Dual-motor elevator traction system and control method thereof

An elevator traction and control method technology, applied to elevators, lifts, transportation and packaging in buildings, etc., can solve problems such as elevator falling, shutdown repair, customer dissatisfaction, etc., to reduce system costs, reduce maintenance pressure, and reduce The effect of downtime losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the present invention is described in detail.

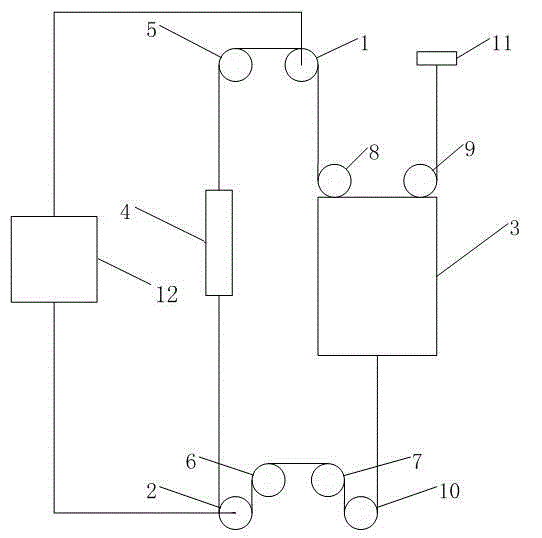

[0015] The structure diagram of the double-motor elevator traction system of the present invention is as follows: figure 1 As shown, it includes two traction machines at the top and bottom of the hoistway, upper traction sheave 1, lower traction sheave 2, traction rope, car 3, counterweight 4, guide wheel A5, reverse rope pulley A8, reverse rope Sheave B9, car rope head plate 11, and detection and control system 12 for detecting the operation of the elevator. The two traction machines are connected to the counterweight 4 through the traction rope and the guide wheel A5. The other end of the counterweight 4 is connected to the lower traction machine. The traction sheave 2 is connected, the counterweight 4 is located behind the car 3, and the upper end of the car 3 is fixed on the car rope head plate 11, and the traction sheave 1 is connected through the reverse sheave A8 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com