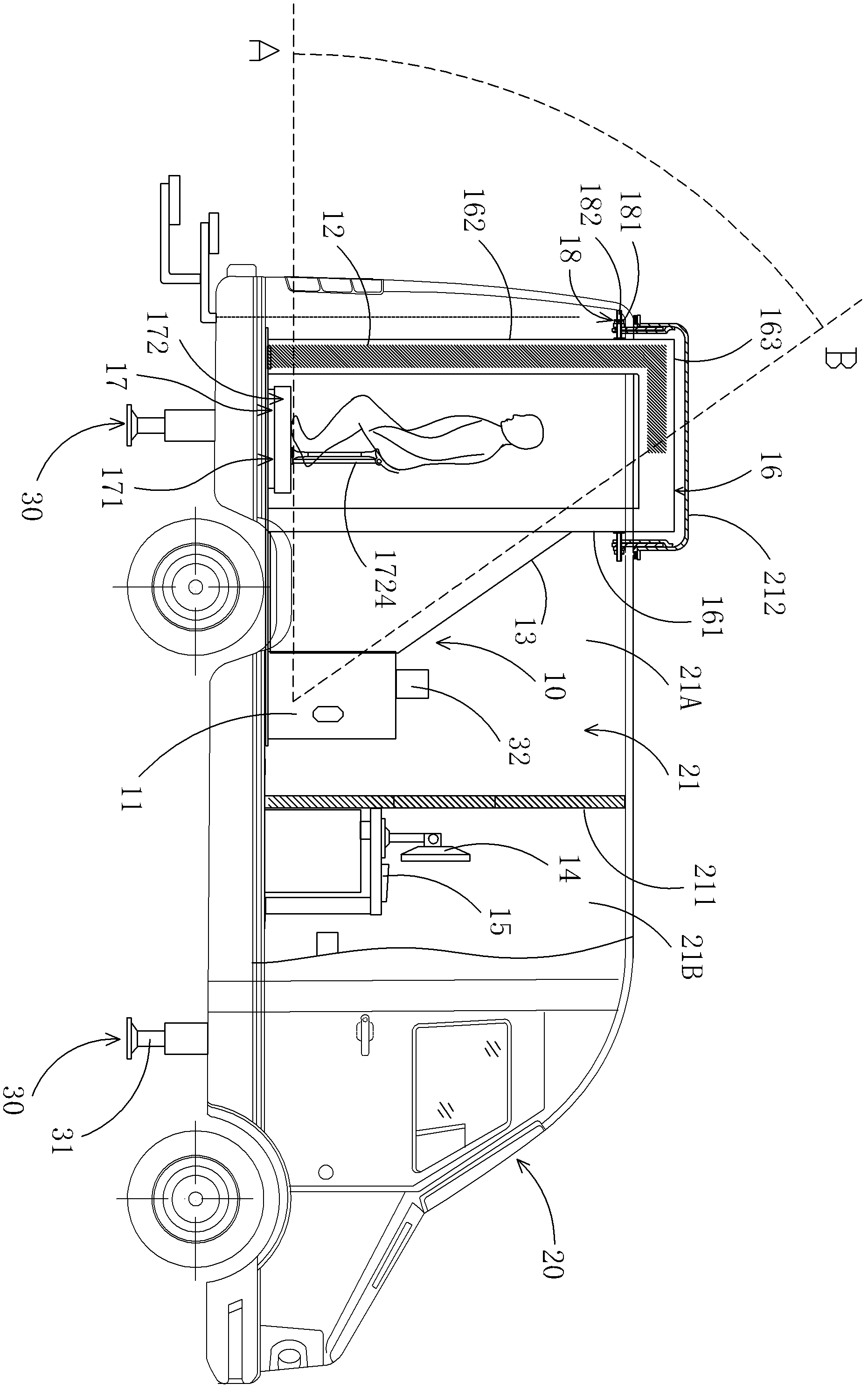

Pass-type human body safety inspection system

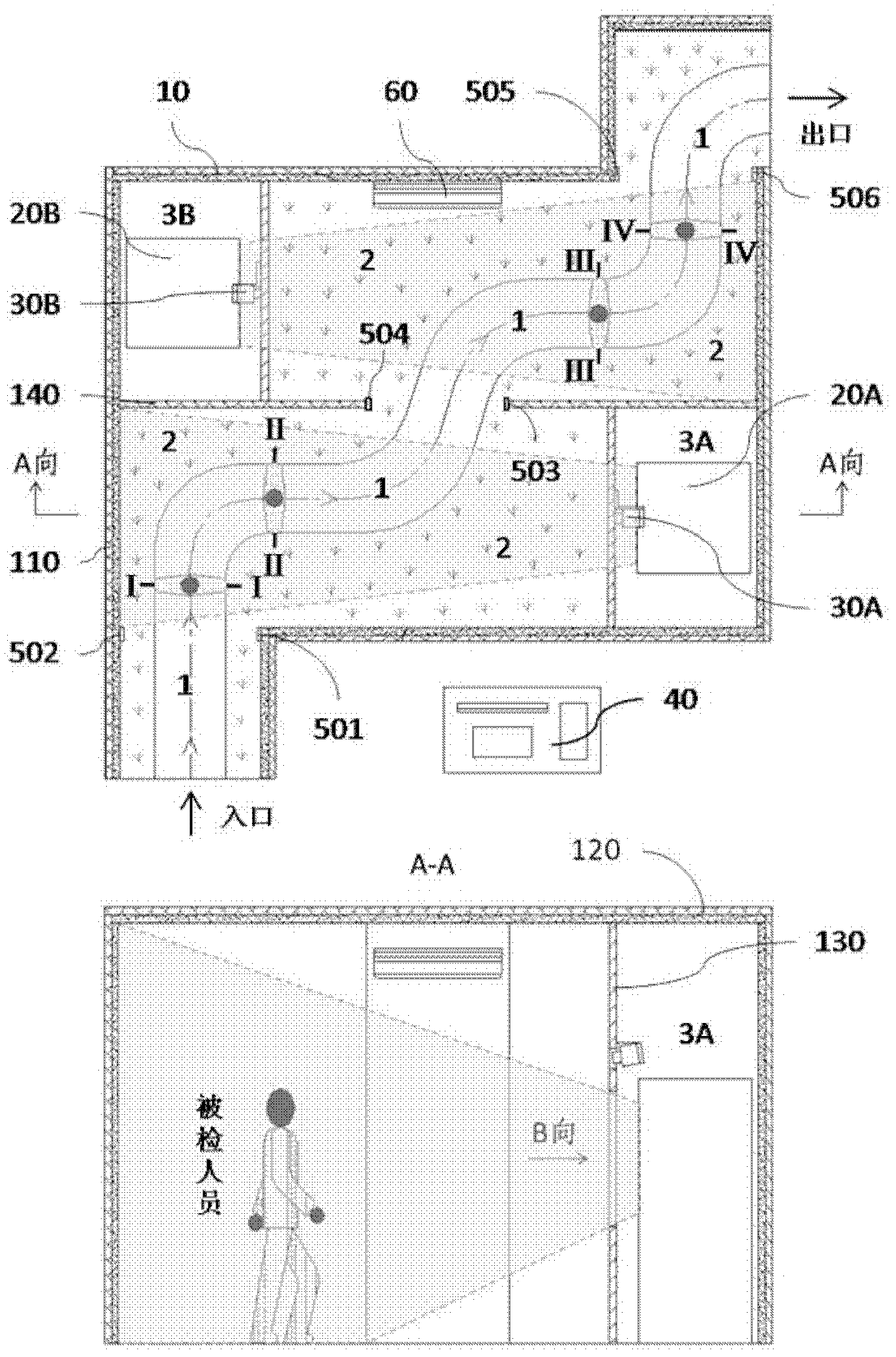

ActiveCN103163565AReduce adverse effectsQuality improvementGeological detection using milimetre wavesWhole bodyEngineering

The invention discloses a pass-type human body safety inspection system. Inspected people accept safety inspection through an inspection channel. According to the pass-type millimeter wave human body safety inspection system, the whole body of the inspected people can be scanned dynamically to obtain human wave millimeter wave images and optical images, and therefore inspection of forbidden objects hidden in human garments and automatic alarm can be achieved.

