Construction method of ikebana socket water stop curtain for dual spindle soil-cement stirring mill

A technology for a cement-soil mixer and a cement-soil mixing pile, which is applied in the directions of infrastructure engineering, construction, sheet pile walls, etc., can solve problems such as split ends, and achieve the effects of ensuring safety, saving project costs, and saving construction sites.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

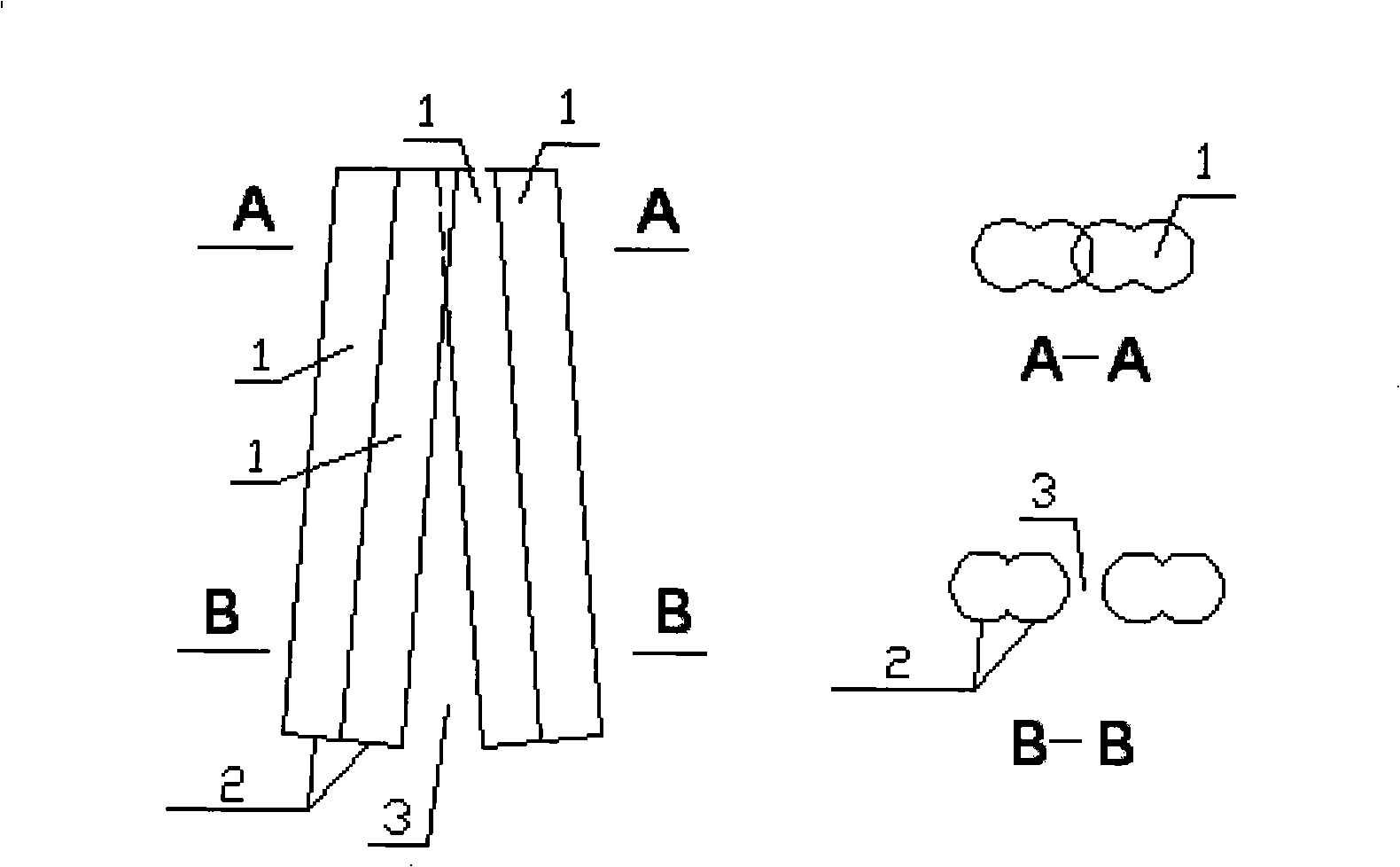

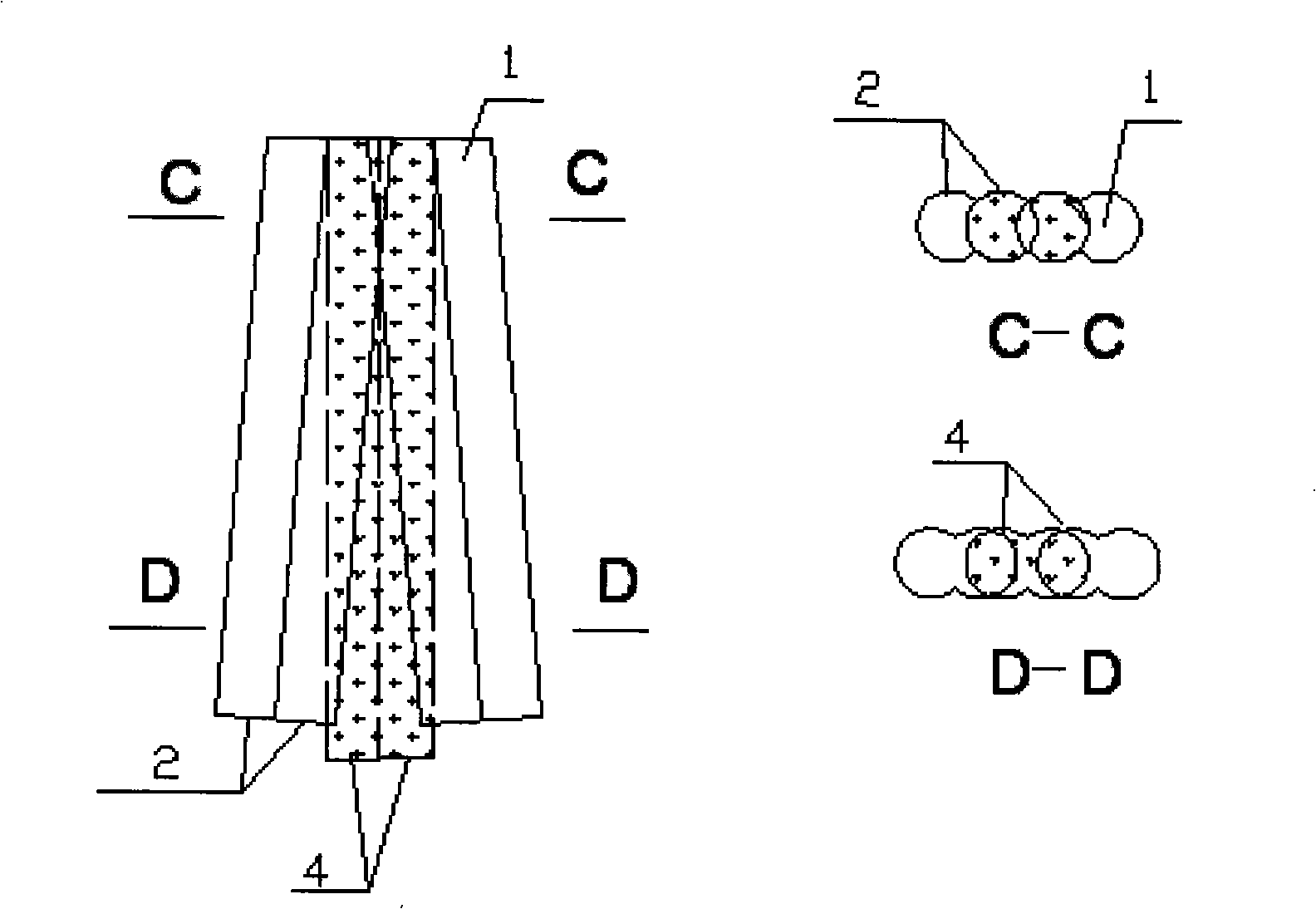

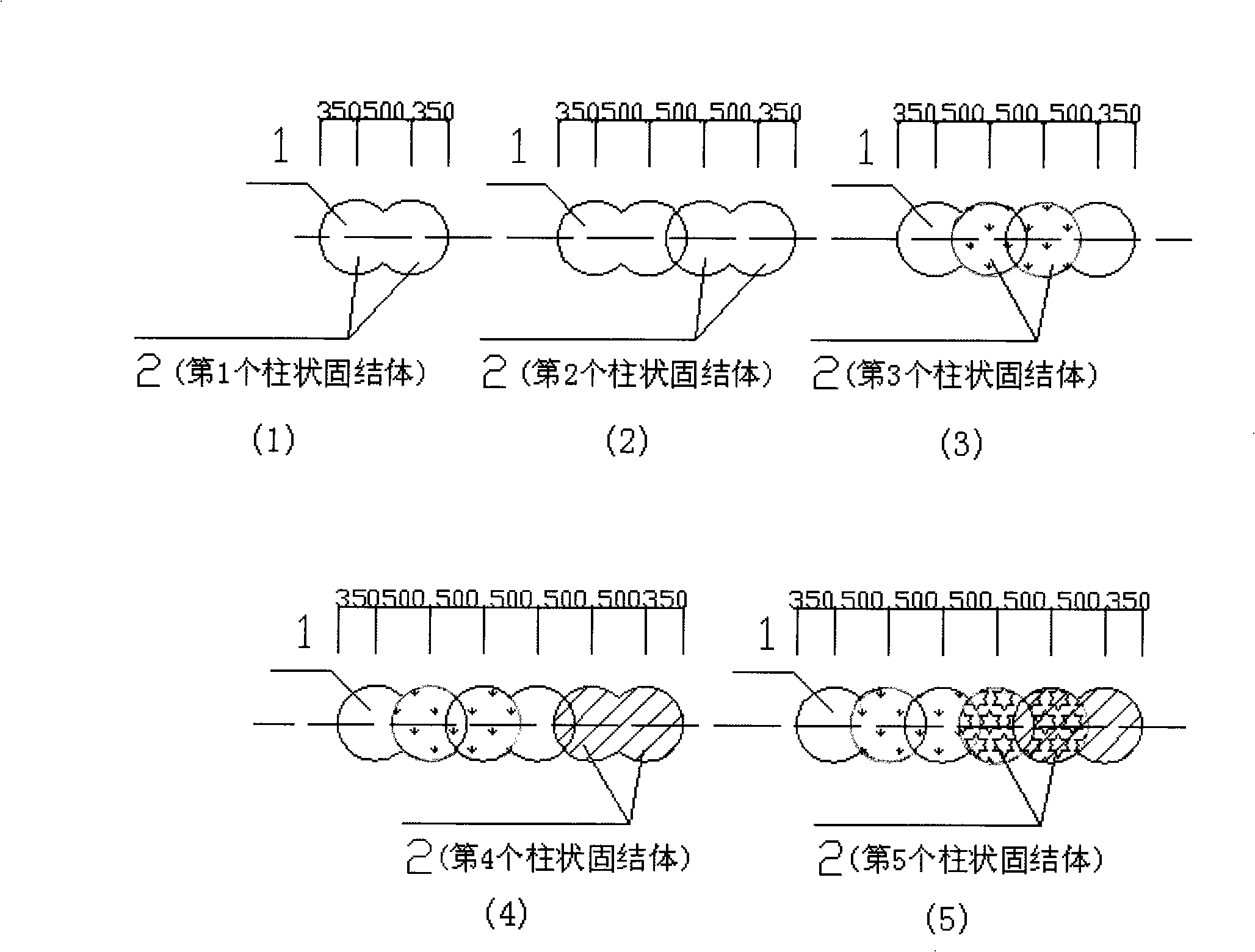

[0031] The basement pit of a project on Zhongshan Road, Nanjing City, Jiangsu Province is 6m deep, and the four sides of the pit are 160m long. From the ground to 4m below the ground is silty clay, below 4m is silt, and 1.5m below the ground is groundwater. In order to prevent the groundwater