Patents

Literature

136 results about "Flight inspection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flight inspection refers to the periodic evaluation of navigational aids used in aviation, such as flight procedures and electronic signals, to ensure they are safe and accurate. Unlike flight tests, which analyze the aerodynamic design and safety of the aircraft itself, flight inspection comprises reviewing flight procedures (such as routes, approaches and departures) to ensure navigational support is sufficient, there are no obstacles and the procedure is reliable.

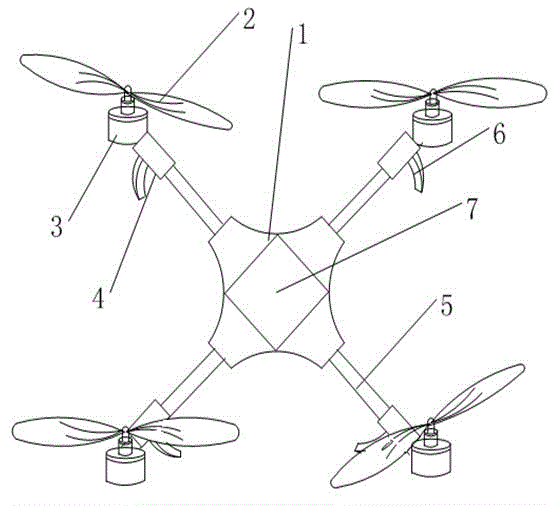

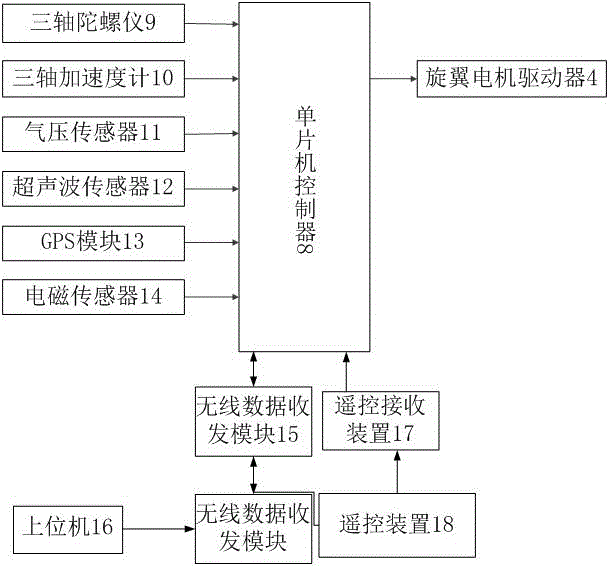

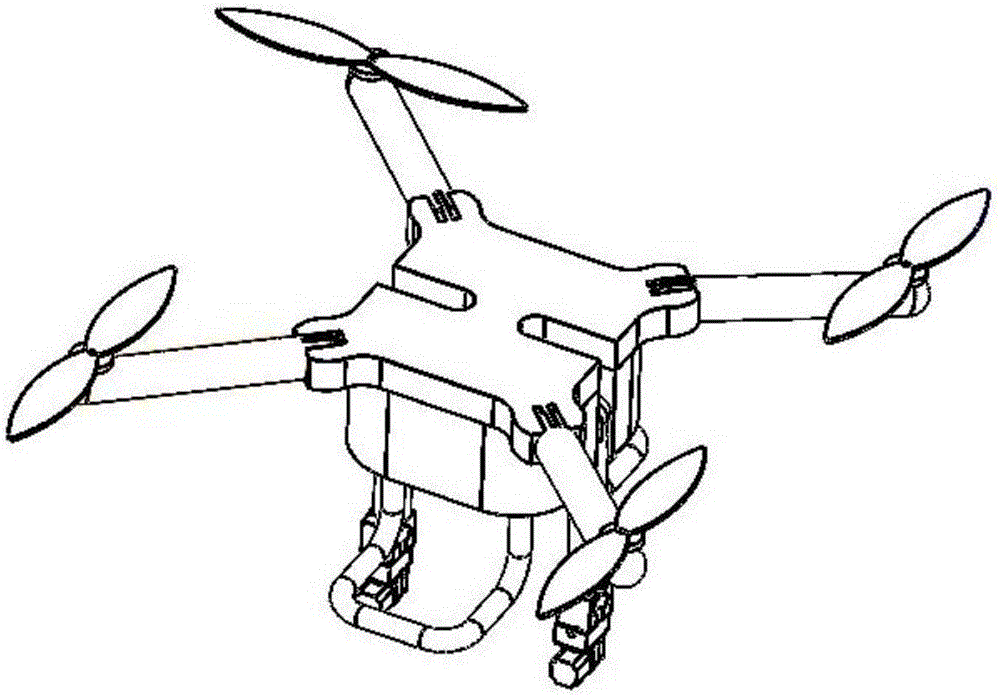

High-tension transmission line inspection robot based on multi-rotor aircraft and method using robot

InactiveCN102941920AGood ability to work online in real timeGuaranteed real-time online work abilityApparatus for overhead lines/cablesAircraftsSimulationHigh pressure

The invention discloses a high-tension transmission line inspection robot based on a multi-rotor aircraft, which comprises a four-rotor aircraft and an inspection system, wherein a double-power module supplies power to the four-rotor aircraft and the inspection system; the four-rotor aircraft comprises a robot body, four rotors, four rotor motors and four rotor motor drivers, the rotors, the rotor motors and the rotor motor drivers are matched, the four rotors are fixedly arranged on respective rotor motors, and the four drivers are respectively connected with respective rotor motors 3; and the inspection system performs shooting and data transmission on high-tension transmission lines. The robot disclosed by the invention performs air flight inspection based on four rotors, and is high in air flight stability and good in inspection speed. Through wireless camera shooting control, a visible light camera can be moved to a position near a suspected fault point so as to realize the emphasized detection of suspected fault points of the high-tension transmission lines.

Owner:NANJING UNIV OF SCI & TECH

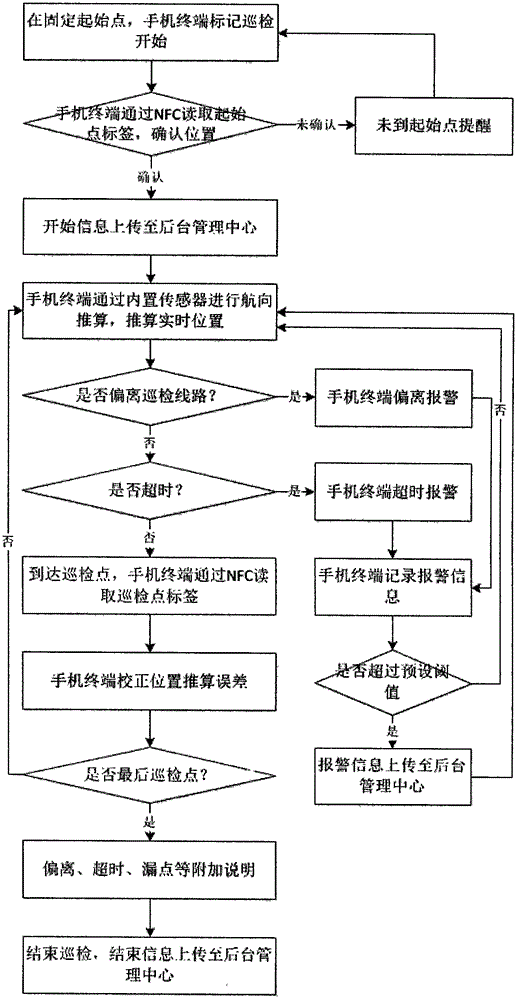

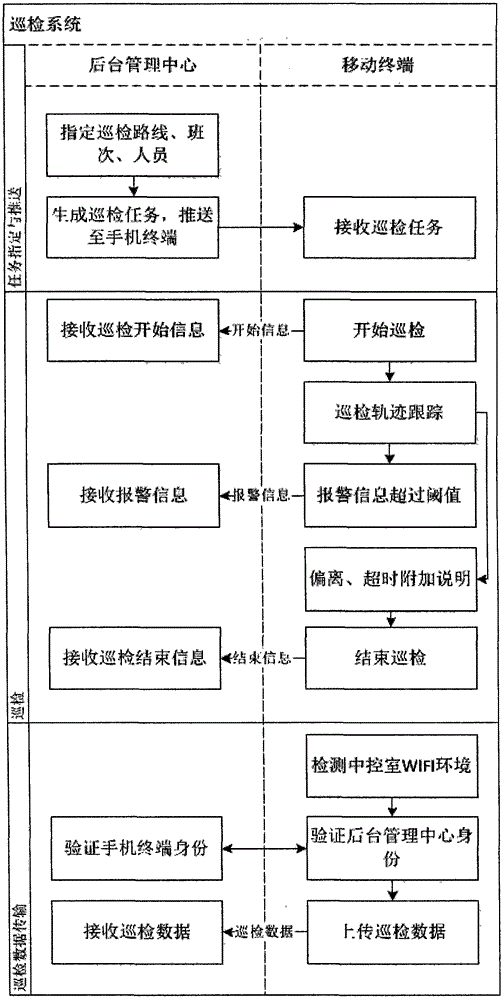

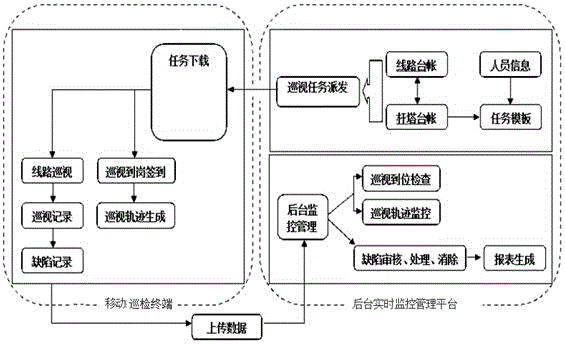

Inspection method and inspection system based on multi-sensor intelligent terminal

InactiveCN104978775AReduce data volumeChecking time patrolsGeneral Packet Radio ServiceAccelerometer

The invention discloses an inspection method and an inspection system. The inspection system comprises a background management center, and an intelligent mobile terminal, such as an android mobile terminal, supporting NFC (Near Field Communication), a gyroscope, an electronic compass and an accelerometer. The method comprises the steps of prearranging an inspection route and the inspection time by the background management center, and appointing an inspector; automatically generating an inspection task by the background management center, and sending the inspection task to the appointed inspector; when the inspector reaches the fixed starting point, reading the label of the starting point by the intelligent mobile terminal so as to start the inspection; in the inspection process, calculating the displacement distance away from the former known point through an accelerometer and a gyroscope of the intelligent mobile terminal so as to calculate the current position, thus drawing and recording the inspection route; when the inspector reaches the next inspection point, reading the label of the inspection point, correcting the calculating error of the terminal position, and repeating the process until the inspector reaches the last inspection point; additionally remarking the excursion, overtime and point leakage conditions, and marking the finish of the inspection; after the inspector returns to a central control room to access WIFI (Wireless Fidelity) of the central control room, automatically authenticating the identity by the background management center and the mobile terminal and transmitting the inspection records; and carrying out statistical analysis on the inspection records including the inspection route by the background management center so as to assist performance management and decision. According to the inspection method and the inspection system, the intelligent mobile terminal can be used for recording the route of the inspector in real time, and monitoring and alarming the condition that the inspector deviates the inspection route and inspects overtime and the like in real time, the problems that the existing off-line inspection system only can be used for monitoring the inspector through scattered inspection points and cannot master the inspection state in real time can be solved, and meanwhile, the defects that in order to realize the functions, the originally used on-line inspection system is high in cost and cannot be flexibly changed as whole wiring construction is needed can be overcome. Particularly, the inspection method and the inspection system provided by the invention can be applied to outdoor inspection, and also can be applied to indoor inspection, thus effectively overcoming the defect that the inspection system based on GPS (Global Positioning System), GIS (Geographic Information System) and GPRS (General Packet Radio Service) cannot be effectively applied to indoor inspection.

Owner:江苏中科泛联物联网科技股份有限公司

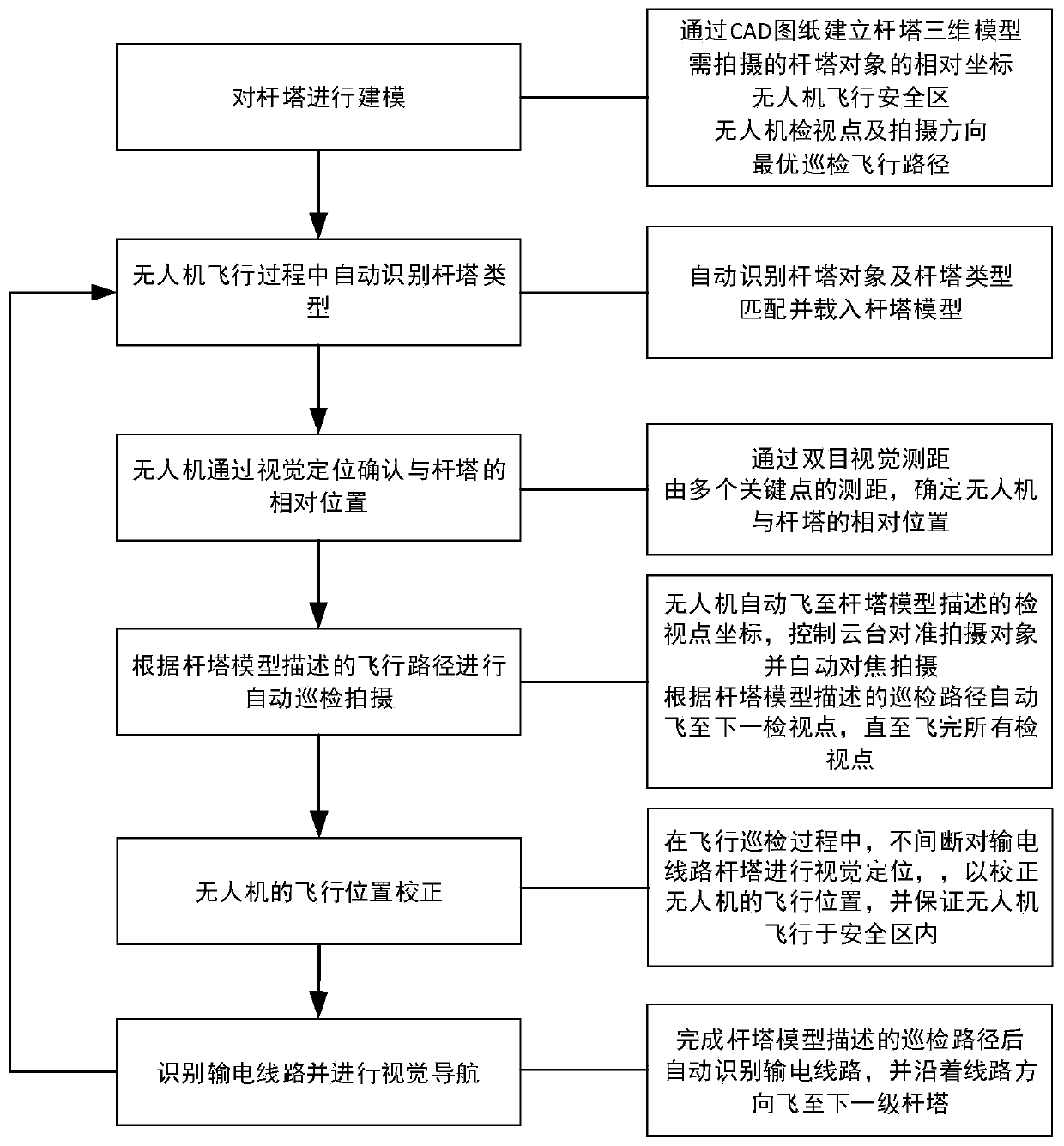

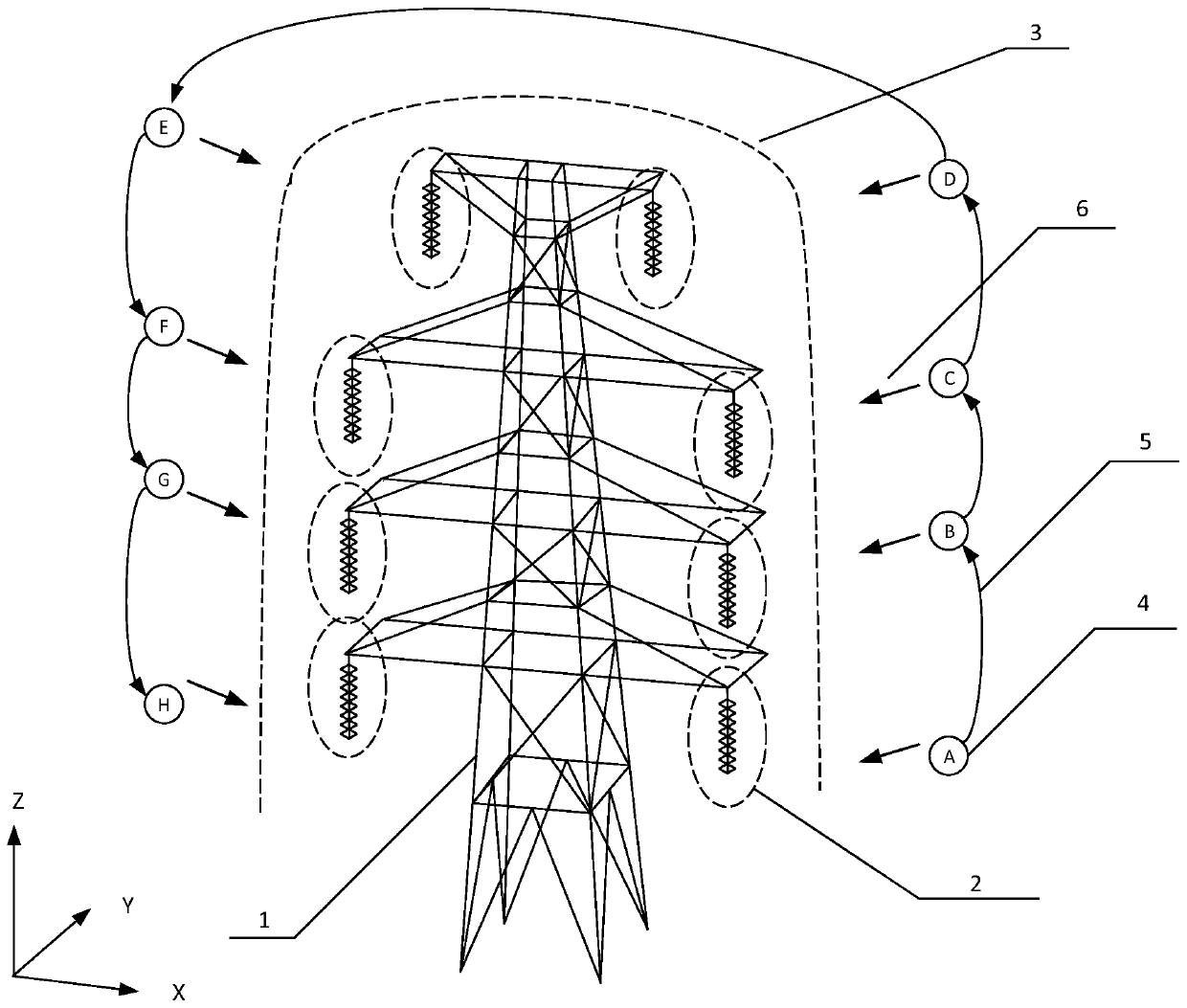

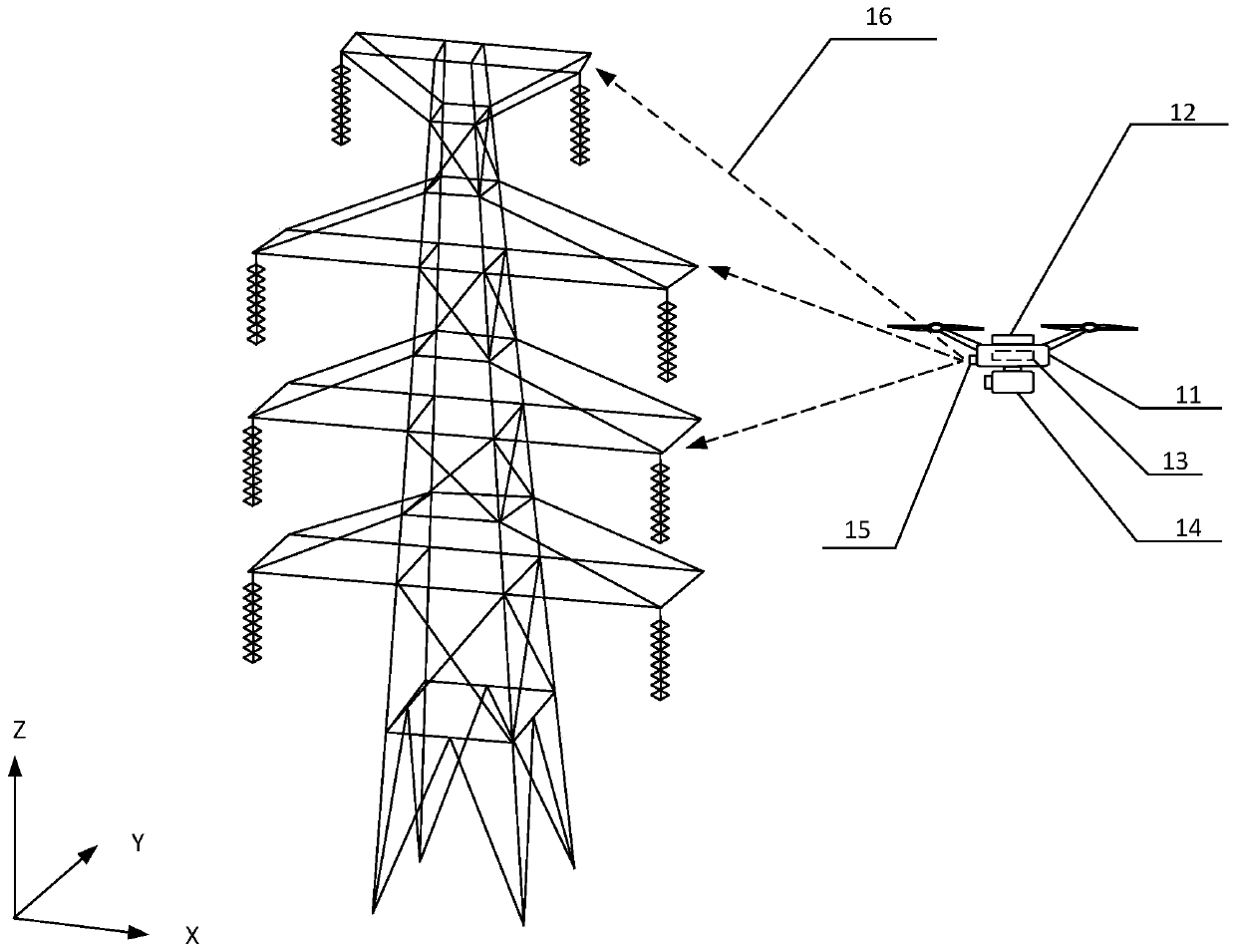

Pole tower model matching and visual navigation-based power unmanned aerial vehicle and inspection method

ActiveCN110133440AAchieve autonomous inspectionImprove inspection efficiencyFault location by conductor typesDesign optimisation/simulationUncrewed vehicleTower

The invention discloses a pole tower model matching and visual navigation-based power unmanned aerial vehicle and an inspection method. In an unmanned aerial vehicle, a depth image of a front end of the unmanned aerial vehicle is acquired by a dual-eye visual sensor, distance between the unmanned aerial vehicle and a front object is further measured, a surrounding image is acquired by a cloud deckand a camera, the object is further identified, and the flight gesture of the unmanned aerial vehicle is controlled by flight control of unmanned aerial vehicle. The method comprises the steps of performing pole tower model building on different types of power transmission line pole towers; automatically identifying the power transmission line pole towers and pole tower types by the unmanned aerial vehicle during the flight process, matching and loading a pre-built pole tower model; performing visual positioning on the power transmission line pole towers by the unmanned aerial vehicle, and acquiring relative positions of the unmanned aerial vehicle and the pole towers; and performing flight inspection by the unmanned aerial vehicle according to optimal flight path. By the unmanned aerialvehicle, the modeling workload is greatly reduced, and the model universality is improved; and the inspection method does not dependent on absolute coordinate flight, the flexibility is greatly improved, the cost is reduced, and the power facility safety is improved.

