Patents

Literature

79 results about "Woodchipper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A tree chipper or woodchipper is a machine used for reducing wood (generally tree limbs or trunks) into smaller woodchips. They are often portable, being mounted on wheels on frames suitable for towing behind a truck or van. Power is generally provided by an internal combustion engine from 3 horsepower (2.2 kW) to 1,000 horsepower (750 kW). There are also high power chipper models mounted on trucks and powered by a separate engine. These models usually also have a hydraulic crane.

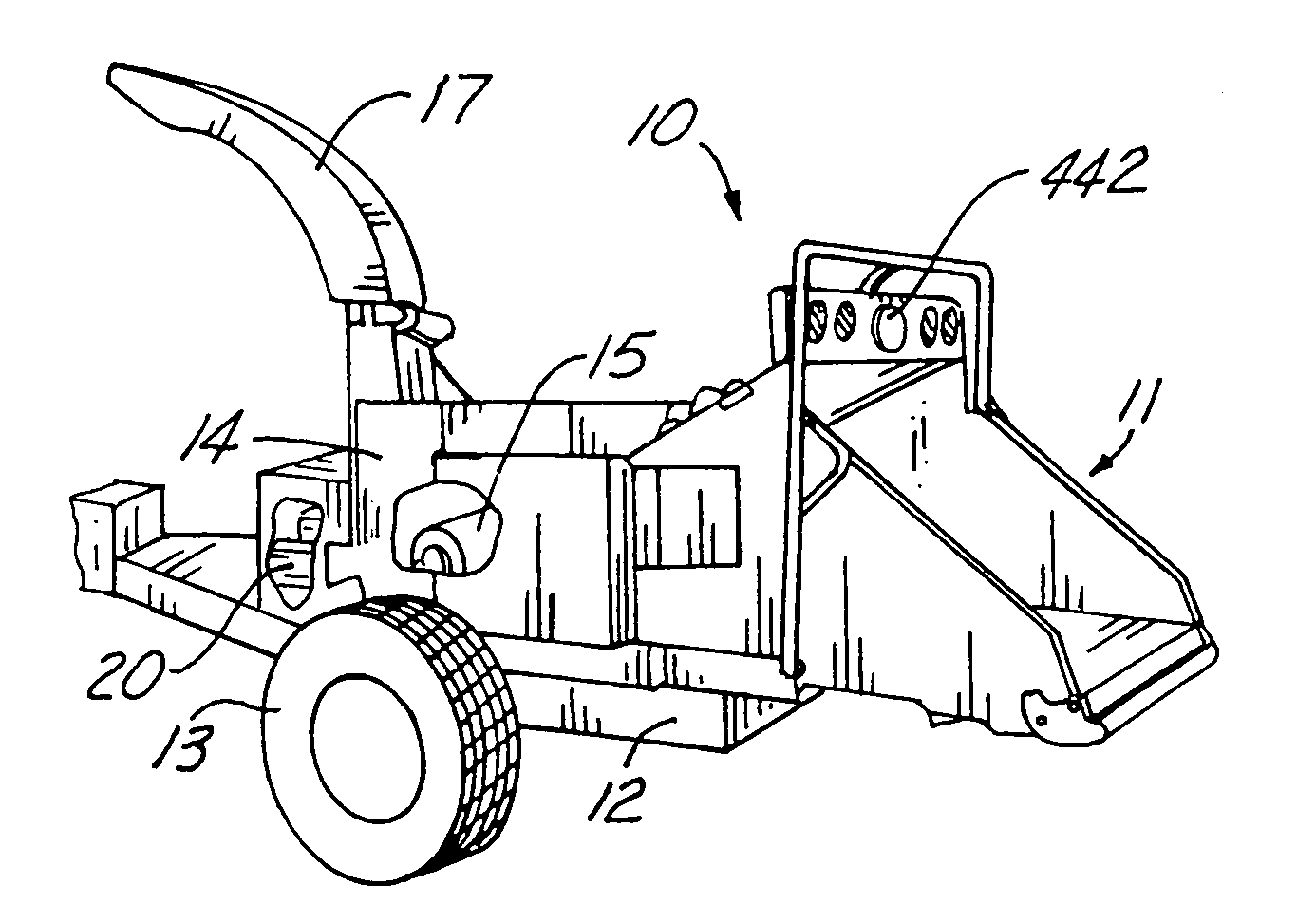

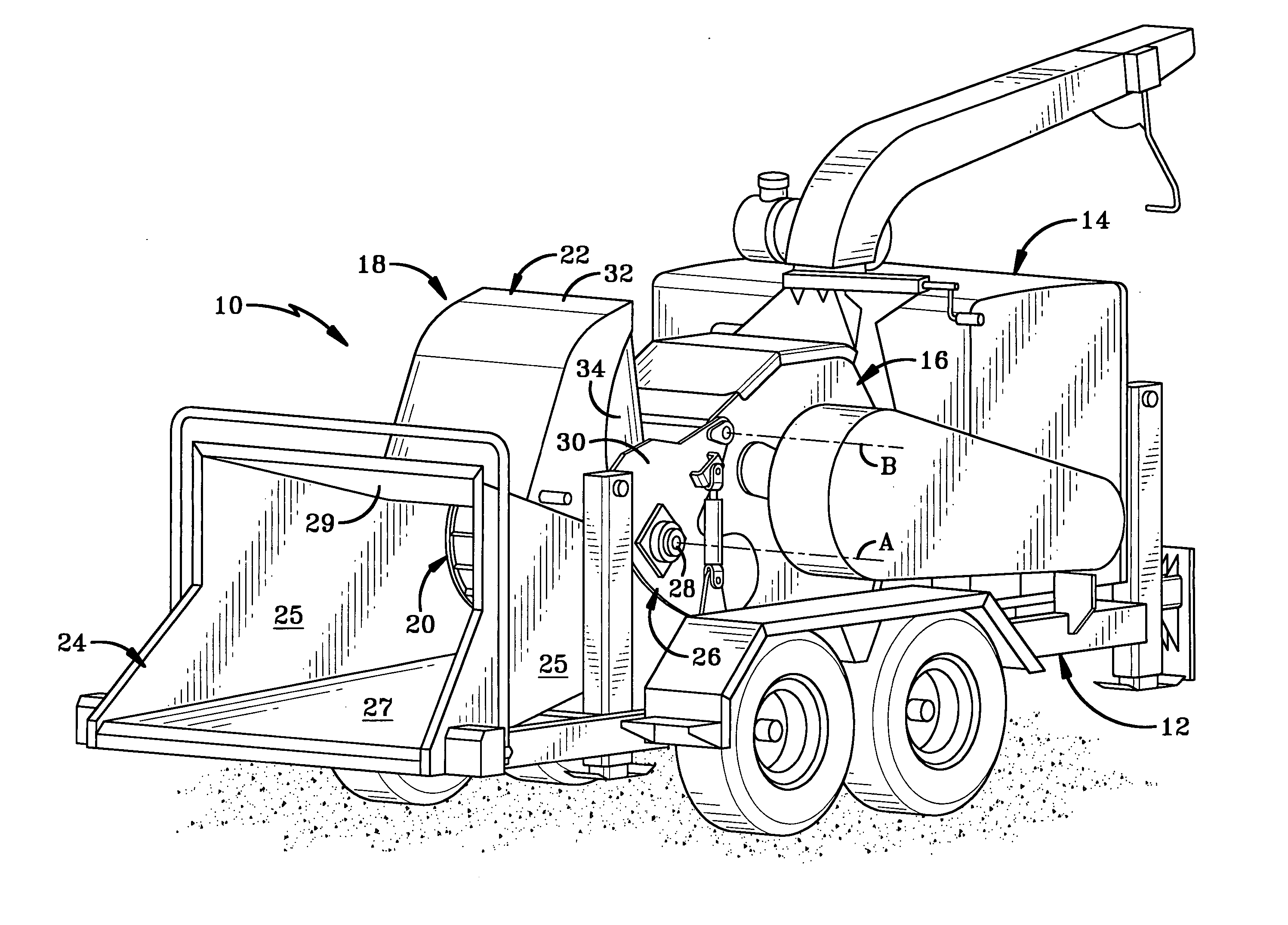

