Configurable product model quality inspection method

A quality inspection and product model technology, applied in special data processing applications, instruments, electrical and digital data processing, etc. Check and supervise, improve the effect of product design quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A configurable product model quality inspection method, based on the model quality inspection system platform seamlessly integrated on the CATIA software, customizes the configuration check items according to the existing digital management standards and modeling specifications, and then according to the configured check items The product model corresponding to the design data in the CATIA software is used for quality inspection and inspection result management analysis.

[0044] The model quality inspection system platform is seamlessly integrated in the CATIA software in the form of a menu, including a data communication client and a browser. The client includes a menu module, a check item module, a check item configuration module, and a model checking CATIA integration module. The browser end includes a model quality inspection data management platform.

[0045] The menu module corresponds to the inspection interface displayed on the CATIA interface, and is used to ...

Embodiment 2

[0057] A configurable product model quality inspection method, based on the model quality inspection system platform seamlessly integrated on the CATIA software, customizes the configuration check items according to the existing digital management standards and modeling specifications, and then according to the configured check items The product model corresponding to the design data in the CATIA software is used for quality inspection and inspection result management analysis.

[0058] The model quality inspection system platform is seamlessly integrated in the CATIA software in the form of a menu, including a data communication client and a browser. The client includes a menu module, a check item module, a check item configuration module, and a model checking CATIA integration module. The browser end includes a model quality inspection data management platform.

[0059] The described product model corresponding to the design data in the CATIA software is carried out quality...

Embodiment 3

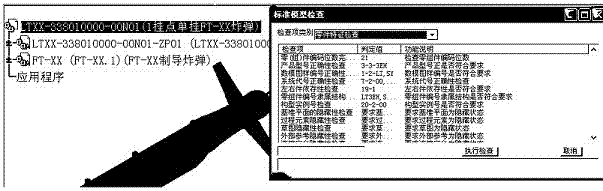

[0073] Such as figure 1 As shown, first open an assembly model 1 to be checked, and display the structure tree 2 of the entire assembly corresponding to the assembly model 1 on the CATIA interface. By clicking the model check tool bar embedded in the CATIA software, the check interface 3 of the standard model pops up. Select "All" in the inspection item category, and the system starts to run the analysis and perform 61 inspections.

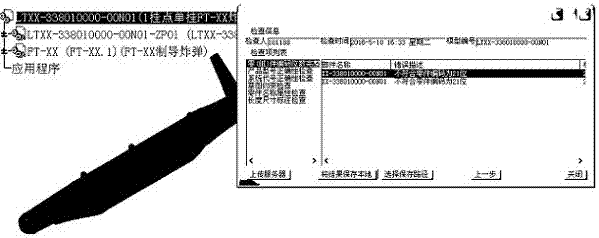

[0074] Such as figure 2 As shown, after the system has completed 61 inspections, the inspection result 4 pops up. The interface displays the inspector, inspection time, inspection object number (model number) and problem items detected by the model. At the same time, the error content is located and the cause of the problem is analyzed. Error results can be stored locally in the form of tables for designers to view, or uploaded to the model quality inspection data management module for statistical summary analysis to find quality weak links, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com