Owner:NUCTECH CO LTD +1

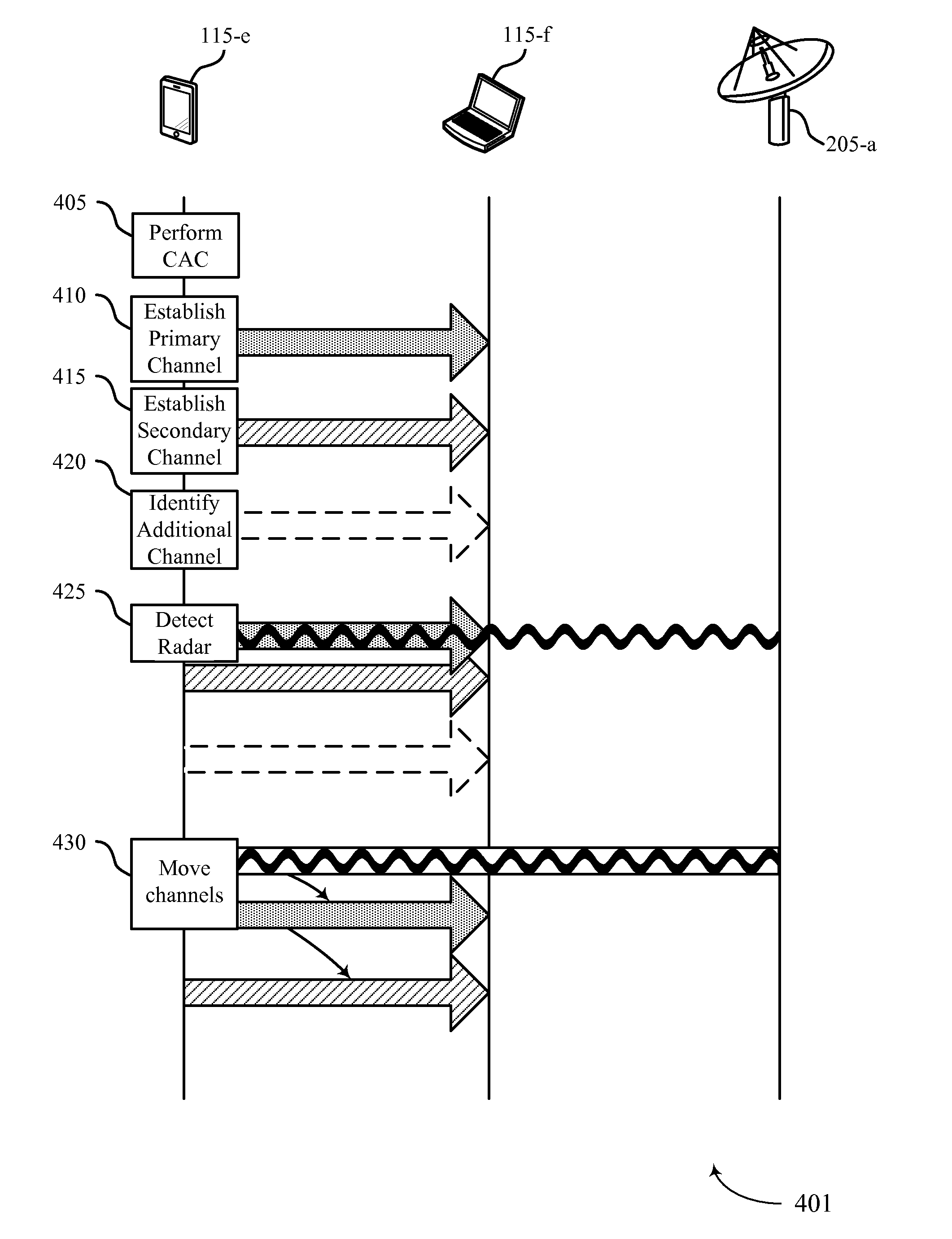

Soft access point master mode using dual wideband channels

Methods, systems, and devices are described for wireless communication at an AP. A station (STA) serving as a soft access point (SAP) in master mode may be configured to support communication over two radar channels (e.g., a primary and secondary channel) simultaneously. The STA may detect radar on the primary channel and move the primary channel to the secondary channel; meanwhile, the secondary channel may be moved to a channel in a non-radar subband. In some cases, the STA may establish a primary channel in a non-radar subband and then advertise a single bandwidth capacity. the STA may then perform a channel availability check (CAC) on a radar subband. If the CAC is successful, the STA may establish a secondary channel on the radar subband (or move the primary channel to the radar subband) and advertise a dual bandwidth capacity.

Owner:QUALCOMM INC

Configurable product model quality inspection method

InactiveCN107145622AValid checkEffective supervisionGeometric CADDesign optimisation/simulationVisual inspectionModel quality

The invention discloses a configurable product model quality inspection method. The method comprises the following steps that: on the basis of a model quality inspection system platform which is seamlessly integrated on CATIA (Computer-graphics Aided Three-dimensional Interactive Application) software, according to an existing digital management standard and modeling norm, carrying out user-defined configuration on check items; and then, according to the configured check items, carrying out quality inspection and an inspection result management analysis on a product model corresponding to design data in the CATIA software. Through the model quality inspection system platform, a user can carry out the user-defined configuration on the check items, and meanwhile, according to the check items configured by the user, a three-dimensional model designed in the CATIA software is subjected to the quality inspection and the inspection result management analysis. Through the model quality inspection system platform, a three-dimensional part designed through the CATIA software can be normatively, quickly and automatically subjected to quality detection so as to realize effective inspection and supervision for the quality of the three-dimensional model.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

