Supporting arch hidden digging top-down construction method

A construction method and technology of underground excavation, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve the problems of large number of excavation divisions, large structural force conversion, repeated disturbance of surrounding rock, etc., and achieve construction safety and effective Guarantee, large construction work area, and the effect of controlling land subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

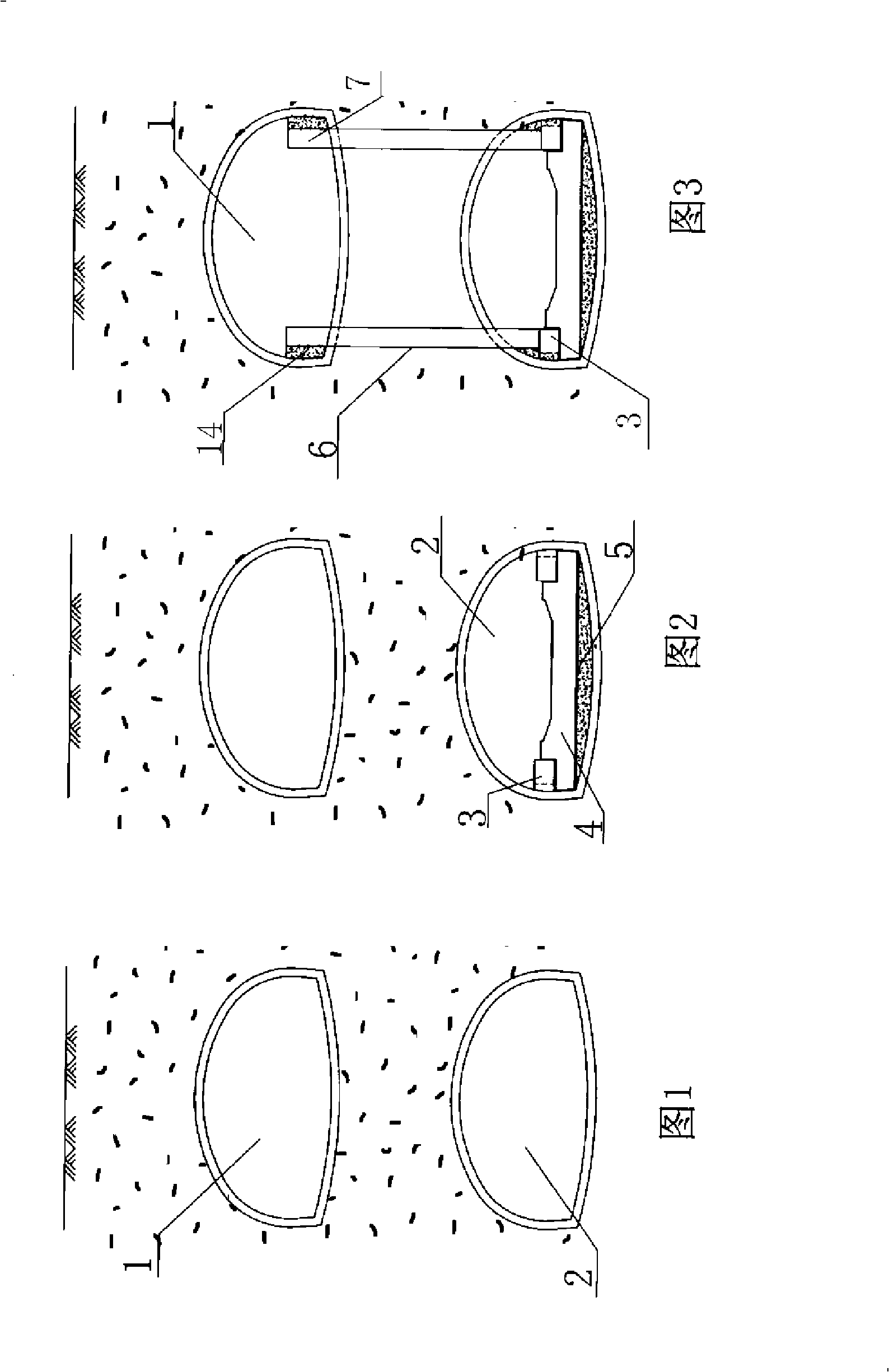

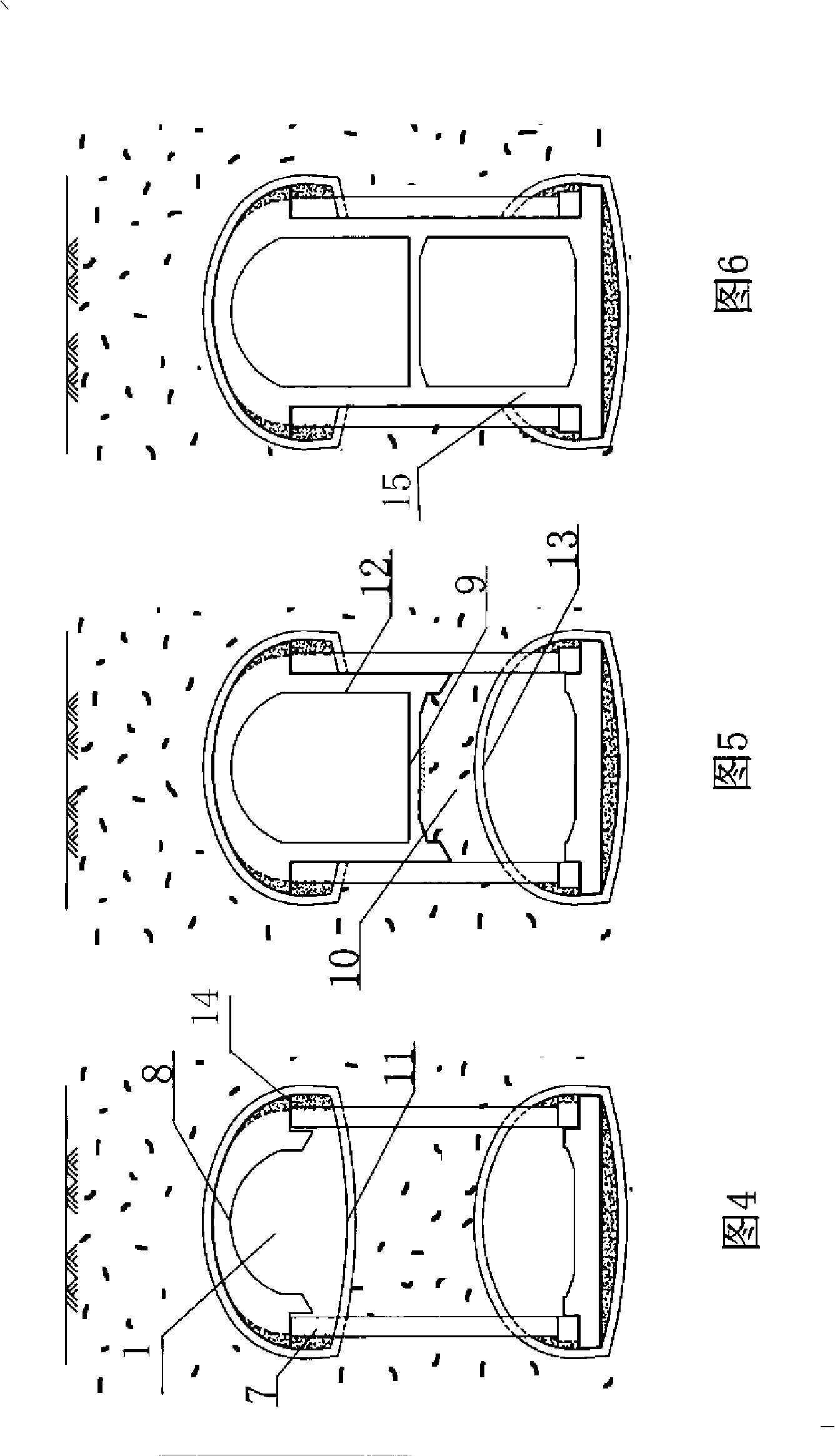

[0049] Embodiment 1, referring to Figures 1 to 6, this embodiment is a single-span two-story vault frame structure system, and the steps of its construction method are as follows:

[0050]Step 1 Refer to Figure 1. Build the advanced pipe shed and the first group of advanced small conduits in the construction shaft, and grout the ground to reinforce the ground. According to the design elevation of the upper frame and the lower frame, the top soil and the bottom corresponding to the underground structure design space In the soil body, along the longitudinal direction of the underground project, the lower pilot tunnel 2 is firstly constructed by the underground excavation method, and then the upper pilot tunnel 1 is constructed by the underground excavation method, so as to provide a working surface for the underground engineering construction;

[0051] Step 2 Referring to Fig. 2, the waterproof layer 5 at the bottom of the lower pilot tunnel is laid, the lower frame structure bot...

