Construction method of big-diameter PHC prefabricated pipe pile and piling machine for implementing method

A technology of PHC pipe piles and prefabricated pipe piles, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of low bearing capacity of single piles, difficulty in coordination, and mud flow on the ground, so as to improve the bearing capacity of pile foundations Force, the effect of solving the soil plug effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Embodiments of the present invention will be described in detail below.

[0066] see Figure 1-3 , the construction method of the large-diameter PHC prefabricated pipe pile provided by the present invention, comprises the following steps:

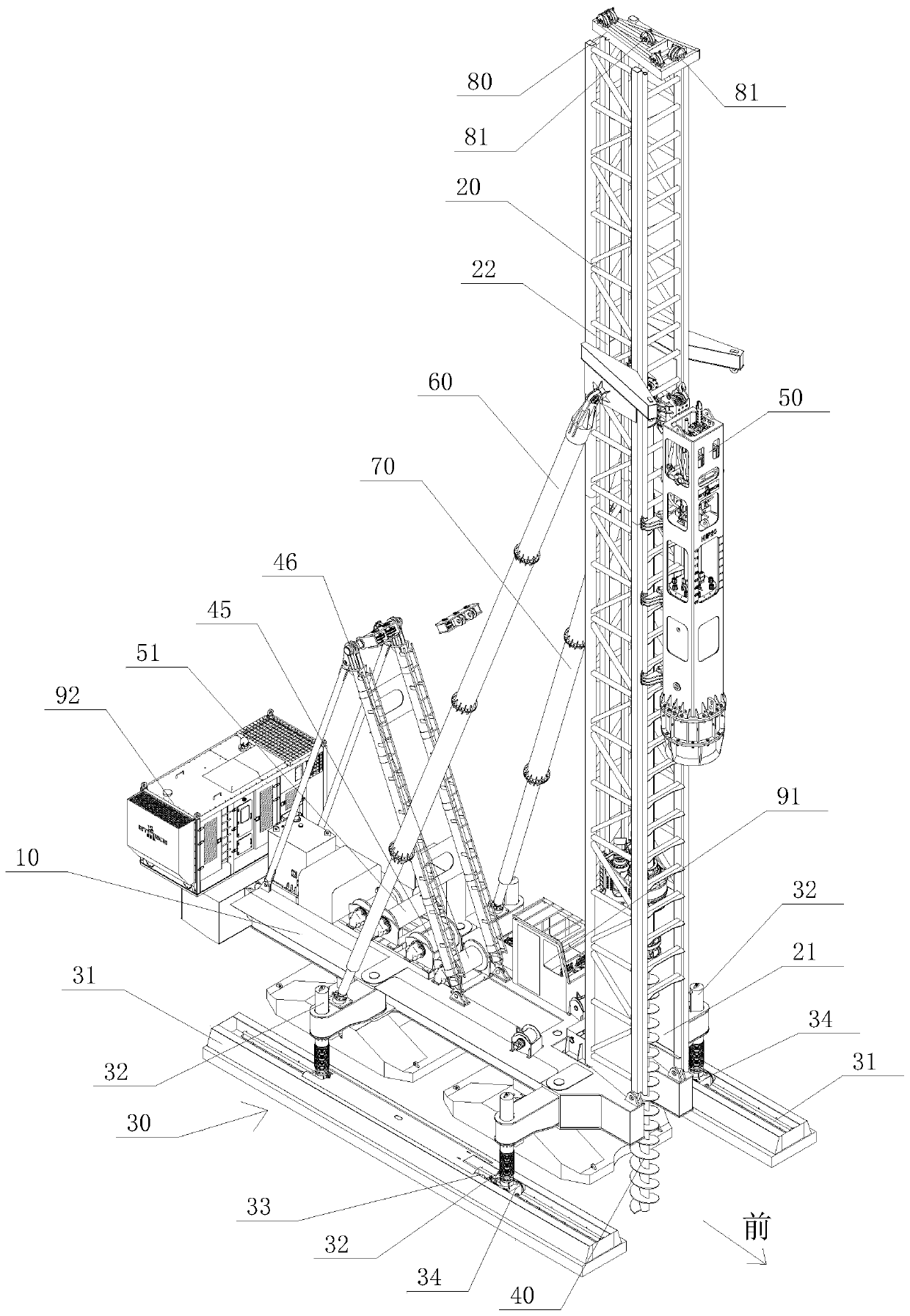

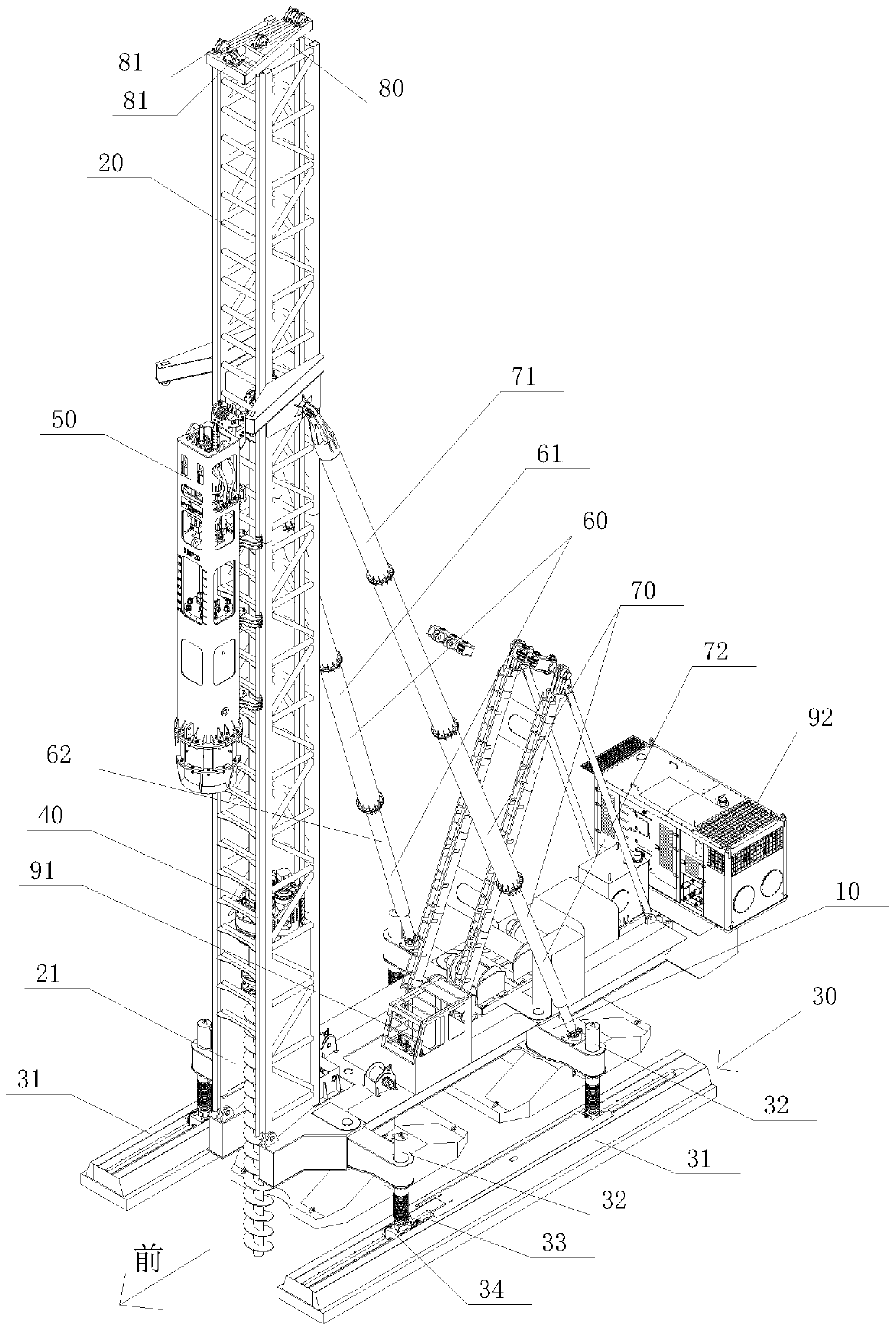

