Power transmission line insulator, line fault inspection method and inspection system

A transmission line and line fault technology, applied in fault location, radio wave measurement system, fault detection by conductor type, etc., can solve problems such as inaccurate positioning in complex terrain areas, line and tower coordinate errors, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

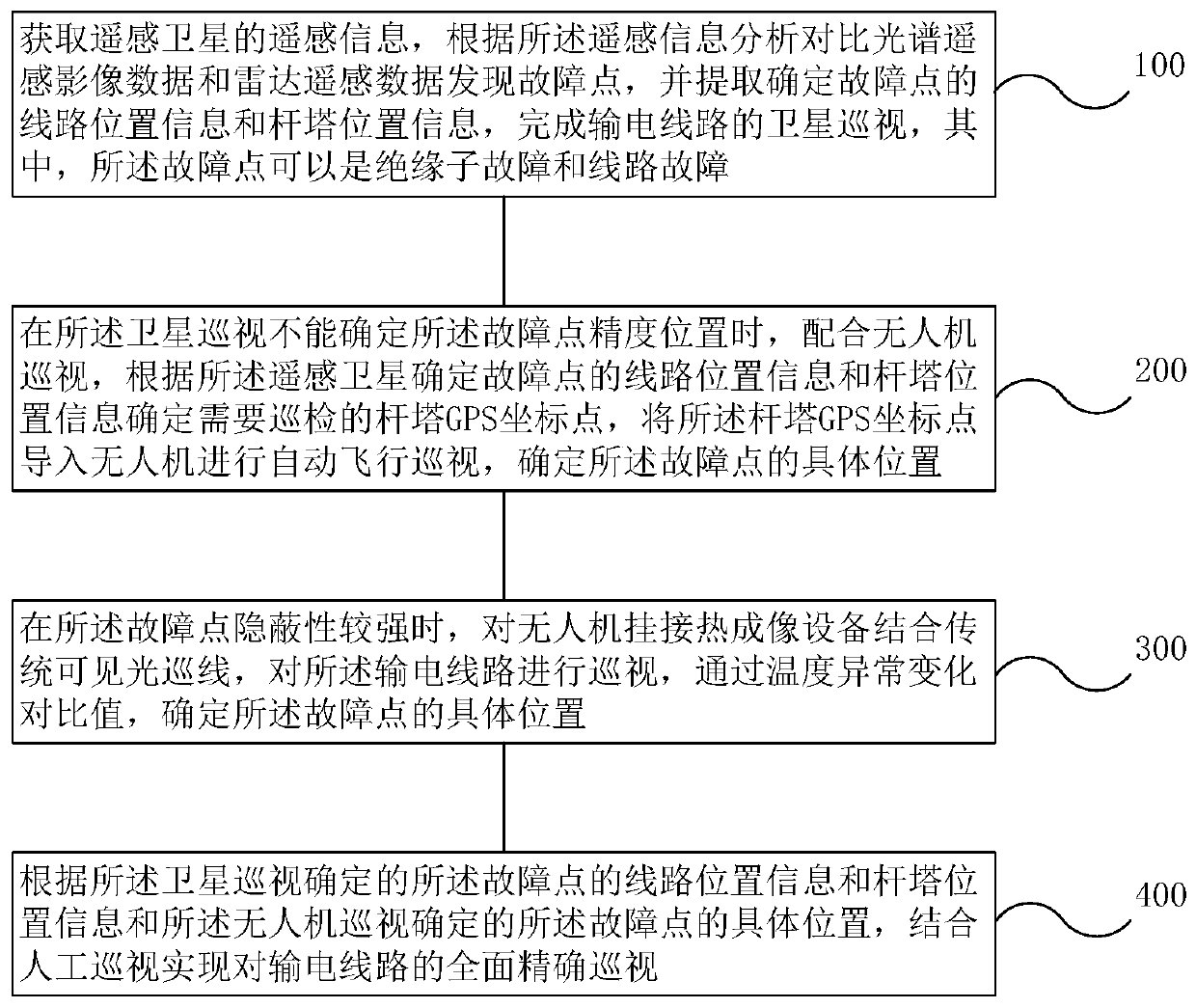

[0053] The embodiment of the present application provides a power transmission line insulator and a line fault inspection method, which are used in the field of transmission line inspection. figure 1 As shown, the inspection method includes the following steps:

[0054] 100. Obtain remote sensing information from remote sensing satellites, analyze and compare spectral remote sensing image data and radar remote sensing data to find fault points according to the remote sensing information, and extract line location information and tower location information to determine fault points, and complete satellite inspection of power transmission lines, wherein , the fault point may be an insulator fault or a line fault.

[0055] 200. When the satellite patrol cannot determine the precise location of the fault point, cooperate with the drone patrol to determine the GPS coordinate point of the tower that needs to be inspected according to the line position information and the tower posit...

Embodiment 2

[0060] The embodiment of the present application provides a power transmission line insulator and a line fault inspection method, which are used in the field of transmission line inspection. The inspection method includes the following steps:

[0061] 100. Obtain remote sensing information from remote sensing satellites, analyze and compare spectral remote sensing image data and radar remote sensing data to find fault points according to the remote sensing information, and extract line location information and tower location information to determine fault points, and complete satellite inspection of power transmission lines, wherein , the fault point may be an insulator fault or a line fault.

