Bracket type overhanging scaffold and construction method thereof at erection time

A technology of cantilevered scaffolding and corbels, which is applied to the accessories of scaffolding, scaffolding supported by house structure, construction, etc., can solve the problems affecting the structural stability of cast-in-place slabs, reducing the strength of shear walls, etc. Construction progress, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

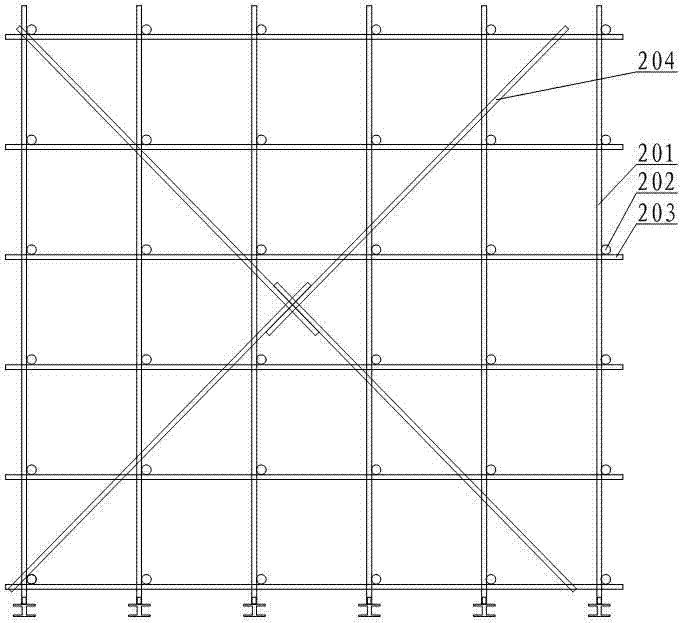

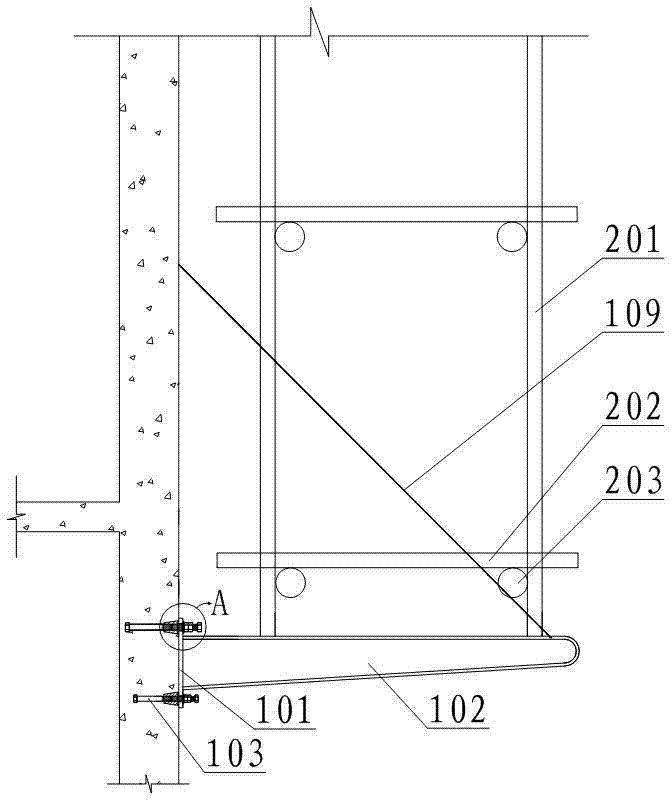

[0031] Such as figure 1 and figure 2 As shown, the corbel-type cantilevered scaffold includes scaffolding and a plurality of cantilevered support seats, wherein the plurality of cantilevered support seats are connected at the same level of the shear wall and distributed at equal intervals in the longitudinal direction. The cantilever support seat includes a connecting plate 101, a steel beam 102, a threaded connector 103 and an outer limit nut 104. One end of the steel beam 102 is connected to the end surface of the connecting plate 101 and is perpendicular to the connecting plate 101, and one end of the threaded connector 103 passes through the connecting plate. The plate 101 is embedded in the shear wall, the outer limit nut 104 is provided with an internal thread matching the external thread of the threaded connector 103, the outer limit nut 104 is sleeved on the threaded connector 103, and the connecting plate 101 is located between the shear wall and the Between the out...

Embodiment 2

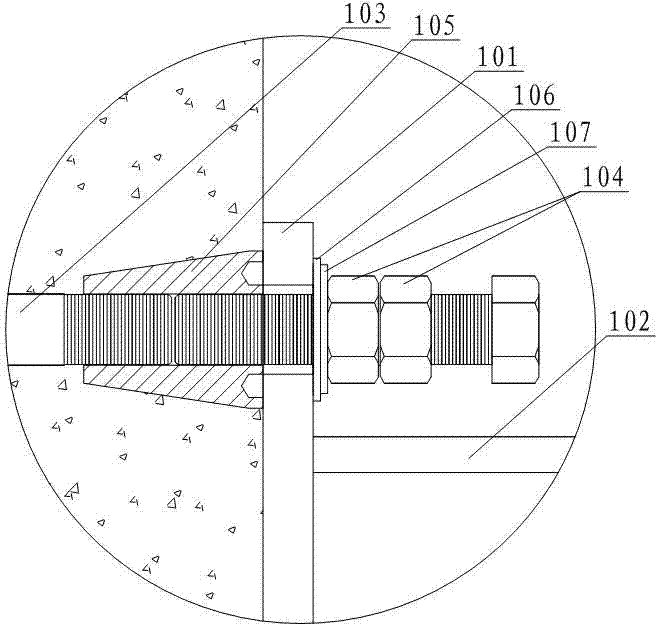

[0036] Such as image 3 As shown, the present embodiment has the following improvements on the basis of Embodiment 1: the cantilever bearing seat of this embodiment also includes a tapered sleeve 105, a flat washer 106 and an elastic washer 107, wherein the tapered sleeve 105. The end face of the end with the larger diameter is flush with the outer wall surface of the shear wall, and the end face is concave to form an annular groove. The tapered sleeve 105 is provided with an internal thread that matches the external thread of the threaded connector 103. The tapered sleeve 105 is located in the shear wall and is connected to the threaded connector 103 by thread matching. The flat gasket 106, elastic pad The pieces 107 are all sleeved on the threaded connector 103 and located between the connecting plate 101 and the outer limit nut 104, the flat washer 106 is in contact with the connecting plate 101, and the two ends of the elastic washer 107 are in contact with the flat washer...

Embodiment 3

[0038] This embodiment is improved as follows on the basis of Embodiment 2: the threaded connector 103 of this embodiment uses two bolts, one bolt is located inside the shear wall, and the head of the other bolt is located outside the shear wall, The other ends of the two bolts opposite to the head end are embedded in the tapered sleeve 105 and connected with the tapered sleeve 105 . In this way, when this embodiment is applied, the cantilevered support seat is fixed or disassembled by adjusting the bolt whose head is located outside the shear wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com