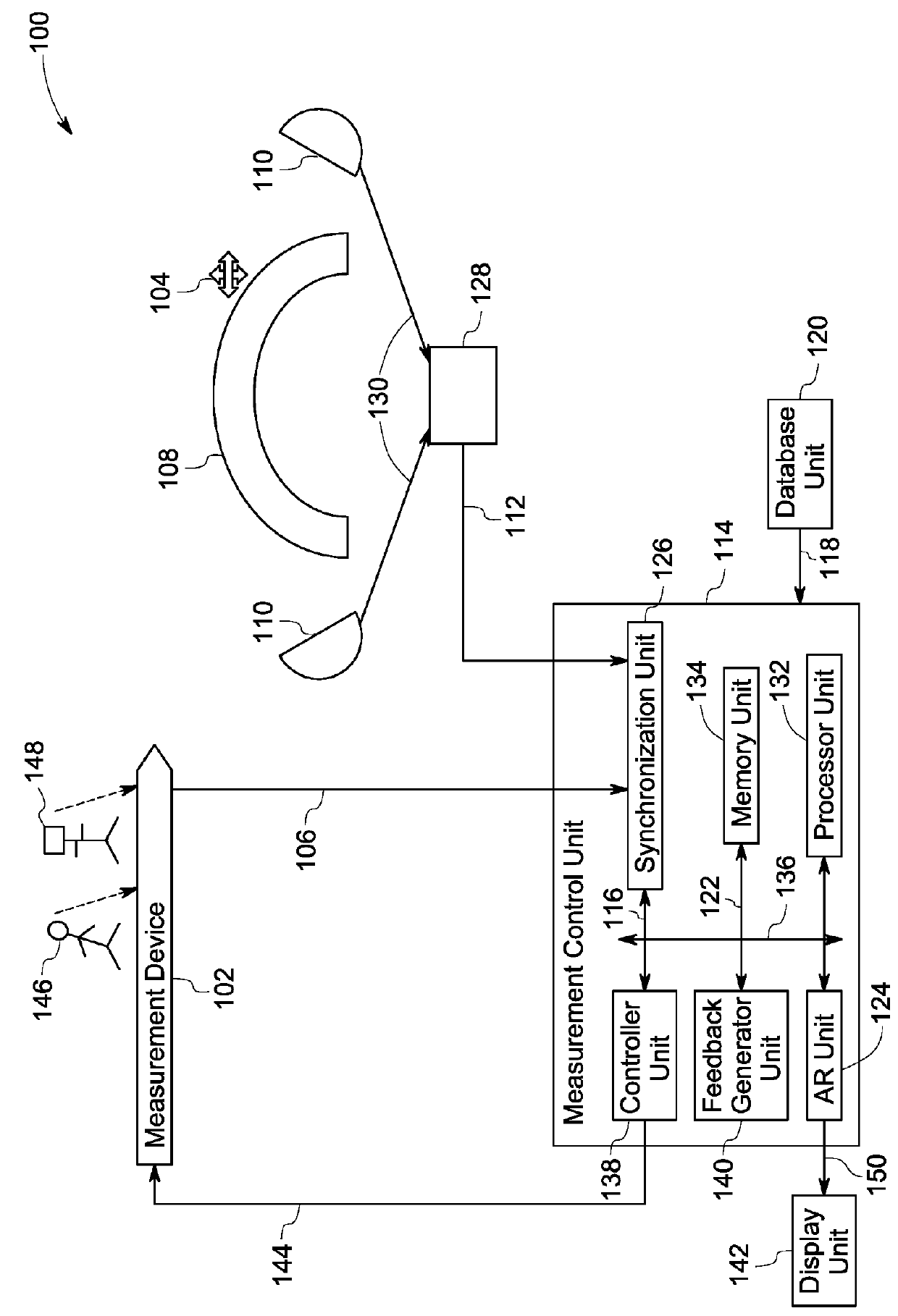

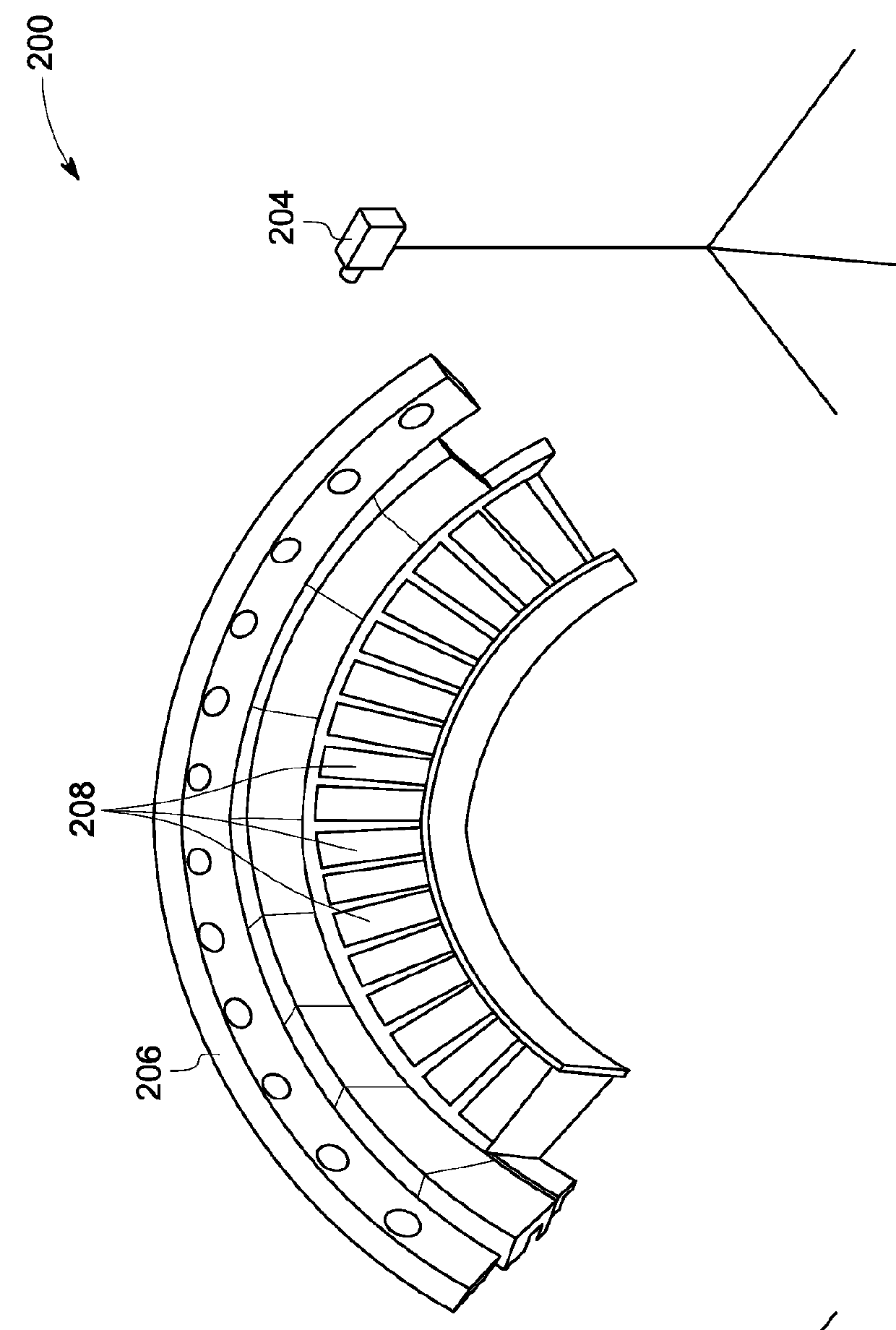

System and method for measurement based quality inspection

A method for inspecting a component includes generating measurement data of the component, using a measurement device coupled to an optical marker device. The method further includes generating co-ordinate data of the measurement device, using the optical marker device and at least one camera. The method includes generating synchronized measurement data based on the measurement data and the co-ordinate data. The method further includes retrieving pre-stored data corresponding to the synchronized measurement data, from a database. The method also includes generating feedback data based on the pre-stored data and the synchronized measurement data, using an augmented reality technique. The method includes operating the measurement device based on the feedback data to perform one or more measurements to be acquired from the component.