Owner:NARI TECH CO LTD

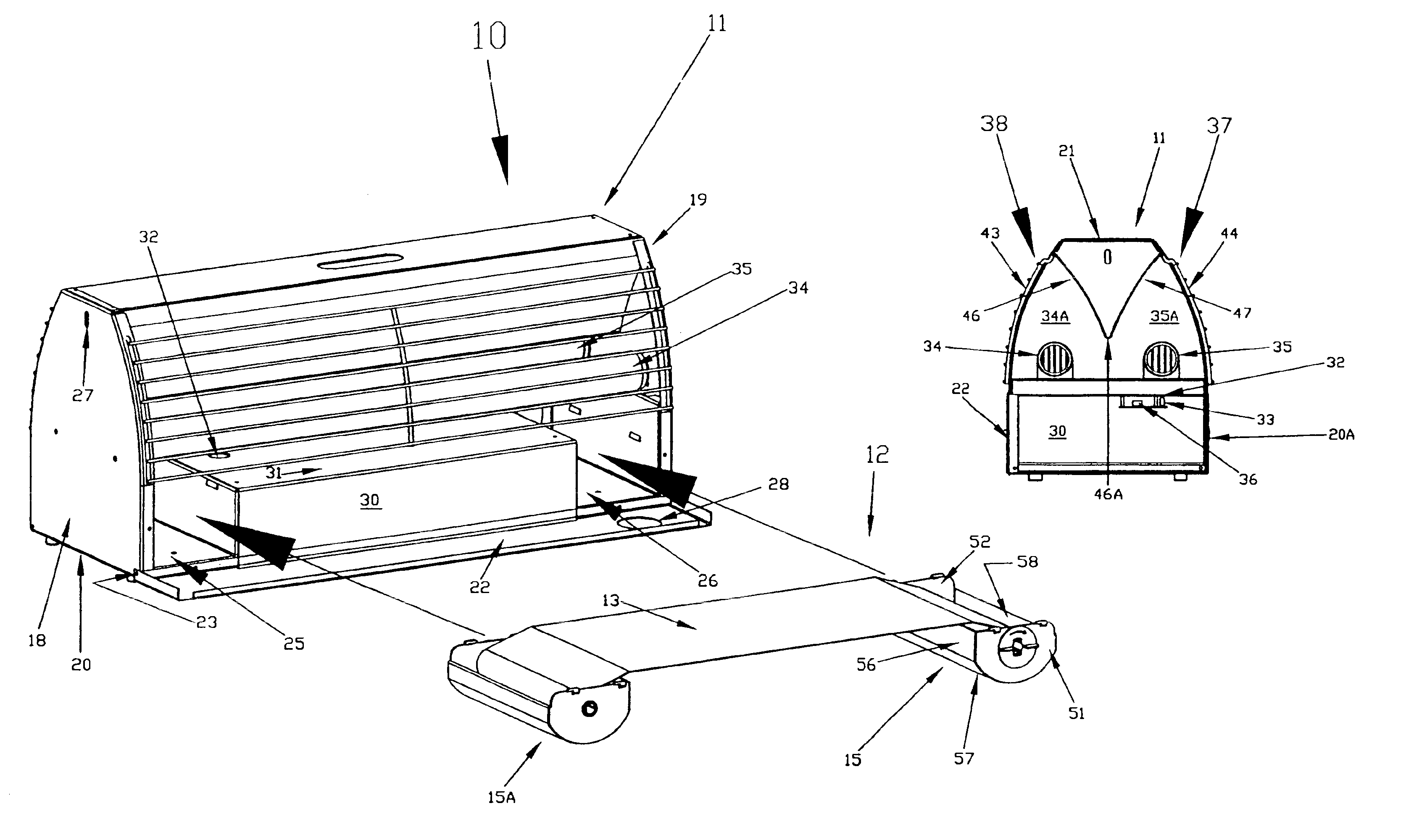

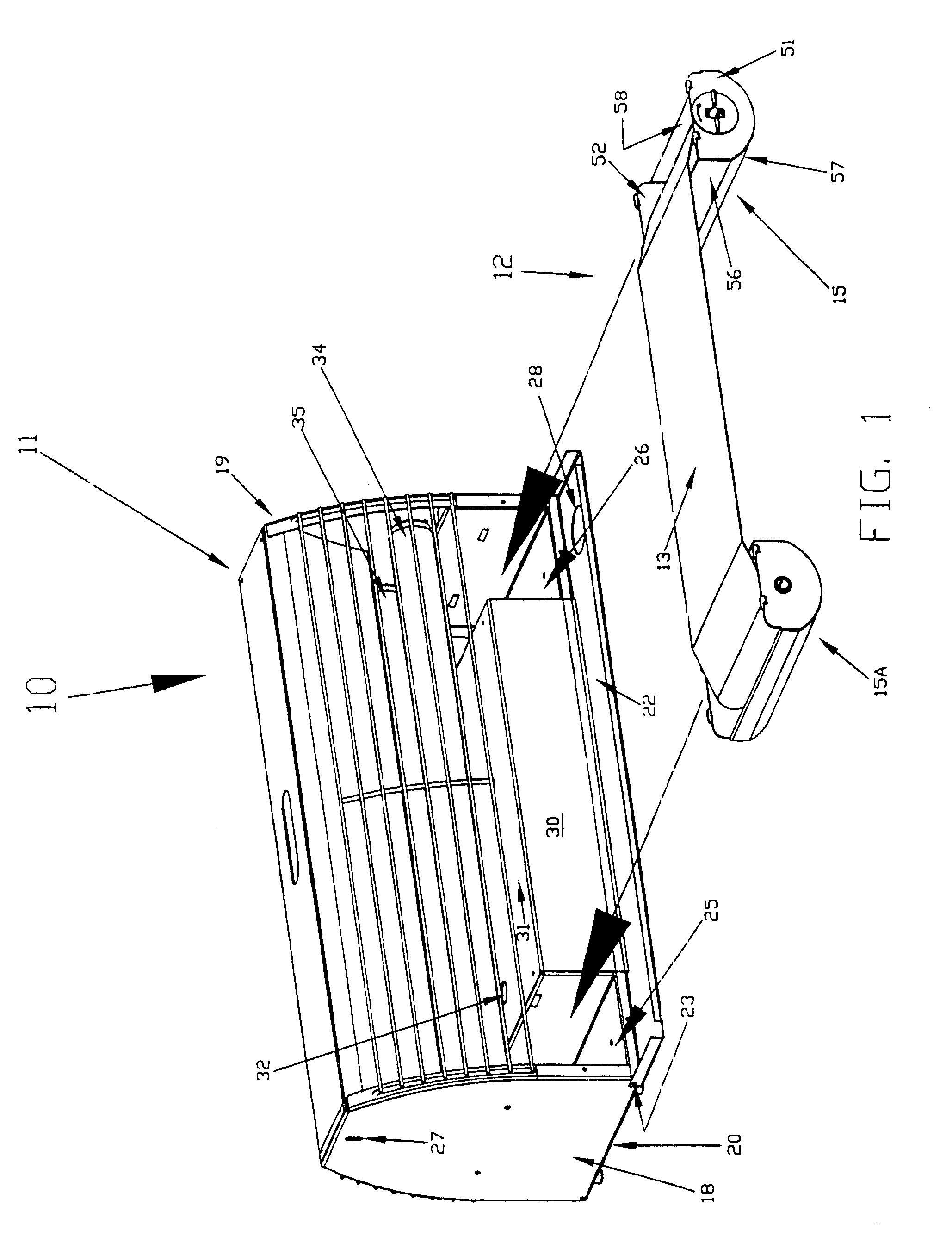

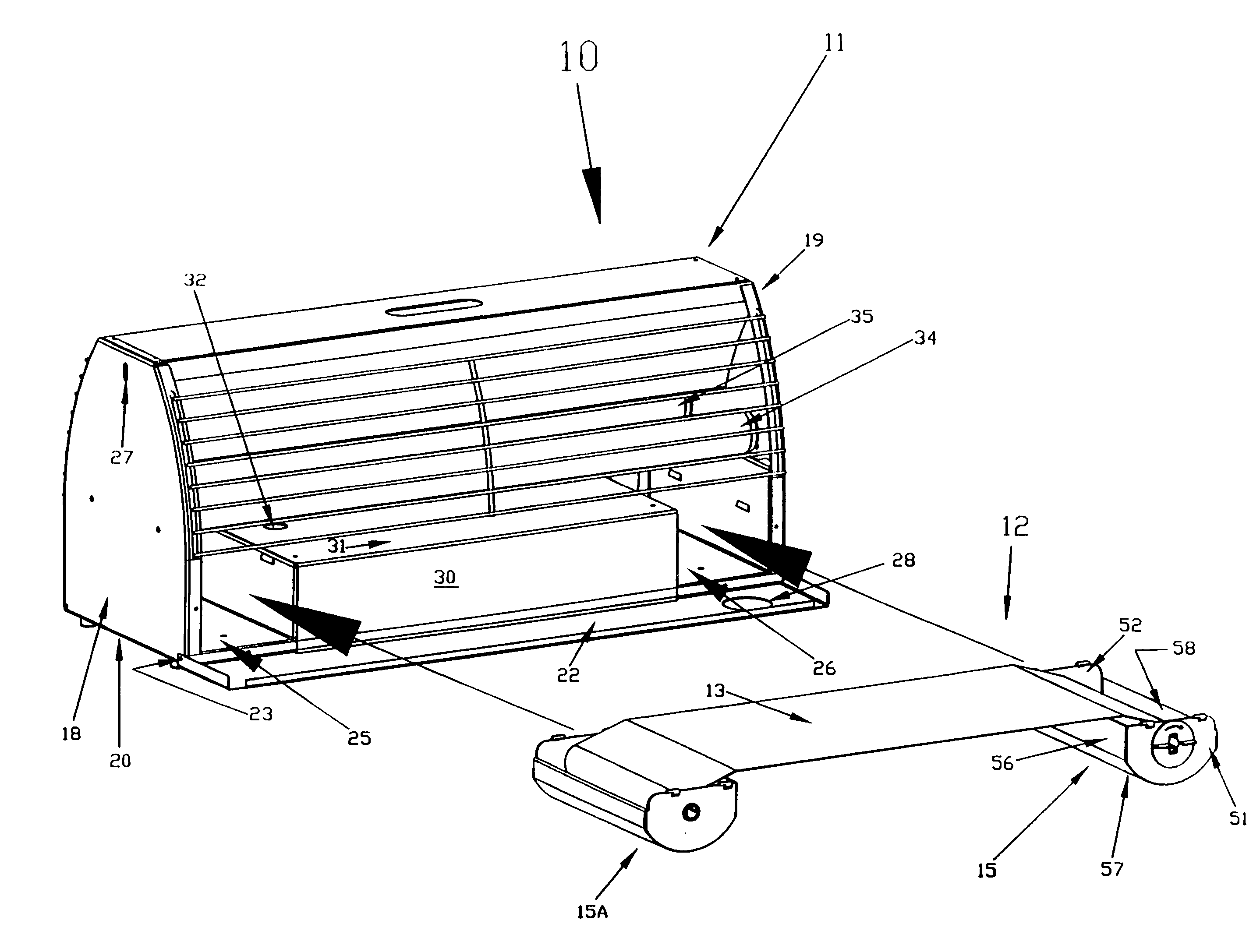

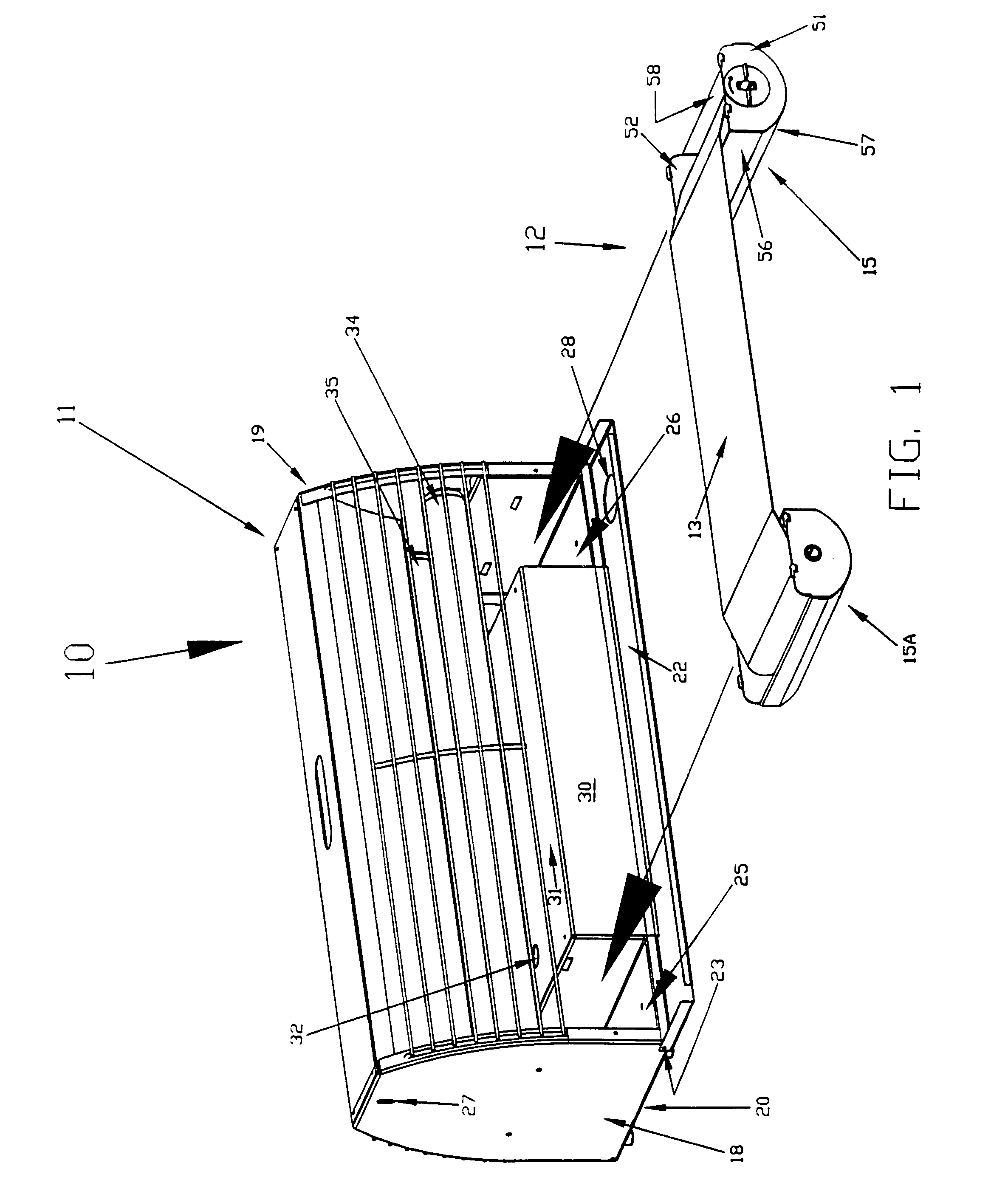

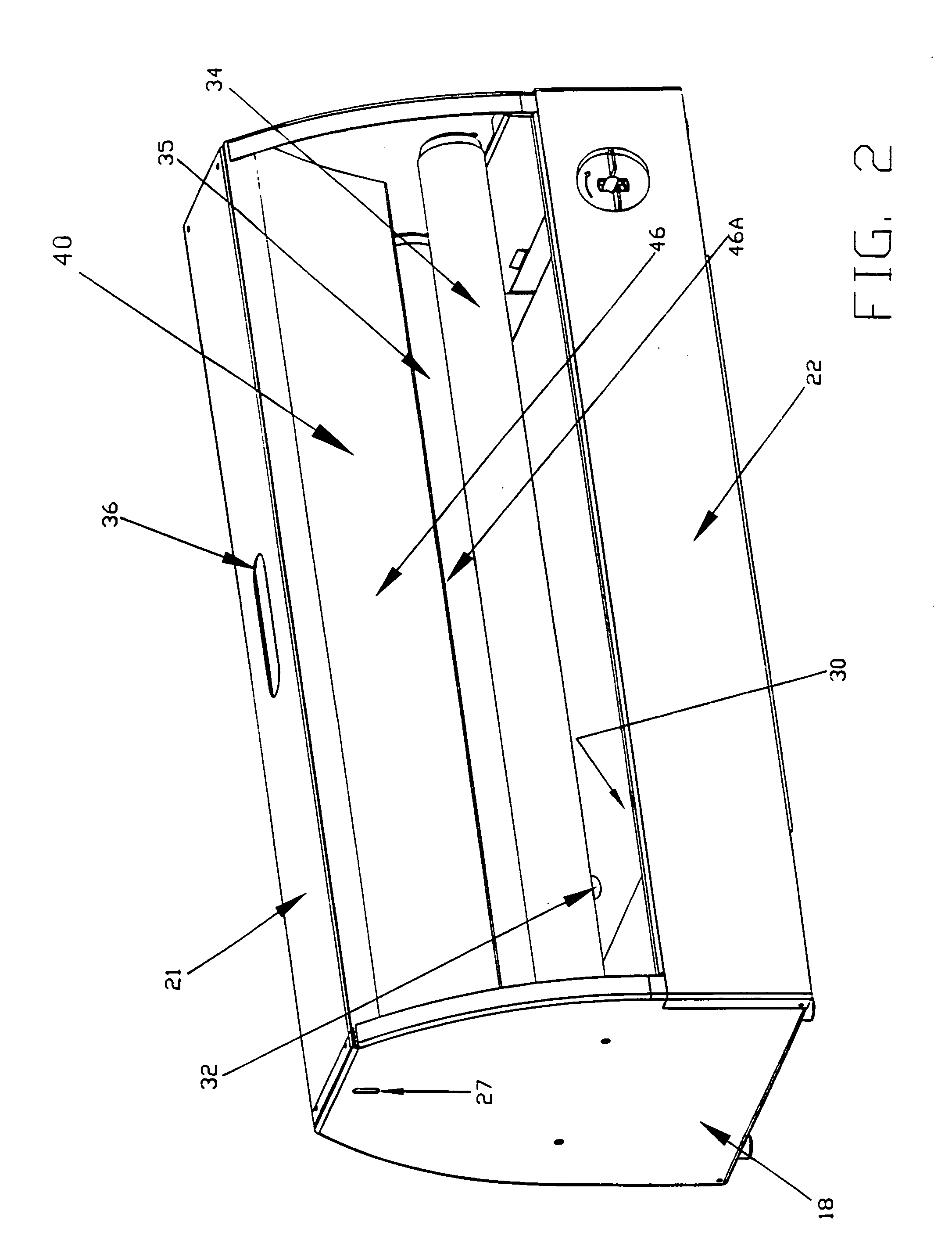

Flying insect trap

A flying inspect trap includes large, multi-directional, oppositely facing ingress openings to elongated chambers housing UV lamps emitting insect attractant light. A disposable cartridge has two sections which mate together to form a container for a roll of adhesive trapping medium. The cartridge sections are opened and spread apart to fit beneath the UV lamps. A motor indexes the adhesive medium so that some unused portion is always available for trapping insects until the roll is exhausted. The spent roll is then rolled into one cartridge section externally; and the two cartridge sections are coupled together to encase the spent roll for disposal.

Owner:PARACLIPSE SYST

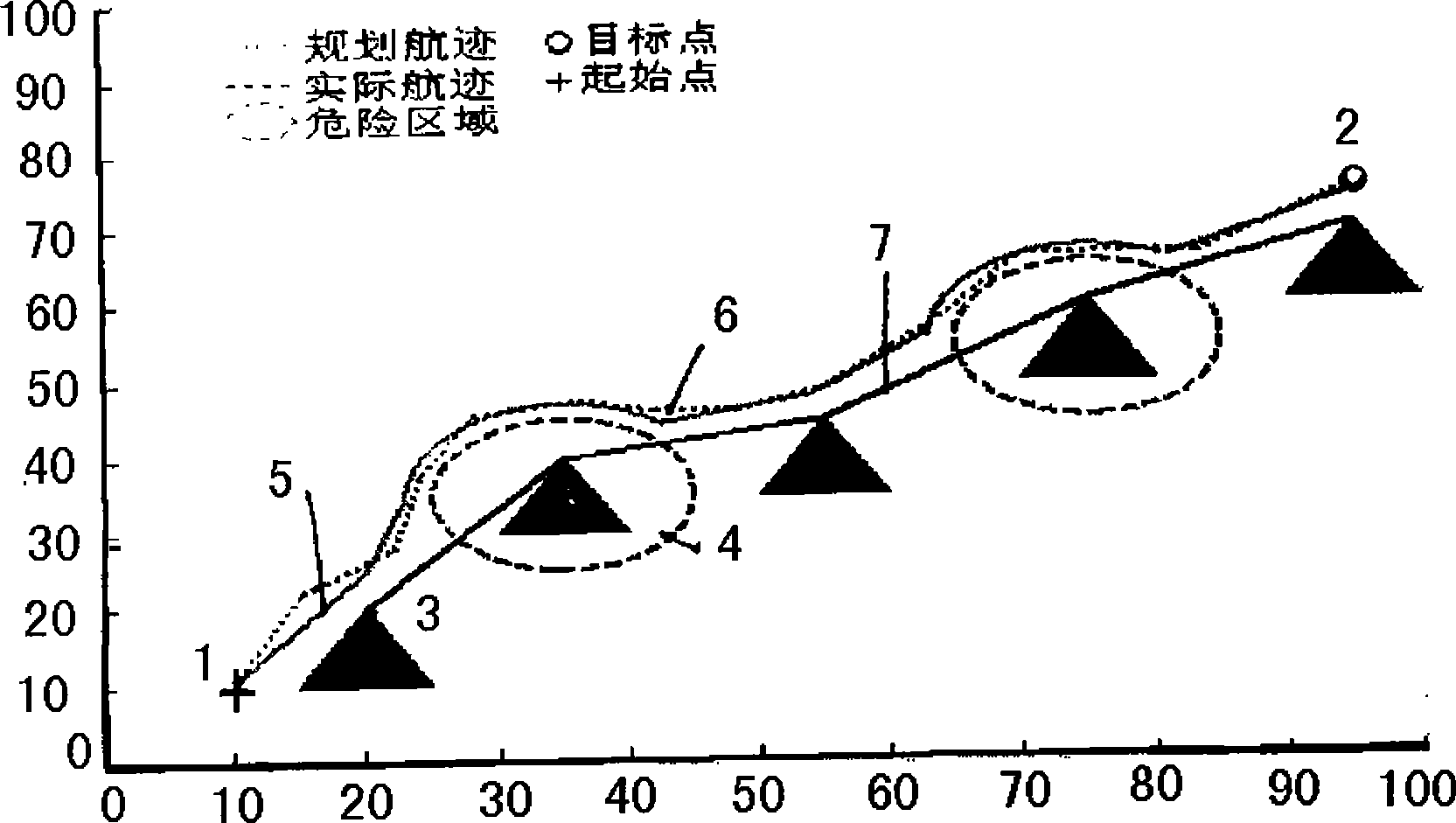

Electric power circuit detection method by polling flying robot

InactiveCN101477169AHigh technical requirementsHigh experience requirementFault locationVehicle position/course/altitude controlTask completionDimensional simulation

The invention discloses a method for detecting an electric power circuit by a flight inspection robot, and belongs to the technical field of noncontact type detection of the electric powder circuit. The method uses a minitype helicopter as a carrier; firstly, a two-dimensional simulation detection model of the flight inspection robot for the electric power circuit is established; secondly, a mathematical description method is used for establishing a target function, a constraint condition target function and a programming variable for the two-dimensional simulation detection model; and finally, according to a programming flight path designed by the two-dimensional simulation detection model, the flight inspection robot inspects the electric power circuit. The method overcomes the disadvantages that a working mode of manual inspection and manual paper medium recording can not ensure the in-place of inspectors and has inaccurate or irregular defect description, and avoids the problems that the manned helicopter used for inspection has high requirement on technique and experience of workers, the workers are required to wear specific work clothes and manpower and material resources are consumed largely. Though disposable input is large, the quality and efficiency for task completion of the method is far higher than that of the prior other modes.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Power line inspection real-time monitoring management system

InactiveCN105956672AImprove inspection efficiencyGuaranteed inspectionData processing applicationsEngineeringComputer terminal

The invention discloses a power line inspection real-time monitoring management system. The system comprises a background real-time monitoring management platform and a mobile inspection terminal, wherein the background real-time monitoring management platform stores basic data corresponding to a plurality of power transmission lines and can perform management and maintenance on the corresponding basic data of each power transmission line according to a received corresponding maintenance and management instruction; and the mobile inspection terminal is used for obtaining a newly created line inspection task from the background real-time monitoring management platform, assisting inspection personnel to perform inspection job filling, line inspection trajectory tracking and risk point data filling tasks in a line inspection task process, and uploading an inspection job, line inspection trajectory tracking, risk point data and the like to the background real-time monitoring management platform. According to the system, on one hand, intelligent real-time monitoring of a power line inspection on-duty situation can be effectively carried out; and on the other hand, the line inspection job process is standardized and the timeliness and convenience of line inspection data record standardization as well as line inspection task sending and result recovery are achieved.

Owner:STATE GRID CHONGQING ELECTRIC POWER +1

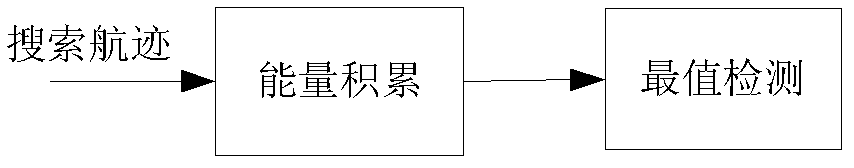

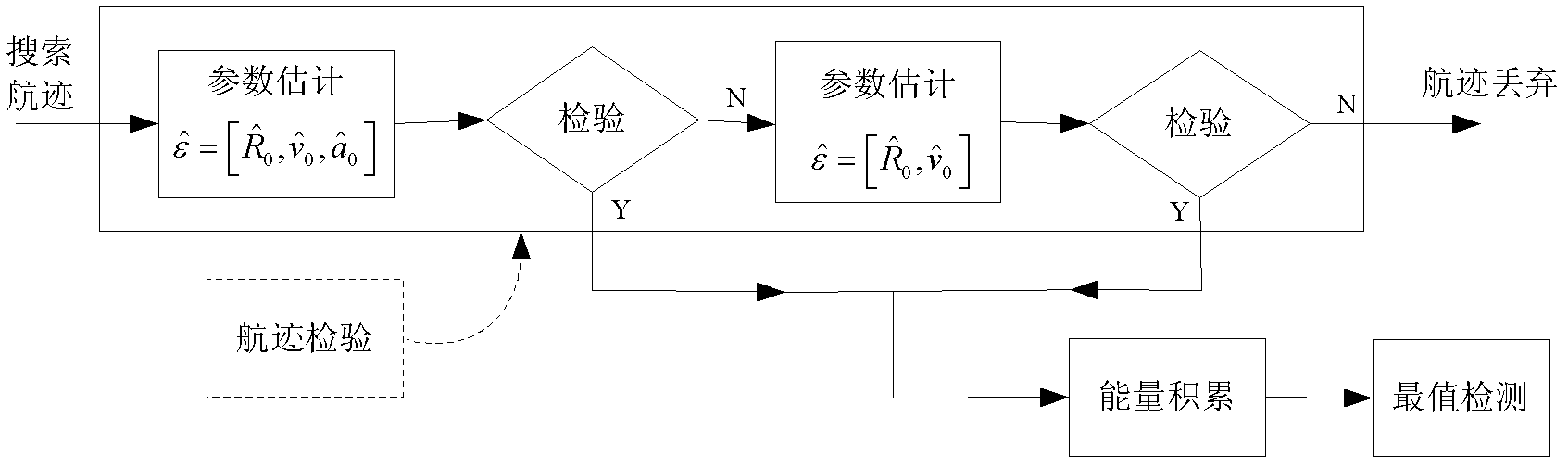

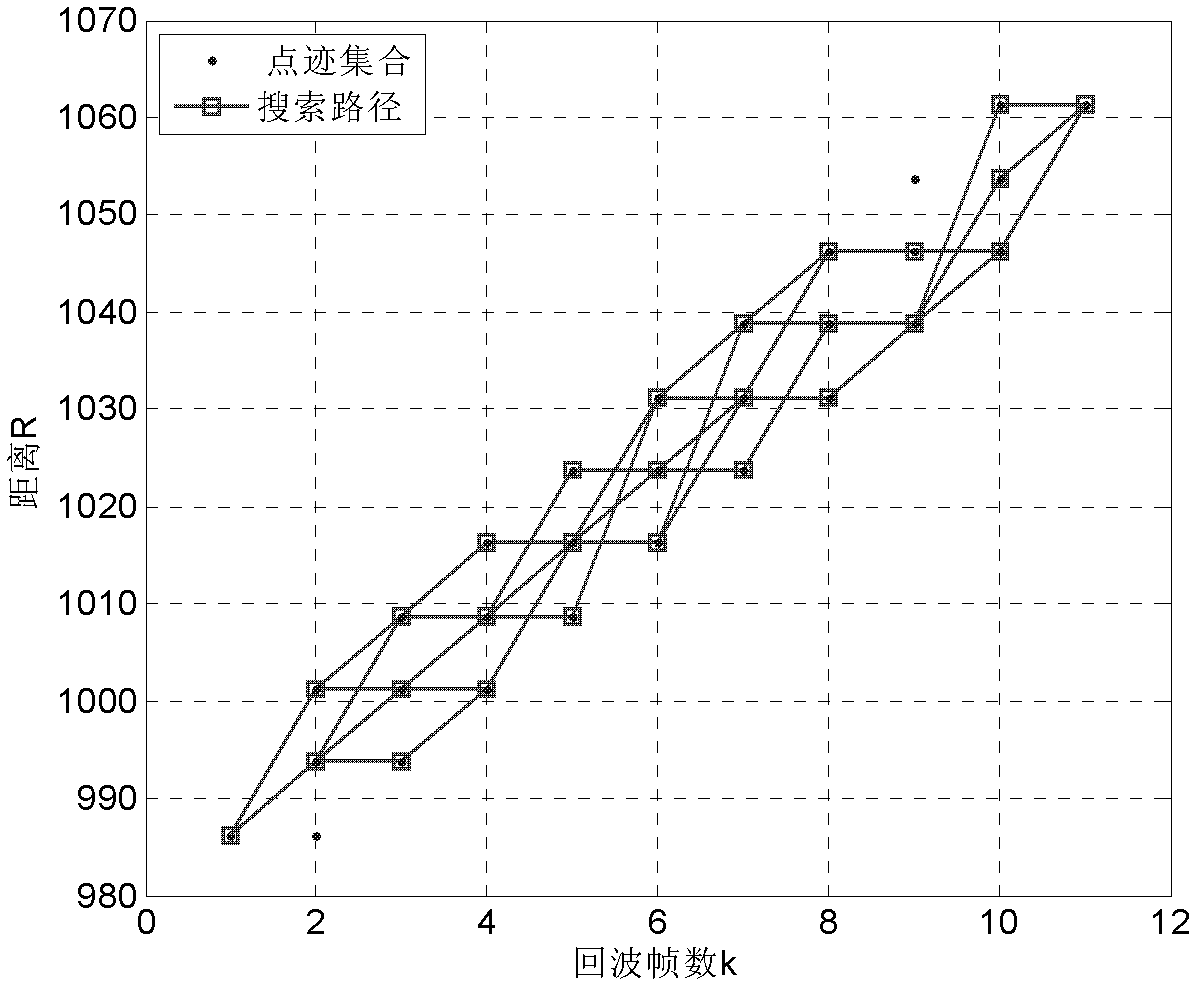

Track-before-detect method based on flight path inspection

InactiveCN102419437AImprove accuracyEasy to detectRadio wave reradiation/reflectionTrack-before-detectRadar

The invention discloses a track-before-detect method based on a flight path inspection. The method comprises the following steps: receiving multiple frames of echo pulse of a target by radar, and exhausting all flight paths among the multiple frames of target echo; performing the flight path inspection on each flight path by using a set target movement model according to a regression analysis method, screening out the flight path in constant speed and constantly accelerated motion from all the flight paths; performing the energy accumulation on all flight paths subjected to the flight path inspection, then selecting the maximum energy accumulation value to compare with a threshold to obtain a detection result. The method can obtain the trajectory with the constantly accelerated or constant speed motion characteristic, the trajectory is approximate to the real trajectory; therefore, the accuracy of flight path acquisition is improved, and the TBD (track-before-detect) tracking performance is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