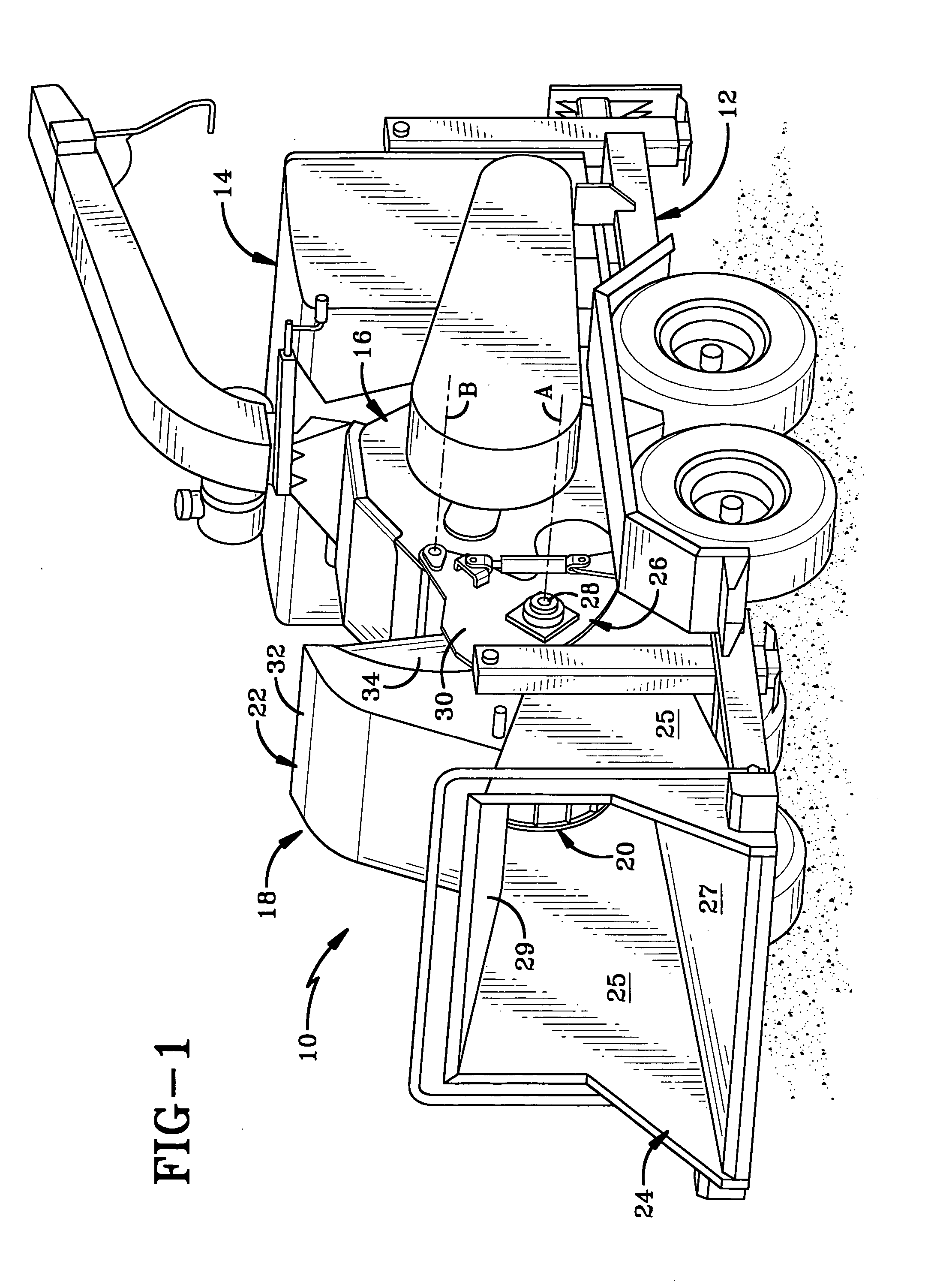

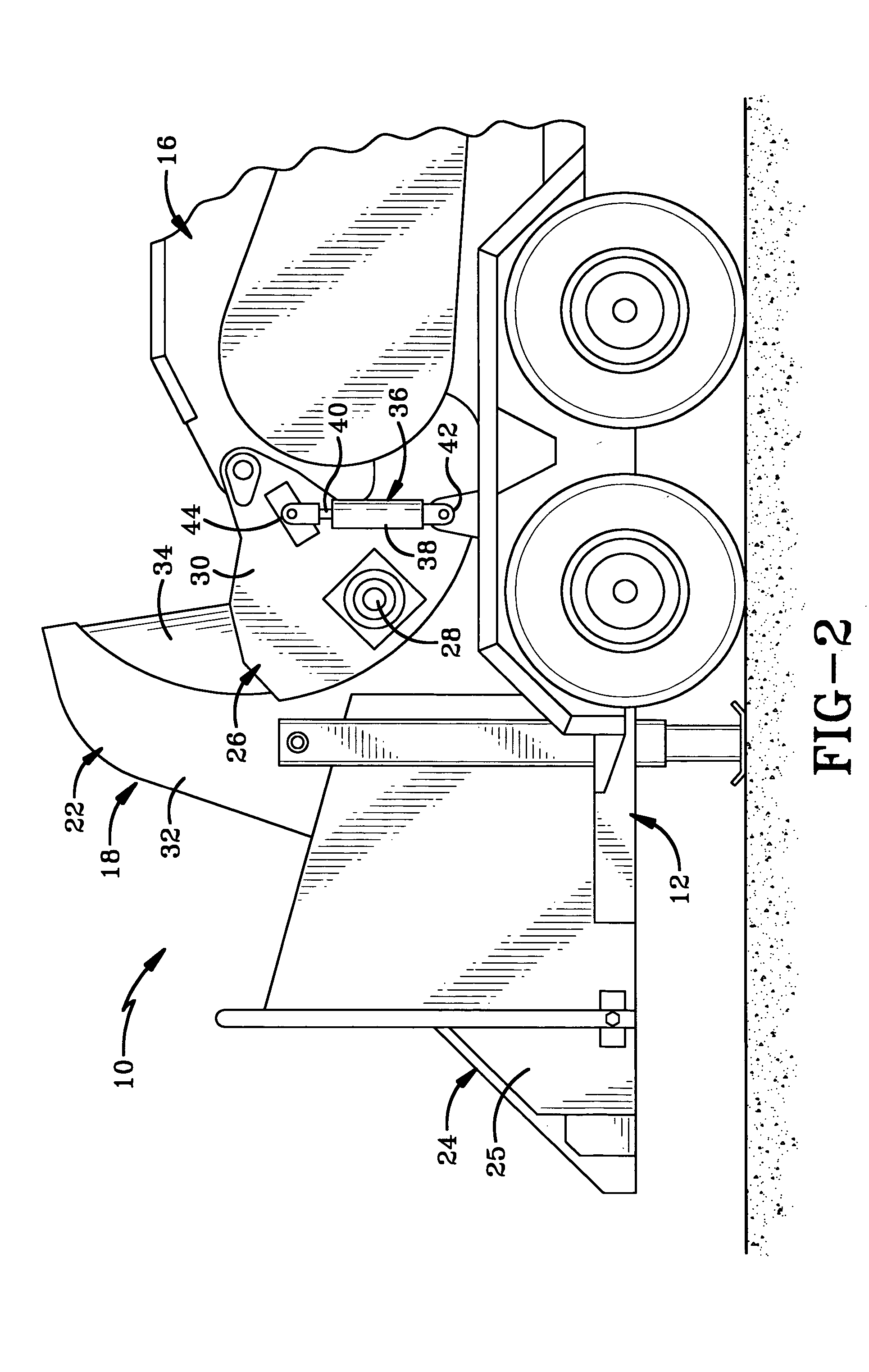

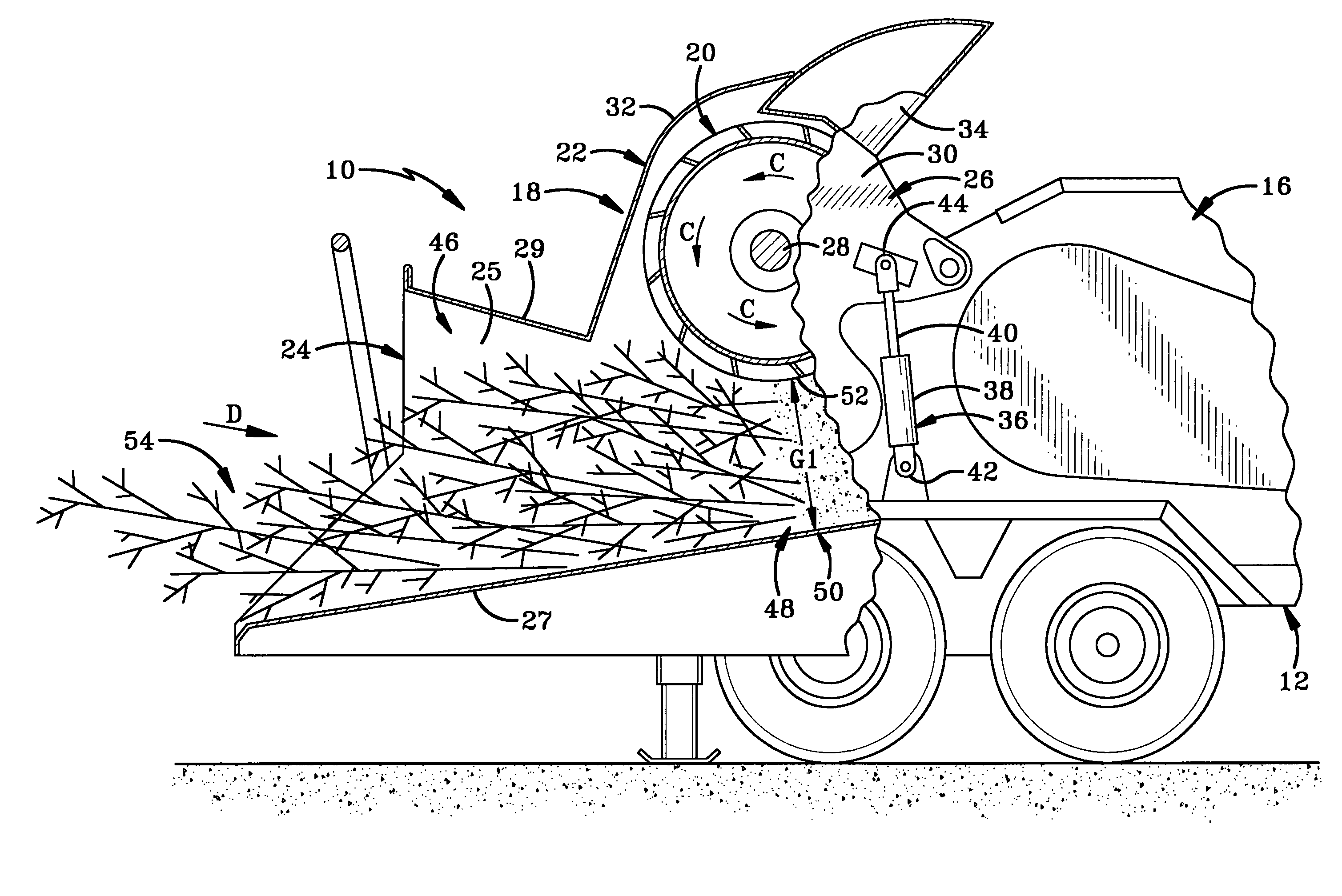