Owner:NUOVO PIGNONE TECH SRL

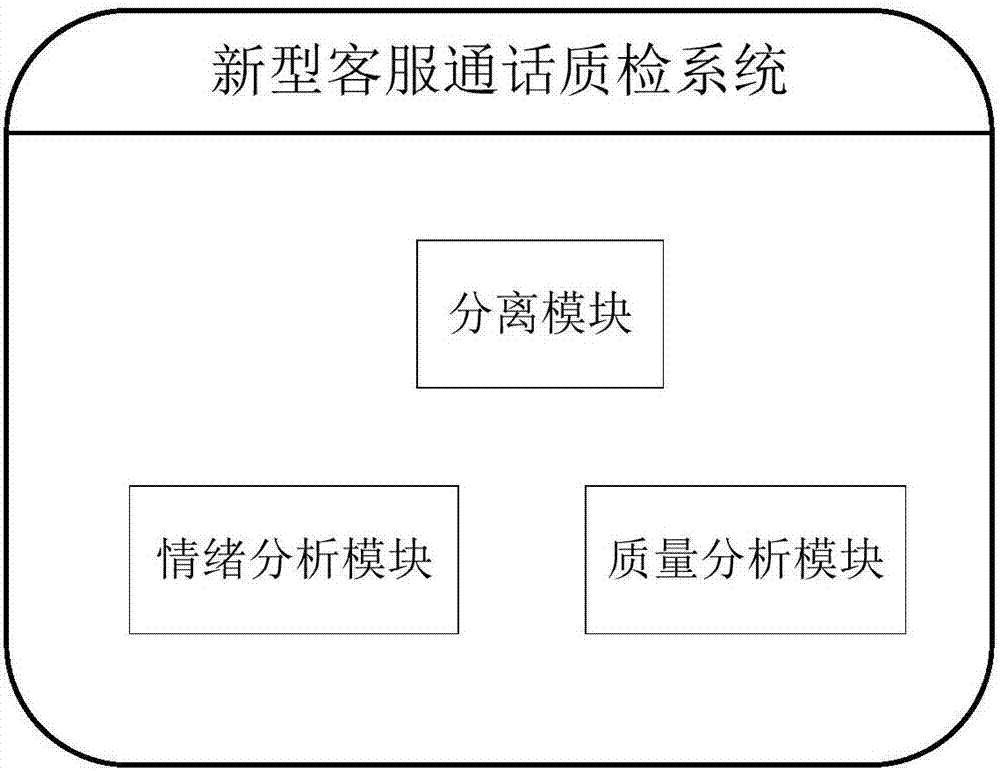

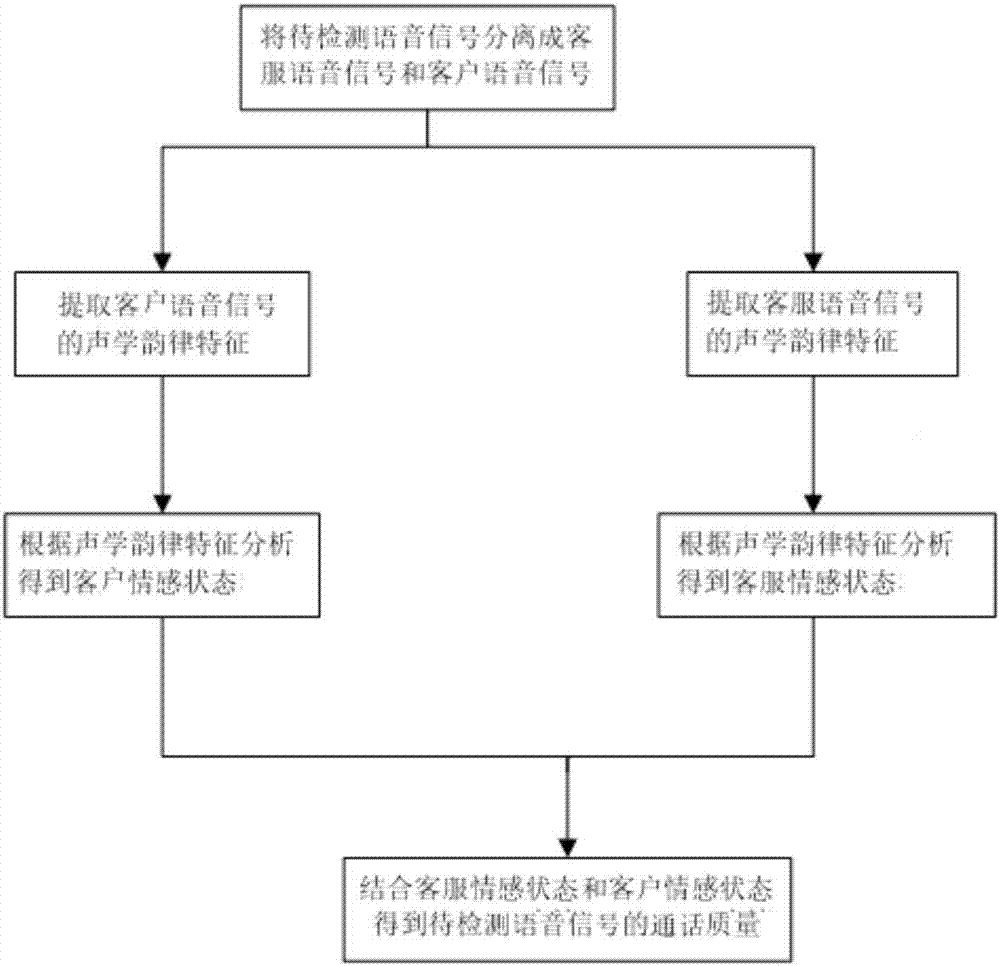

Novel call quality inspection system and method of customer service personnel

InactiveCN107464573AAutomatically check call qualityImprove efficiencySpeech analysisSpecial service for subscribersElectricityVisual inspection

The invention provides a novel call quality inspection system and a method of customer service personnel. The system comprises a separation module, an emotion analysis module and a quality analysis module, wherein the separation module preprocesses a voice signal to be detected and separates a customer service personnel sound fragment from a customer sound fragment in a sound track; the emotion analysis module performs analysis to obtain a customer service personnel emotion state and a customer emotion state; and the quality analysis module performs analysis to obtain the quality of a call according to the customer service personnel emotion state and the customer emotion state. The quality of the call between the customer service personnel and a customer is automatically inspected by using an artificial intelligence technology; whether phenomena such as anger and impatience exist in the call is detected; a quality inspection person is not required to be arranged for control; the quality of an incoming call or an outgoing call can be automatically detected; and the efficiency and speed are high.

Owner:EMOTIBOT TECH LTD

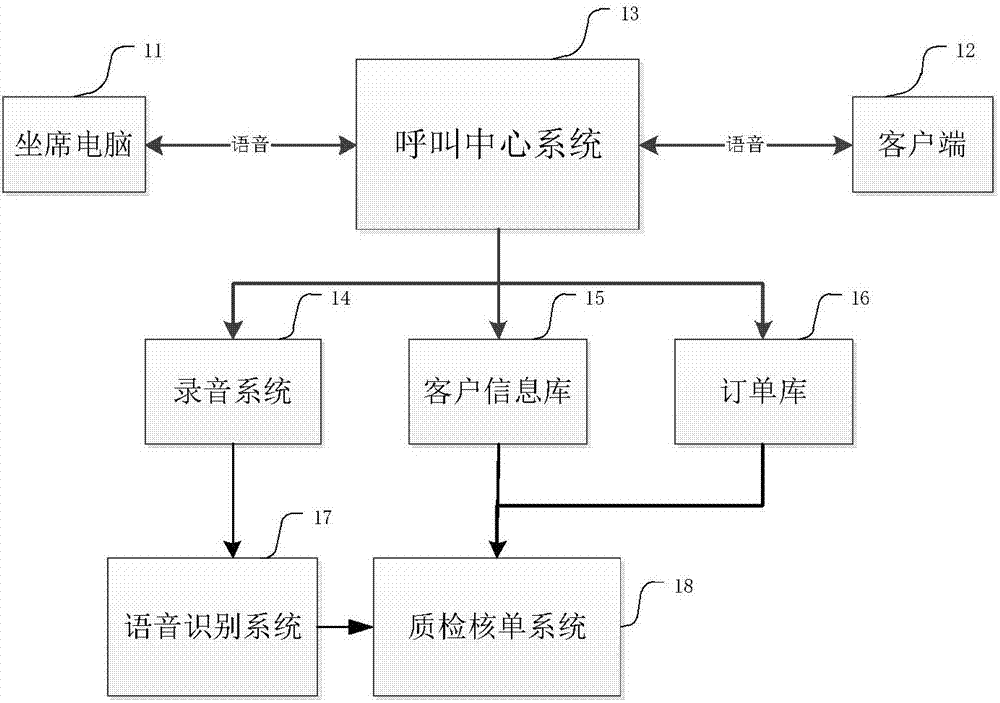

Intelligent order checking and quality inspection system based on speech recognition

InactiveCN106981291AReduce manual workloadShorten the verification timeSpecial service for subscribersSpeech recognitionInformation repositoryVisual inspection

The invention discloses an intelligent order checking and quality inspection system based on speech recognition. The intelligent order checking and quality inspection system comprises a service agent computer, a client, a calling center system, a recording system, a client information base, an order library, a speech recognition system and an order checking and quality inspection system; the recording system transmits communication speeches to the speech recognition system synchronously when the service agent computer makes speech communication with client via the calling center system; the speech recognition carries out speech recognition on the communication speech in real time, converts speeches into character information, and transmits the character information to the order checking and quality inspection system; the order checking and quality inspection system is connected with the client information base and the order library via API, obtains client information, order information and delivery information, compares the client information, order information and delivery information with the character information, carries out matching item by item according to order checking strategies, and forms an order checking report. The system can save labor cost, and improves the order checking efficiency.