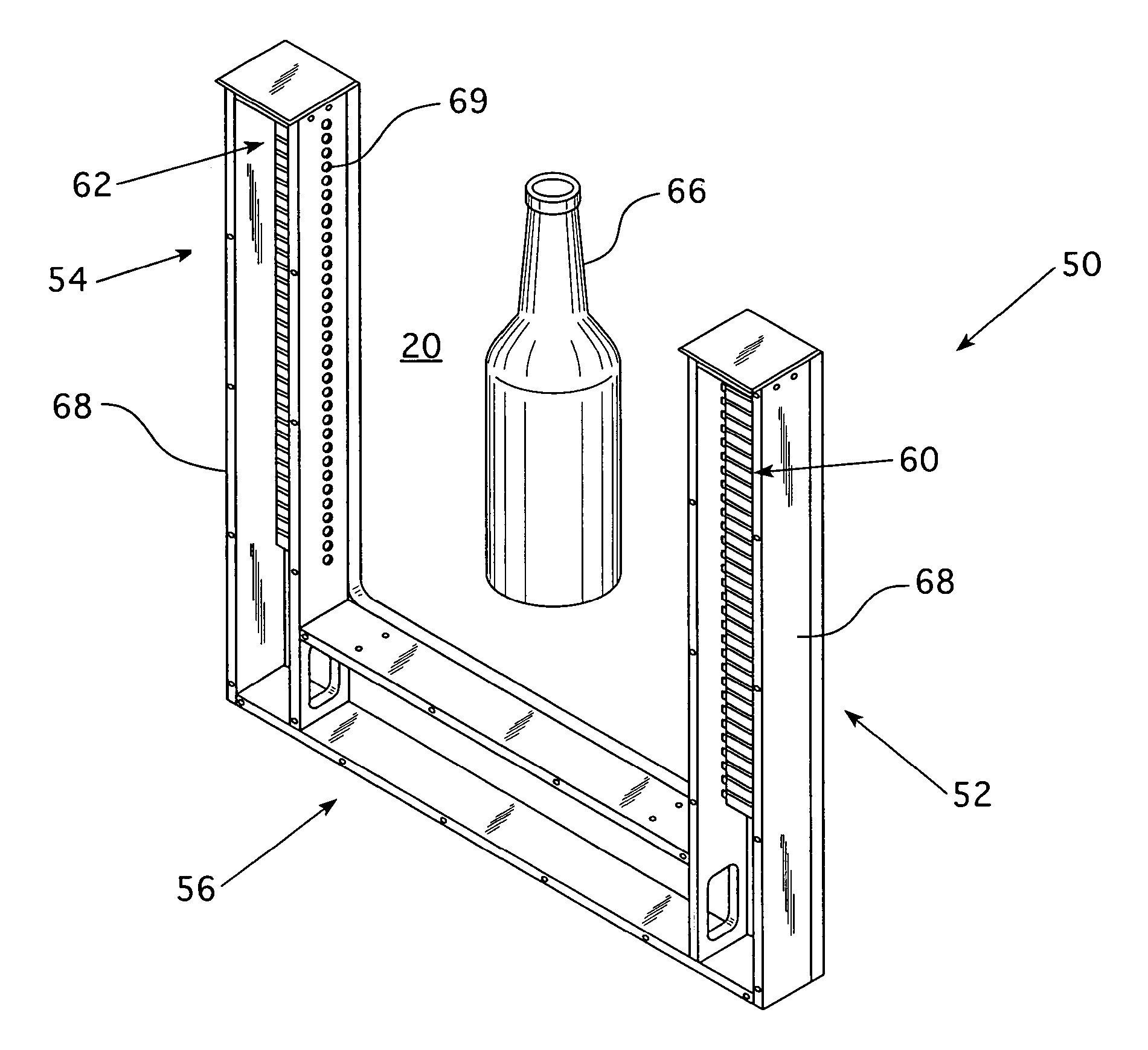

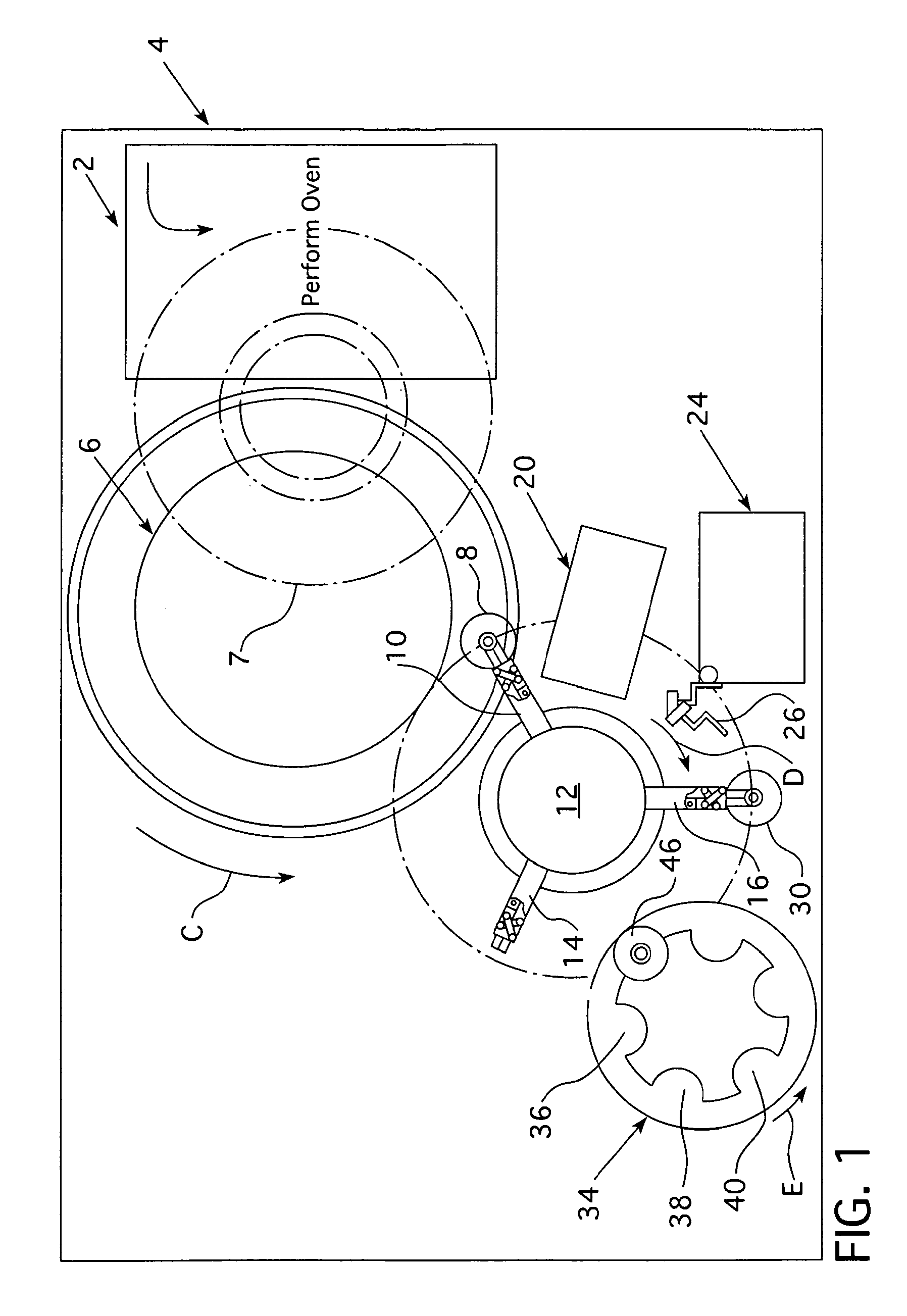

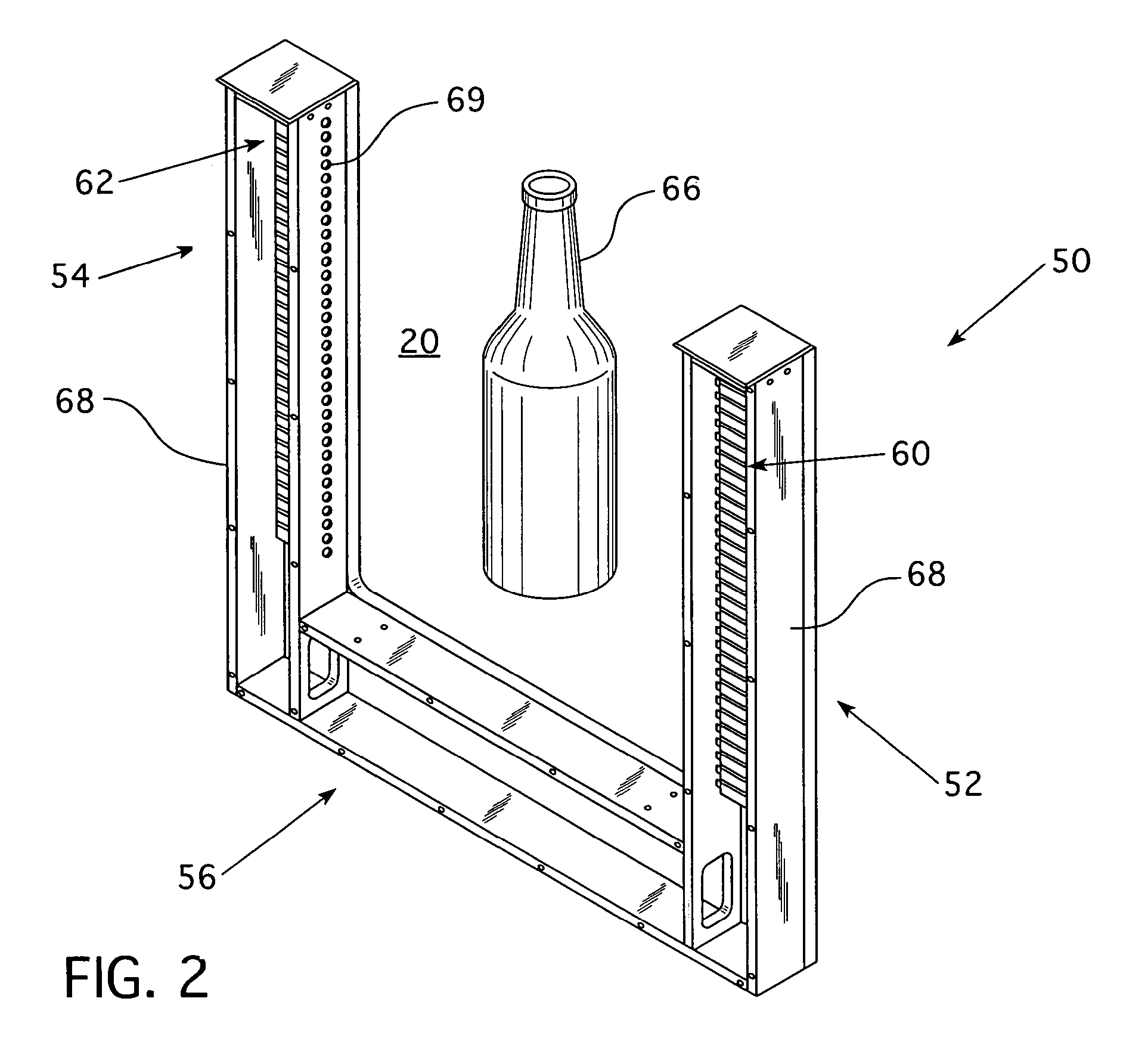

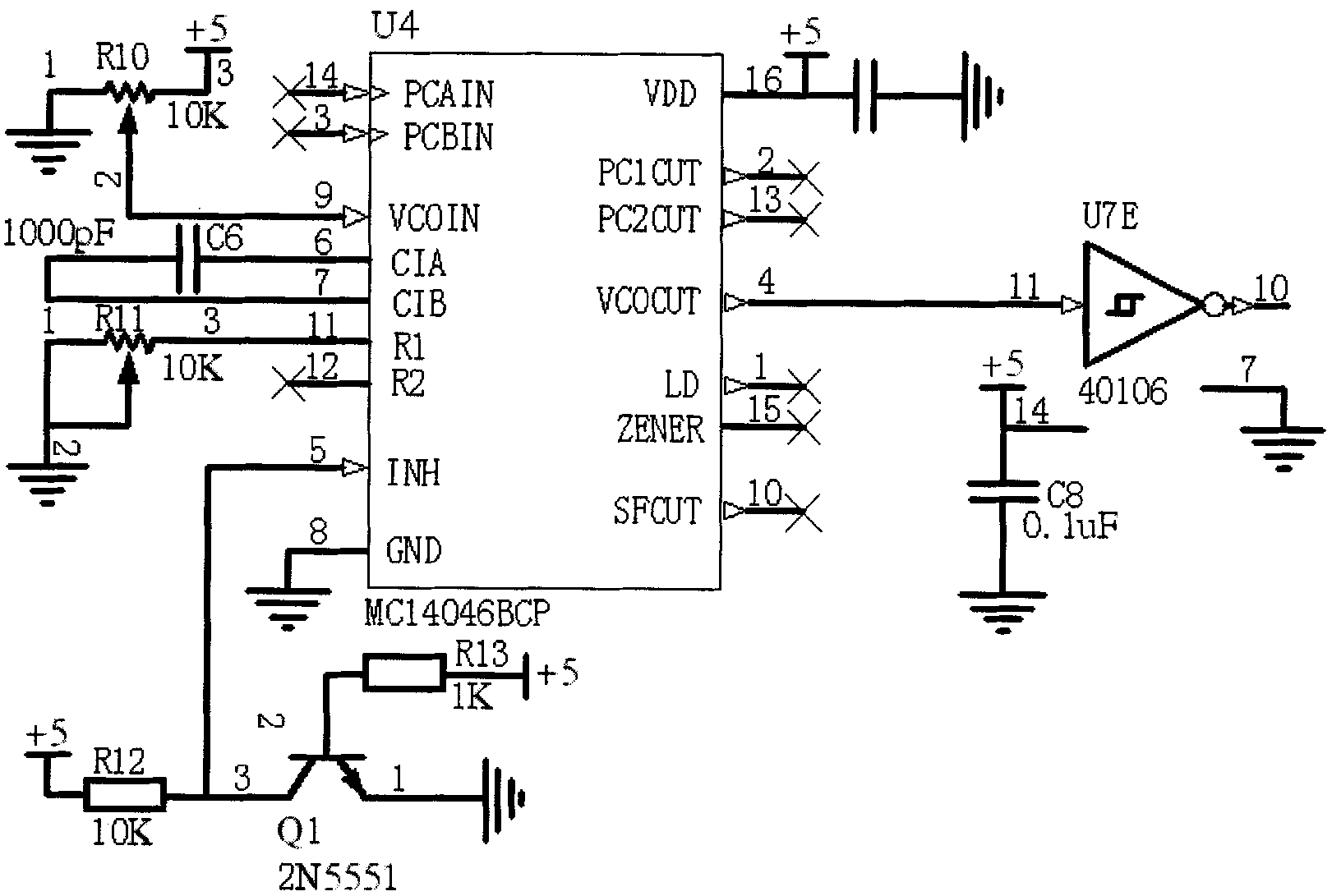

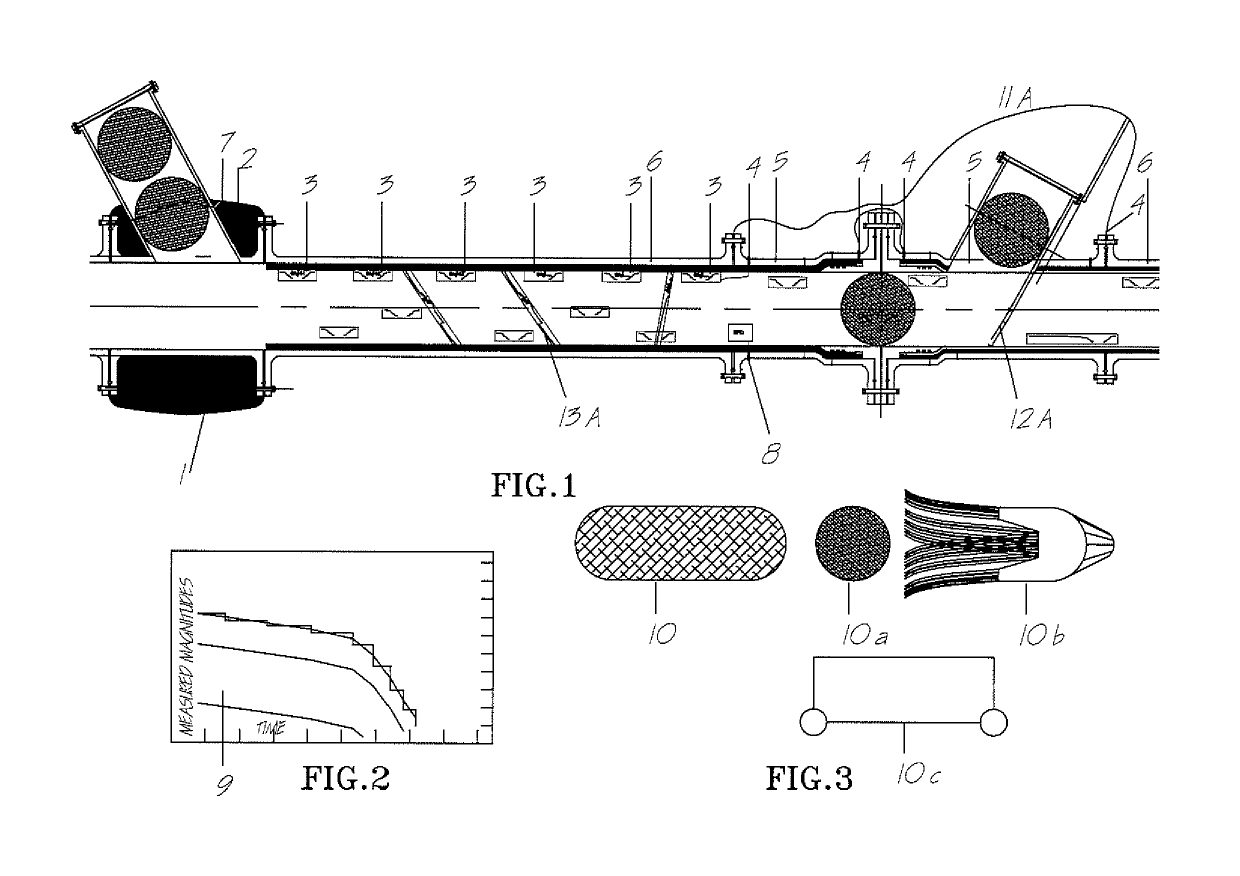

In-line inspection system for vertically profiling plastic containers using multiple wavelength discrete spectral light sources

ActiveUS7924421B2Counting objects on conveyorsPhotoelectric discharge tubesPhotovoltaic detectorsPhotodetector

Systems and methods for in-line inspection of plastic blow molded containers. The inspection system may comprise a plurality of emitter assemblies arranged in a vertical array. Each emitter assembly may cyclically emit light energy in at least two different narrow wavelength bands at a container as the container passes through an inspection area. The system may also comprise a plurality of broadband photodetectors arranged in a vertical array, each photodetector facing at least one of the emitter assemblies with the inspection area therebetween such that the photodetectors are capable of sensing light energy that passes through the container when it is in the inspection area. The system may also comprise a processor in communication with the photodetectors for determining a characteristic of the container based on signals from the photodetectors.

Owner:AGR INT

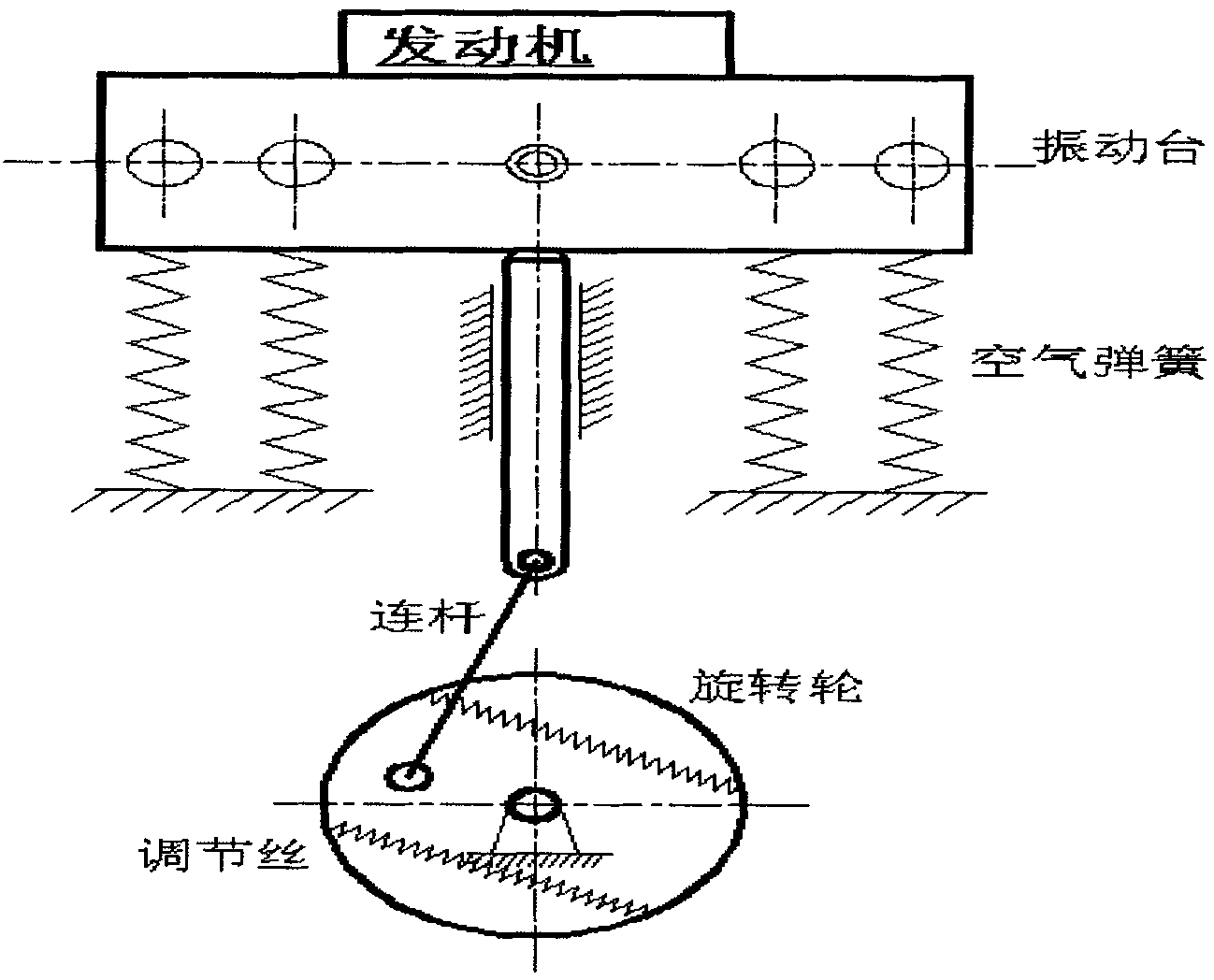

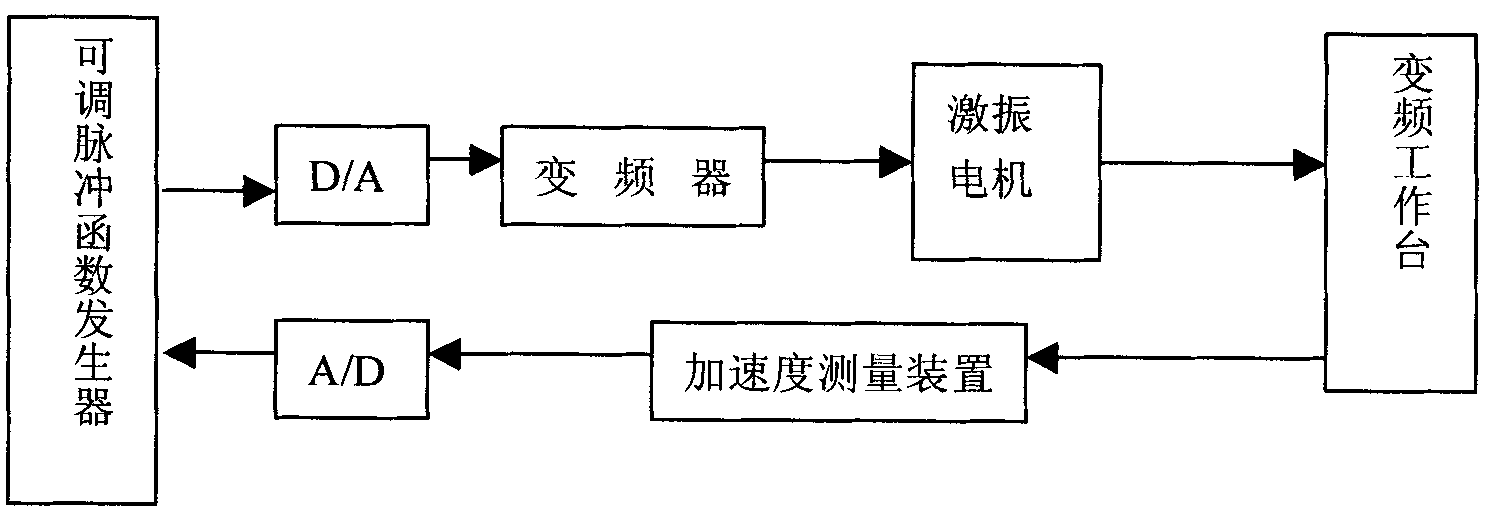

Method for quality inspection of active fault and diagnosis of intelligent fault of engine

InactiveCN101839805ALow costImprove reliabilityInternal-combustion engine testingNeural learning methodsNon linear mappingReliability engineering

The invention discloses a method for quality inspection of active fault and diagnosis of intelligent fault of an engine, which corresponds the symptom of the fault with corresponding frequency for quality inspection of the active fault when the engine is not disassembled. The method specifically comprises the steps of: sequentially loading signals with different frequencies from low frequency to high frequency by a vibrating device to an engine system according to the principle of a relationship between the frequencies and the fault; resonating by the signals with the same frequency; determining the symptom of the fault generated by the signals at the frequency or frequency band; collecting corresponding fault information; extracting the eigenvector of the fault for the collected fault information by a wavelet analysis method as an input eigenvector of inheriting and optimizing wavelet neural network input nodes; and obtaining a network training sample to diagnose on-line measured data. A study sample of the invention has the advantages of easy acquirement, strong pertinence, high accuracy, low cost and the like. An optimized network has the characteristics of good nonlinear mapping and high convergence speed, and can effectively diagnose the fault of the engine.

