LNG ship engine room upper portion flat straight region multi-segment connecting construction type construction method

A technology of LNG ship and construction method, which is applied in the field of multi-segment continuous construction in the flat area above the LNG ship engine room, and can solve the problem of consumption of crane resources, crane resources and supporting manpower kinetic energy consumption, and the inability to pre-assemble segmental outfitting And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

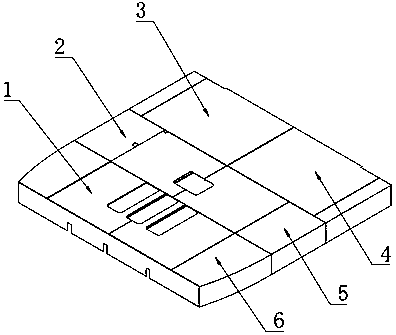

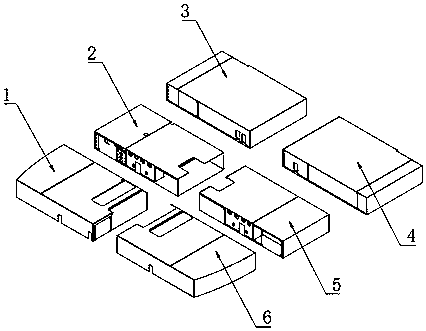

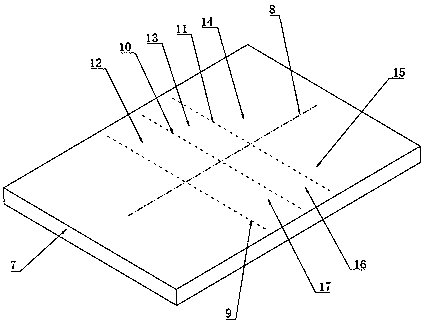

[0037] In one embodiment, a multi-segment continuous manufacturing method for the flat area above the engine room of an LNG ship includes the following steps:

[0038] Step 1. Make the base plate of EG01P segment 1, the base plate of EG02P segment 2, the base plate of EG03P segment 3, the base plate of EG03S segment 4, the base plate of EG02S segment 5 and the base plate of EG01S segment 6, the EG01P segment The bottom plate of section 1 is set out 50 mm toward the stern direction and the side direction, the bottom plate of the EG02P section 2 is set out 50 mm toward the side direction, and the bottom plate of the EG03P section 3 is set out toward the bow end direction and the side direction. Stake out 50 mm, the bottom plate of the EG03S segment 4 is staked out 50 mm to the bow direction and the side direction, the bottom plate of the EG02S segment 5 is staked 50 mm to the side direction, and the bottom plate of the EG01S segment 6 is to the side Stake out 50 mm in both the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com