Shock-wave pressure-sensor on-site inspection and sorting method

A pressure sensor and sensor technology, applied in the direction of measuring fluid pressure, instruments, measuring devices, etc., can solve the problems of poor operability, high unevenness, large errors, etc., and achieve the effect of reducing and improving the amount of data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

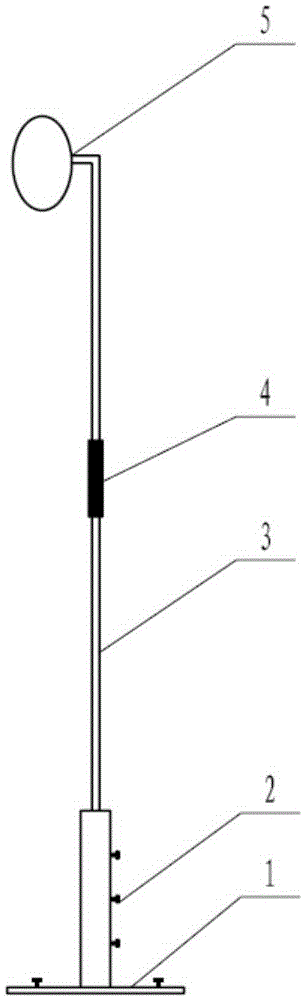

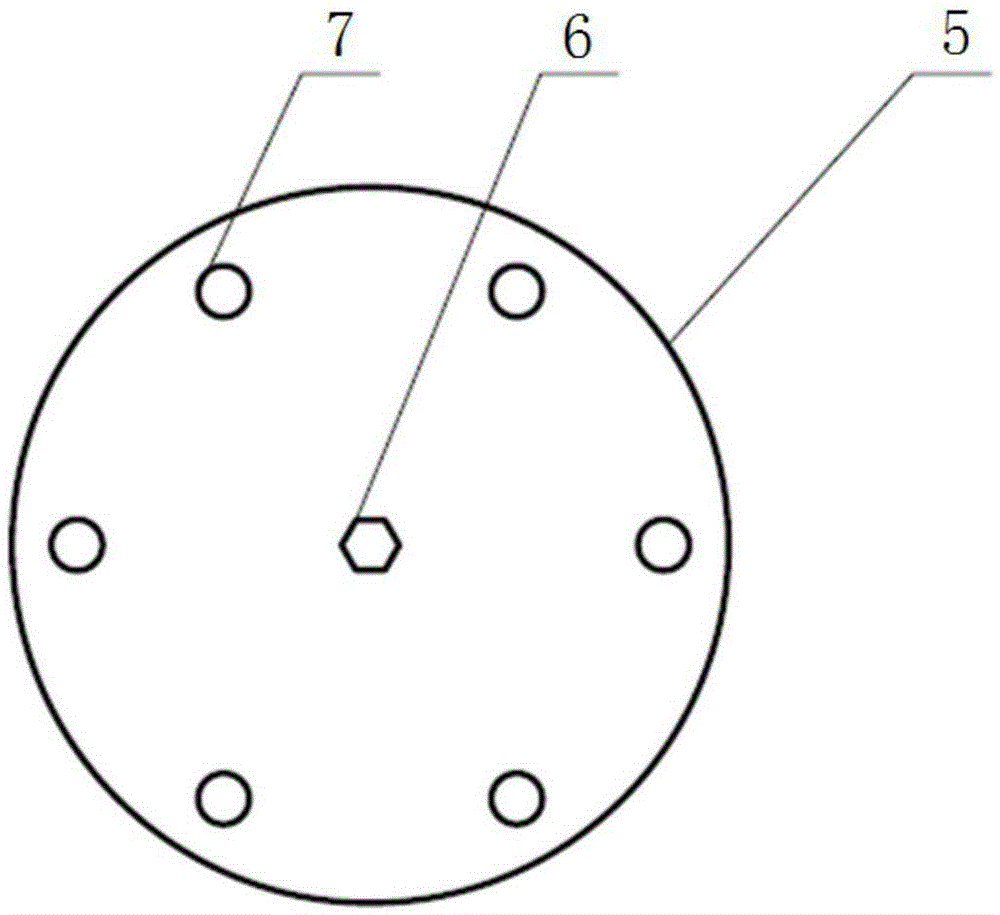

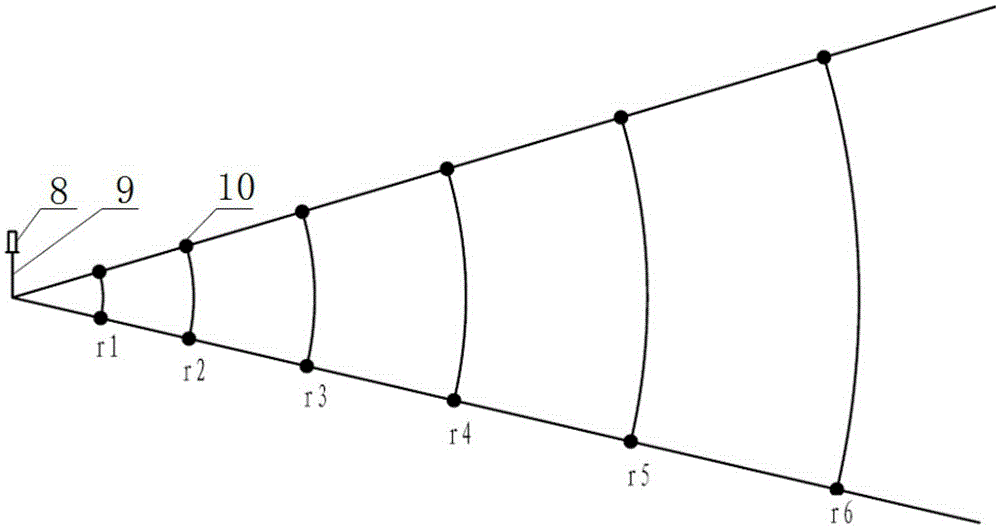

[0026] The invention is an on-site detection method of a shock wave pressure sensor based on sensors arranged in the air, comprising the following steps:

[0027] (1) According to the explosion equivalent required by the test and the distance from the charge center, the Sadovsky formula is used to estimate the shock wave overpressure value at different distances, and the range of the sensor used at each distance is determined according to the estimated value; according to Range determination The number of pressure sensors to be checked is twice the number of sensors required for the corresponding range test.

[0028] (2) Use 1kg TNT spherical bare powder as the standard explosion signal source, place it on the concrete platform near the static explosion test site in the sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com