Owner:TONGJI UNIV

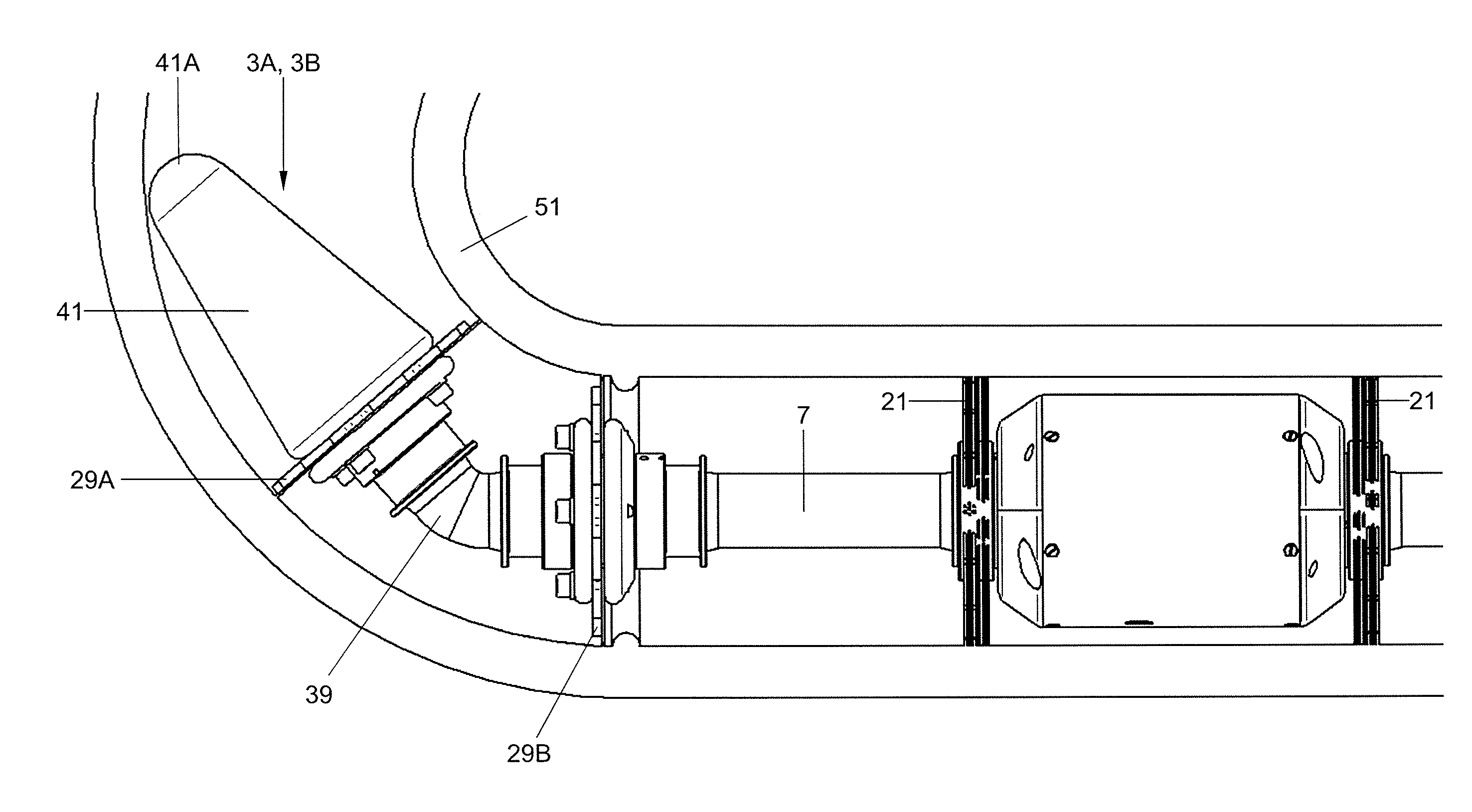

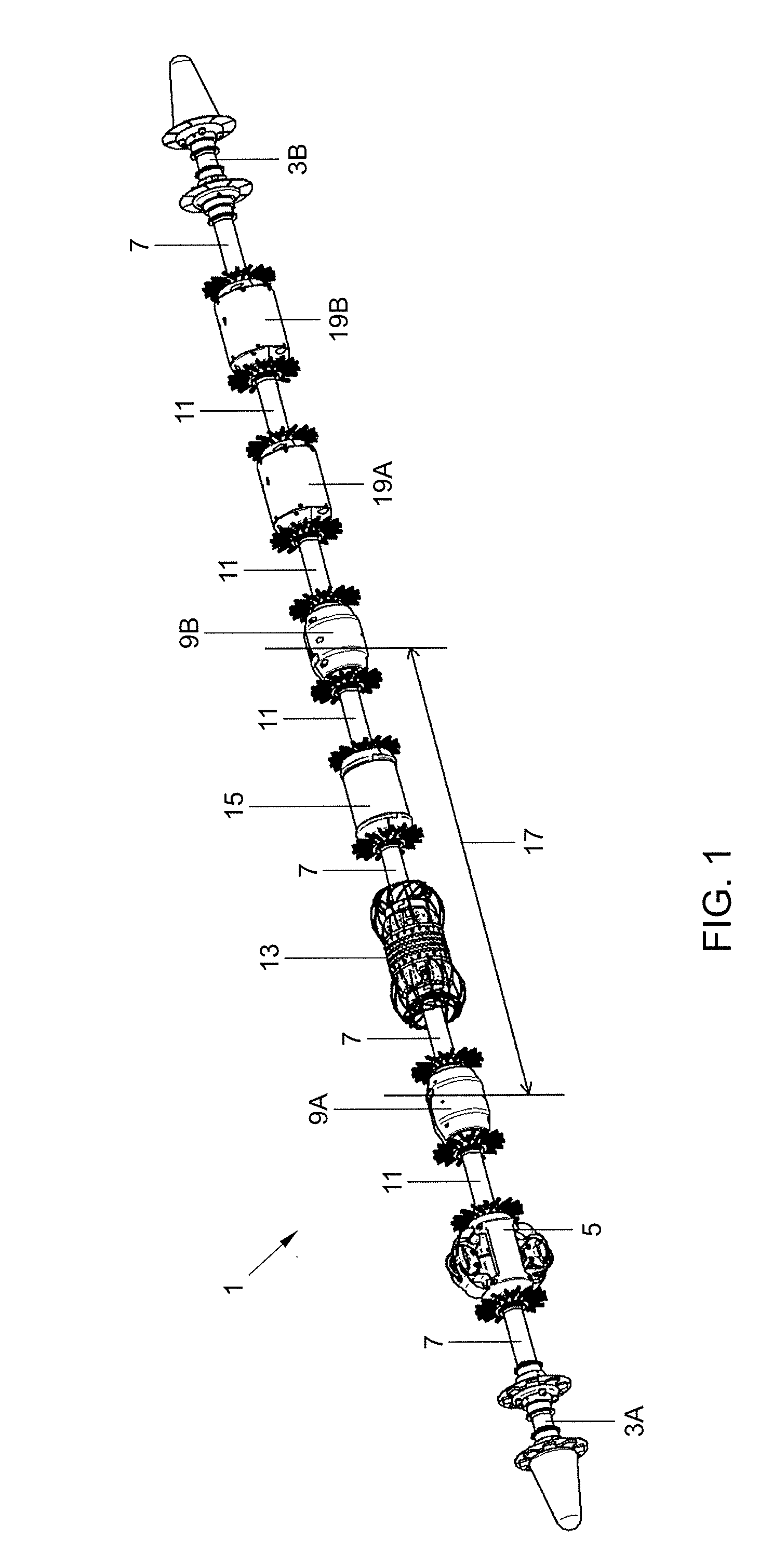

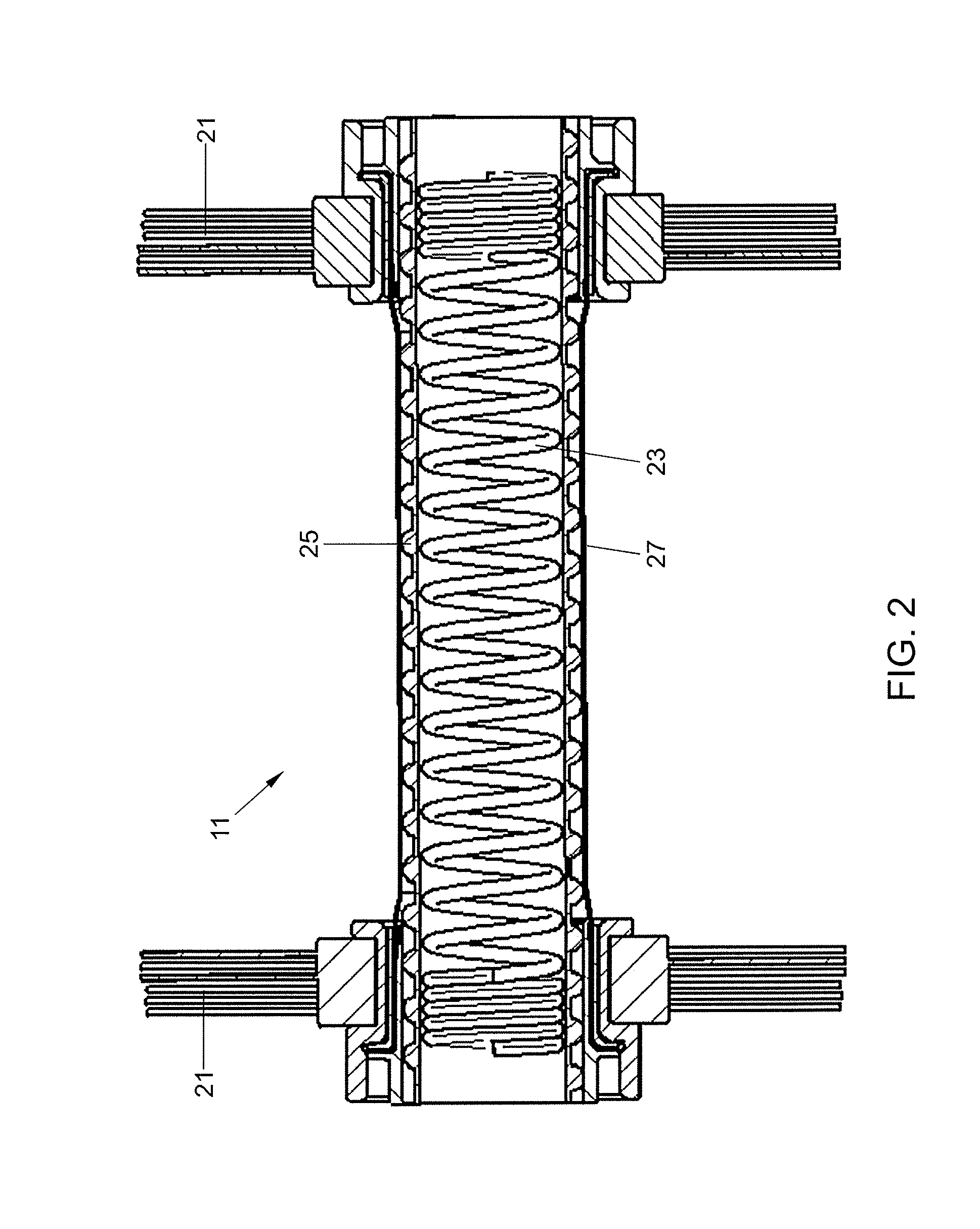

Tool, method, and system for in-line inspection or treatment of a pipeline

ActiveUS20150330551A1Less cumbersome in assemblyCumbersome operationAnalysing solids using sonic/ultrasonic/infrasonic wavesVibration measurement in fluidEngineeringUltrasonic testing

A tool, method, and system for in-line inspection or treatment of a pipeline, with the tool including a first traction module on a first longitudinal end, and a second traction module on a second end. The tool includes at least one work module, such as an encoder module and / or an ultrasonic testing module, which is positioned between the first and second traction modules. A plurality of flexible connecting elements each interconnect one of the first and second traction modules for articulation to the at least one work module. Each of the first and second traction modules has at least one sealing element that causes propulsion in response to a fluid flow in a pipeline to be inspected or treated in one direction and allows relatively unhindered passing of the fluid flow in an opposite direction.

Owner:ROENTGEN TECHNISCHE DIENST BV

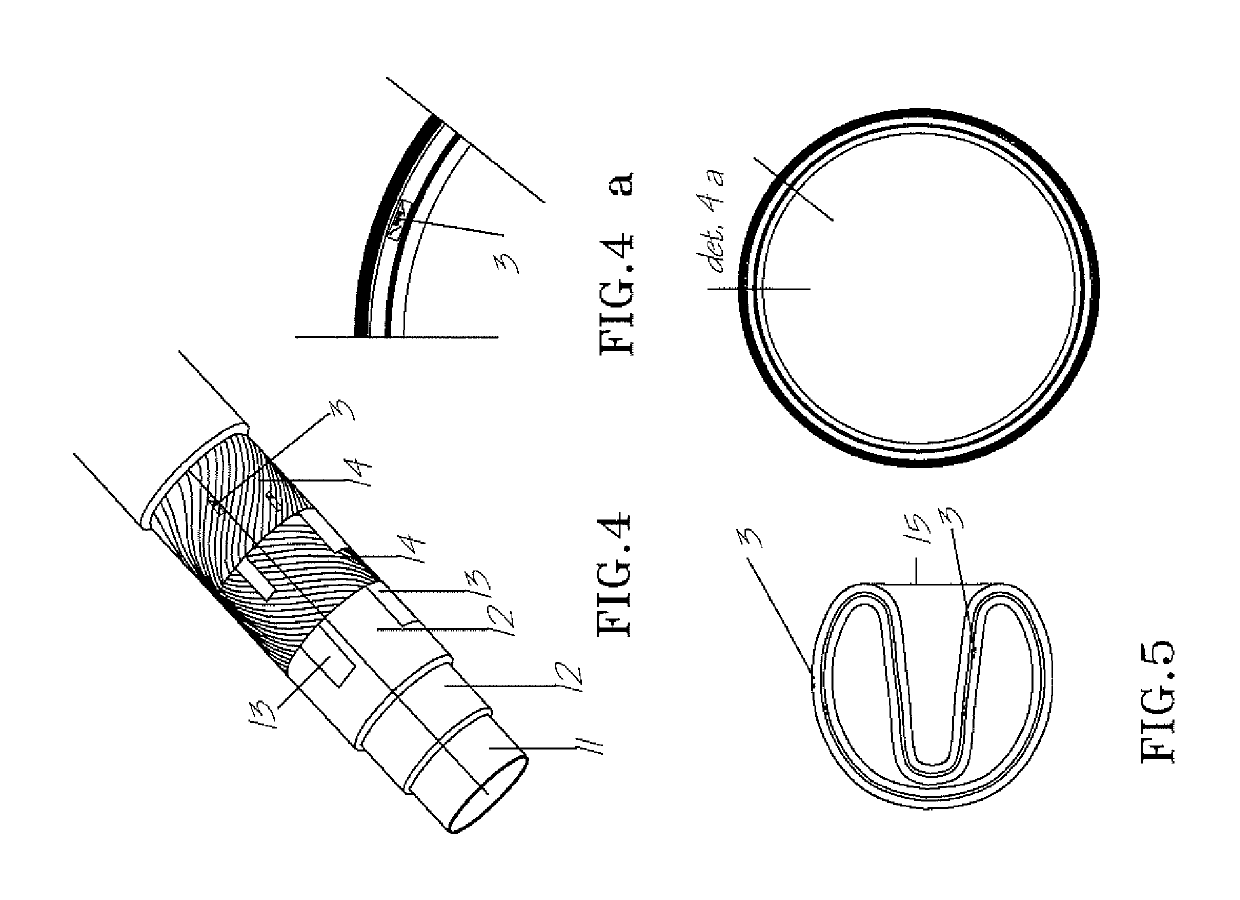

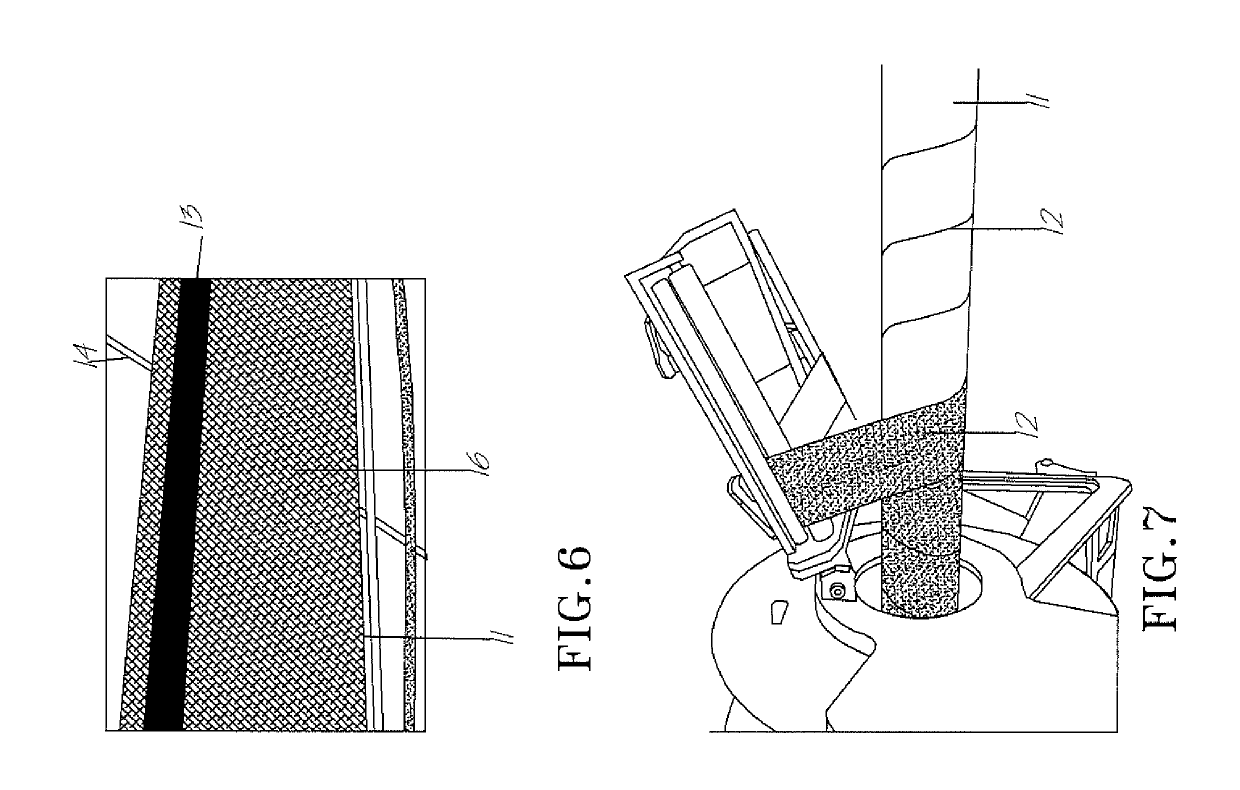

In line inspection method and apparatus for performing in line inspections

An apparatus and method for performing inline inspections of pipelines of composite structure installed in a host pipeline or standing alone comprising a multiplicity of sensor / transducers located on or within the pipe structure to measure and record various pipeline properties, an activation / reading / storage device to activate read and collect measurement results from the sensor transducers, an automatic launch and recovery system for the activation / reading / storage device, and a database / storage / analytical device to receive, analyze and interpret results from collected data and transmit appropriate instructions to a pipeline operator or remotely activated system for action. The remote reading of sensor / transducers may be accomplished by a device running through the pipeline or passing over or near the pipeline, where ground-level handheld or wheeled vehicle mounted, fixed wing or rotary aircraft, hovercraft watercraft or satellite based instrumentation can record the location and condition of a pipeline.

Owner:SMART PIPE COMPANY

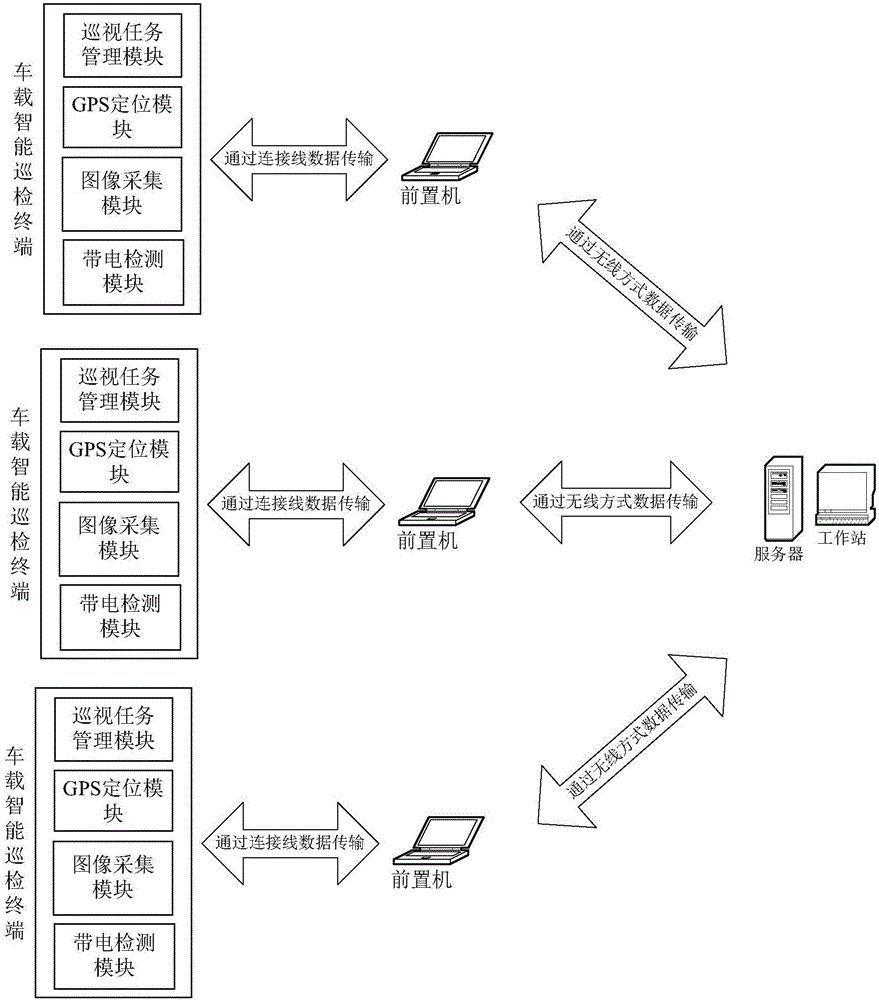

Smart inspection system for distributing line based on vehicle-mounted mobile terminal and inspection method

InactiveCN106296864AImprove inspection efficiencyImprove power supply reliabilityData processing applicationsRegistering/indicating during manufacturing processInformatizationMaster station

The invention discloses a smart inspection system for a distributing line based on a vehicle-mounted mobile terminal and an inspection method. The system comprises a vehicle-mounted smart inspection terminal, wherein the vehicle-mounted smart inspection terminal is arranged on the top of a vehicle and mutually communicates with a master station server; the vehicle-mounted smart inspection terminal is configured to generate inspection result data according to received data and uploads the inspection result data to the master station server; the master station server is configured to receive and store the inspection result data uploaded by the vehicle-mounted smart inspection terminal, and analyzes and early warns distributing line faults according to the received data. According to the smart inspection system and the inspection method disclosed by the invention, intelligentization and informatization of distributing line inspection are realized by adopting a smart control and information communication technology, the working efficiency of inspection of the distributing line can be effectively improved, labor force is saved, inspection times are increased, potential hazards of equipment are found in time, and the reliability of power supply is improved.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

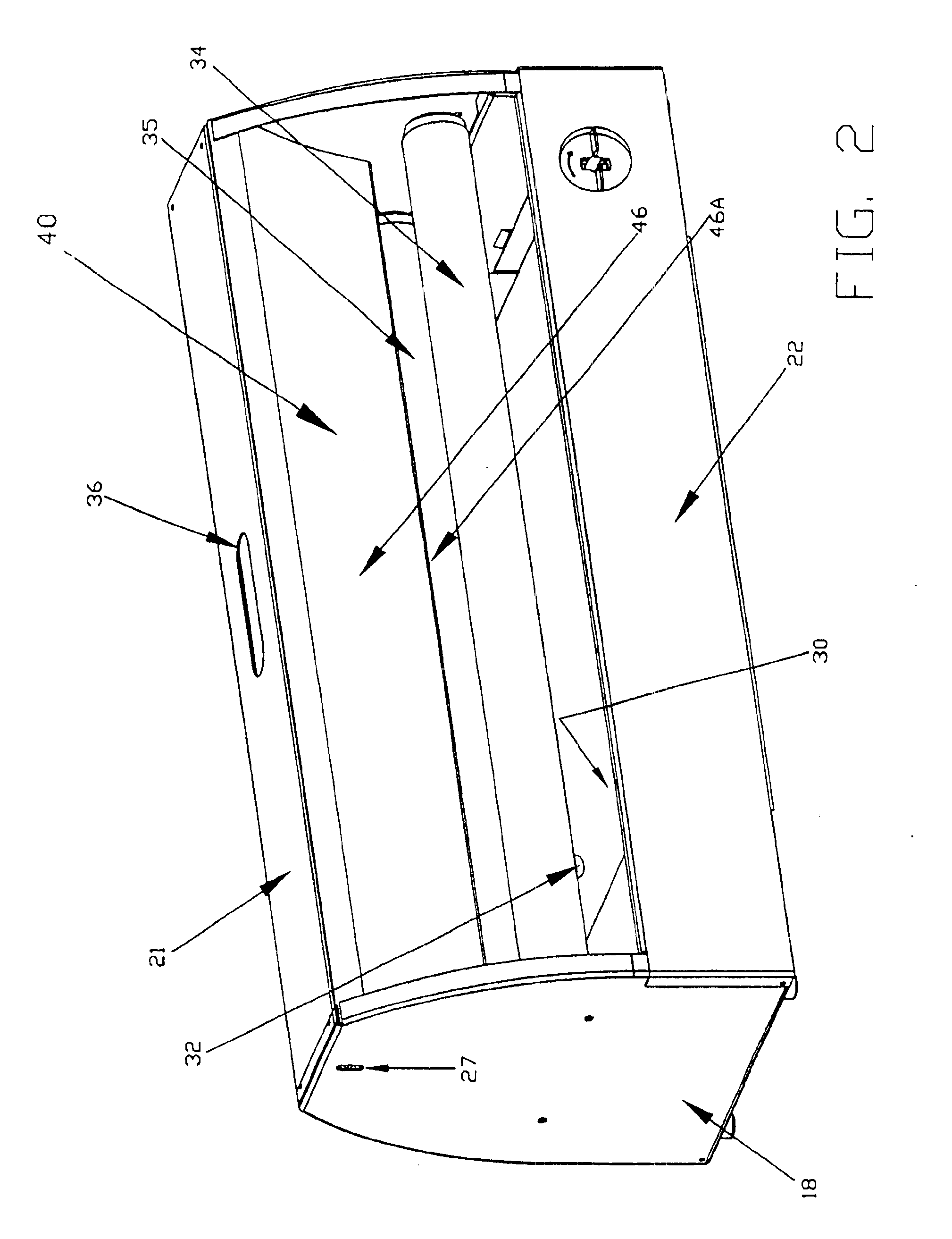

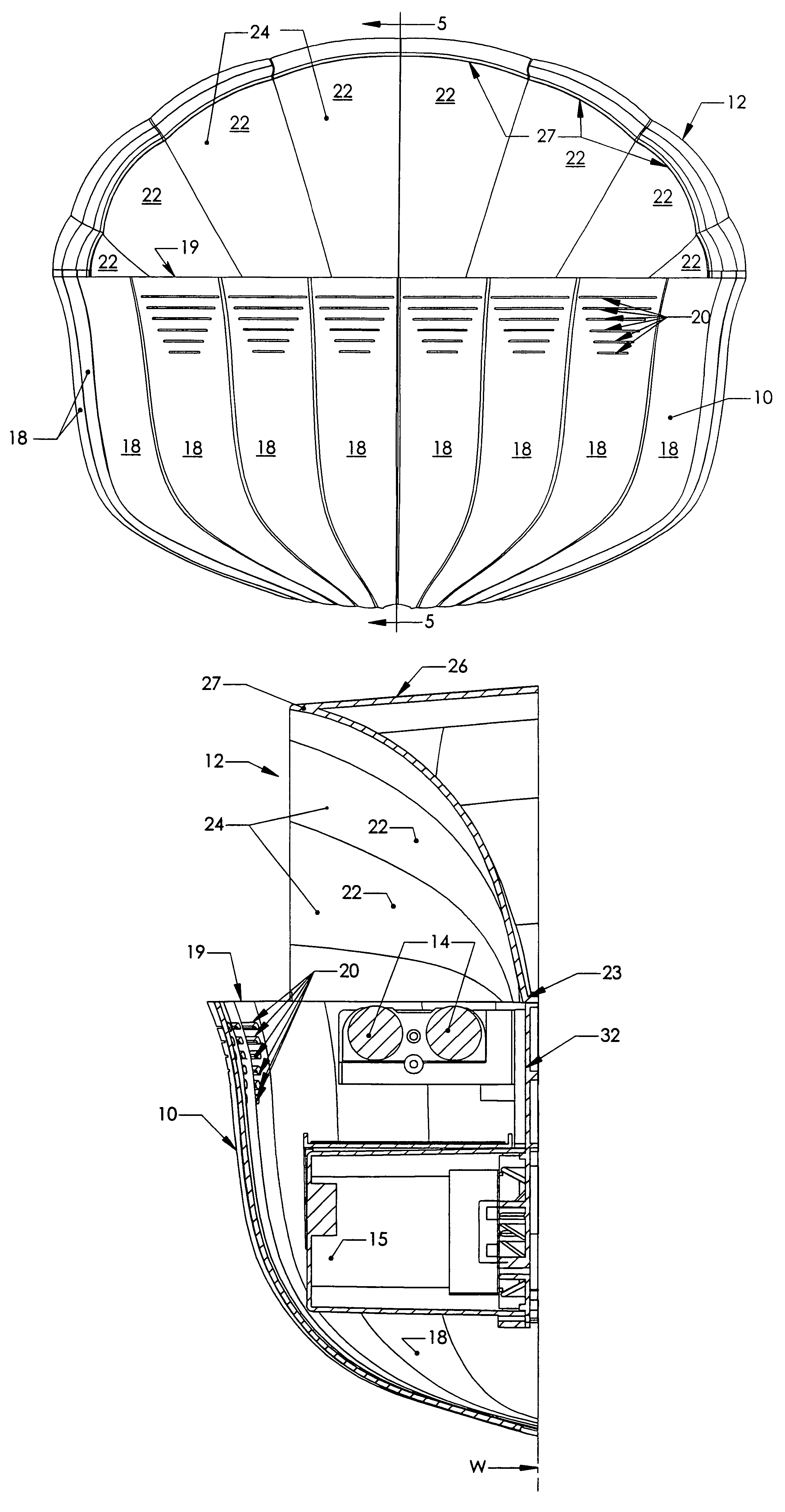

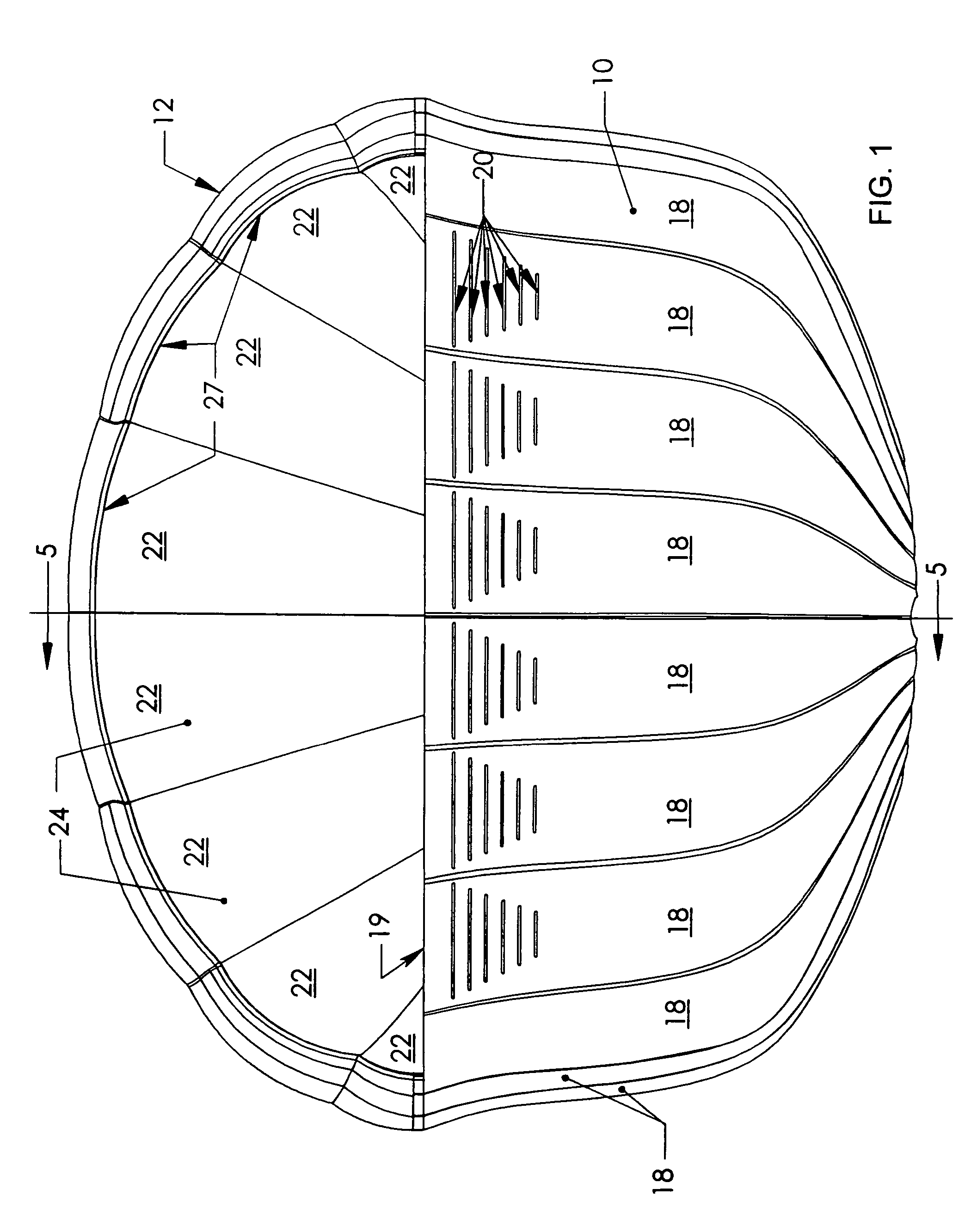

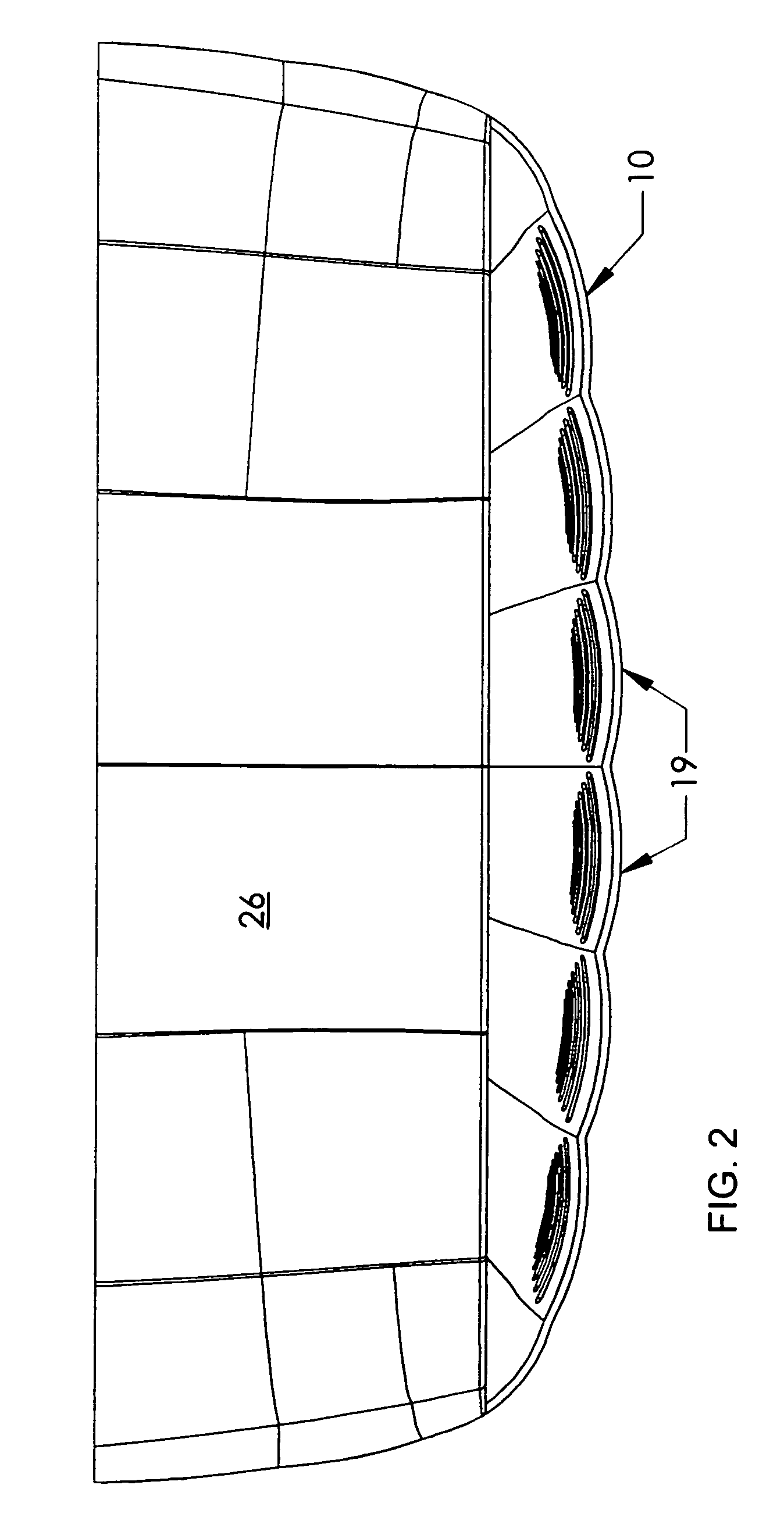

Flying insect trap

ActiveUS7036268B2Increase attractionAvoid shiningLighting elementsFree standingEngineeringInsect trap