Owner:SHANGHAI HANGDONG TECH CO LTD

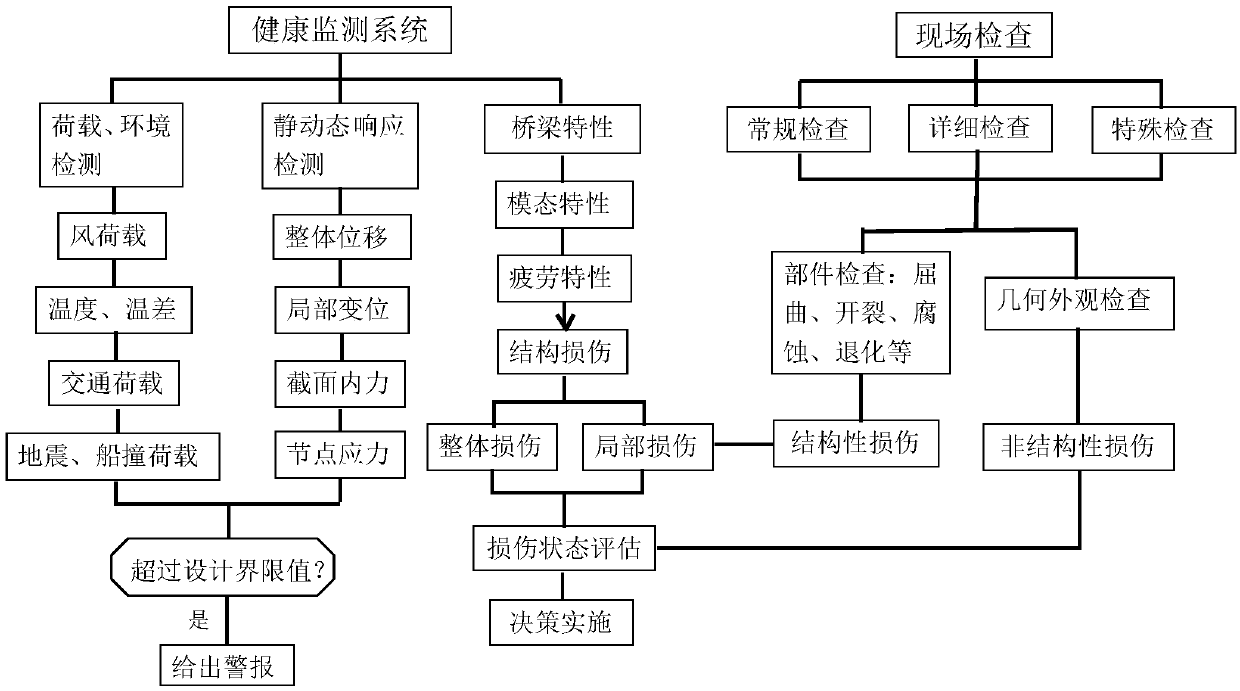

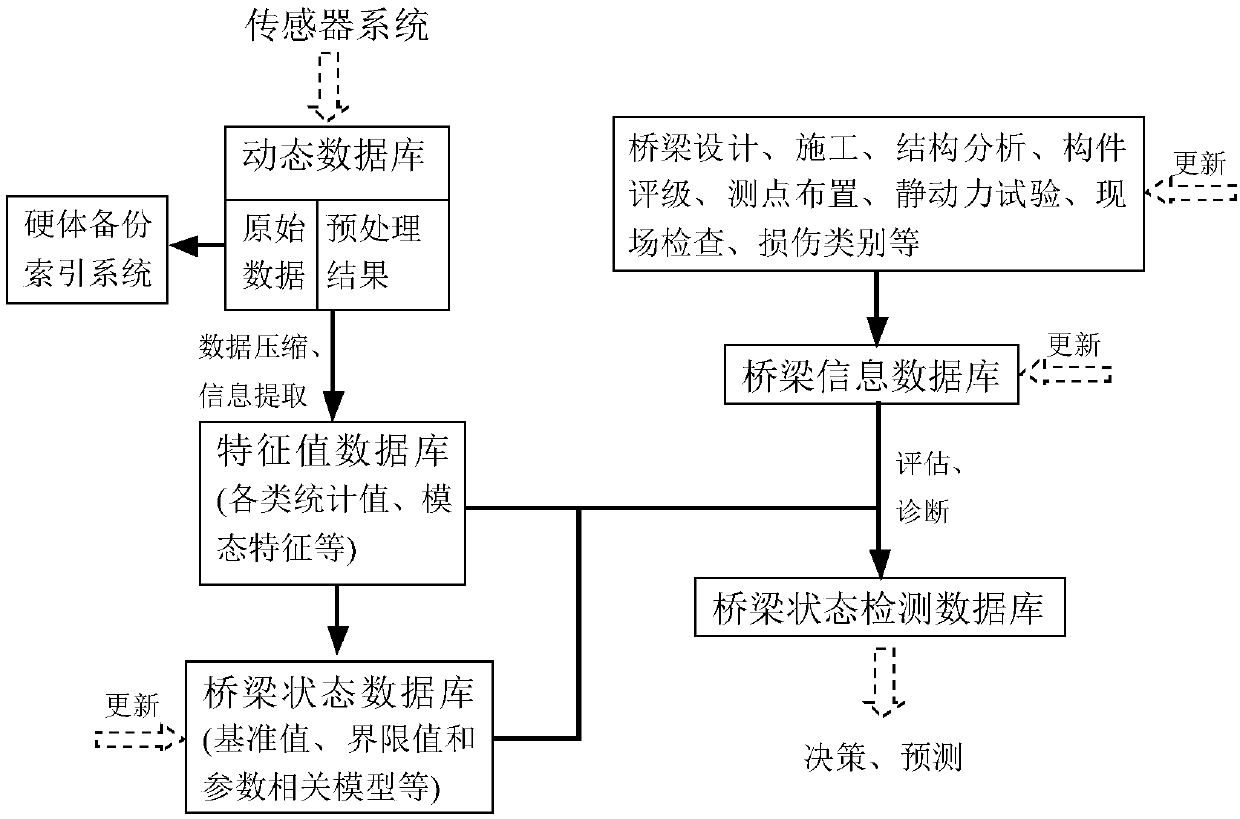

A bridge inspection and monitoring integrated health condition assessment system and a use method thereof

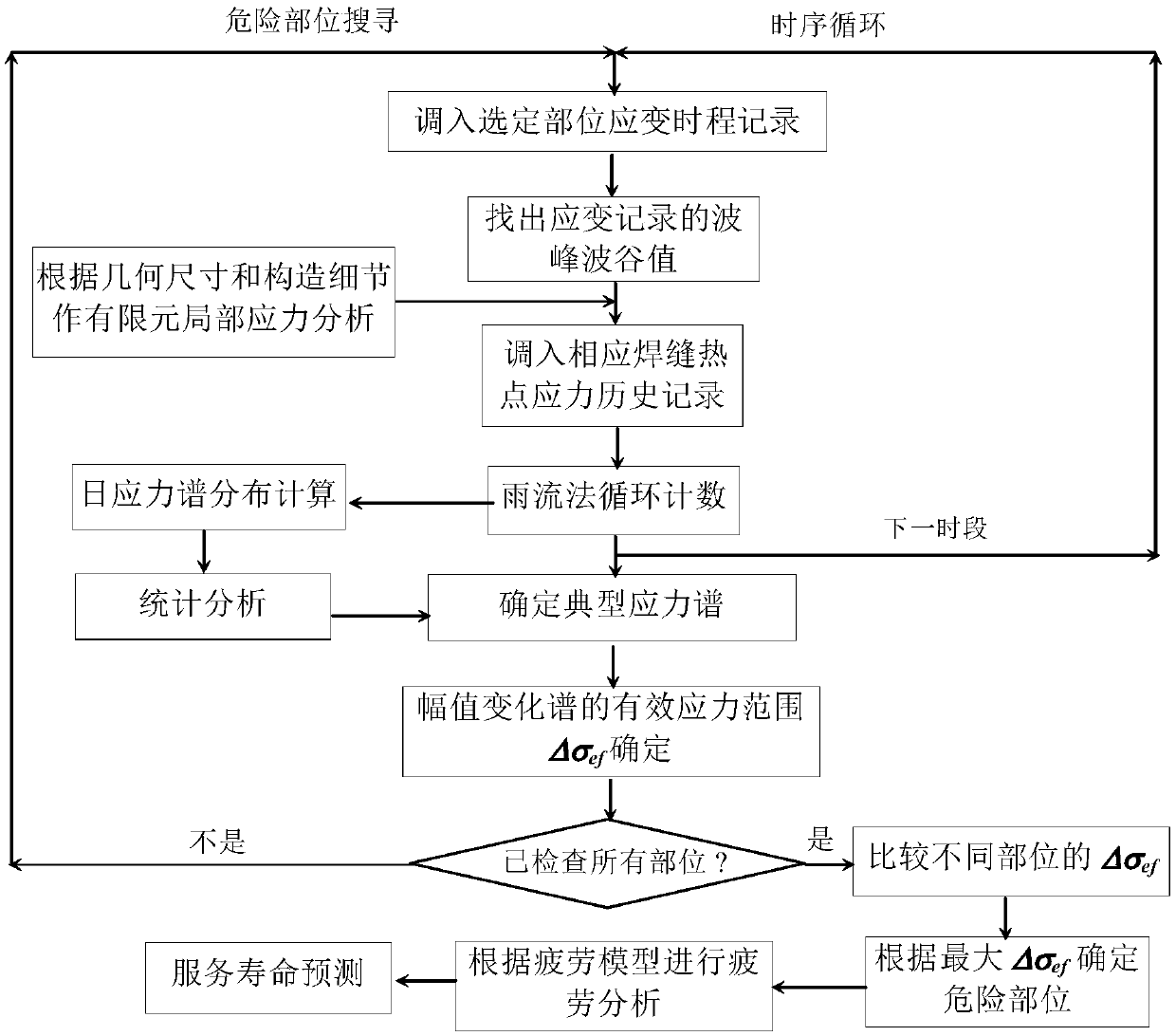

InactiveCN109559025AEffective maintenanceGuaranteed to workDigital data information retrievalDesign optimisation/simulationEngineeringUsability inspection

The invention discloses a bridge inspection and monitoring integrated health condition evaluation system and a use method thereof, belongs to the field of building bridges, and adopts the technical scheme that the bridge inspection and monitoring integrated health condition evaluation system comprises a health monitoring system and an on-site inspection part which are combined for use, and the health monitoring system comprises a data management system, a component rating system and a damage evaluation system; the data management system is used for managing detection data of the sensor systemand a preset database; the component rating system is used for rating importance, danger degree and vulnerability of the bridge components; the damage assessment system is used for assessing the damage assessment state; the on-site inspection portion includes conventional inspection, detailed inspection, and special inspection to evaluate a damage state of the component. The invention also discloses a use method of the system. The system has the advantages that the engineering decisions can be scientifically guided, effective maintenance, repair and reinforcement work can be carried out on thebridge, and the service life of the bridge is prolonged. The method is suitable for the bridge structure detection and monitoring.

