Collision-preventing protection system and method for electric spark machine tool

A technology of electric discharge machine tool and protection system, which is applied in the direction of electric processing equipment, metal processing equipment, accessory devices, etc., can solve the problems that the anti-collision system cannot be activated in time, reduces the machining accuracy of the machine tool, and is difficult to debug, so as to reduce the downtime of the machine tool Loss, save the effect of replacing shaft accessories and reduce safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

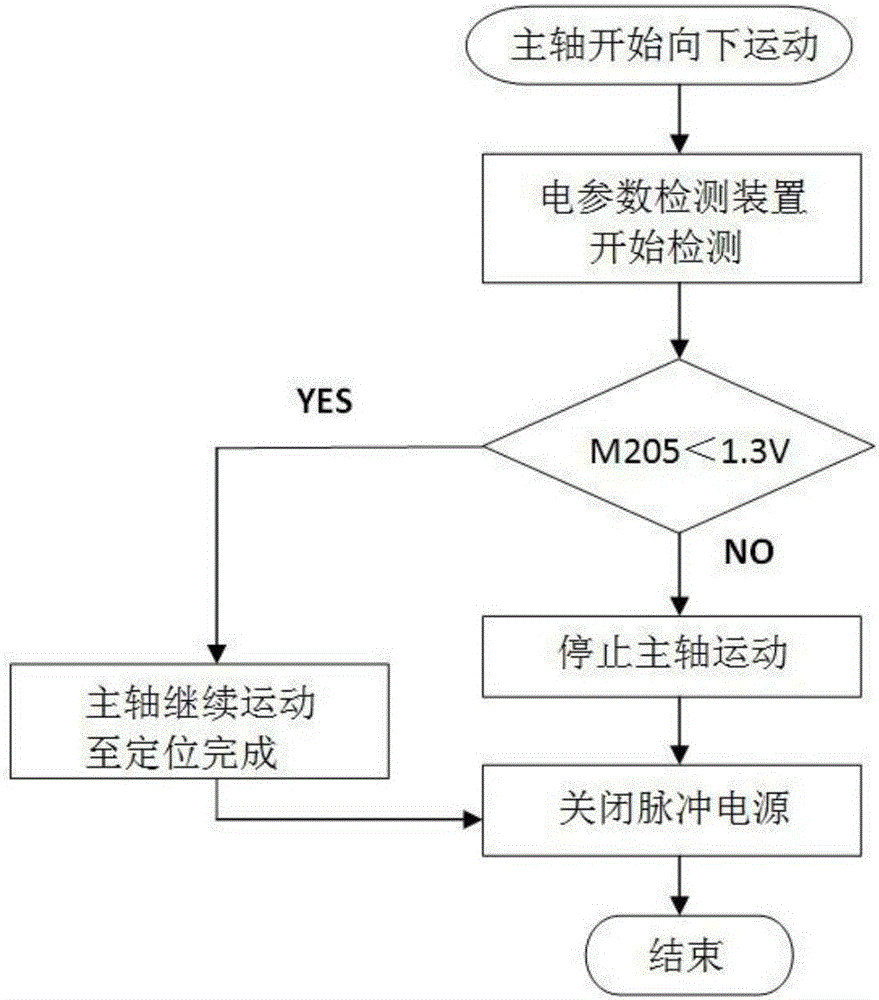

[0019] The present invention is described in further detail below in conjunction with accompanying drawing:

