Long-span steel structure corridor construction method

A construction method and steel structure technology, applied in the direction of building structure, construction, construction material processing, etc., can solve the problems of occupying a large site, large installation site, unsuitability, etc., and achieve small construction site, fast speed, and low hoisting The effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

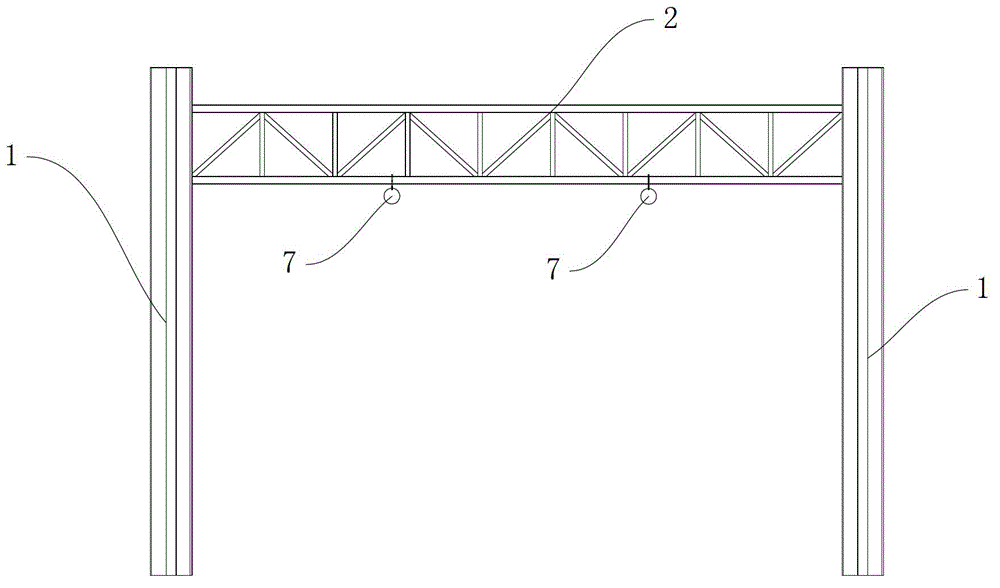

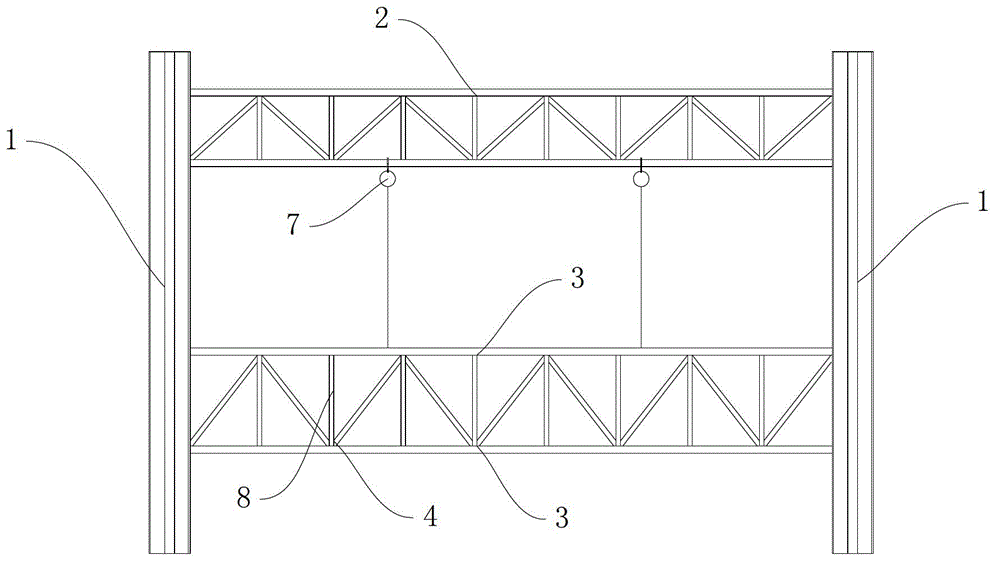

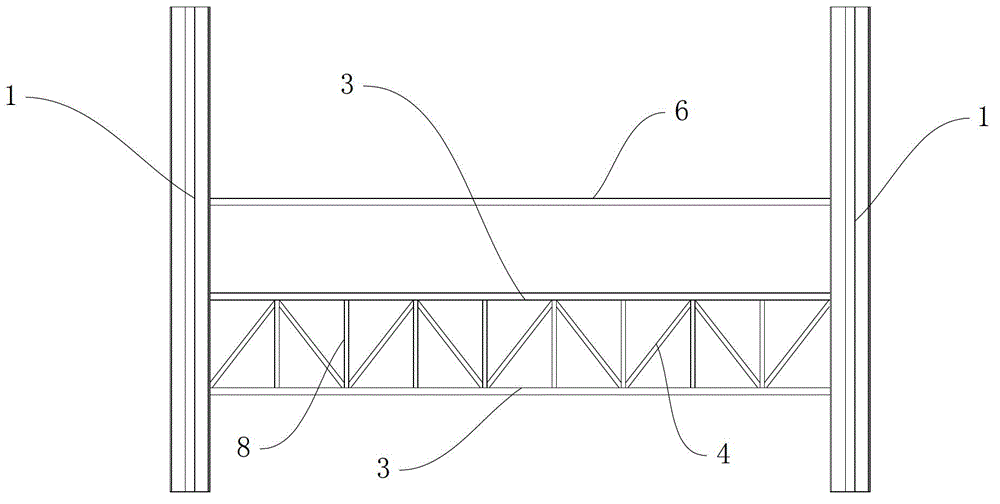

[0013] As shown in the figure, the construction method of the long-span steel structure corridor described in this embodiment, such as figure 1 As shown, the supporting steel columns 1 on both sides of the span are installed first, and the auxiliary truss 2 is installed between the two supporting steel columns 1 . Then if figure 2 As shown, the horizontal horizontal steel beam 3 is hoisted with the auxiliary truss 2 as the lifting point 7, and then the supporting steel beam 8 and the diagonal steel beam 4 between the upper and lower horizontal horizontal steel beams 3 are installed. Then as image 3 As shown, the auxiliary truss 2 is removed, and then the vertical horizontal steel beam between the two horizontal steel beams 3 and the horizontal tie rods are installed, and finally the horizontal steel beam 6 required for construction is installed.

[0014] On the other hand, the elastic deformation of the high-altitude steel beam due to its own weight is obtained through cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com