Prepressing method of flushing type bridge rubber raft

A bridge and rubber technology, which is applied in the preloading field of flushing bridge rubber rafts, can solve the problems of affecting the construction flow, occupying the construction plane, and adverse traffic effects, and achieves the effects of intuitive weight, saving construction sites, and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

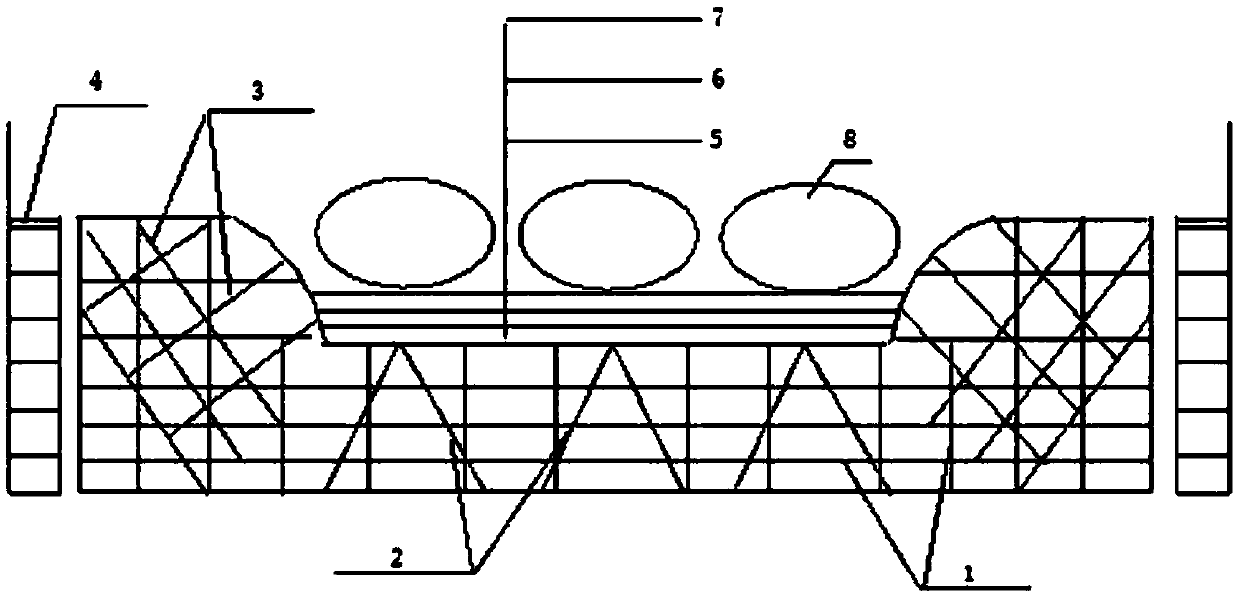

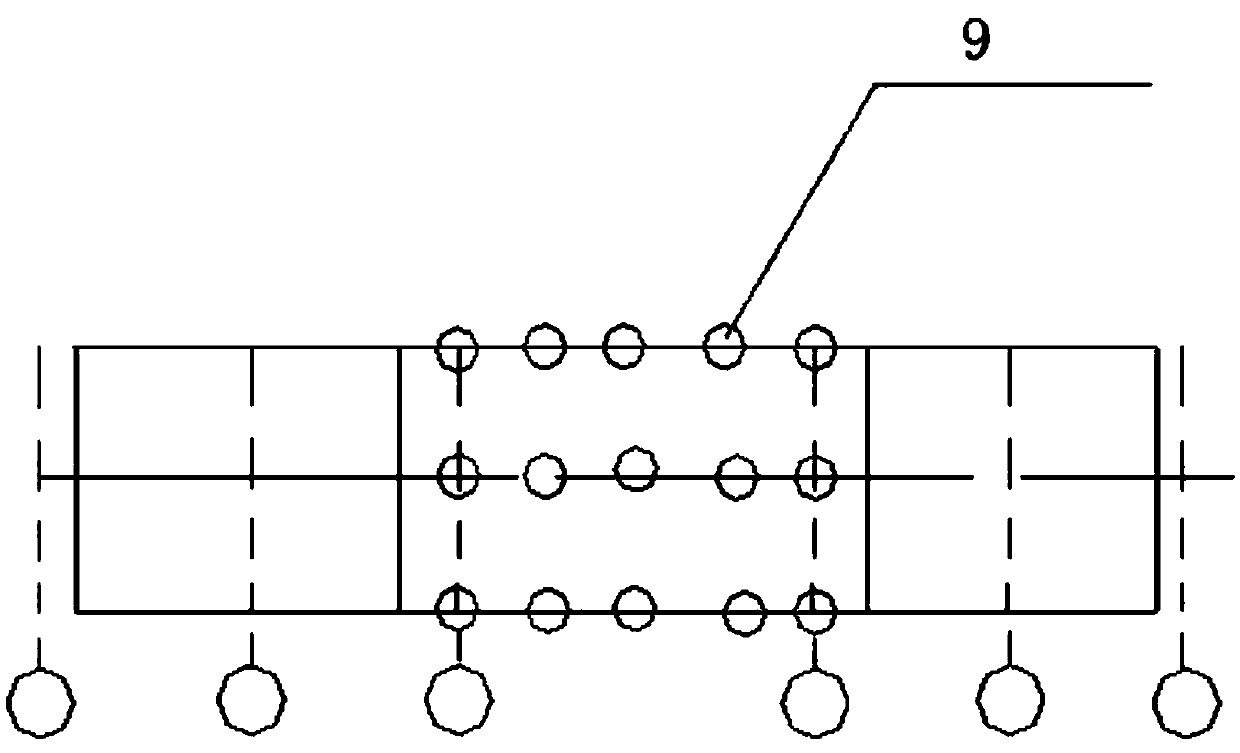

[0023] as attached figure 1 , 2 As shown, the preloading device of the flushing bridge rubber raft includes a box girder scaffold 1, and on the box girder scaffold 1, a three-layer material consisting of I-beam 5, wooden square 6 and plywood 7 is arranged from bottom to top. Bottom mold, diagonal struts 2 are arranged below the bottom mold, encryption rods 3 are arranged on both sides of the bottom mold, water bags 8 are placed on the bottom mold, and scaffolding boards 4 are installed on both sides of the encryption rod.

[0024] The preloading method of flushing type bridge rubber raft, it comprises the following steps:

[0025] (1) Preparatory work: water bag pre-pressed box girder scaffold 1, erection of I-beam 5, wooden square 6, plywood 7, and settlement observation point 9, which must be carried out after the box girder scaffold 1, bracket and formwork pass the inspection. Preload. According to the construction requirements, the size of the pre-pressed water bag 8 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com