Robot automatic surfacing and visual inspection system of track gear discs

A visual inspection, automatic surfacing technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high labor cost, low equipment utilization rate, high work intensity, etc., to optimize process parameters and The effect of high consistency of path, welding quality and high degree of equipment automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with drawings and embodiments.

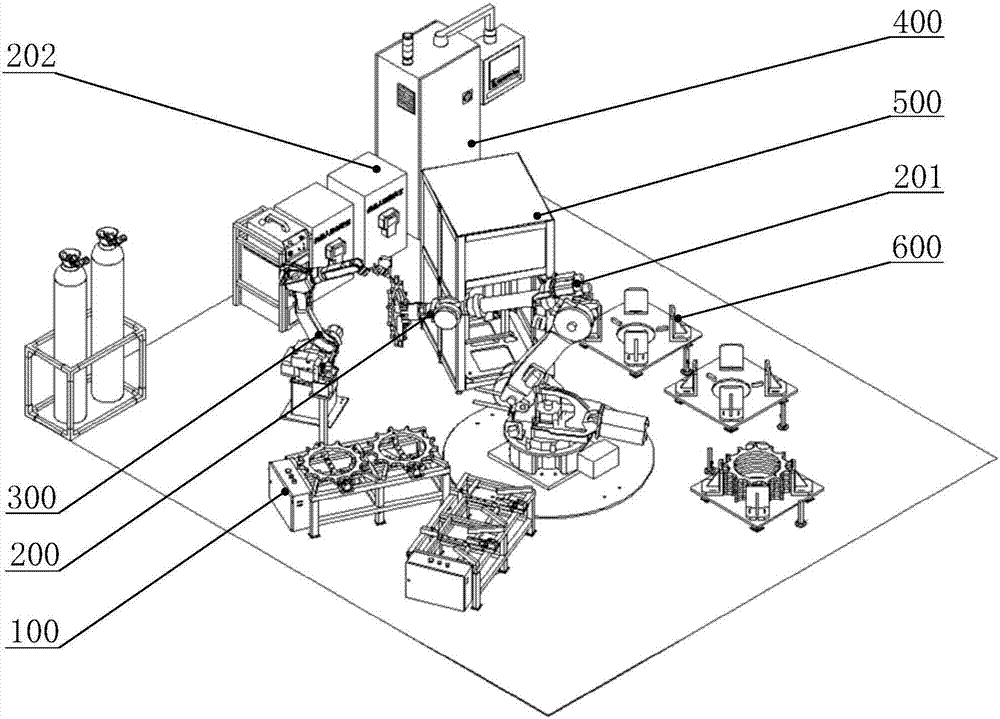

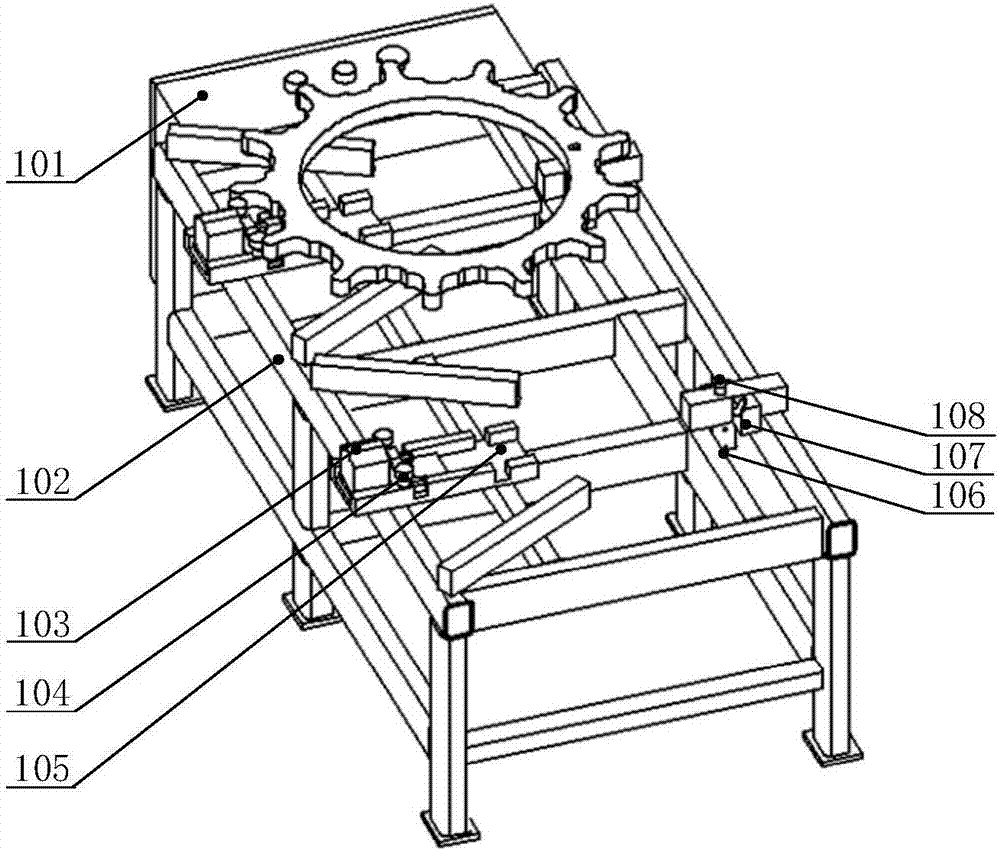

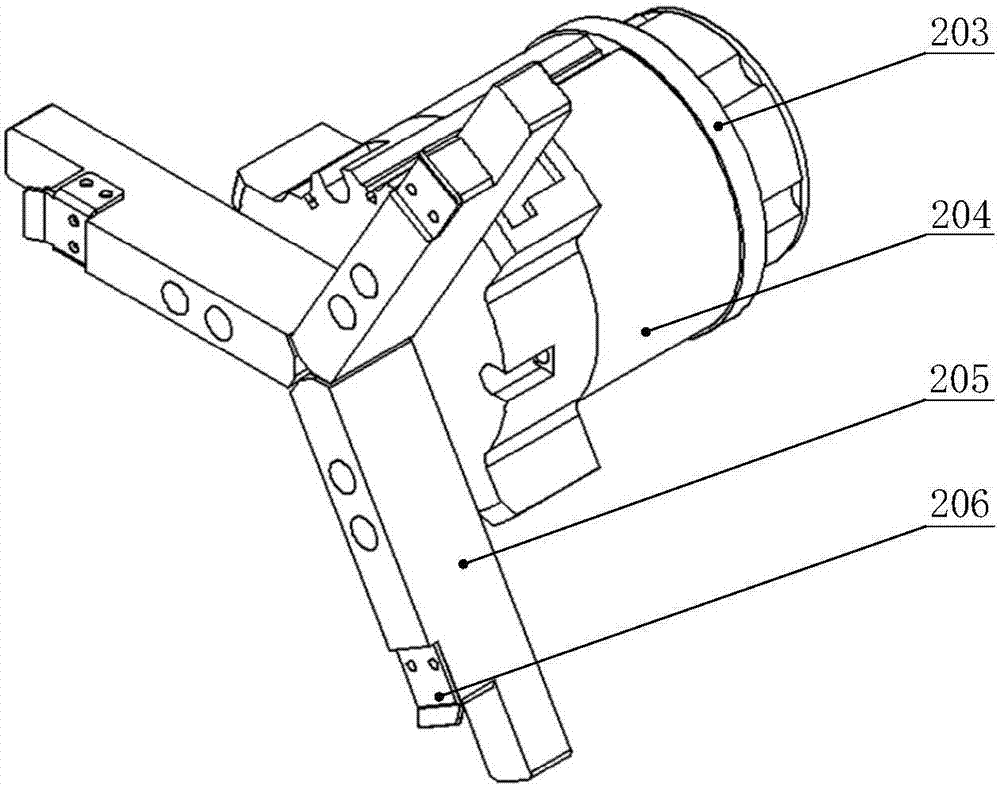

[0031] as attached figure 1 As shown, a system specifically implemented in the present invention includes two fixed silos 100 , a handling robot system 200 , a welding robot system 300 , an intelligent control system 400 , a visual inspection system 500 and two mobile silos 600 . The handling robot system 200 is set in the central area of the ground, and the fixed silo 100, the welding robot system 300, the intelligent control system 400, the visual inspection system 500 and the mobile hopper 600 are all placed around the handling robot system 200; the fixed silo 100 is set in The loading station, the welding robot system 300 is placed at the welding station, the visual inspection system 500 is arranged at the inspection station, the mobile bin 600 is arranged at the unloading station, and the intelligent control system 400 is connected with the welding robot system 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com