Owner:ANHUI TRANSPORTATION HLDG GRP CO LTD

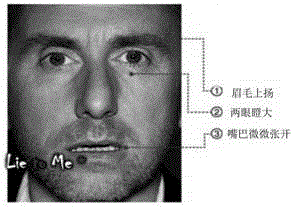

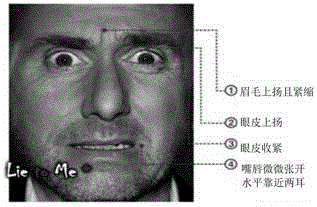

Safety check graph discrimination system including video analysis and graph discrimination method

InactiveCN104834902AThe results of the analysis are comprehensiveAcquiring/recognising facial featuresAlgorithmComputer-aided

The invention discloses a safety check graph discrimination system including video analysis and a graph discrimination method. The graph discrimination system comprises an image collecting terminal, a safety check device, and a graph discrimination terminal. The image collecting terminal, the safety check device and the graph discrimination terminal are connected through network communication. The image collecting terminal acquires the image information of persons under safety check and transmits the image information to the graph discrimination terminal. The safety check device conducts safety inspection on articles under safety check, and obtains the safety check image information of the articles under safety check and transmits the safety check image information to the graph discrimination terminal. The graph discrimination terminal identifies and analyzes the image information of the persons under safety check, and gives feedback of prompt information to users through a display unit of the graph discrimination terminal. The graph discrimination terminal displays the image information of safety check, and image information of persons under safety check, and the prompt information. The safety check graph discrimination system including video analysis and the graph discrimination method are advantageous in that the real-time video of the safety check device is transmitted to the graph discrimination terminal through a camera; users can watch the real-time high definition videos at the on-site field of the safety check device, and can conduct computer-assisted analysis on facial expressions and behaviors of the persons under safety check, and thereby the analysis results can be more comprehensive.

Owner:NUCTECH CO LTD

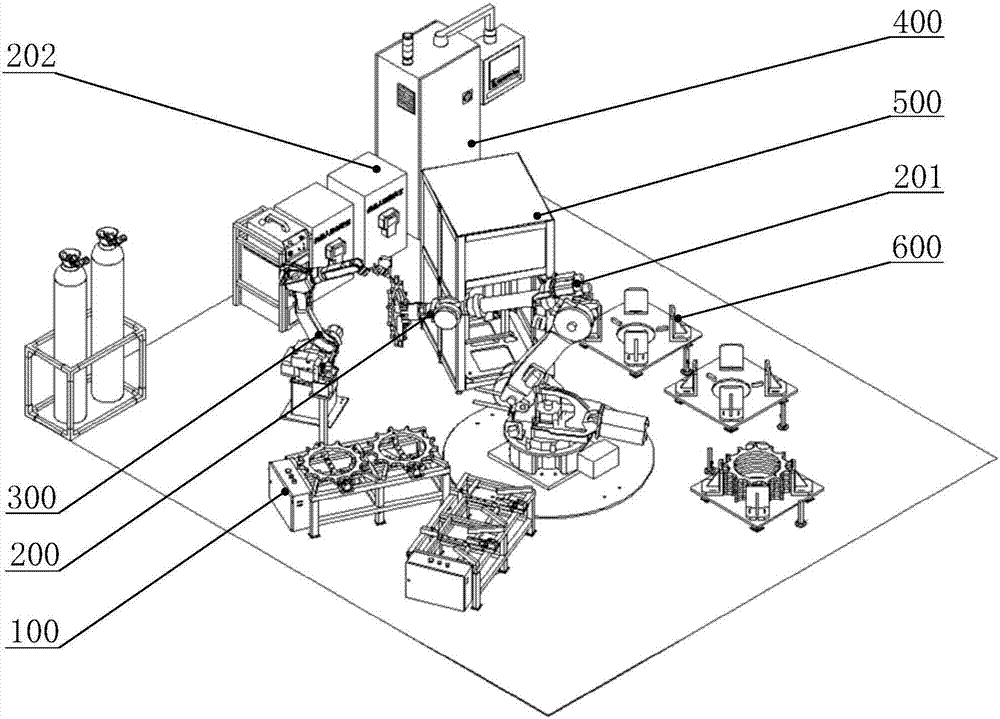

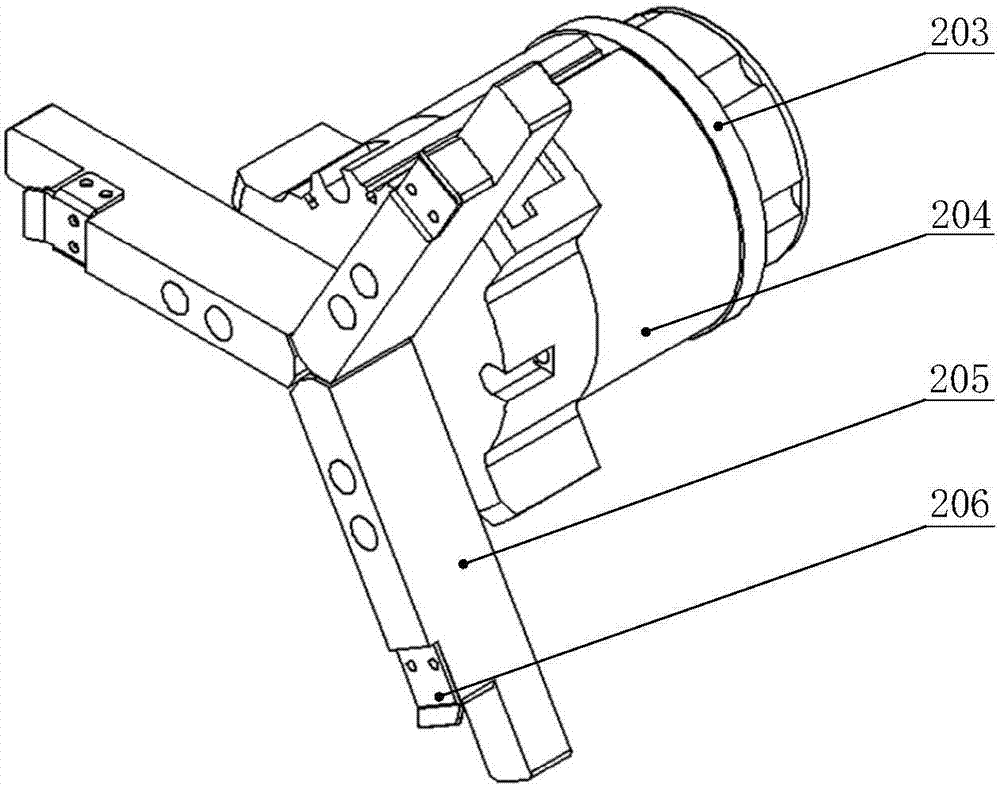

Robot automatic surfacing and visual inspection system of track gear discs

ActiveCN106862813ASimple processOptimization pathWelding/cutting auxillary devicesAuxillary welding devicesRobotic systemsSimulation

The invention discloses a robot automatic surfacing and visual inspection system of track gear discs. The robot automatic surfacing and visual inspection system comprises fixed material bins, a transfer robot system, a welding robot system, an intelligent control system, a visual inspection system and moving material bins. The fixed material bins are arranged at feeding stations. The welding robot system is put at a welding station. The visual inspection system is arranged at an inspection station. The moving material bins are arranged at discharging stations. The fixed material bins are used for feeding. The transfer robot system is used for firstly transferring the track gear discs to the welding robot system from the fixed material bins to be welded, then transferring the track gear discs to the visual inspection system to be subjected to welding quality inspection and finally transferring the track gear discs to the moving material bins. According to the robot automatic surfacing and visual inspection system, the functions of automatic feeding of the track gear discs, double robot cooperative welding, welding quality online inspection, finished product separating stacking and the like are achieved; the equipment automation degree is high; manual intervention is not needed in the whole process; and the welding quality consistency is high.

