Coastal environment high pier hydraulic self-creeping formwork construction method

A construction method and high pier technology, applied in the direction of bridge parts, erection/assembly of bridges, bridges, etc., can solve the problems of poor joint control, prone to wrong platform, low safety factor, etc., to improve the convenience and safety of construction The effect of high degree of standardization, saving construction site and high degree of standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

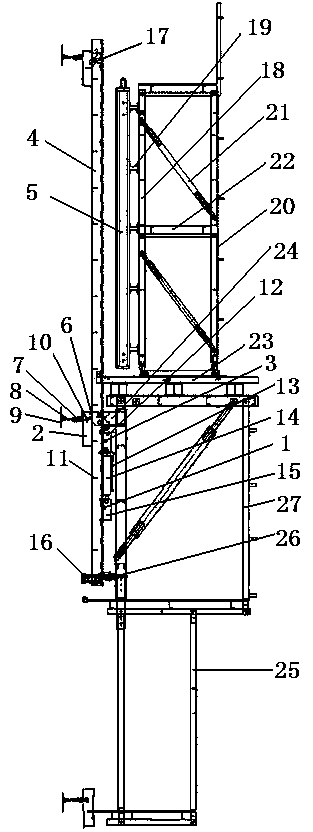

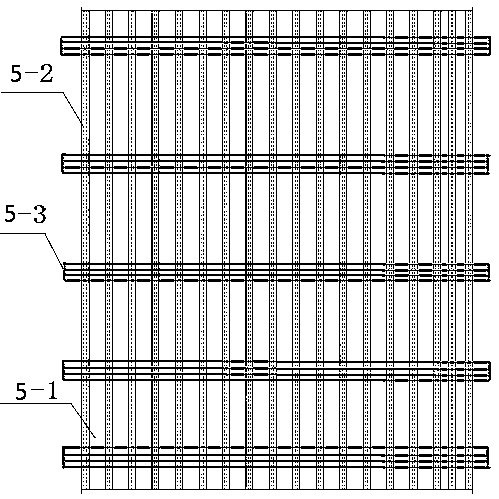

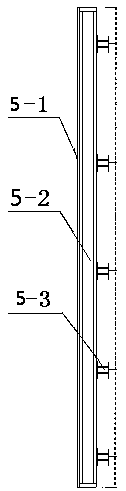

[0059] The specific embodiment: the specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

[0060] A hydraulic self-climbing formwork construction method for a high pier in a coastal environment, which specifically includes the following steps:

[0061] (1) Construction of the initial section of the tower column:

[0062] The starting section of the tower column is a solid structure. Firstly, the steel bars and tower crane embedded parts of the starting section of the tower column are pre-embedded during the construction of the cap. (The formwork adopts a large steel form, and the tie rods are set to pull in opposite directions), and the concrete for the initial section of the tower column is poured; the concrete for the initial section of the tower column is poured in solid form, with a height of 1m, and vibration is strengthened during the concrete pouring process of the initial section of the tower column to ensu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com