outside the foundation pit from flowing into the foundation pit and ensure the safety of the foundation pit construction and the buildings around the foundation pit, it is necessary to set up a water-stop curtain around the foundation pit. Since the foundation pit is located in the center of the city, the construction site is limited. At the same time, in order to save the project cost, a single row of water-stop curtain is designed on the periphery of the foundation pit. The design pile bottom depth of the cement-soil mixing pile 1 is 12m, and the design pile top depth is the ground. Then a construction method of double-axis cement-soil mixer flower arrangement socketed water-stop curtai...

Embodiment 2

[0048] The basement pit of a project on Zhujiang Road, Nanjing City, Jiangsu Province is 10m deep, and the four sides of the pit are 180m long. The ground to 4m below the ground is clay, 4m to 7.5m below the ground is sandy, 7.5m below is silt, and 1.3m below the ground is groundwater. In order to prevent the groundwater outside the foundation pit from flowing into the foundation pit and ensure the safety of the foundation pit construction and the buildings around the foundation pit, it is necessary to set up a water-stop curtain around the foundation pit. Since the foundation pit is located in the center of the city, the construction site is limited. At the same time, in order to save the project cost, a single row of water-stop curtain is designed on the periphery of the foundation pit. The depth of the pile bottom of the cement-soil mixing pile 1 is 16m, and the depth of the pile top is designed to be the ground. Then a construction method of a double-axis cement-soil mixer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com