Mounting and fixing assembly with self-locking structure for chipping machine fly cutter

A technology of self-locking structure and fixing components, which is used in the manufacture of veneer chips, manufacturing tools, wood processing appliances, etc., can solve the problems of high use limitations, impracticality, inconvenient installation of flying knives, etc., and achieves convenient use and precise control. Tilt angle, good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

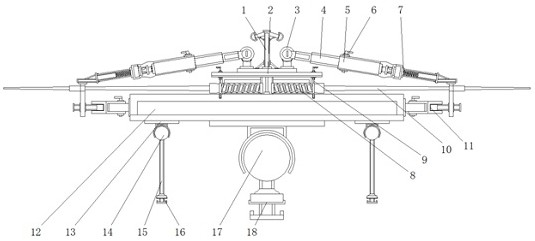

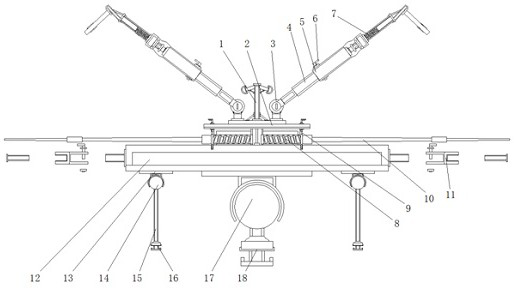

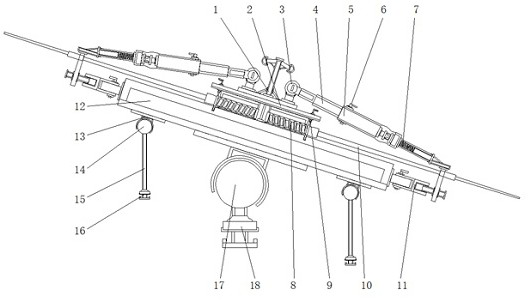

[0031] Such as Figure 1-7 As shown, an installation and fixing assembly with a self-locking structure based on the chipper flying knife includes a baffle frame 1, the lower end of the baffle frame 1 is fixedly equipped with a cutter head lock plate 2, and the top end of the cutter head lock plate 2 Steering shafts 3 are fixedly installed on both sides, and two sets of spherical end buffer structures are arranged on both sides of the top of the baffle frame 1, and the spherical end buffer structures are made of elastic rubber to prevent the two sets of extension rods 4 from turning Collision phenomenon occurs when the shaft rotates, and the safety of the device is high;

[0032] The steering shaft 3 is provided with ring structures on both sides. The fixed end of the bottom side is fixedly connected with the cutter head lock plate 2, and the rotating end of the middle ring is connected with the extension rod 4. The extension rod 4 is a rotating structure, and the extension rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com