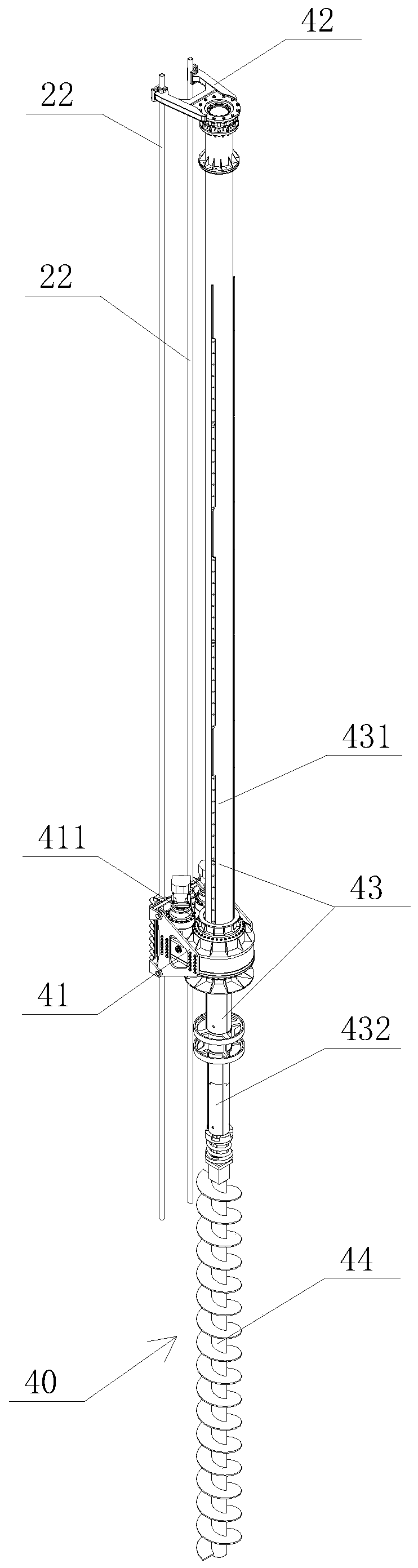

[0067] (1), the pile driver is in place, and the large-diameter PHC prefabricated pipe pile driver is moved to the area to be constructed. The pile driver has an integrated hammer drilling center, so that the tower of the large-diameter PHC prefabricated pipe pile driver 20. The hammer drilling center on the front side is located directly above the pile position of the pile foundation to be constructed; wherein, the large-diameter PHC prefabricated pipe pile driver includes a main engine platform 10, a tower frame 20, a moving mechanism 30, a hole guide device 40, and a piling hammer 50. The first telescopic diagonal brace 60, the second telescopic diagonal brace 70;

[0068] (2), inclination angle adjustment, adjust the length of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com