Owner:ZHEJIANG UNIV

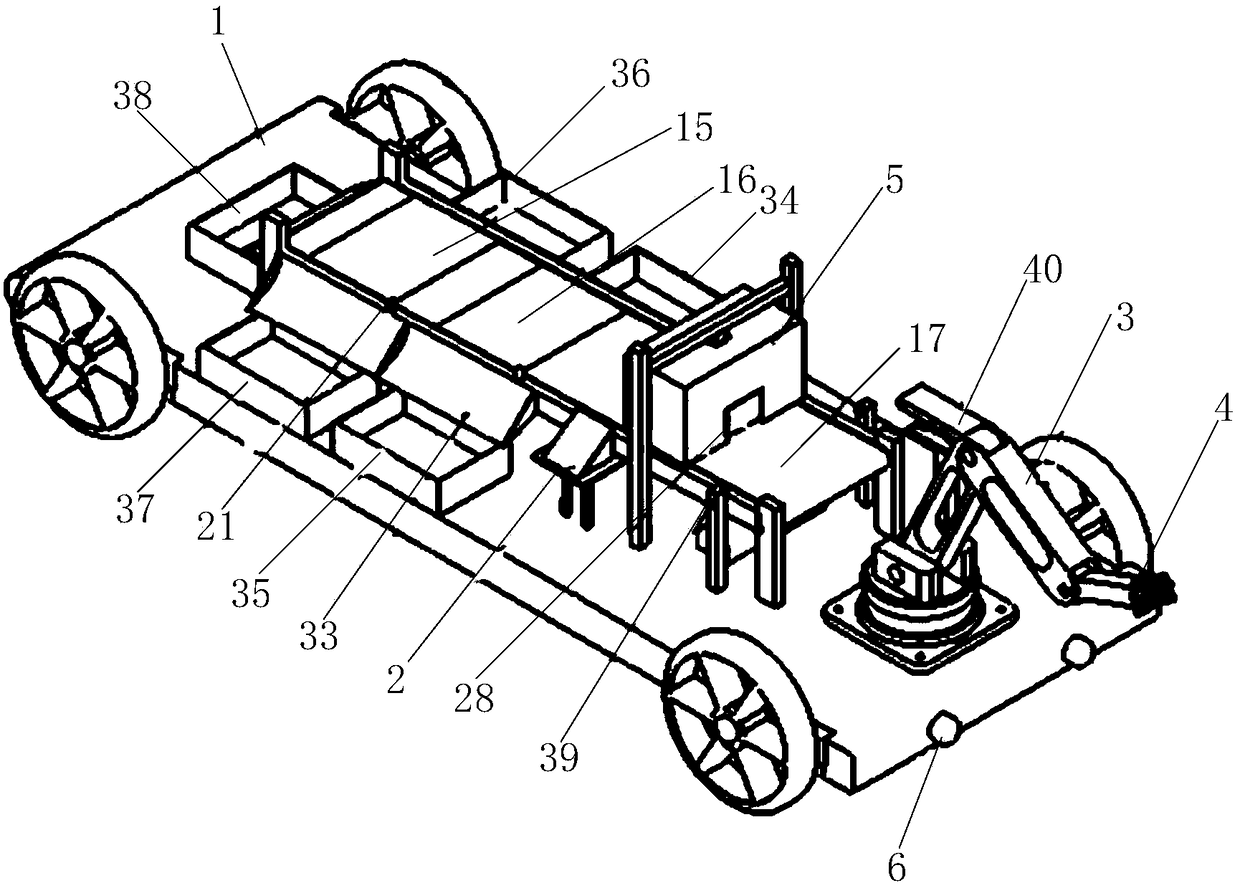

Device for nondestructive picking, quality inspection and classification of table grapes and control method of device

PendingCN109342431AInvestigation of vegetal materialOptically investigating flaws/contaminationElectricityMobile vehicle

The invention discloses a device for nondestructive picking, quality inspection and classification of table grapes and a control method of the device. A mechanical arm picking device is arranged at one end of a mobile vehicle, wherein a mechanical arm comprises a multi-joint mechanical arm and an end picker; target identification equipment and control equipment are respectively arranged on both sides of the mobile vehicle; a conveying system is arranged in the middle position of the mobile vehicle; a quality inspection box is arranged above the conveying system; classification packing devicesare arranged on both sides and a tail end of the conveying system; the mobile vehicle, the mechanical arm picking device, the target identification equipment and the conveying system are electricallyconnected with the control equipment. Picked grapes are conveyed into the quality inspection box by the conveying system to determine grades of the grapes; the grapes are conveyed to the classification packing device by the conveying system after determining the grades, and are classified by entering different fruit boxes according to the corresponding grades, thereby realizing picking, grade detection and classification packing of the grapes.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Movable X-ray human body whole safety inspection system

InactiveCN102657537AOvercoming damageOvercome the disadvantage of not being able to conduct whole-body non-contact inspectionsForeign body detectionNuclear radiation detectionElectricityHuman body

The invention discloses a movable X-ray human body whole safety inspection system, which comprises a motor vehicle and an X-ray scanning and imaging system arranged in the motor vehicle and used for generating sector-shaped X-ray beams, wherein the X-ray scanning and imaging system comprises an X-ray generator, an X-ray detector, a collimating component for making X-rays form thin sector-shaped ray beams through a narrow aperture for emitting, an image acquiring and processing device for converting a signal output by the detector into a visible image, a control device, a vertical frame and an inspection channel; the X-ray generator and the collimating component are connected with the vertical frame; the inspection channel is formed on the inner lower part of the vertical frame; the X-ray detector and the control device are electrically connected with the image acquiring and processing device respectively; and after an inspected person enters the inspection channel, a movable platform loading the inspected person moves through the sector-shaped X-ray beams, and the sector-shaped X-ray beams are projected onto the X-ray detector after penetrating through the body of the inspected person, and are transmitted to the image acquiring and processing device to generate a visible whole body perspective image.

