A fuel injector equipped with a fuel filter device

A fuel filter and fuel injector technology, applied in fuel injection devices, charging systems, mechanical equipment, etc., can solve problems such as failure of internal combustion engine performance, loss of production enterprises, and impact on fuel injection efficiency, so as to reduce downtime losses and prolong service life Longer life and lower operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

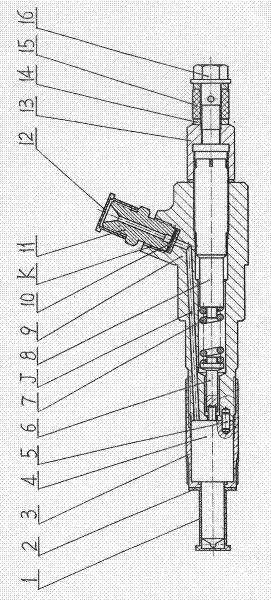

[0011] The specific implementation of the present invention will be described below in conjunction with the accompanying drawings.

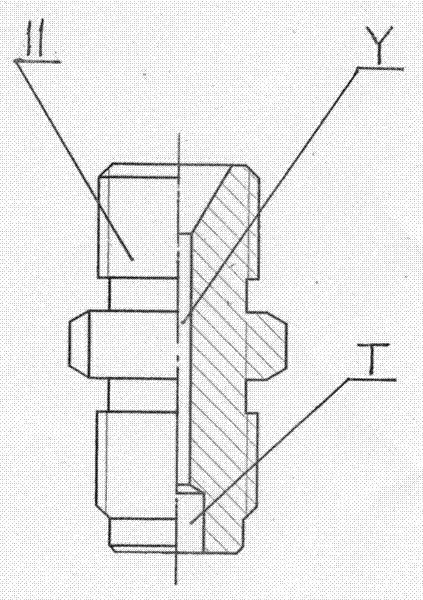

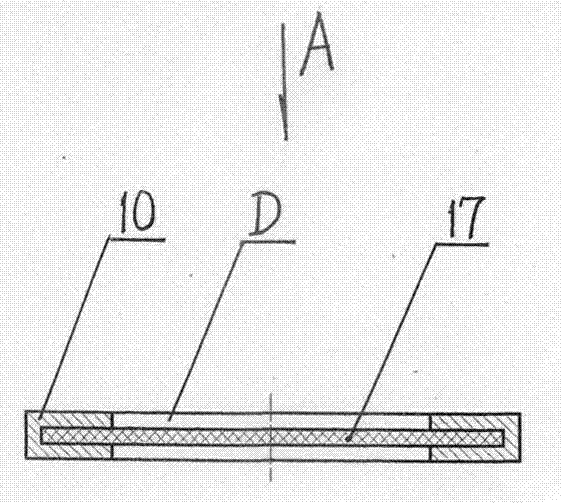

[0012] refer to figure 1 , the inner cavity of the injector body 9 is equipped with a push rod 6, a pressure regulating spring 7, and a pressure regulating screw 8. The fuel injection end is connected to the fuel injection nozzle coupler 4 by a positioning pin 5 and a tight cap 3, and the pressure regulating end is connected by a protective cap 13 Pipe connection bolts 16 are equipped in the gasket 14 and the antifouling gasket 15, and the pressure regulating screw 8 is blocked in the inner cavity of the fuel injector body 9. There is a pipe joint connection hole K on the side of the big end of the fuel injector body 9, and a fuel filter device composed of a filter gasket 10 and a reaming fuel inlet pipe joint 11 is installed inside, and the outer cover protective cap 12 (remove the protective cap 12 when connecting the fuel inlet pipe) , the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com