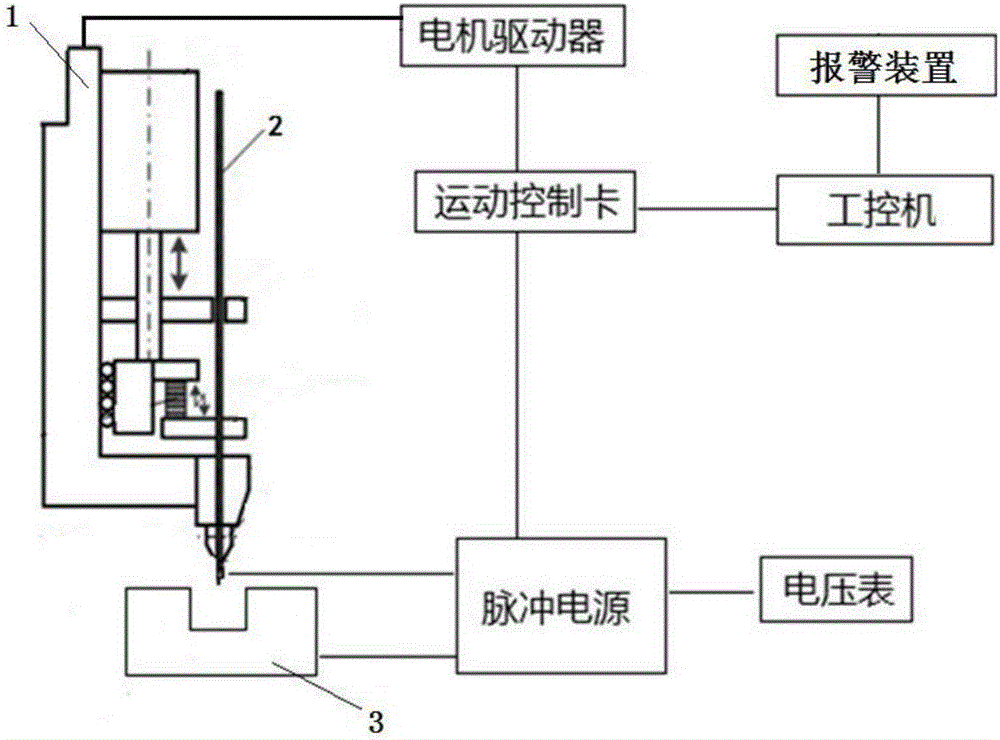

[0020] An anti-collision protection system for an electric discharge machine tool, comprising a motor driver, a motion control card, a pulse power supply, a voltmeter, an industrial computer and an alarm device, the industrial computer is respectively connected to the motion control card and the alarm device, and the motion control card passes through The signal lines are respectively connected to the motor driver and the pulse power supply. The motor driver controls the spindle to move up and down through the motor. The pulse power supply is respectively connected to the positive pole of the electrode wire and the negative pole of the workpiece, and the collected information is fed back to the motion control card. There is an external voltmeter for observing voltage conditions.

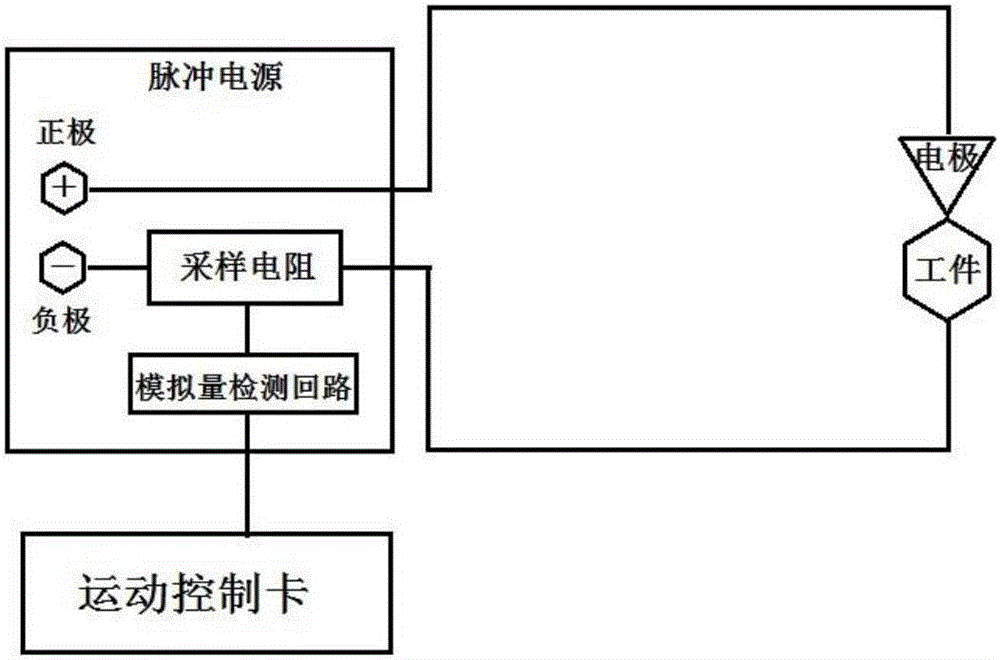

[0021] Preferably, the pulse power supply includes an analog quantity detection circuit, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com