Inspection tool for automobile instrument panel support

An automobile instrument panel and inspection tool technology, which is applied in the field of tooling and fixtures, can solve the problems of unsuitability for large-scale inspection requirements, low inspection efficiency, and high instrument cost, and achieves improved inspection speed and accuracy, high inspection efficiency, and inspection tools. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

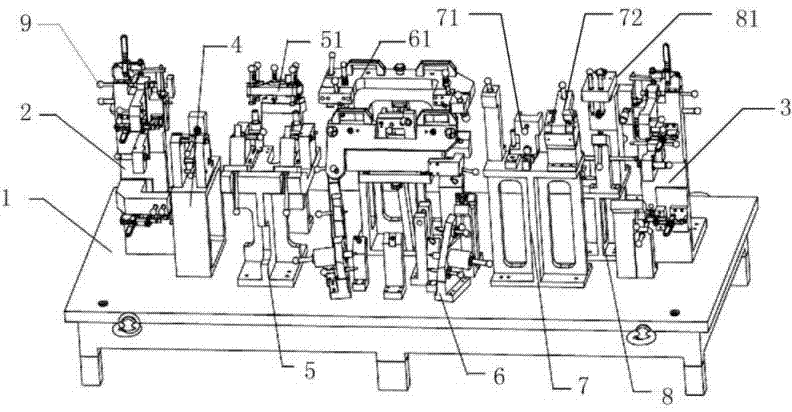

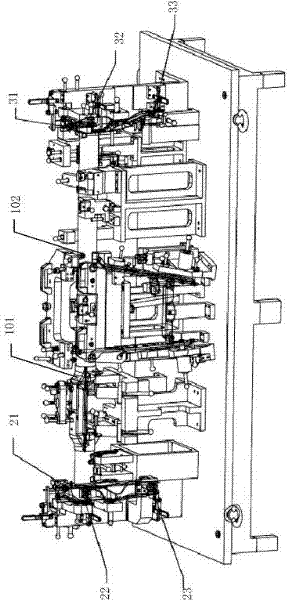

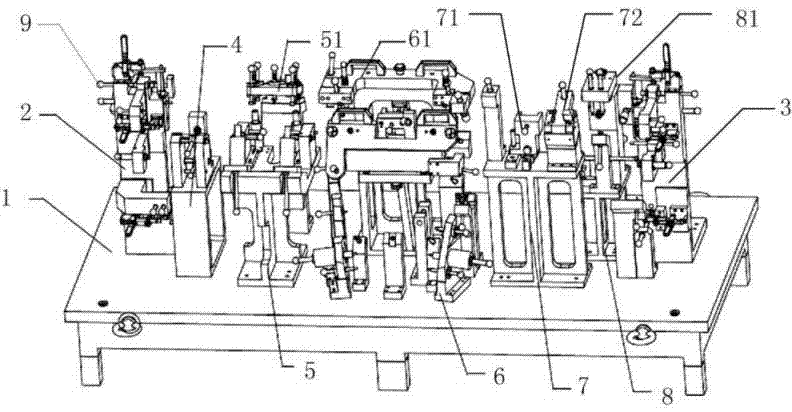

[0013] An automobile instrument panel bracket inspection tool of this embodiment, such as Figure 1~Figure 2 As shown, for the quality inspection of the vehicle instrument panel bracket 101 to be tested, the vehicle instrument panel bracket 101 is provided with a plurality of mounting holes 102, including a base 1, and the symmetrically arranged left end frame 2 and right end frame are fixed on the base 1 3; the left end frame 2 and the right end frame 3 are respectively provided with a left reference group and a right reference group for positioning in the X-axis, Y-axis and Z-axis directions of the vehicle instrument panel bracket 101, and the left reference group includes left reference blocks 21, 22 and 23 , the right reference group includes right reference blocks 31 , 32 and 33 . The base 1 between the left end frame 2 and the right end frame 3 is sequentially installed with five supporting vertical frames: the first supporting vertical frame 4, the second supporting ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com