Anchor pipe skeleton and its support method

A frame and anchor pipe technology, which is applied in excavation, foundation structure engineering, sheet pile walls, etc., can solve the problems that the physical and mechanical properties and hydraulic properties of the soil cannot be improved at the same time, so as to overcome poor self-stability, safe and reliable process, The effect of small construction site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

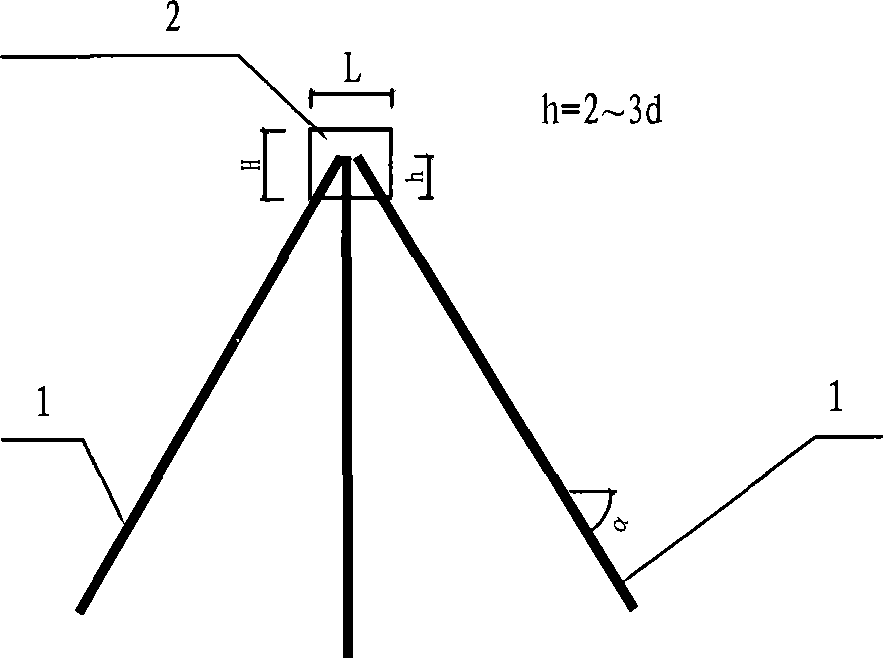

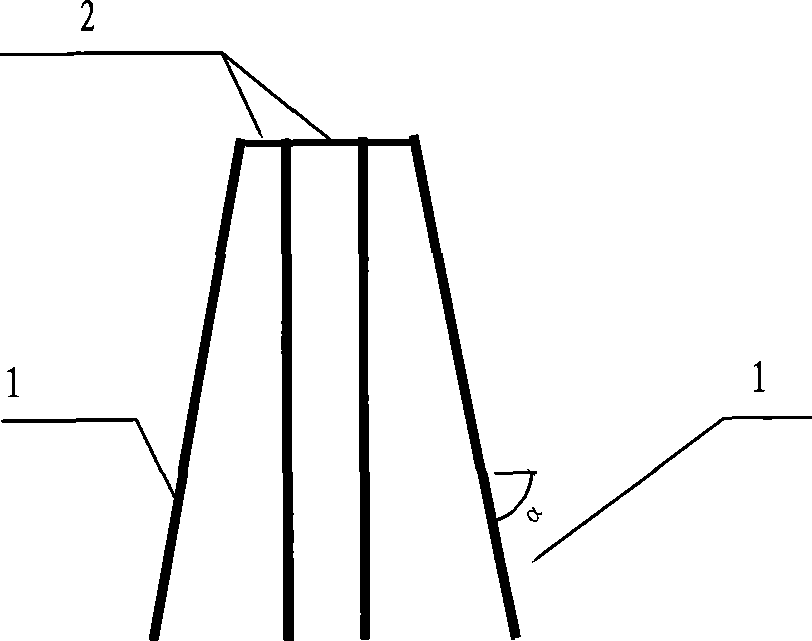

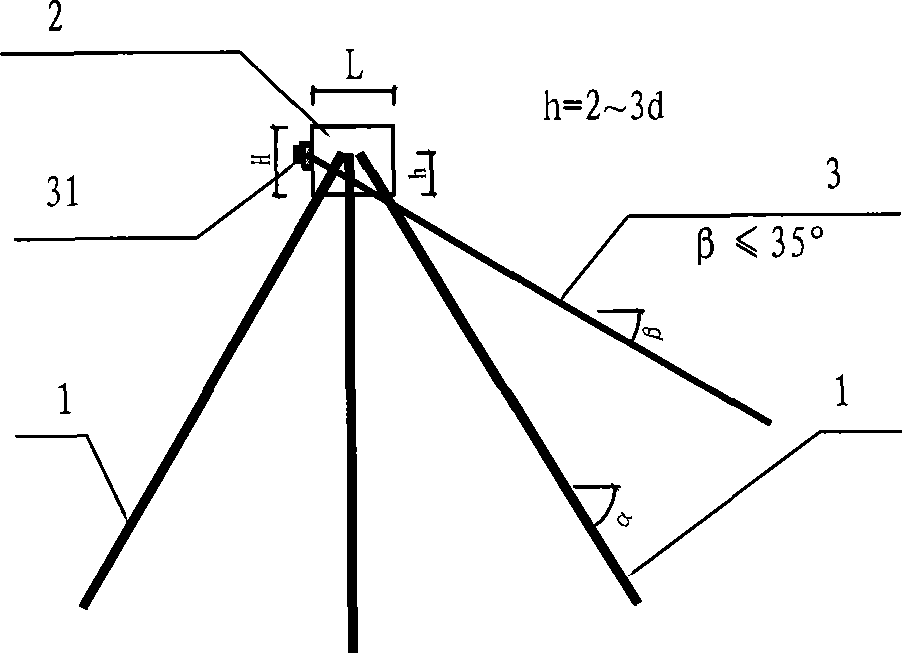

[0042] The anchor pipe frame of the present invention is a new type of slope reinforcement structure developed based on prestressed anchor cables, steel pipe piles and frame beams. The structure is composed of prestressed anchor cables, steel pipe piles and frame top beams. The steel pipe piles are all mechanized drilling construction, and the top beam of the frame is prefabricated assembly type or cast-in-place type, the structure construction is convenient, and the construction has little disturbance to the surrounding buildings; the construction has low requirements for site conditions and clearance, and is suitable for any soil layer conditions , especially for the following projects:

[0043] 1) Highway, railway slope permanent reinforcement project or landslide control project;

[0044] 2) Building foundation pit slope support engineering. The construction of the anchor pipe frame has little influence on the disturbance of nearby buildings, and the noise is small, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com