Embodiment 2

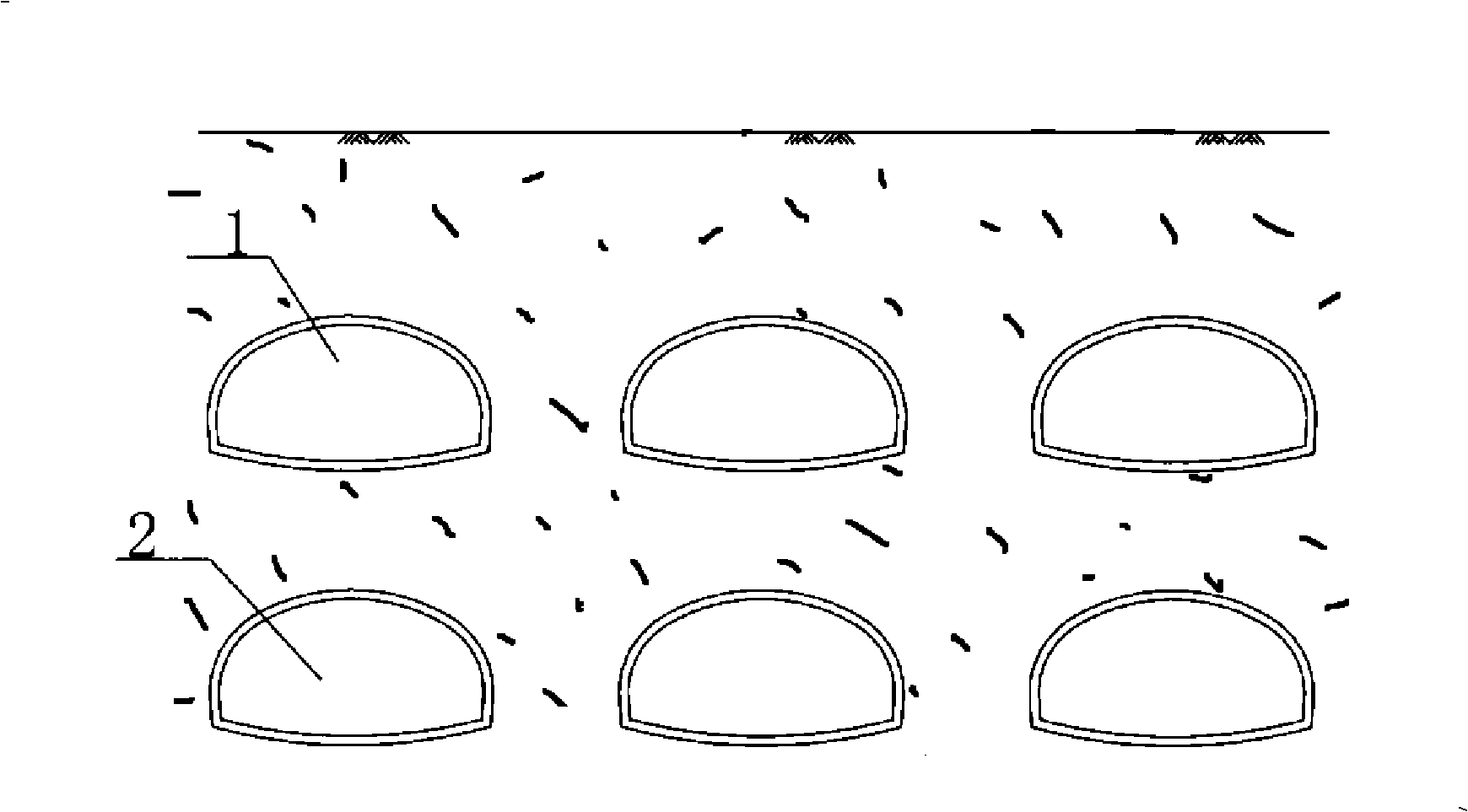

[0056] Example 2, see Figure 7 ~ Figure 14 , the present embodiment is a five-span two-story vault frame structure system, the upper pilot tunnel 1 and the lower pilot tunnel 2 are two or more pairs, and the distance between the two pairs of pilot tunnels is the middle span, and the middle span is an even-numbered span. The steps of its construction method are as follows:

[0057] Step 1 see Figure 7 In the construction shaft, the advanced pipe shed and the first group of advanced small conduits are constructed, and the ground is reinforced by grouting. According to the design elevation of the upper frame and the lower frame, three lower pilot tunnels are excavated at the odd spans of the lower frame by using the underground excavation method first. 2. Then use the underground excavation method to excavate three upper pilot holes 1 at the odd spans of the upper frame to provide a working surface for underground engineering construction. Each pair of pilot holes is a span; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com