Intelligent inspection system

A technology of intelligent inspection and inspection points, which is applied in inspection time inspection, instrumentation, data processing applications, etc. It can solve problems such as reporting, inspection personnel who cannot go out to work, inspection quality cannot be guaranteed, etc., to improve work efficiency , save the effect of later work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with specific drawings and embodiments.

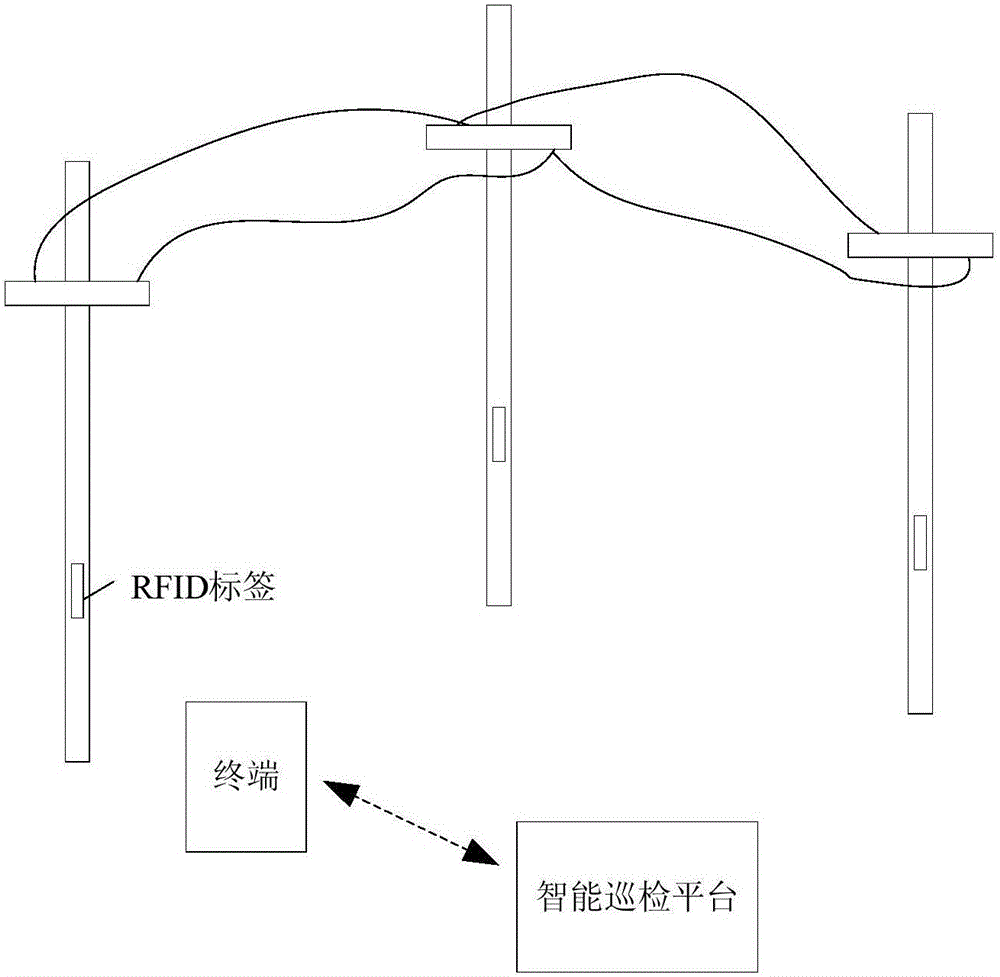

[0052] The present invention proposes an intelligent inspection system, such as figure 1 As shown, including terminals, intelligent inspection platforms and RFID tags;

[0053] The intelligent inspection application (i.e. APP software) is installed on the terminal. The intelligent inspection platform is a web terminal, which is usually set on a background server and can communicate with the terminal in real time through the 2G / 3G wireless network; the RFID tag is set at the inspection point, It is usually bound to the electric pole of each inspection point; when inspectors conduct inspections of power facilities, they can quantify the inspection work by scanning the RFID tags bound to the inspection points through the terminal, and can control the inspection personnel to realize Inspection quality control. The following is a detailed introduction to the intel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com