A flying inspect trap has a source of UV light to attract insects and an adhesive sheet to trap them. A concave housing which encloses the light source and the trapping medium has a series of narrow light-transmissive slits in a front wall to permit a direct partial viewing of the source from the front of the unit to enhance insect attraction. A cover mounted above the housing has a reflecting surface in the form of a band shell which reflects light from the source out into the room as well as downwardly in front of the unit, and prevents light from shining directly or indirectly on the wall above the housing.

Owner:PARACLIPSE SYST

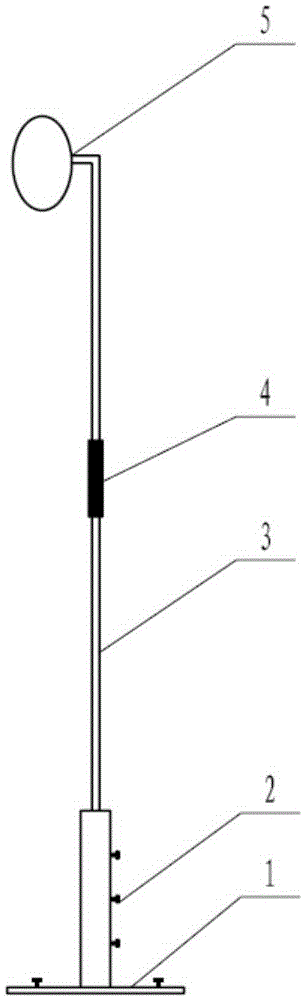

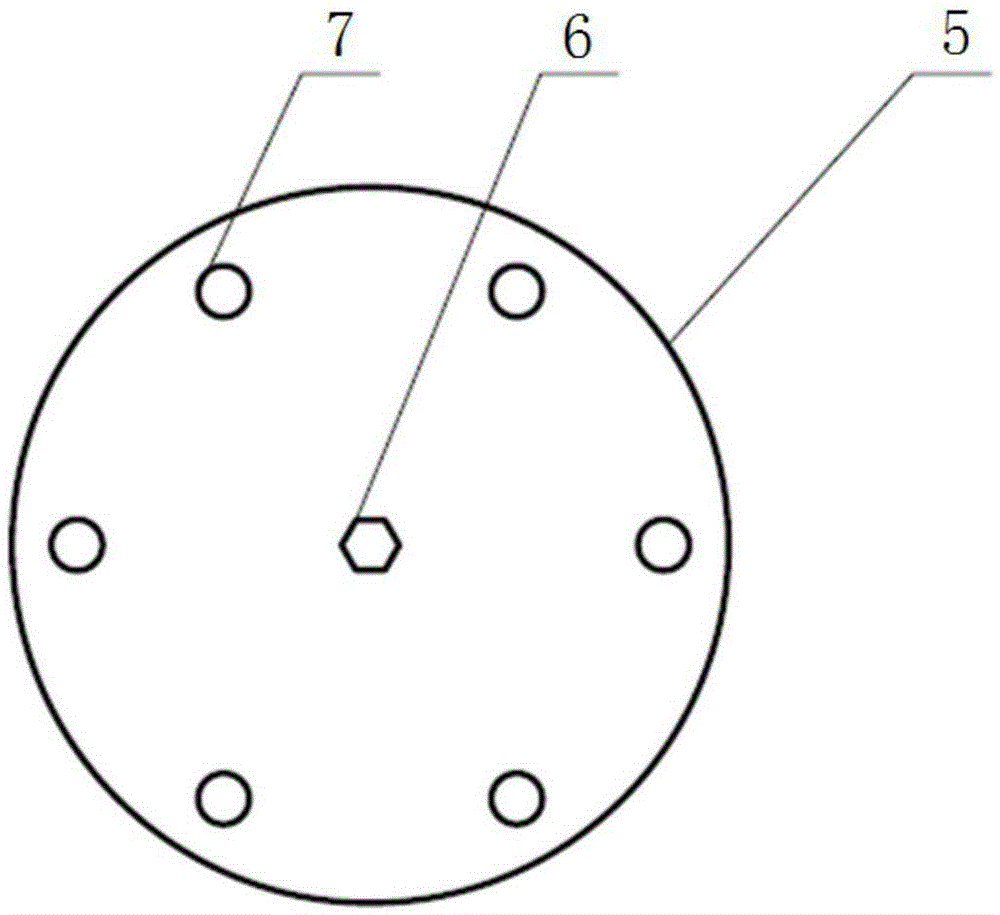

Inspection tool for automobile instrument panel support

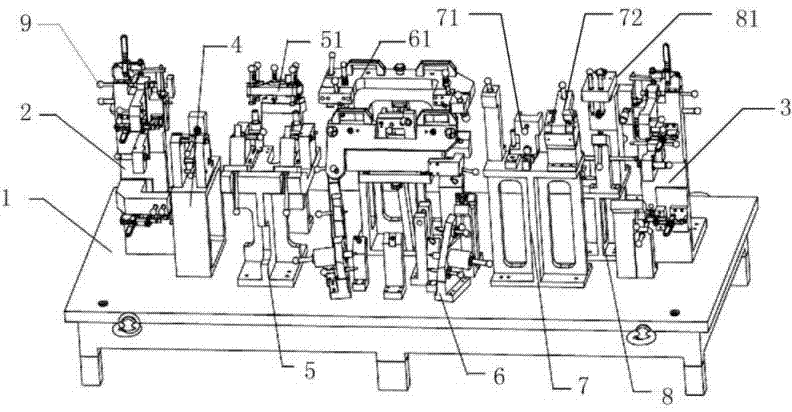

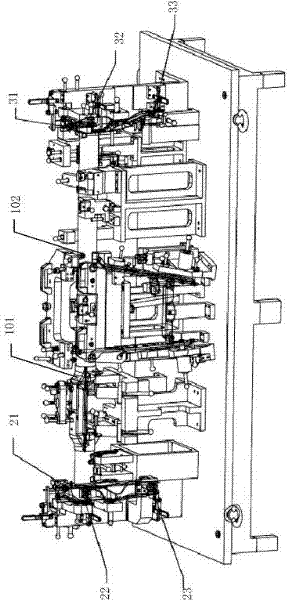

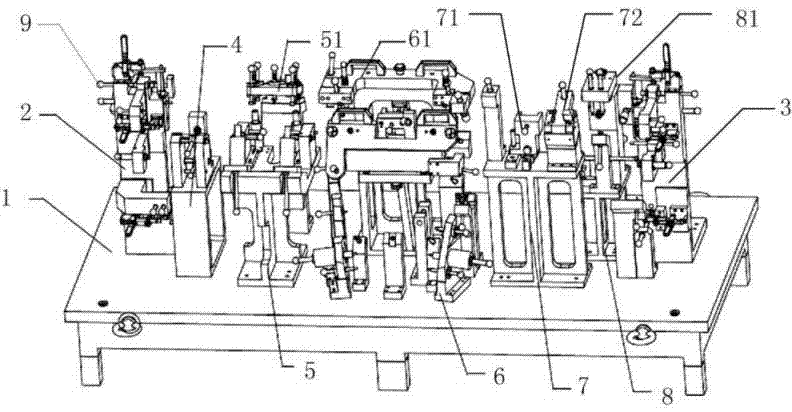

InactiveCN102419144ASimple structureLow costMechanical diameter measurementsDashboardVisual inspection

The invention discloses an inspection tool for an automobile instrument panel support, which is used for quality inspection of a to-be-detected automobile instrument panel support (101), wherein a plurality of installing holes (102) are arranged in the automobile instrument panel support (101), the automobile instrument panel support (101) comprises a base (1), a left end rack (2) and a right end rack (3) which are symmetrically arranged are fixed on the base (1), the position of the base (1), which is between the left end rack (2) and the right end rack (3), is sequentially provided with five supporting vertical racks: a first supporting vertical rack (4), a second supporting vertical rack (5), a third supporting vertical rack (6), a fourth supporting vertical rack (7) and a fifth supporting vertical rack (8), and the positions of the supporting racks correspond to the structure of the automobile instrument panel support (101). According to the inspection tool, the inspection speed and accuracy are improved, the operation is convenient and quick, the inspection efficiency and accuracy are high, the design requirements and the production quality requirements of a product are met, the structure is simple, and the cost is low.

Owner:奇昊汽车系统(苏州)有限公司

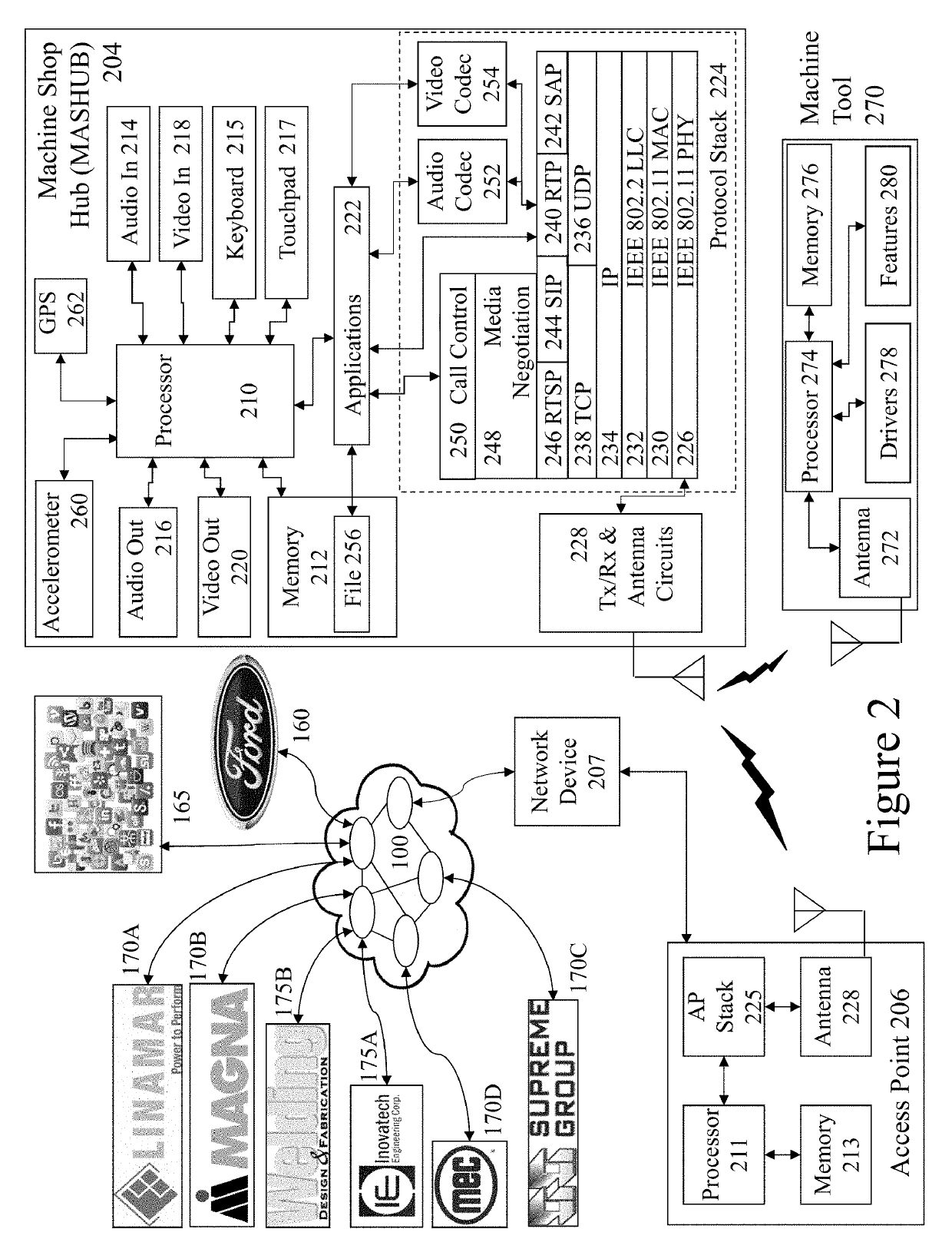

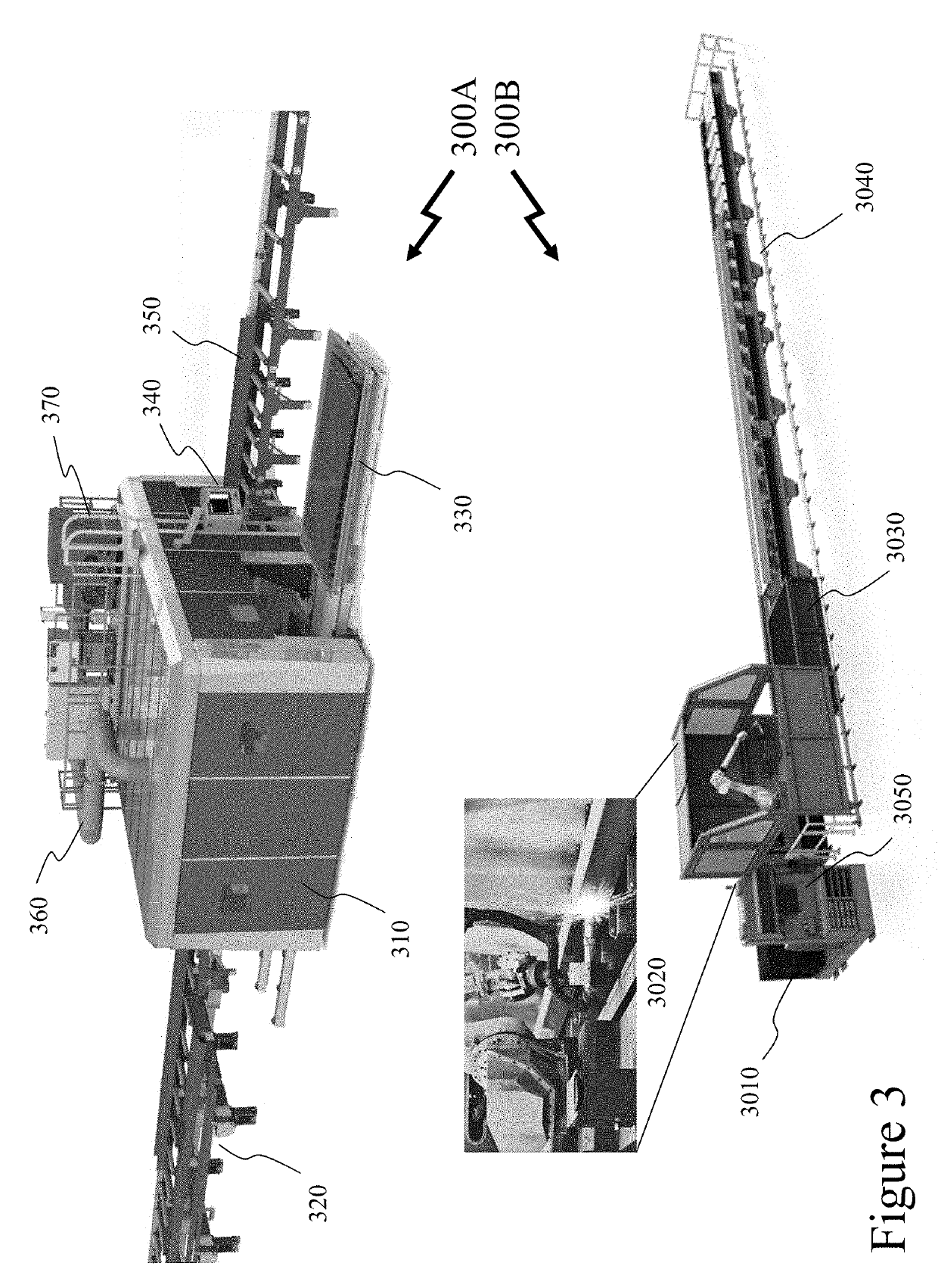

Direct client initiated CNC tool setting

ActiveUS20170255183A1Reduce restrictionsProgramme controlProgramme-controlled manipulatorNumerical controlVisual inspection

Computer numerical control (CNC) machines execute a process automatically unless a condition occurs that triggers one or more alarms that terminate the process. Accordingly, CNC laser cutting post-process inspection is usually non-existent or minimal. However, with CNC laser welding it is more common for a visual inspection or automated inspection to be performed to verify that the process was completed. Similar issues occur when single piece parts are required in addition to which executing an offline inspection requires additional complexity in re-working any piece part. Accordingly, embodiments of the invention provide enterprises and facilities employing CNC laser cutting / welding systems with a means to overcome these limitations. Further, providing intuitive user interfaces allows the user to perform tasks directly through a touch screen interface they are viewing the work piece / piece-parts upon.

Owner:LINCOLN ELECTRIC CO OF CANADA LP

Flight mode CdZnTe inspection system and inspection method

ActiveCN105510952AImprove work efficiencyIncrease in sizeMethod using image detector and image signal processingX-ray spectral distribution measurementFlight timeMeasurement precision

The invention discloses a flight mode CdZnTe inspection system and inspection method and belongs to the radiation detection field. The inspection system includes a CdZnTe spectrometer and an aircraft; the aircraft flies with the CdZnTe spectrometer, and therefore, a flight inspection function can be realized, and work efficiency of nuclear radiation monitoring can be improved. Since the CdZnTe spectrometer has the advantages of high energy resolution, small size, light weight and excellent portability, after the CdZnTe spectrometer is combined with the aircraft, the aircraft can have high measuring accuracy and long flight time, can fly over a nuclear accident site to perform on-site operation and inspect the accident site, and therefore, radiation doses accepted by workers who enter the site can be decreased, and support can be provided for rescue.

Owner:NUCTECH CO LTD

Direct client initiated CNC tool setting

InactiveUS20190278250A1Programme controlProgramme-controlled manipulatorNumerical controlVisual inspection

Owner:LINCOLN ELECTRIC CO OF CANADA LP

Electric transmission line unmanned plane relay flying inspection method

ActiveCN105204522AEnsure safety and qualityEnsure inspection qualityClosed circuit television systemsTarget-seeking controlMarine engineeringTower

The invention discloses an electric transmission line unmanned plane relay flying inspection method. An unmanned plane, two remote controllers, a standby battery, two sets of image collection and transmission devices, a transport vehicle and electric transmission line post towers to be inspected are provided. The method is characterized in that operators are divided into two groups, the first group is used for controlling the controllable maximal distance of the unmanned plane flying to the first remote controller; then the second group is used for continuously controlling flying inspection by the unmanned plane through the second remote controller, and controlling the controllable maximal distance of the unmanned plane flying to the second remote controller; then the steps are repeated in sequence. According to the method, in the inspection process, through relay flying, two operators can conduct observation of the unmanned plane and returned images in a ground station in the inspection process simultaneously, so that the safety and inspection quality of the unmanned plane can be ensured; the landing time when the unmanned plane returns after the inspection is finished is saved, fine inspection of the single base post towers is realized, the transition time of the operators is saved, and the work efficiency is improved.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

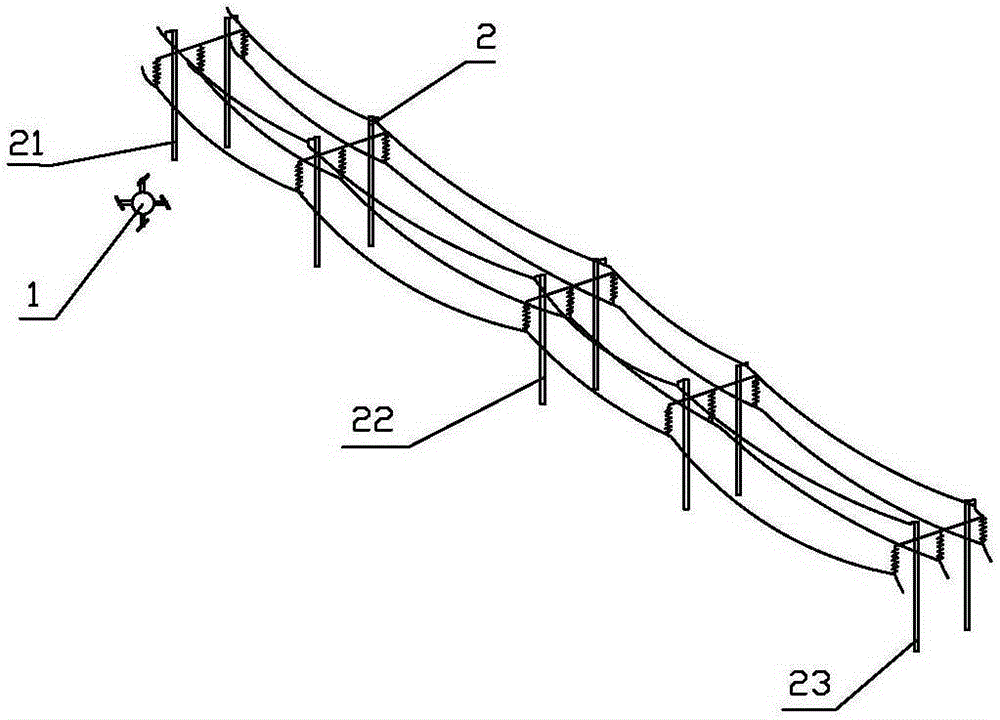

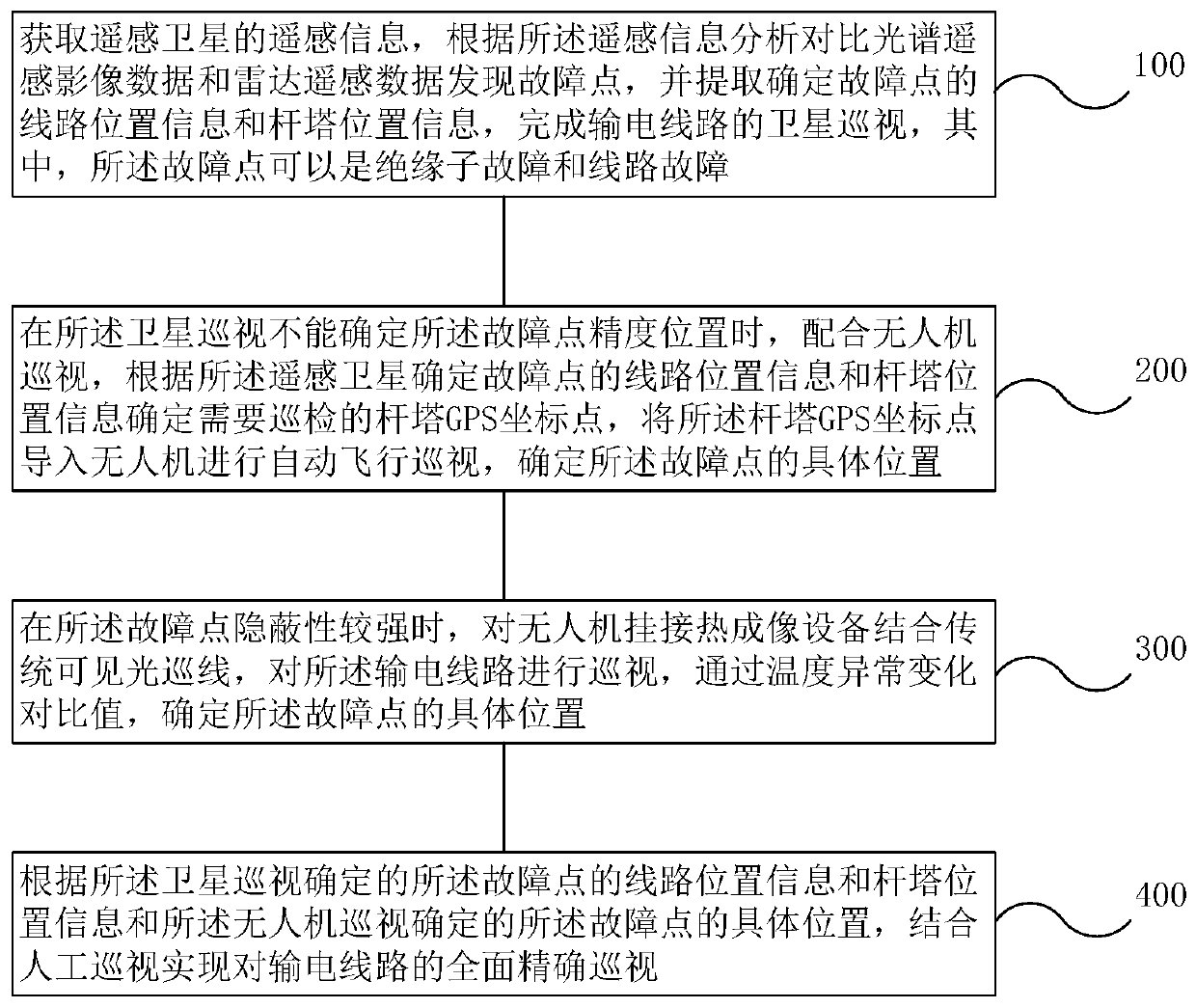

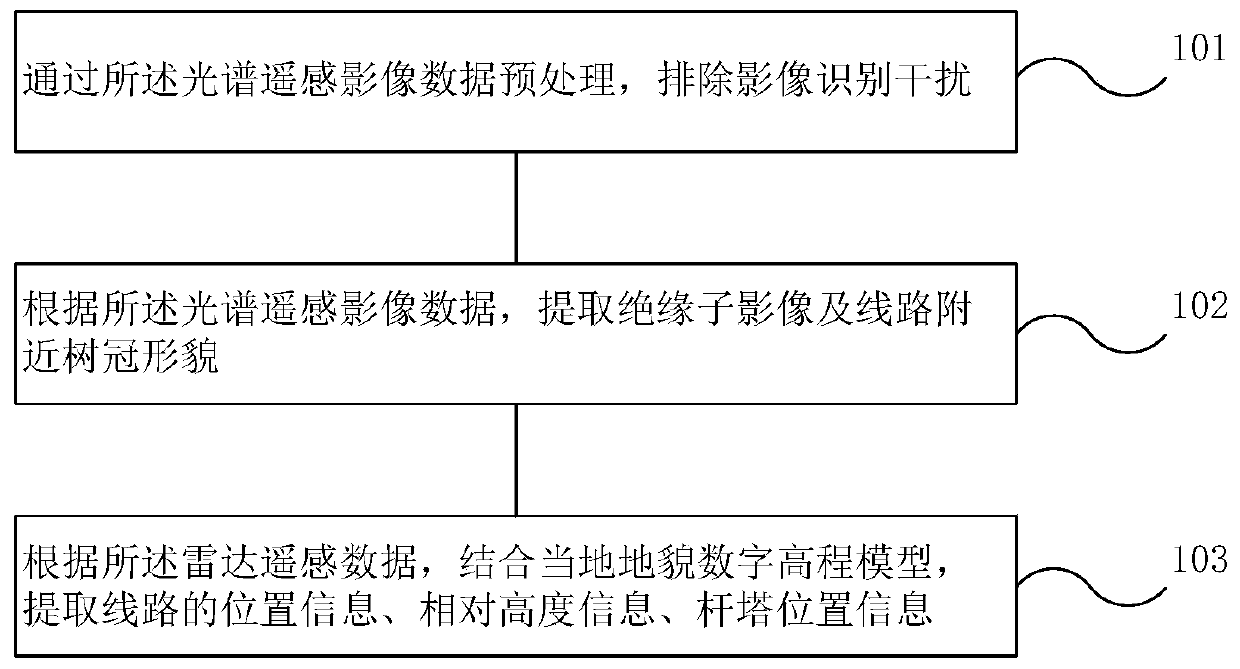

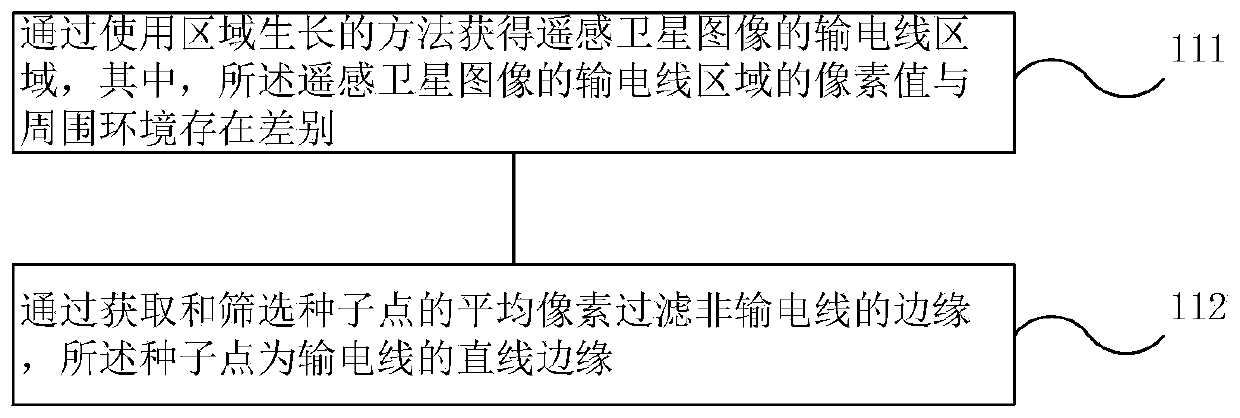

Power transmission line insulator, line fault inspection method and inspection system

