Sharkskin-imitating 3D printing magnetofluid droplet generator and design method

A 3D printing and ferrofluid technology, which is applied to 3D object support structures, electromechanical devices, electrical components, etc., can solve the problems of large amount of ferrofluid, low power generation efficiency, and expensive equipment, and achieves less ferrofluid and high power generation efficiency. , the effect of reducing movement resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

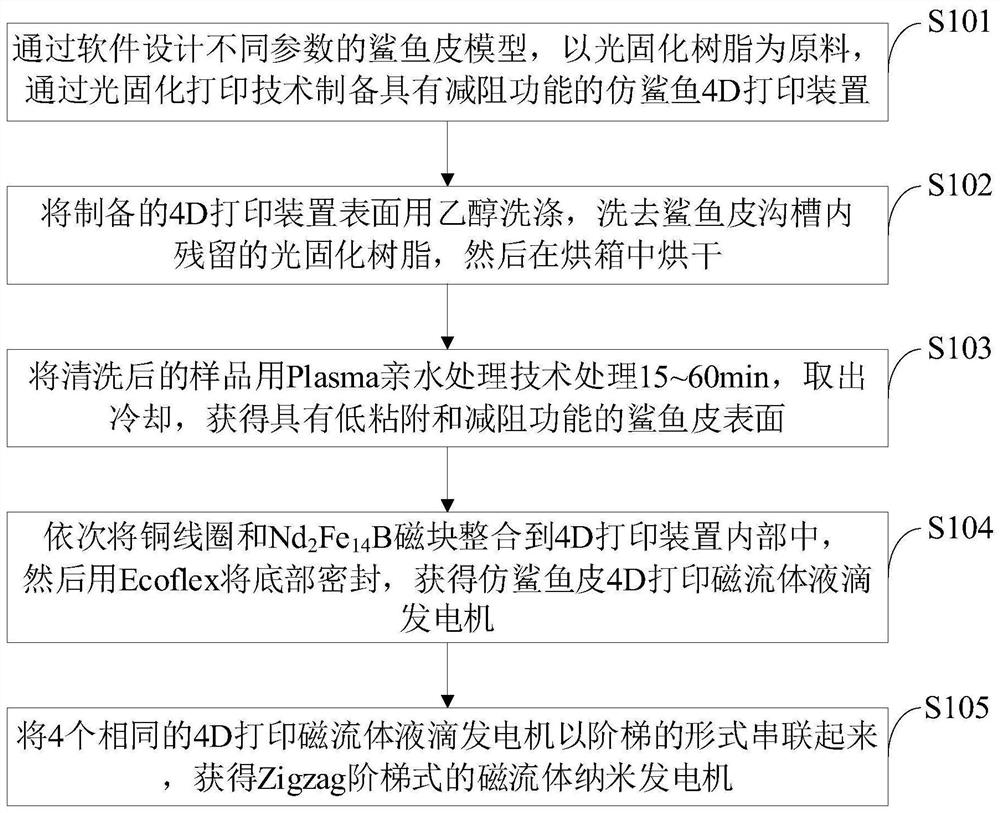

[0051] Such as figure 1 As shown, the preparation method of the imitation shark skin 3D printing ferrofluid droplet generator provided by the embodiment of the present invention includes the following steps:

[0052] S101, design shark skin models with different parameters through software, use photocurable resin as raw material, and prepare a shark-like 3D printing device with drag reduction function through photocurable printing technology;

[0053] S102, washing the surface of the prepared 3D printing device with ethanol to remove the photocurable resin remaining in the shark skin groove, and then drying in an oven;

[0054] S103, treat the cleaned sample with Plasma hydrophilic treatment technology for 15-60 minutes, take it out and cool it, and obtain a shark skin surface with low adhesion and drag reduction function;