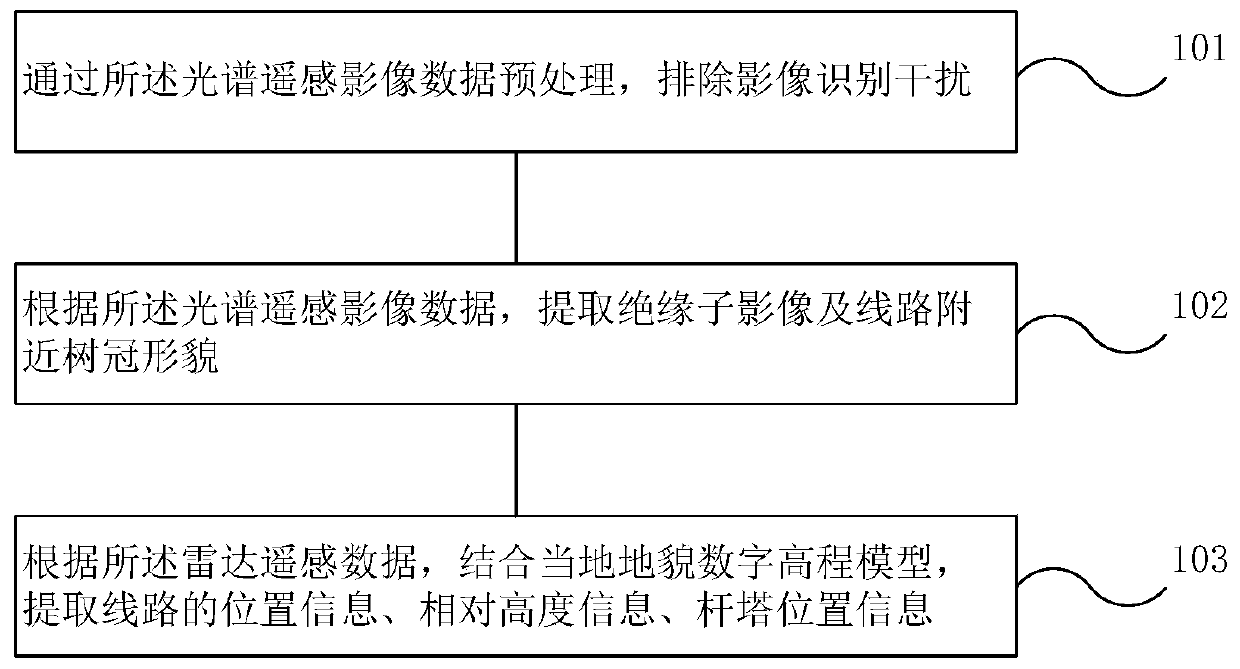

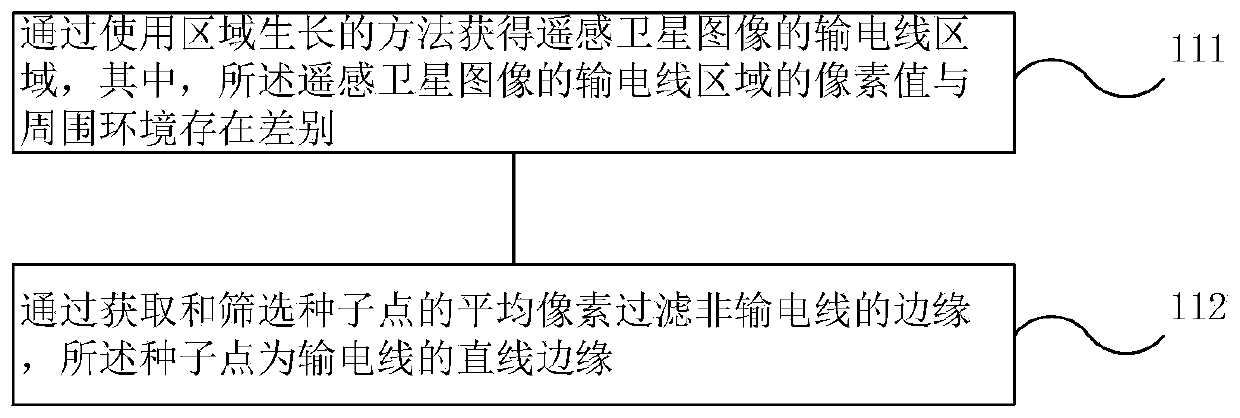

[0062] Specifically, obtain the remote sensing information of the remote sensing satellite, analyze and compare the spectral remote sensing image data and the radar remote sensing data according to the remote sensing information to find fault points, and the method for obtaining the remo...

Embodiment 3

[0093] The embodiment of the present application provides a power transmission line insulator and a line fault inspection system, which are used in the field of transmission line inspection. Figure 5 As shown, the transmission line inspection system 1 includes:

[0094] Emergency evolution model 2, data demand system 3, remote sensing network monitoring technology 4, precise information service plan 5, wherein the remote sensing network monitoring technology 4 and the precise information service plan 5 belong to remote sensing satellite inspection 8, and the remote sensing satellite Patrol 8 is combined with UAV patrol 6 and manual patrol 7 to form sky-ground collaborative observation, realize conventional response mode 9 and fast response mode 10, and realize quasi-real-time monitoring of transmission lines.

[0095] An inspection system for transmission line insulators and line faults, an emergency event evolution model, a data demand system, a remote sensing network monito...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com