ActiveCN111342391AGuaranteed safe operationRealize comprehensive and precise inspectionOptically investigating flaws/contaminationFault location by conductor typesUncrewed vehicleSafe operation

The embodiment of the invention provides a power transmission line insulator, a line fault inspection method and an inspection system. The method comprises the steps of acquiring the remote sensing information of a remote sensing satellite; determining the line position information and the tower position information of a fault point; when the satellite inspection cannot determine the precision position of the fault point, matching with an unmanned aerial vehicle to inspect, determining the coordinate point of a pole tower GPS needing to be inspected according to the remote sensing satellite information, importing the unmanned aerial vehicle to carry out automatic flight inspection, determining the specific position of the fault point, when the concealment of the fault point is high, combining an unmanned aerial vehicle hitching thermal imaging device with the traditional visible light line inspection to inspect, and determining the specific position of the fault point through a temperature comparison value; combining the line position information and the tower position information of the fault point determined by the satellite inspection and the specific position of the fault pointdetermined by the unmanned aerial vehicle inspection with the manual inspection to realize the comprehensive and accurate inspection of a power transmission line, so that the inspection efficiency and accuracy can be improved, the accurate maintenance measures can be taken conveniently, and the safe operation of the line can be better ensured.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

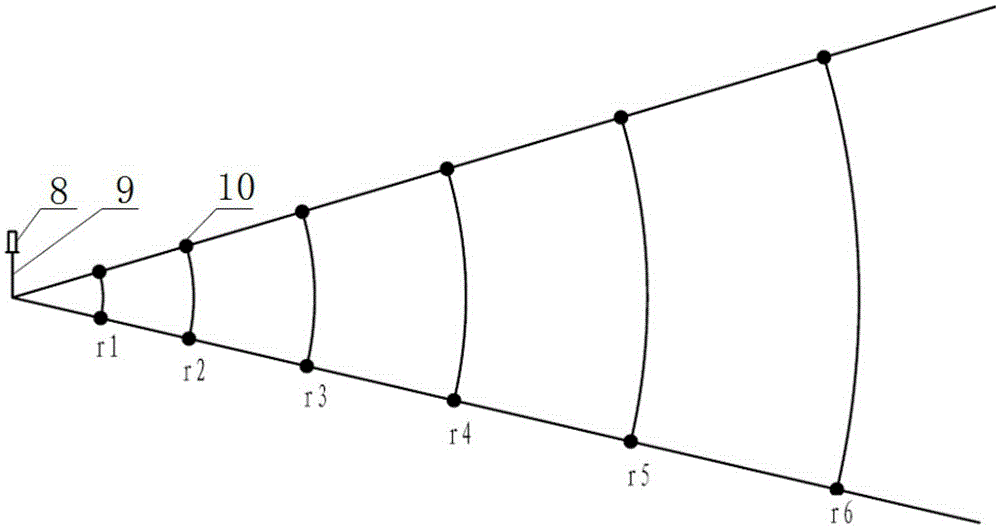

Shock-wave pressure-sensor on-site inspection and sorting method

InactiveCN105403358ARealize on-site selection testThe phenomenon of effective data volume reduction has been improvedFluid pressure measurementShock waveDetonation

The invention provides a shock-wave pressure-sensor on-site inspection and sorting method. The method is characterized in that shock wave overpressure values with different distances are pre-estimated and inspected and sorted pressure sensors of suitable measuring ranges are determined; a bomb holding frame at a detonation center is used to fix a standard explosion signal source; air arrangement sensor installation devices are arranged at each distance; a standard pressure sensor and the inspected and sorted pressure sensors are installed on the air arrangement sensor installation devices; explosion shock wave signals of the standard explosion signal source are collected; 50% inspected and sorted pressure sensors are rejected, wherein a deviation value of test data of the 50% inspected and sorted pressure sensors and the standard pressure sensor on each air arrangement sensor installation device is large. By using the method in the invention, rapid and reliable on-site inspection and sorting of a lot of shock wave pressure sensors can be effectively realized; consistency of the sensors in a same measurement scope can be assessed; the size of the installation devices are small and the weight is light; on-site installation is easy and the method is easy to realize.

Owner:中国兵器工业试验测试研究院

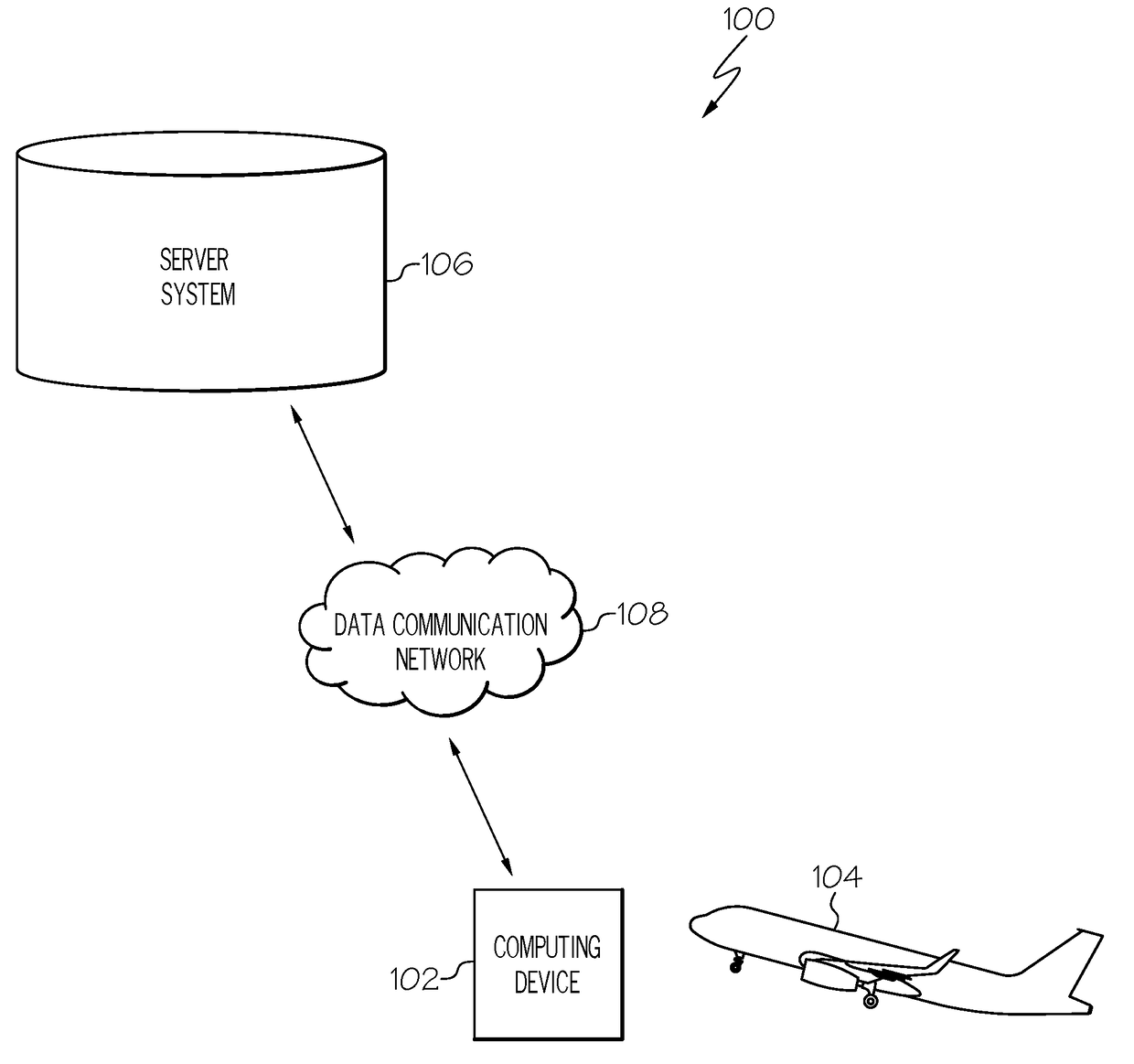

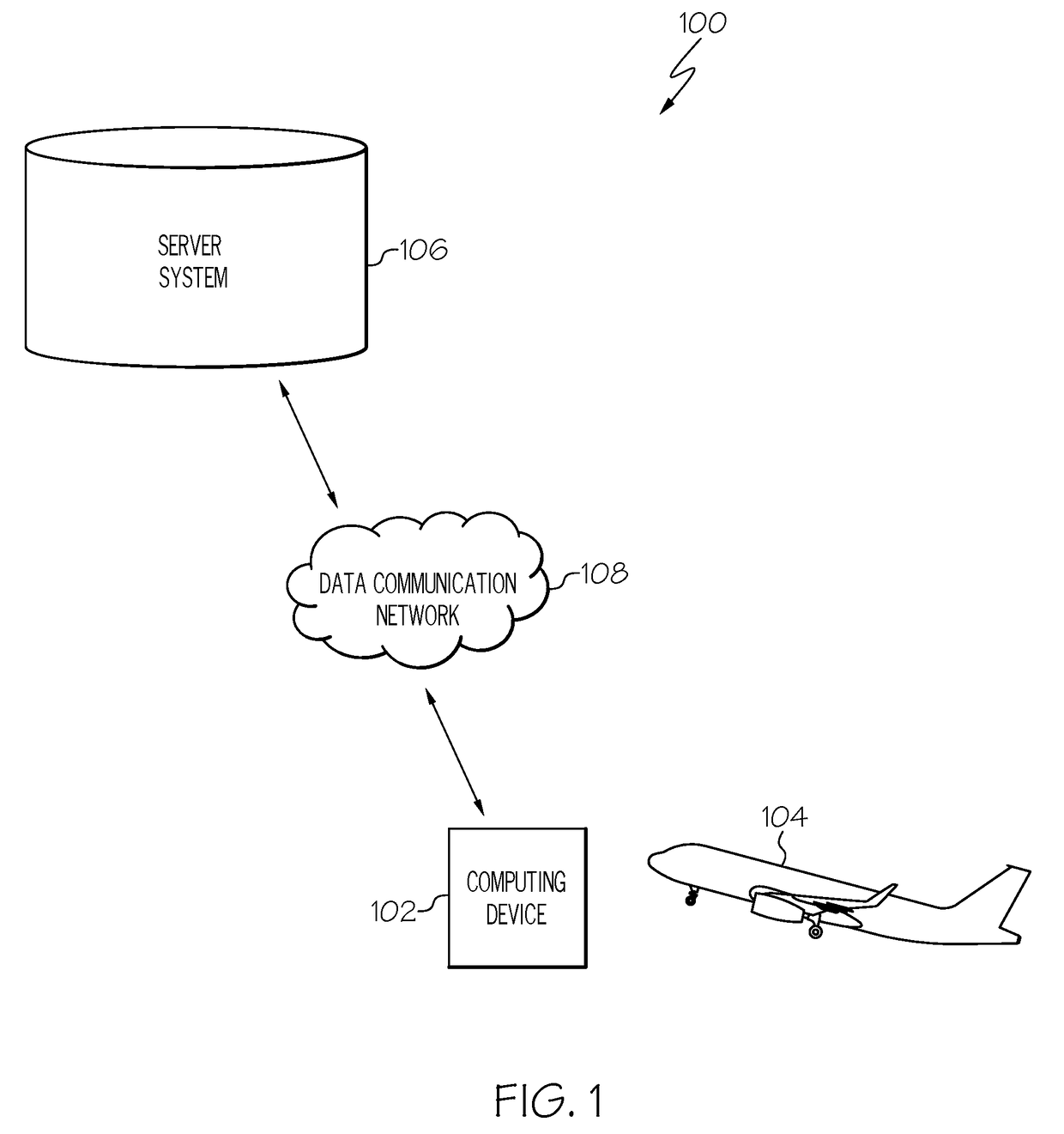

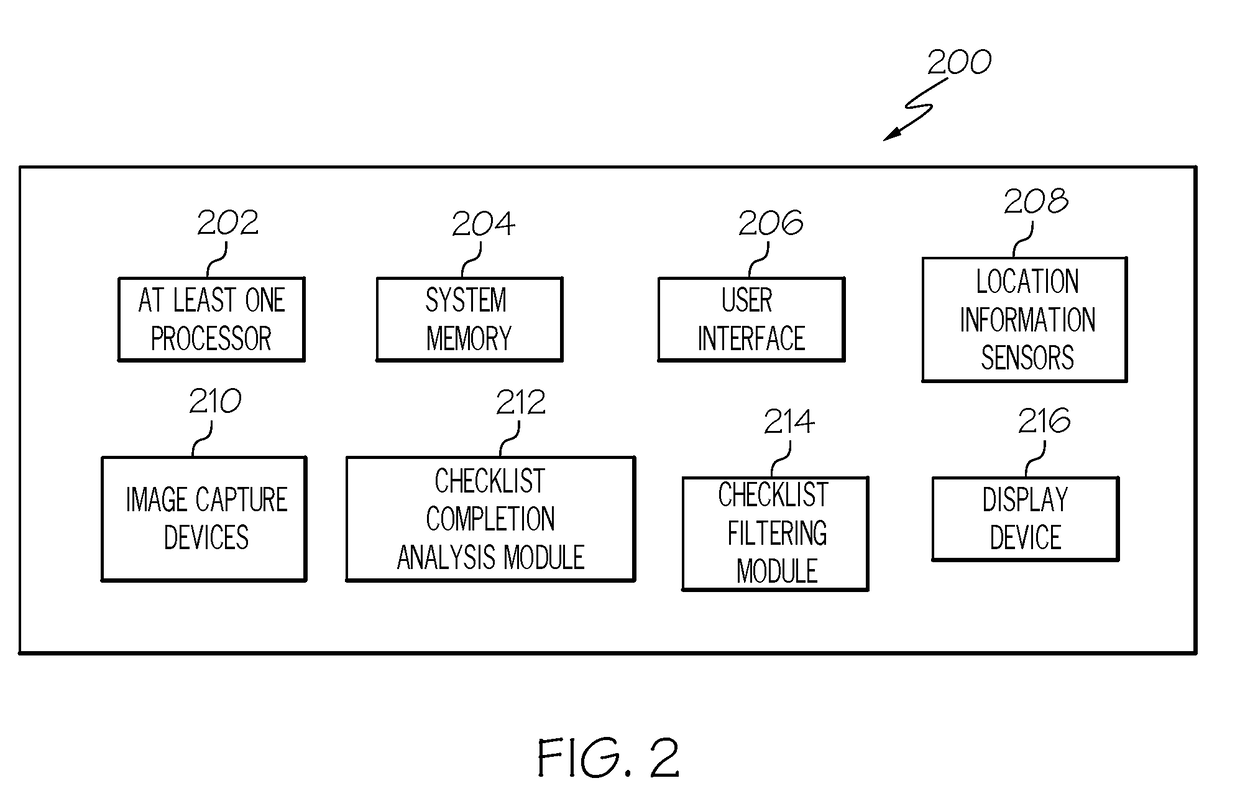

System and method for validating flight checklist items for maintenance and inspection applications

InactiveUS20170291723A1Registering/indicating working of vehiclesElectronic flight bags adaptationsDisplay deviceComputer science

A method for completing a flight checklist for an aircraft is provided. The method obtains, by one or more location sensors, location information for a user; generates a tagged user location, based on the location information; determines that a checklist item is incomplete, based on the tagged user location, wherein the flight checklist comprises the checklist item, and wherein the checklist item is associated with a maintenance inspection for the aircraft; and when the checklist item is incomplete, presenting an alert via a display device.

Owner:HONEYWELL INT INC

Flying insect trap

InactiveUS20050166445A1Expand accessImprove efficiencyInsect catchers and killersTrappingEngineering

A flying inspect trap includes large, multi-directional, oppositely facing ingress openings to elongated chambers housing UV lamps emitting insect attractant light. A disposable cartridge has two sections which mate together to form a container for a roll of adhesive trapping medium. The cartridge sections are opened and spread apart to fit beneath the UV lamps. A motor indexes the adhesive medium so that some unused portion is always available for trapping insects until the roll is exhausted. The spent roll is then rolled into one cartridge section externally; and the two cartridge sections are coupled together to encase the spent roll for disposal.

Owner:LAMBERT C RONALD +2

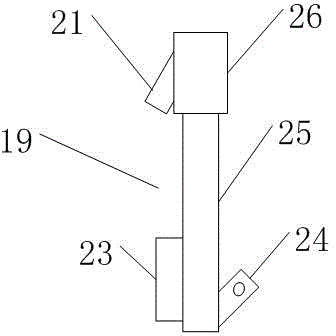

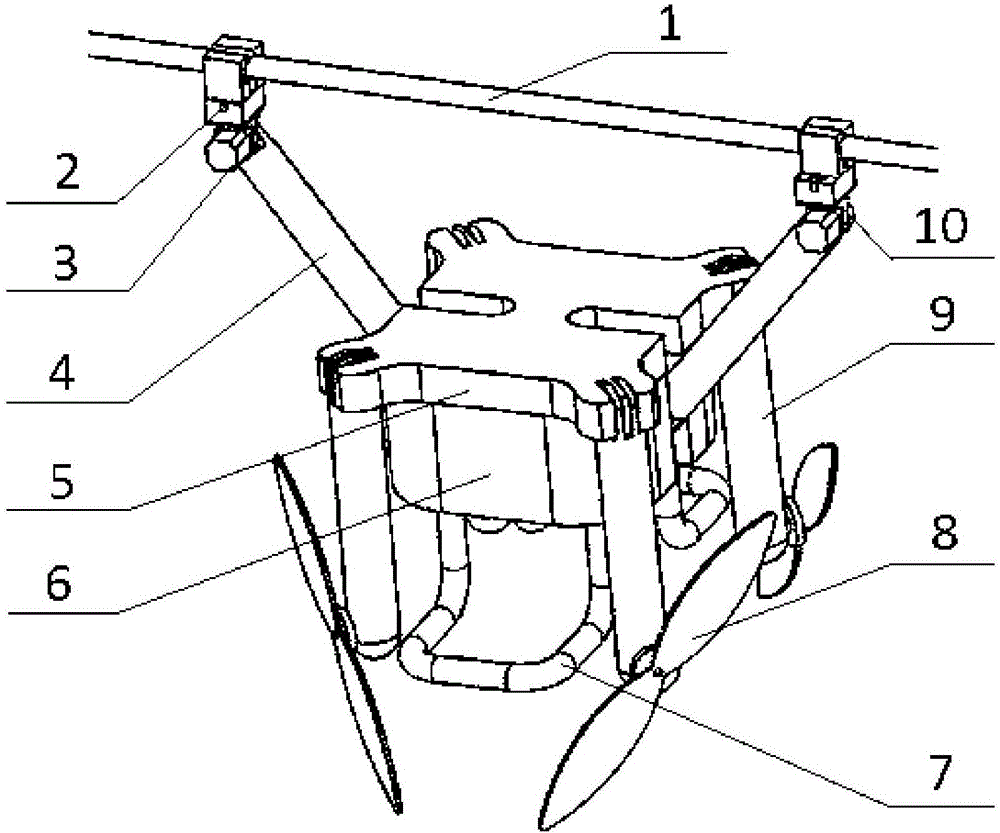

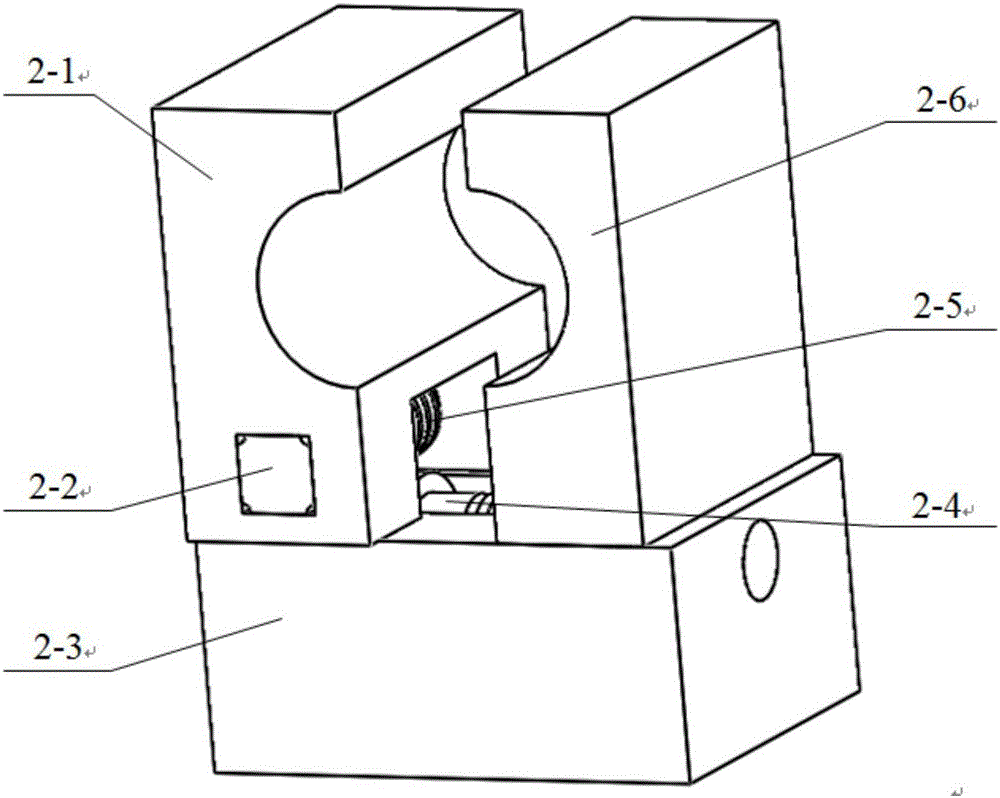

Bionic robot with dual motion modes used for inspecting high voltage transmission lines

The invention discloses a bionic robot with dual motion modes used for inspecting high voltage transmission lines comprising a four-rotor aircraft and two bionic arms connected to the four-rotor aircraft. The bionic robot with the dual motion modes used for inspecting the high voltage transmission lines disclosed by the invention can carry out a flight inspection which can be converted into an on-line mobile inspection only after a possible local damage target is locked. For the high voltage transmission lines with long distances, the bionic robot retains the advantages not only of high efficiency of the flight inspection, but also of high accuracy of on-line inspection robots. In addition, when the environment is not suitable for the flight inspection, the bionic robot can be converted into the on-line mobile inspection to cope with emergency situations because of the dual motion modes. An on-line mobile mechanism utilizes a bionic mechanism which can quickly realize the obstacle negotiation on the high voltage transmission lines and move flexibly so as to be suitable for complex inspection situations.

Owner:XI AN JIAOTONG UNIV

Two-dimensional code-based inspection management method

InactiveCN107688861APatrol real-time updateSubstation equipmentInstrumentsComputer hardwareDepartment management

The invention discloses a two-dimensional code-based inspection management method, which comprises the following steps: storing a primary two-dimensional code of site inspection and a secondary two-dimensional code of department management in a two-dimensional code database; checking and modifying an inspection area of a factory by personnel scanning the two-dimensional code through a smart phonein the primary two-dimensional code and secondary two-dimensional code specified area, thus achieving paperless factory inspection. The factory inspection can be performed through the two-dimensionalcode information, so that the inspection situation of the factory can be known in real time, the access efficiency of inspection information can be improved, and the human resource consumption is reduced.