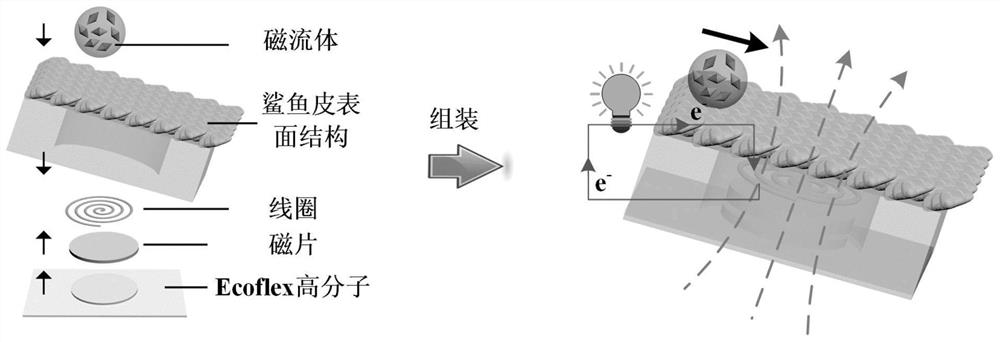

[0055] S104, in turn copper coil and Nd 2 Fe 14 The B magnetic block is integrated into the interior of the 3D printing device, and then the bottom is ...

Embodiment 1

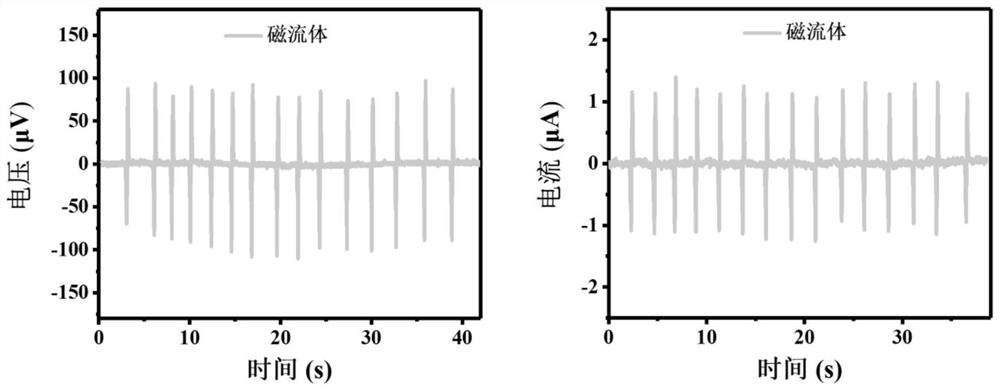

[0071] The preparation method of the imitation shark skin 3D printing ferrofluid droplet generator provided by the embodiment of the present invention includes:

[0072] (1) Shark skin with a groove width of 0.5mm, a groove height of 1mm, a scale area ratio of 0.57, a scale inclination angle of 30 degrees, a horizontal distribution distance of 1mm and a vertical distribution distance of 1mm is designed by software Model, and then use photocurable resin as raw material to prepare a shark-like 3D printing device with drag reduction function through photocurable printing technology.

[0073] (2) Wash the surface of the prepared 3D printing device with ethanol to remove the photocurable resin remaining in the grooves of the shark skin, and then dry it in an oven to remove the ethanol. The cleaned sample was treated with Plasma hydrophilic treatment technology for 15 minutes, taken out and cooled, and a shark skin surface with low adhesion and drag reduction function was obtained. ...

Embodiment 2

[0078] The preparation method of the imitation shark skin 3D printing ferrofluid droplet generator provided by the embodiment of the present invention includes:

[0079] (1) Design a shark skin model with a groove width of 1mm, groove height of 2mm, scale area ratio of 1, scale inclination angle of 0 degrees, scale horizontal distribution distance of 2mm and vertical distance distribution distance of 2mm by software , and then use photocurable resin as raw material to prepare a shark-like 3D printing device with drag reduction function through photocurable printing technology.

[0080] (2) Wash the surface of the prepared 3D printing device with ethanol to remove the photocurable resin remaining in the grooves of the shark skin, and then dry it in an oven to remove the ethanol. The cleaned samples were treated with Plasma hydrophilic treatment technology for 45 minutes, taken out and cooled, and a shark skin surface with low adhesion and drag reduction functions was obtained. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com