Owner:SHENZHEN LIMING ADVANCED IMAGING TECH

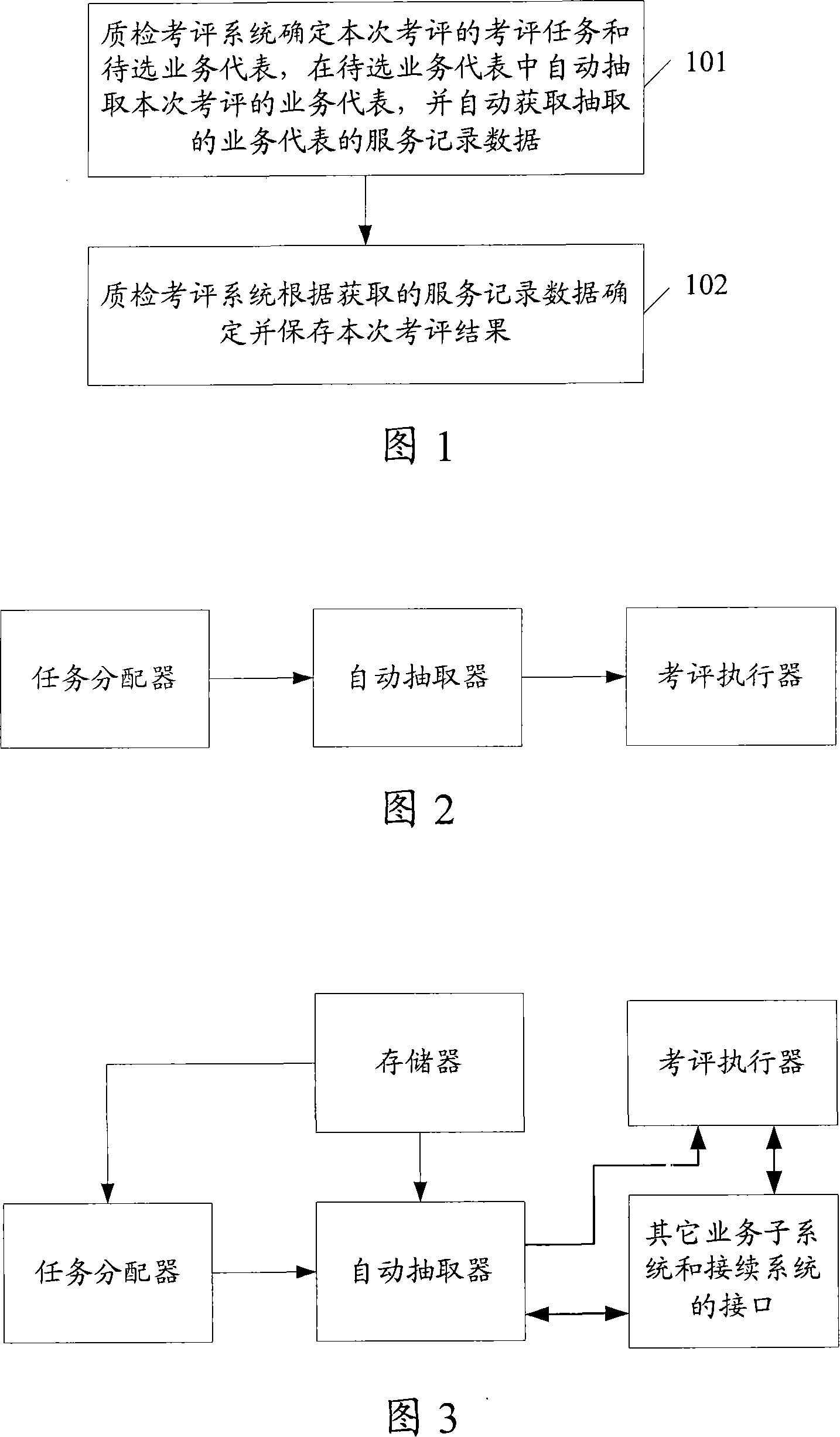

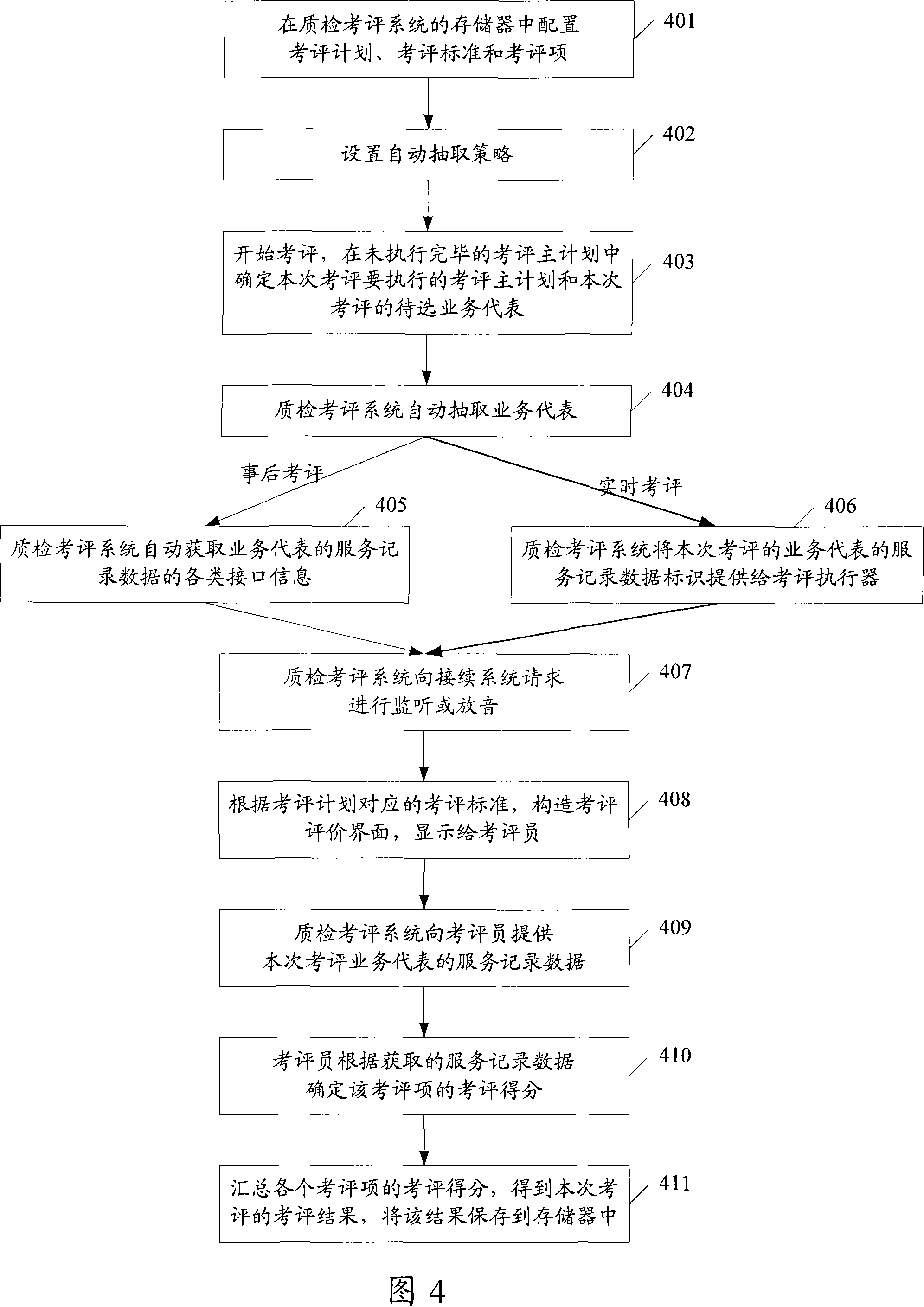

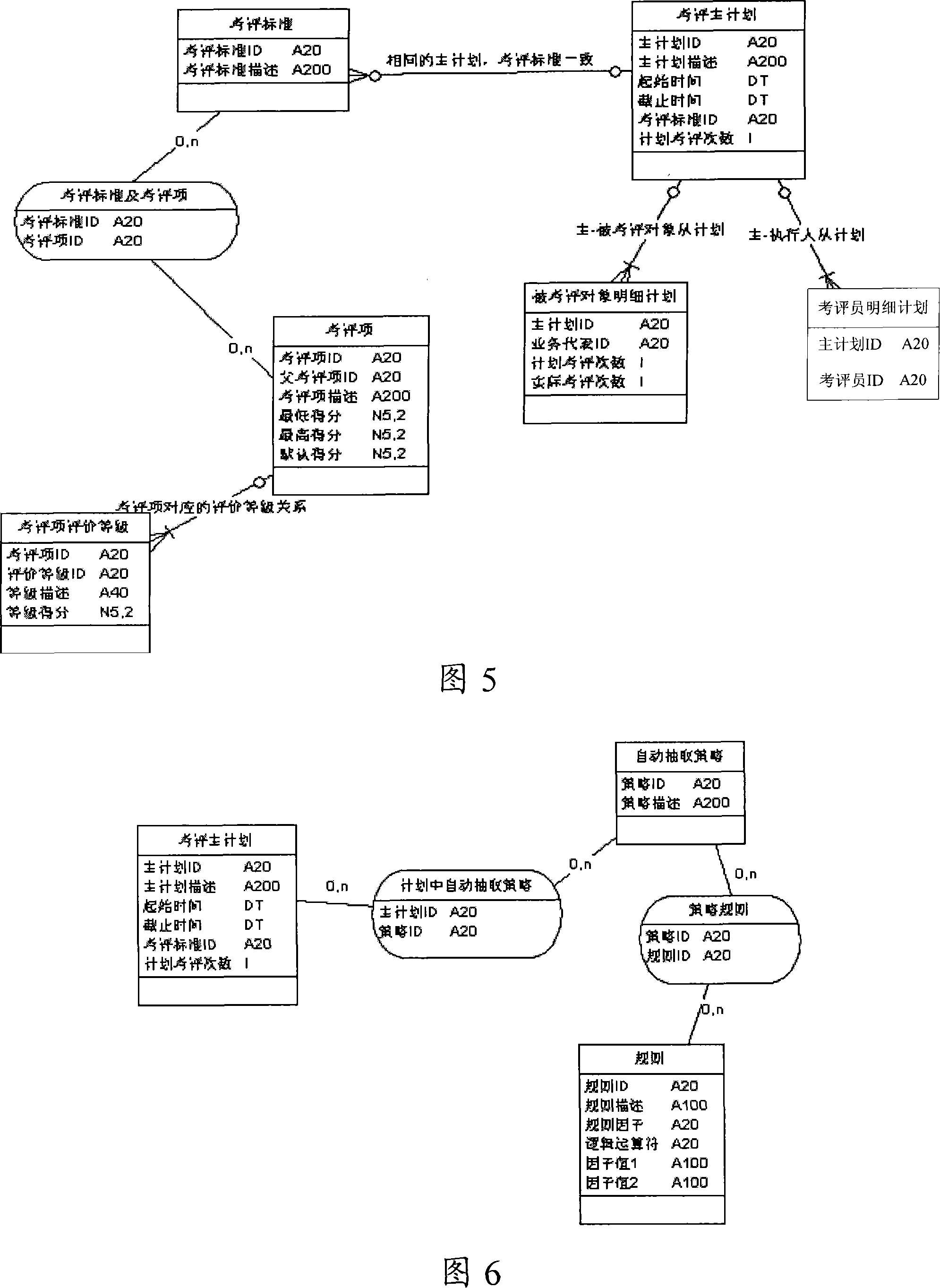

Quality inspection examining method and system

InactiveCN101119406AEnsure fairnessGuarantee fairnessSpecial service for subscribersSupervisory/monitoring/testing arrangementsQuality controlVisual inspection

The invention model discloses a quality evaluation methode, which includes the steps as follows: a quality control evaluation system determines the evaluation target and candidate business representatives; and automatically samples business representatives in the candidate business representatives, and automatically acquire the services record data of the sampled business representatives; the quality control evaluation system determines and saves the evaluation results according to the services record data acquired. The invention model also discloses a quality control evaluation system. The present inventon can ensure the comprehensiveness, the accuracy, the objectiveness, the fairness and integrity of the evaluation results.

Owner:HUAWEI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com