Owner:卢启平

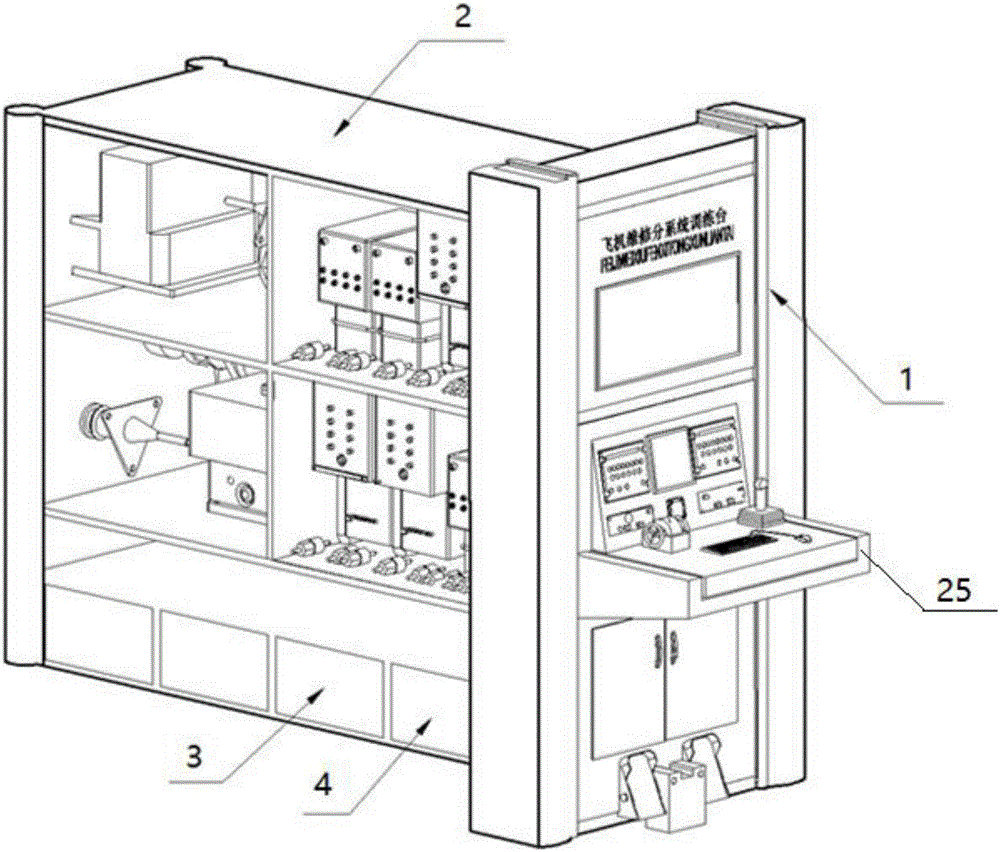

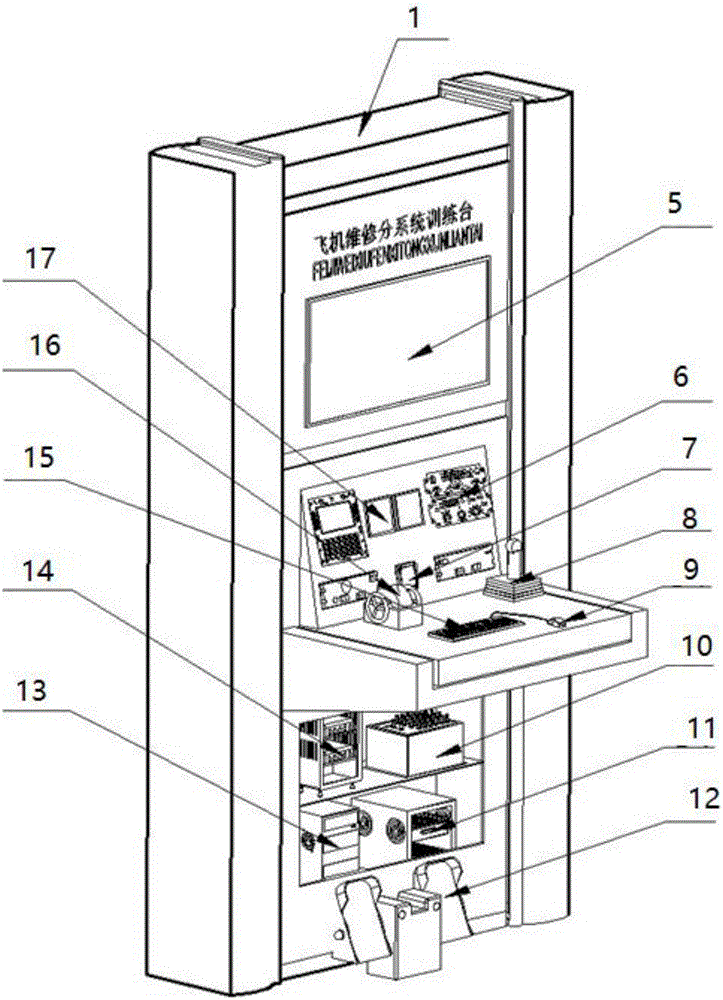

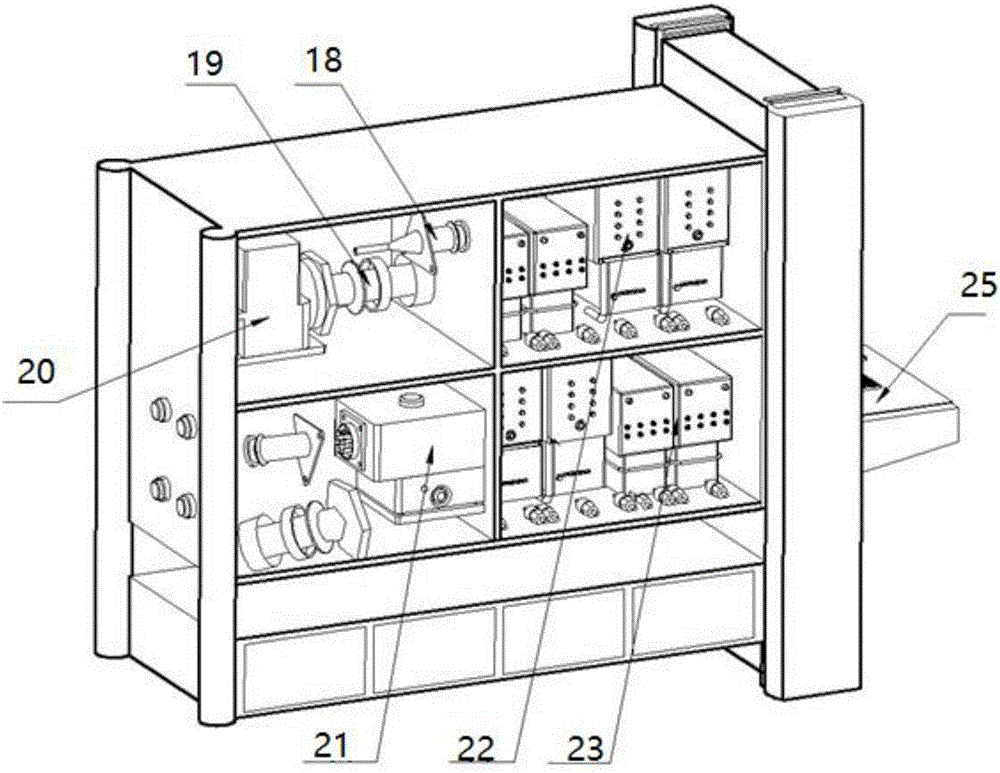

JH-7-A-type aircraft hydraulic system maintenance training bench

ActiveCN106530885AHigh degree of integrationComprehensive level of trainingCosmonautic condition simulationsEducational modelsSystem maintenanceSkill sets

The invention discloses a JH-7-A-type aircraft hydraulic system maintenance training bench. A computer simulation technology is taken as a core. An imitated device of simulation, a driving cabin correlation control panel, a control handle, a pedal, a display and other devices are used and hydraulic system simulation training software and simulation control software are cooperated so as to provide a simulation operation platform which can repeatedly carry out maintenance training for engineering maintenance personnel. Teaching functions of JH-7-A-type aircraft hydraulic system maintenance knowledge learning, maintenance work program and maintenance ability training, training effect examination and the like are realized. A trainee knows a maintenance characteristic of a JH-7-A-type aircraft hydraulic system, function composition, work principles, installation layout and crosslinking relationships of the aircraft hydraulic system and accessories, knows programs of maintenance, performance detection, a flight inspection standard, flight inspection and accessory mounting and dismounting very well, and grasps maintenance inspection, fault determination and elimination methods of the hydraulic system.

Owner:SHAANXI KAIJIE TECH DEV

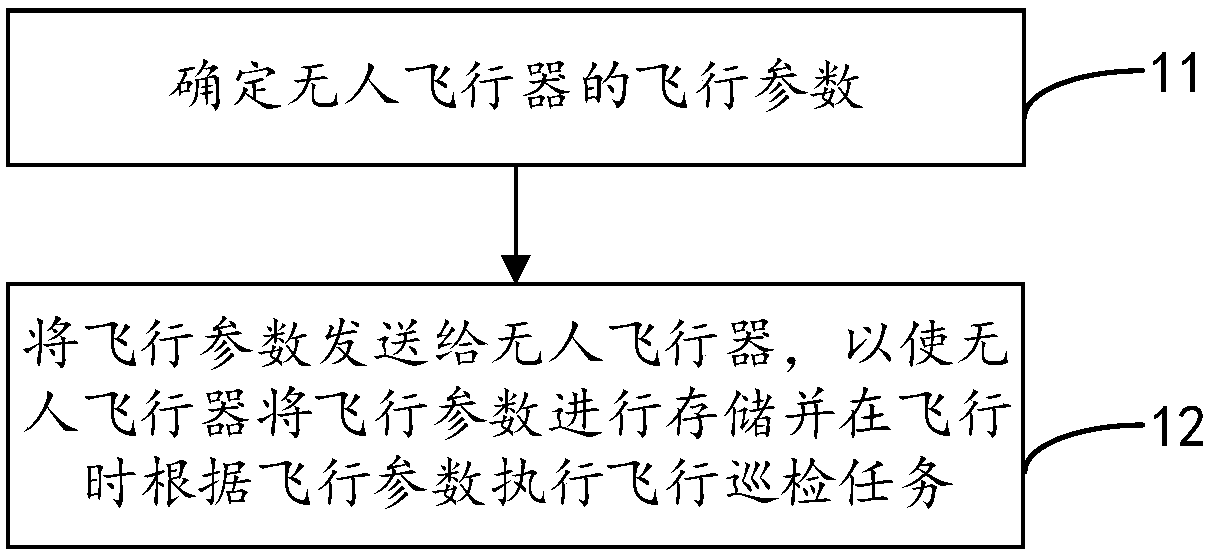

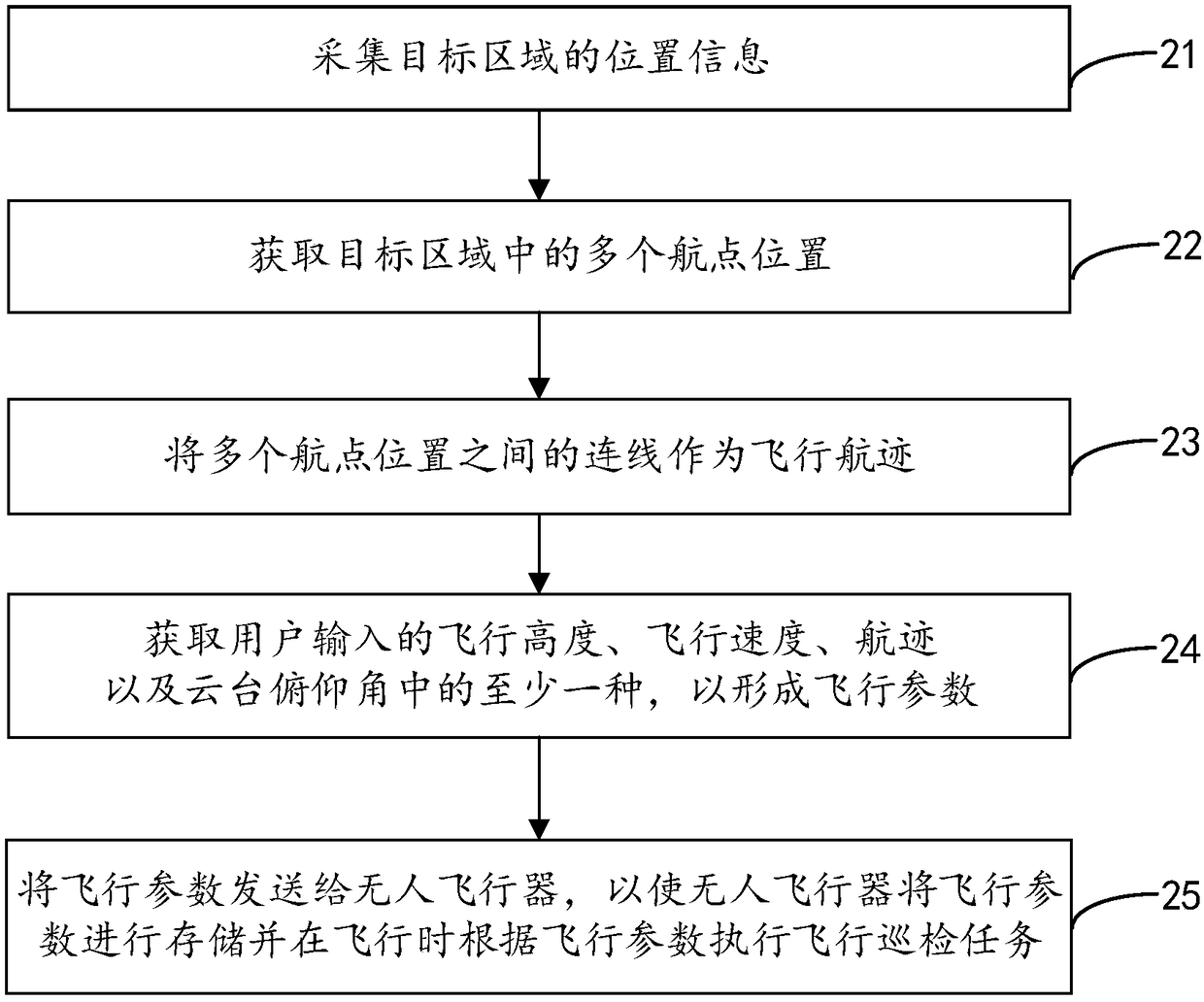

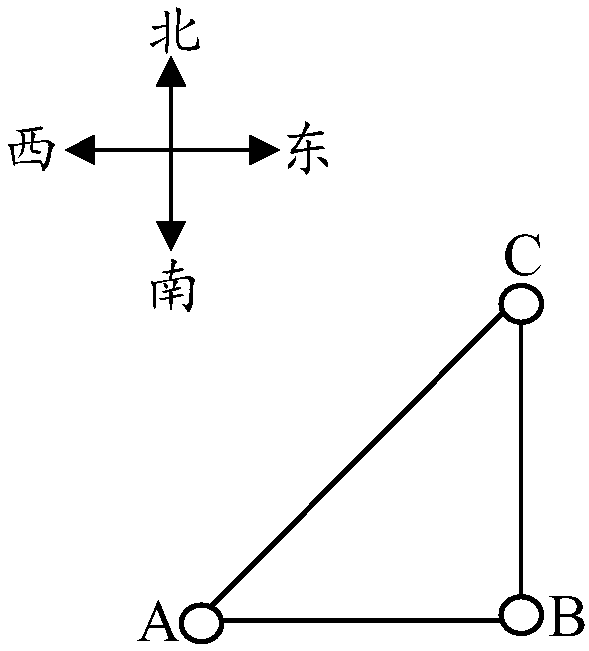

Control method of unmanned aerial vehicle, console, aircraft and control system

InactiveCN108319292AEasy to operateAttitude controlPosition/course control in three dimensionsTerrainFlight vehicle

The invention discloses a control method of an unmanned aerial vehicle, a console, an aircraft and a control system. The method comprises a step of determining flight parameters of the unmanned aerialvehicle (UAV), wherein the flight parameters include at least one of a flight altitude, a flight speed, a flight path, and a pan / tilt angle, and a step of transmitting the flight parameters to the UAV such that the UAV stores the flight parameters and performs a flight inspection mission based on the flight parameters during flight. The aircraft is controlled by acquiring the flight parameters, the flight of the UAV can be controlled without external equipment, the operation of a user is facilitated, the automation degree of the flight inspection of the unmanned aerial vehicle is improved, the UAV adapts to complex environment and terrain in the field well, and the distance and time of the flight inspection of the UAV is improved.

Owner:SHENZHEN INNOVPOWER TECH

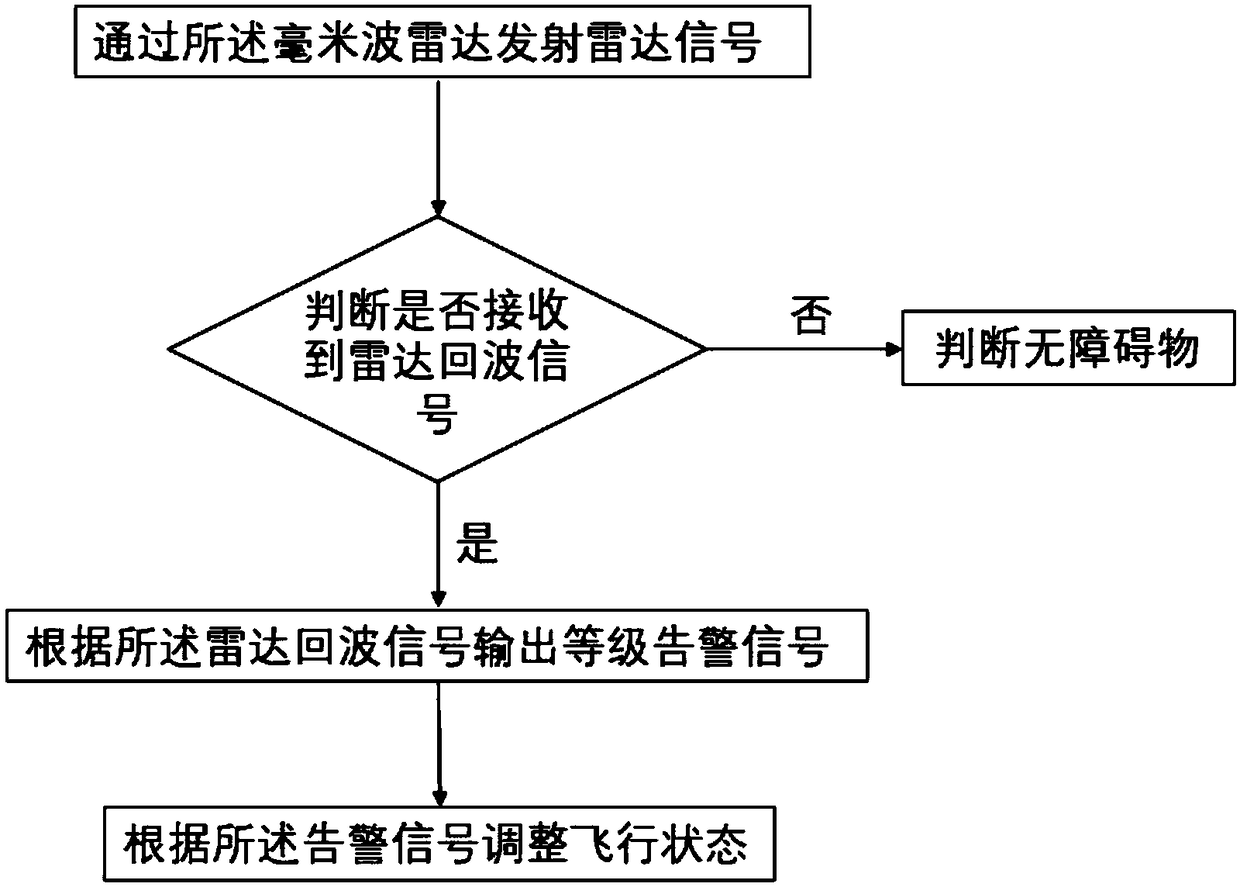

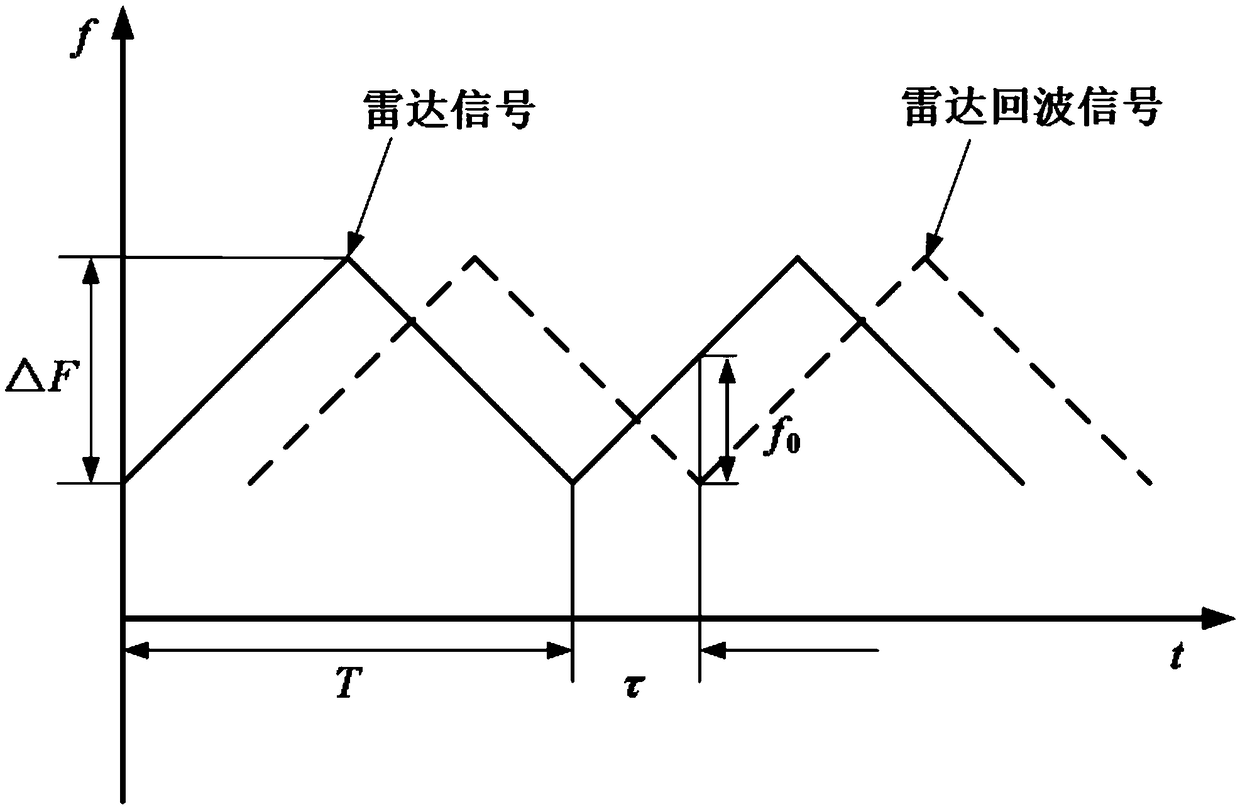

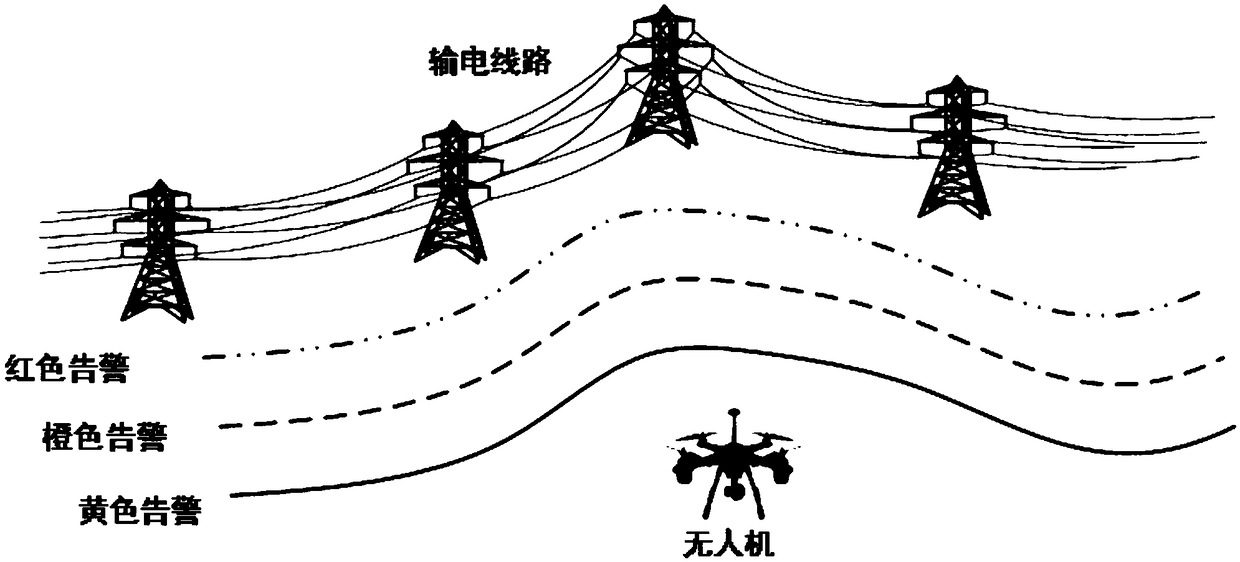

Line inspection unmanned aerial vehicle obstacle avoidance method based on millimeter wave radar and line inspection unmanned aerial vehicle obstacle avoidance system based on millimeter wave radar

InactiveCN108803666AAvoiding Accidents of Collision WiresOvercoming the problem of insufficient recognition accuracyPosition/course control in three dimensionsRadio wave reradiation/reflectionUncrewed vehicleObstacle avoidance

The invention discloses a line inspection unmanned aerial vehicle obstacle avoidance method based on millimeter wave radar and a line inspection unmanned aerial vehicle obstacle avoidance system basedon the millimeter wave radar. The method comprises the following steps that the radar signal is transmitted through the millimeter wave radar, receiving of the radar echo signal is judged and the judgment result indicates no obstacle if the judgment result is no; and if the judgment result is yes, the level alarm signal is outputted according to the radar echo signal; and the unmanned aerial vehicle adjusts the flight state according to the alarm signal. According to the unmanned gyroplane line inspection obstacle avoidance method based on the millimeter wave radar and the unmanned gyroplaneline inspection obstacle avoidance system based on the millimeter wave radar, the millimeter wave radar is arranged on the unmanned aerial vehicle and the level alarm signal is set, and the recognition accuracy of the millimeter wave radar can be the lead level so that the problem of insufficient recognition accuracy of the present obstacle detection method using the sensor can be overcome. Different degrees of danger warning is performed by detecting the obstacle of different directions around the unmanned aerial vehicle in real time and the flight speed and direction are automatically adjusted to realize unmanned aerial vehicle obstacle avoidance so that the accident that the unmanned aerial vehicle collides with the lead can be effectively avoided.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST

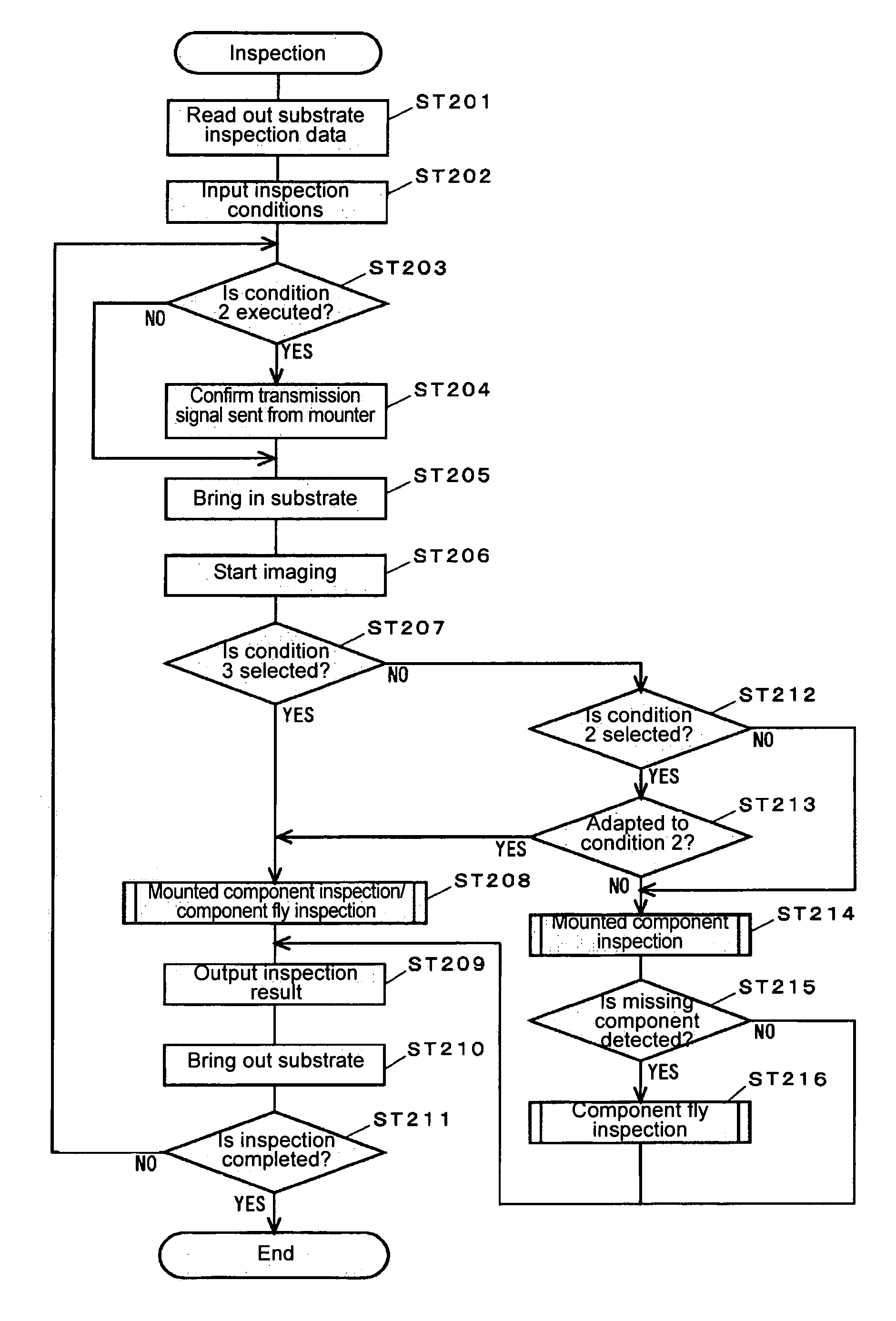

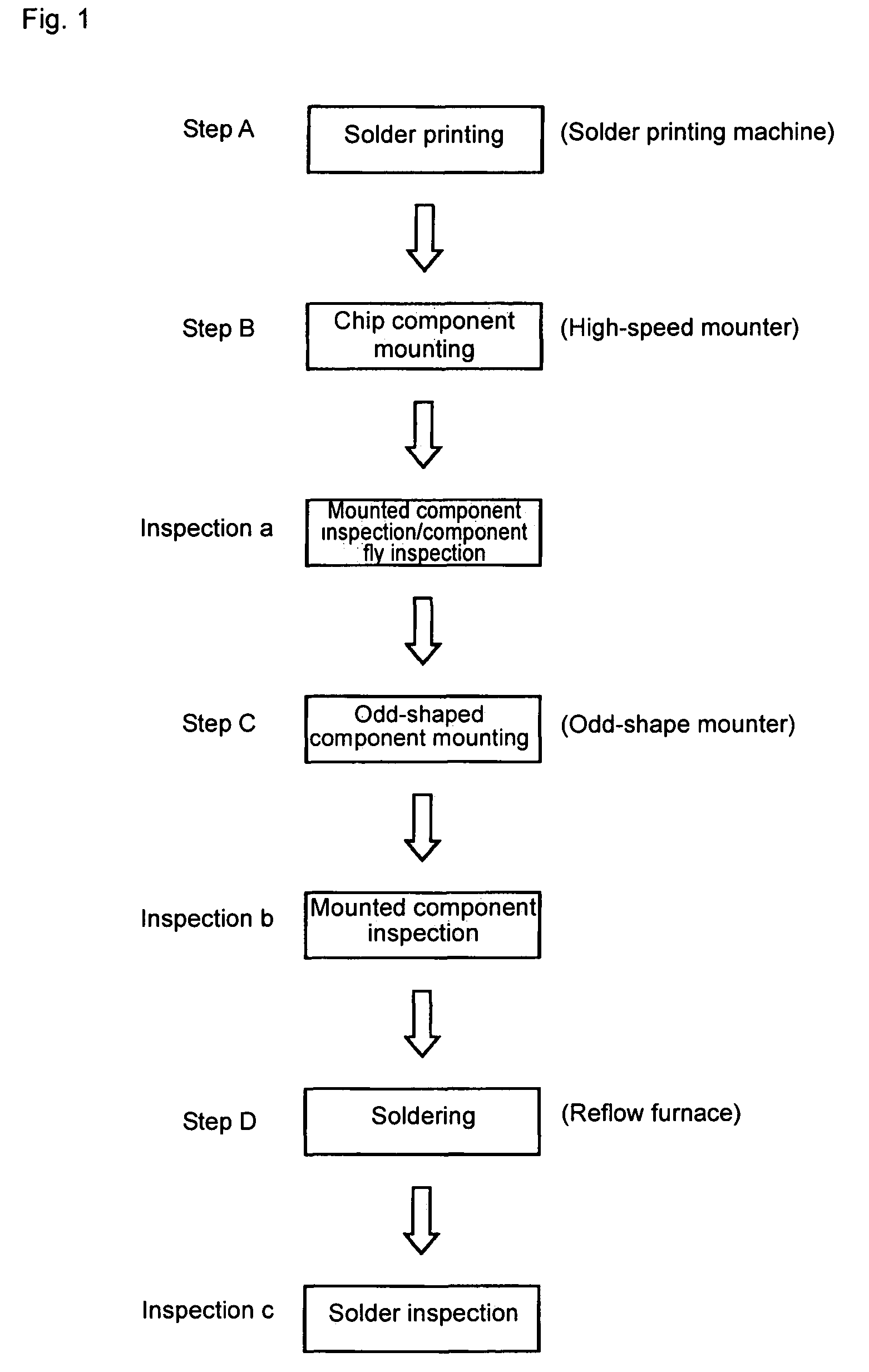

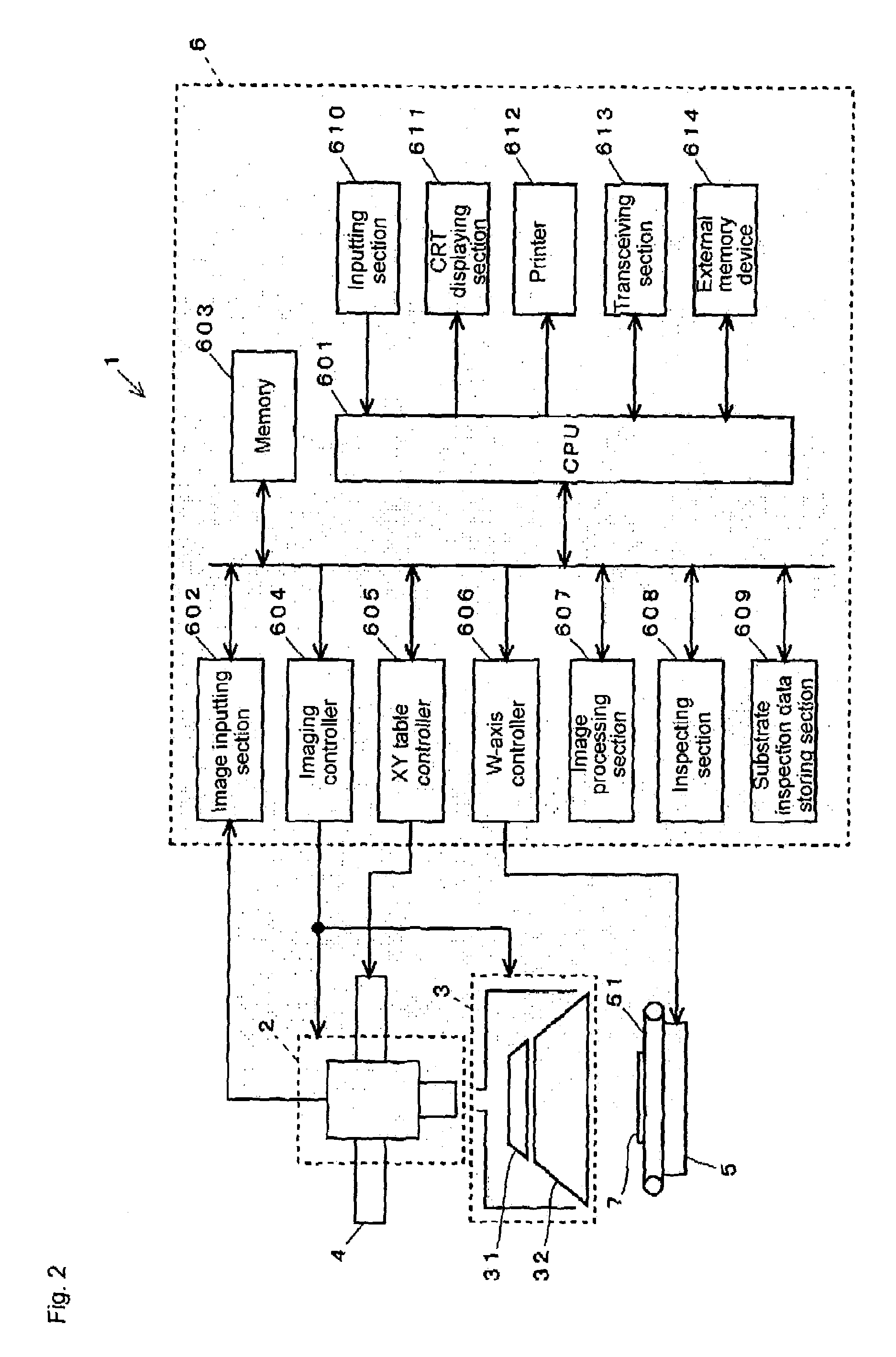

Substrate inspecting method and substrate inspecting apparatus using the method

InactiveUS7114249B2Efficient and accurate detectionQuick checkPrinted circuit assemblingLine/current collector detailsReliability engineeringFlight inspection

Inspection a is executed between a step B of mounting a chip component by a high-speed mounter and a step C of mounting a odd-shaped component by a odd-shape mounter. The inspection a executes not only mounted component inspection for determining a mounted state of a chip component mounted in the preceding step but also component fly inspection for determining whether a chip component is flown to a position where a odd-shaped component is mounted in the next step C. It is possible to execute the component fly inspection in accordance with a condition corresponding to the situation of an actual spot such as a case in which it is detected that a component is missing in mounted component inspection or a case in which the replacement date of an attracting nozzle in a high-speed mounter is approaching.

Owner:ORMON CORP

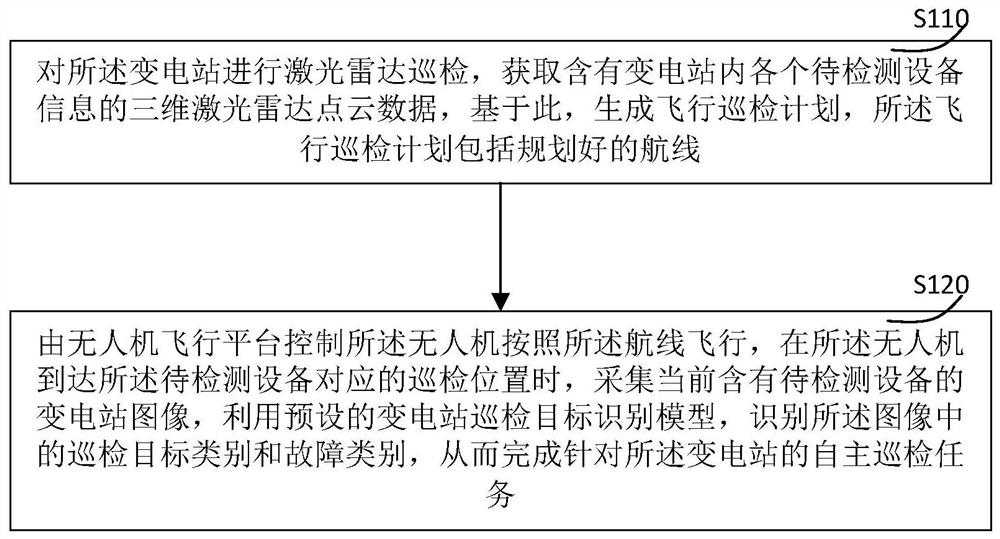

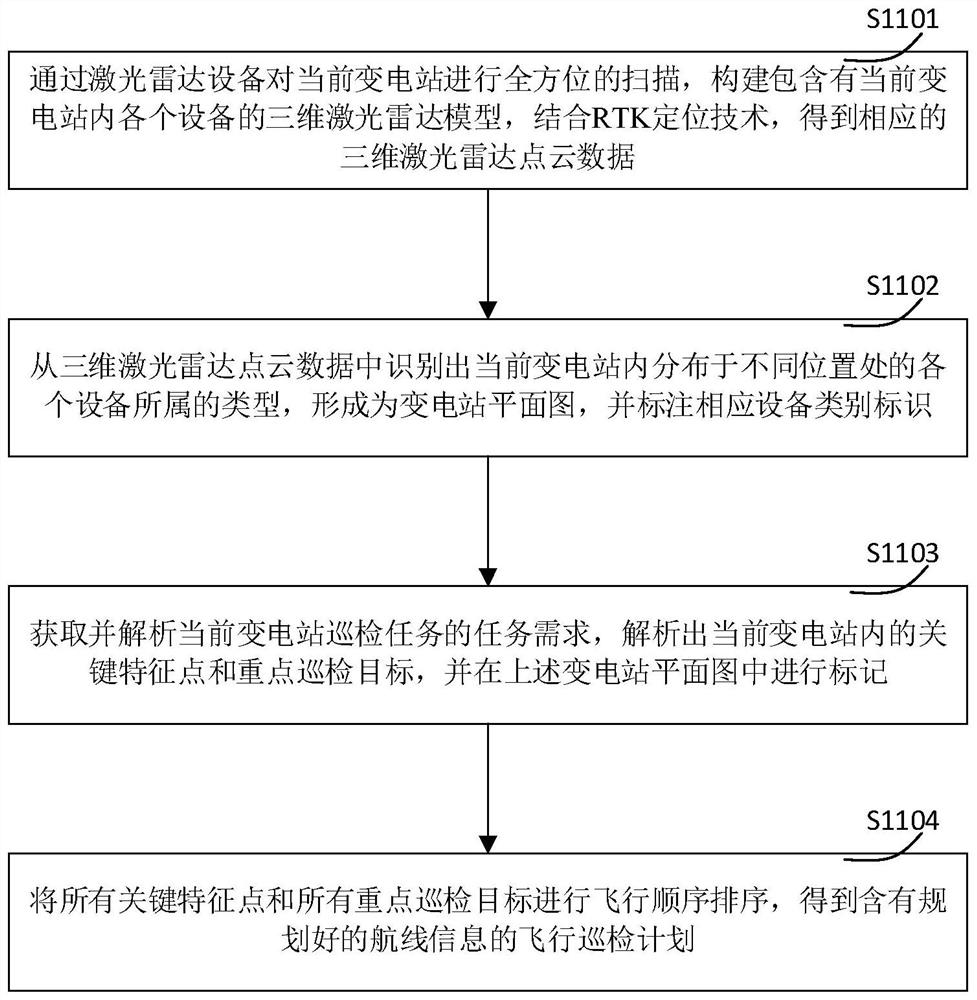

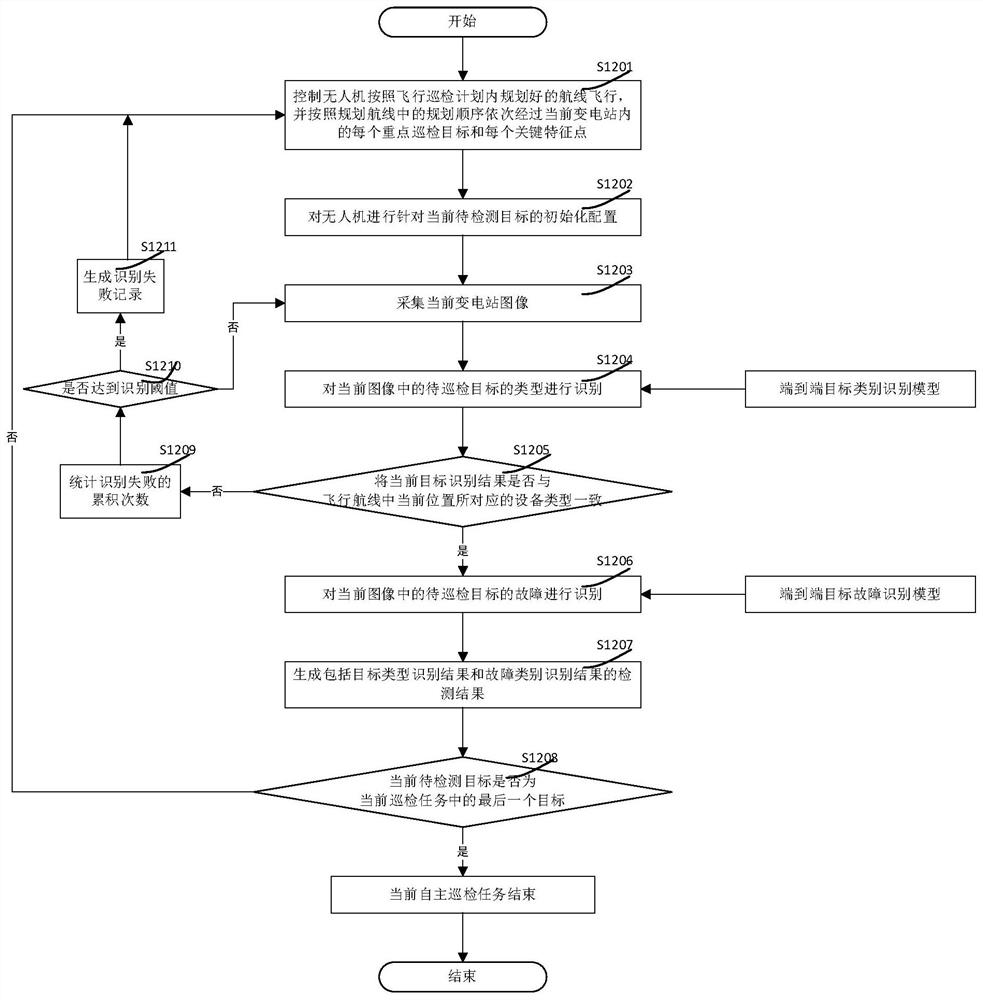

Unmanned aerial vehicle inspection method and system for transformer substation

ActiveCN112884931ASatisfy the accuracy of online diagnosisUnified standardChecking time patrolsCharacter and pattern recognitionPoint cloudUncrewed vehicle

The invention discloses an unmanned aerial vehicle inspection method for a transformer substation, and the method comprises the steps: carrying out laser radar inspection of a current transformer substation, obtaining the three-dimensional laser radar point cloud data of all to-be-detected equipment in the transformer substation, and generating a flight inspection plan containing the planned route information based on the three-dimensional laser radar point cloud data; the unmanned aerial vehicle flight platform controls the unmanned aerial vehicle to fly according to a flight route in the flight inspection plan, when the unmanned aerial vehicle arrives at an inspection position corresponding to the to-be-detected equipment, a current transformer substation image containing the to-be-detected equipment is collected, and an inspection target type and a fault type in the image are identified by using a preset transformer substation inspection target identification model; and the autonomous inspection task of the transformer substation is completed. According to the invention, inspection efficiency and inspection safety are improved, and the online diagnosis precision of the autonomous inspection task is met.

Owner:ZHONGXIN HANCHUANG BEIJING TECH CO LTD

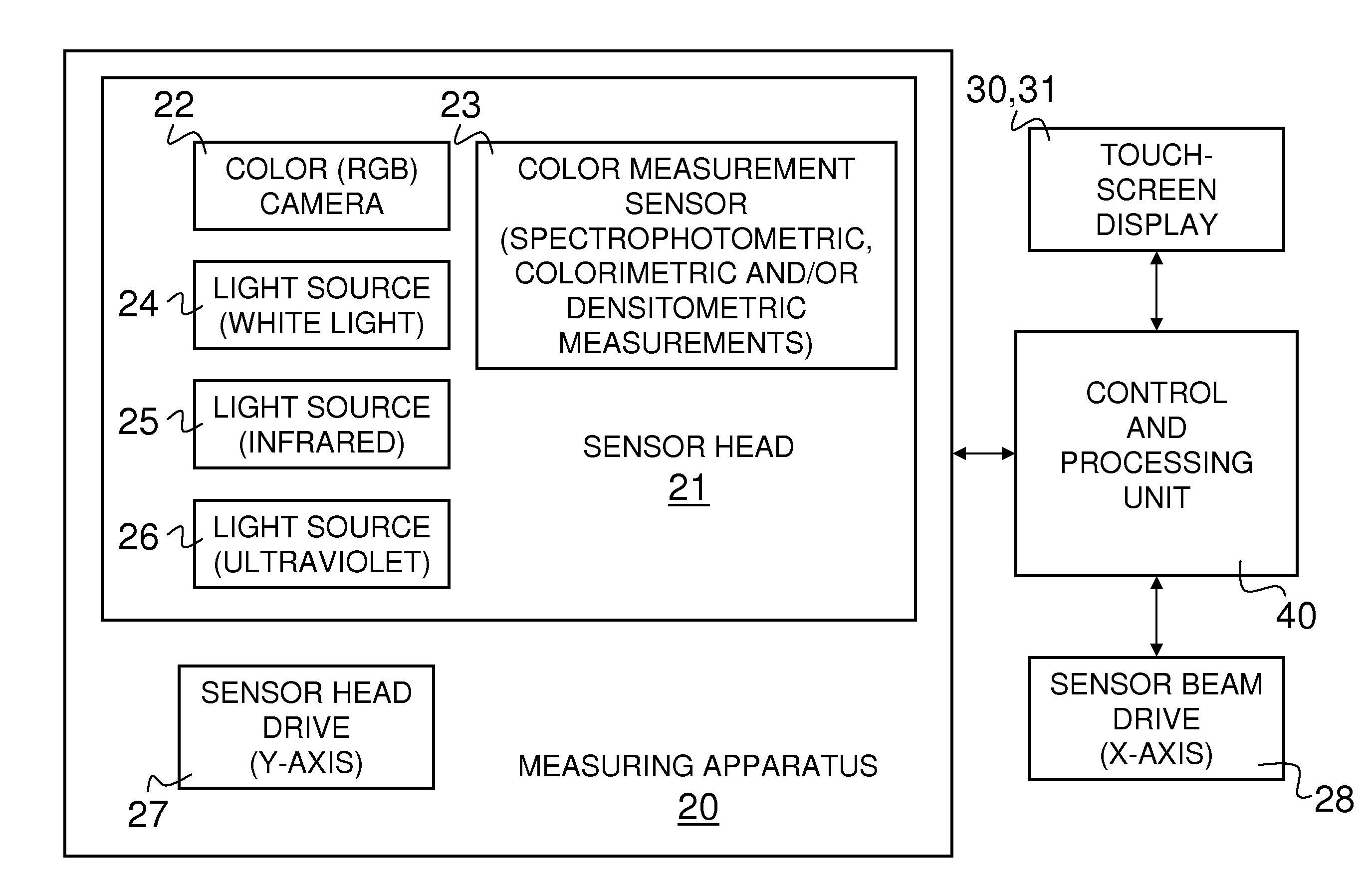

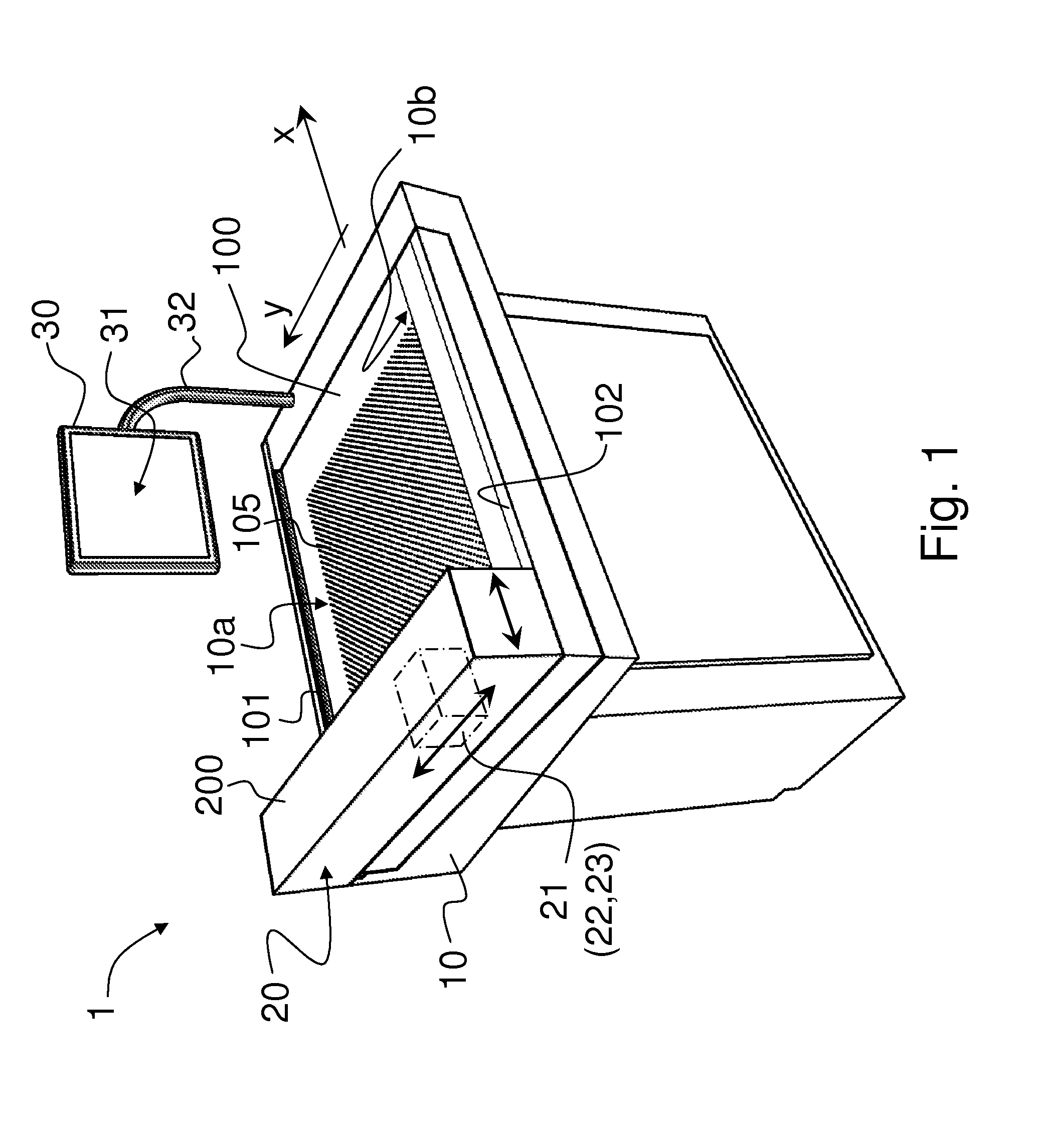

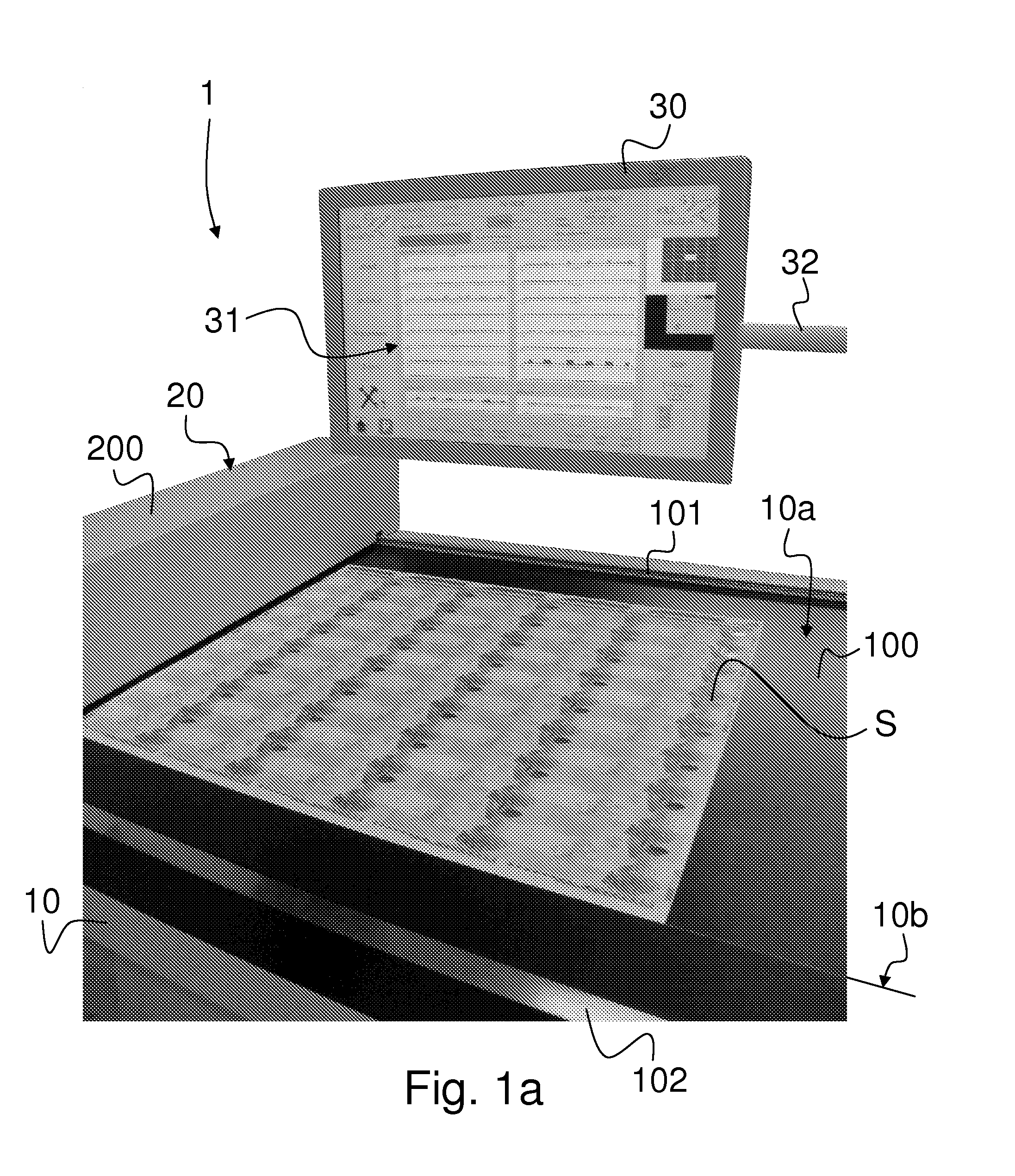

Device for offline inspection and color measurement of printed sheets for the production of banknotes and like printed securities

ActiveUS20150040785A1Easy to measureEasy to set upColor/spectral properties measurementsRotary pressesDisplay deviceMultiple sensor

There is described a device (1) for offline inspection and color measurement of printed sheets for the production of banknotes and like printed securities, comprising (i) a console (10) having a supporting surface (10a) for supporting a sample printed sheet (S), (ii) a multipurpose measuring apparatus (20), which multipurpose measuring apparatus (20) comprises multiple sensors (22, 23) including at least one camera (22) for taking images of selected portions of the sample printed sheet (S) and a color measurement sensor (23) for performing spectrophotometric, colorimetric, and / or densitometric measurements at selected locations on (22, 23) the sample printed sheet (S), (iii) a display (30) for displaying the images taken by the camera (22) and the measurements performed by the color measurement sensor (23), and (iv) a control and processing unit (40) coupled to the multipurpose measuring apparatus (20) and the display (30). The device (1) comprises a move-sensor beam (200) housing the multipurpose measuring apparatus (20), which moveable sensor beam (200) is displaceable along an x-axis over the supporting surface (10a) of the console (10) and over the entire surface of the sample printed sheet (S) located on the supporting surface (10a), the multiple sensors (22, 23) being mounted on a common sensor head (21) which is displaceable within the moveable sensor beam (200) along a y-axis so that the multipurpose measuring apparatus (20) can selectively take images of selected portions of the sample printed sheet (S) by means of the camera (22) or perform measurements at selected locations on the sample printed sheet (S) by means of the color measurement sensor (23). The control and processing unit (40) is configured to control displacement of the moveable sensor beam (200) along the x-axis and of the sensor head (21) along the y-axis.

Owner:KBA NOTASYS SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com