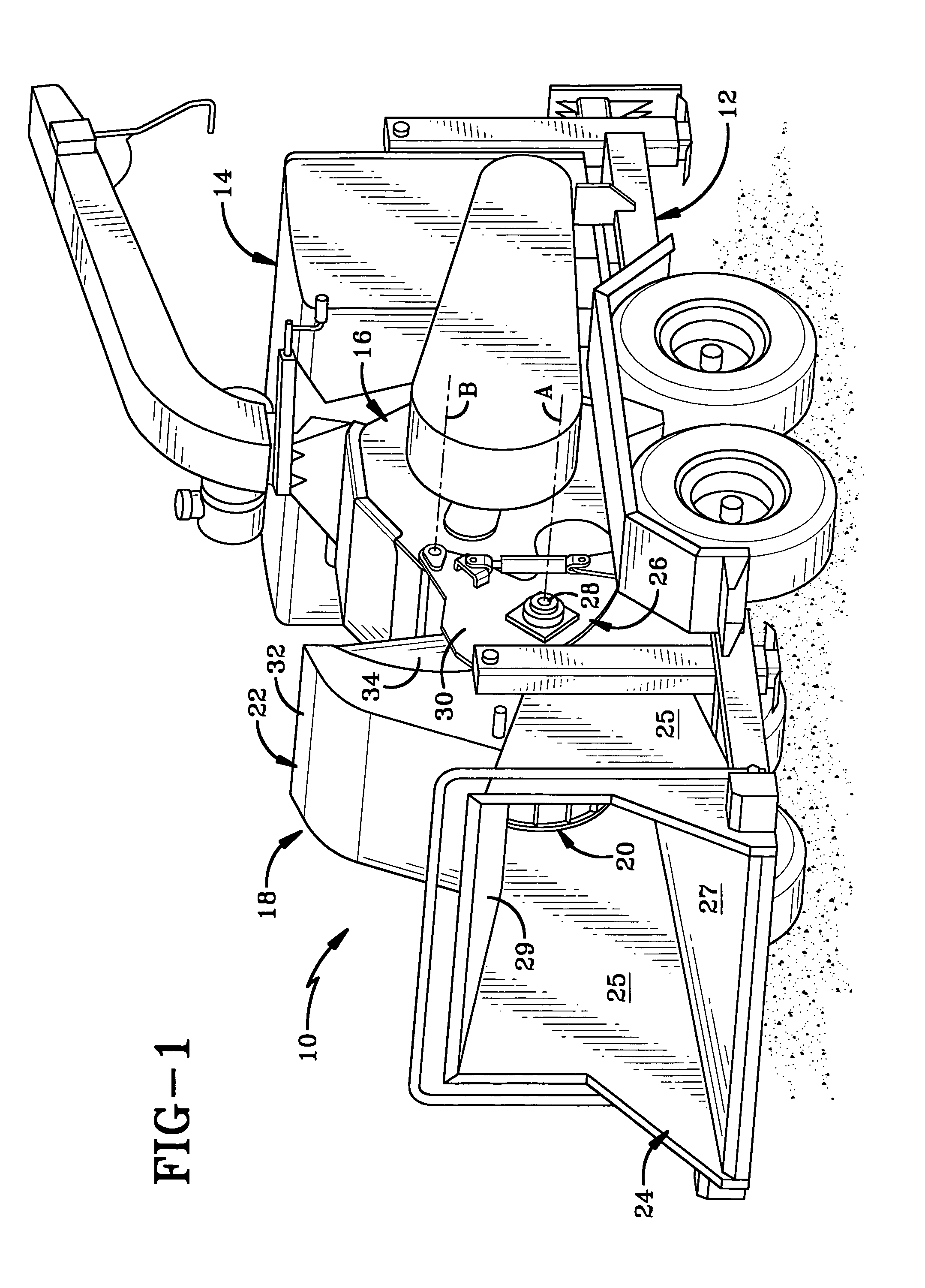

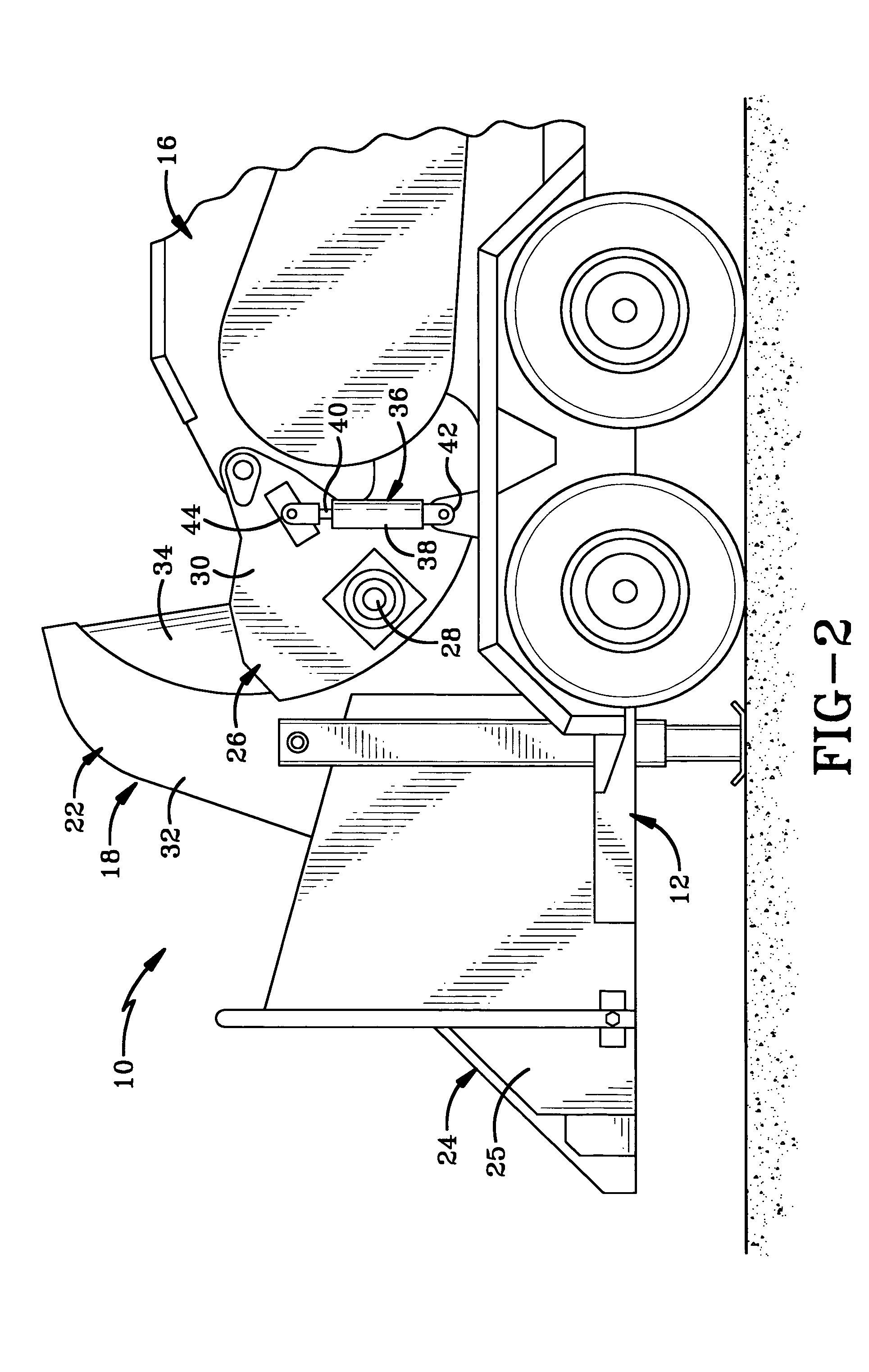

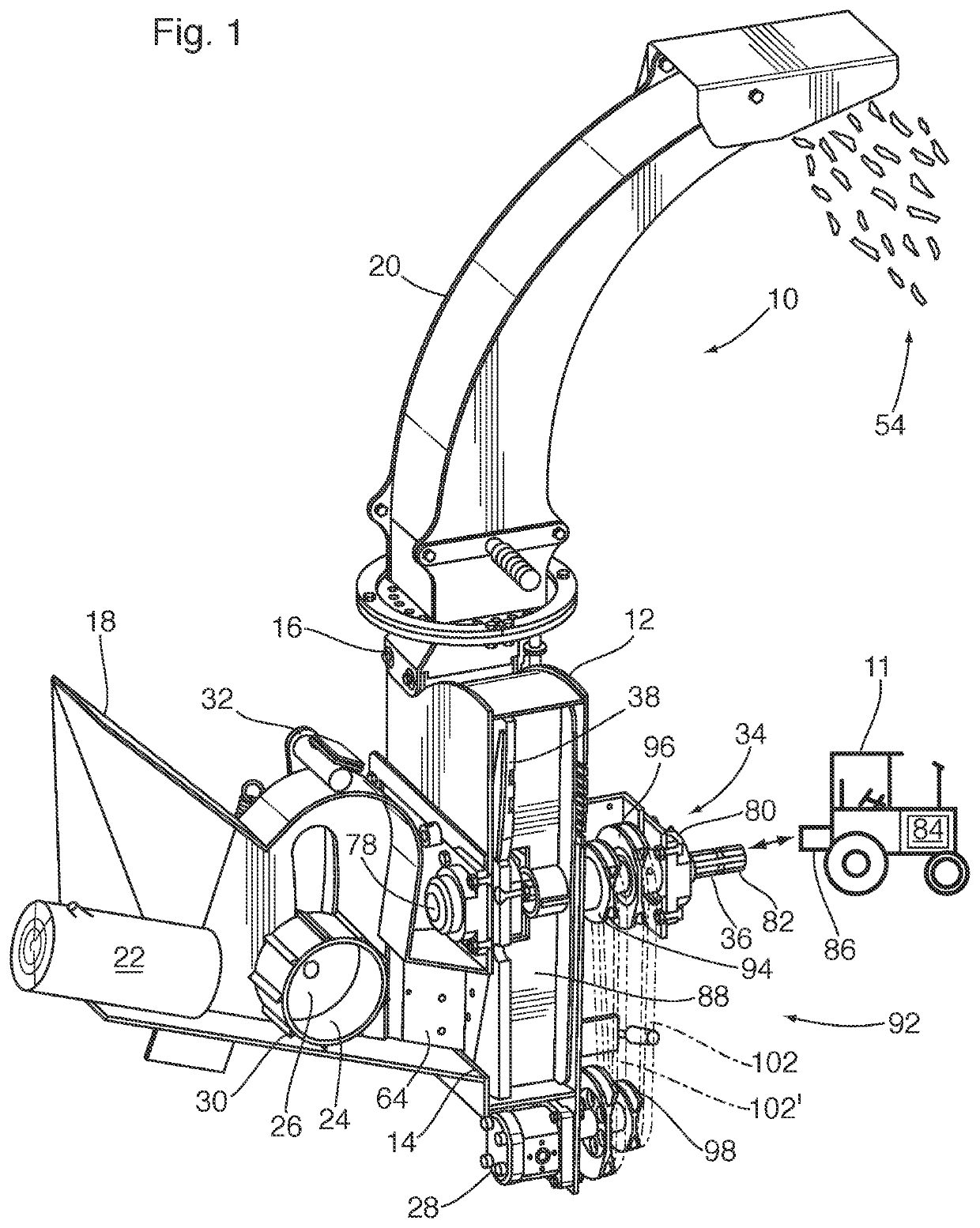

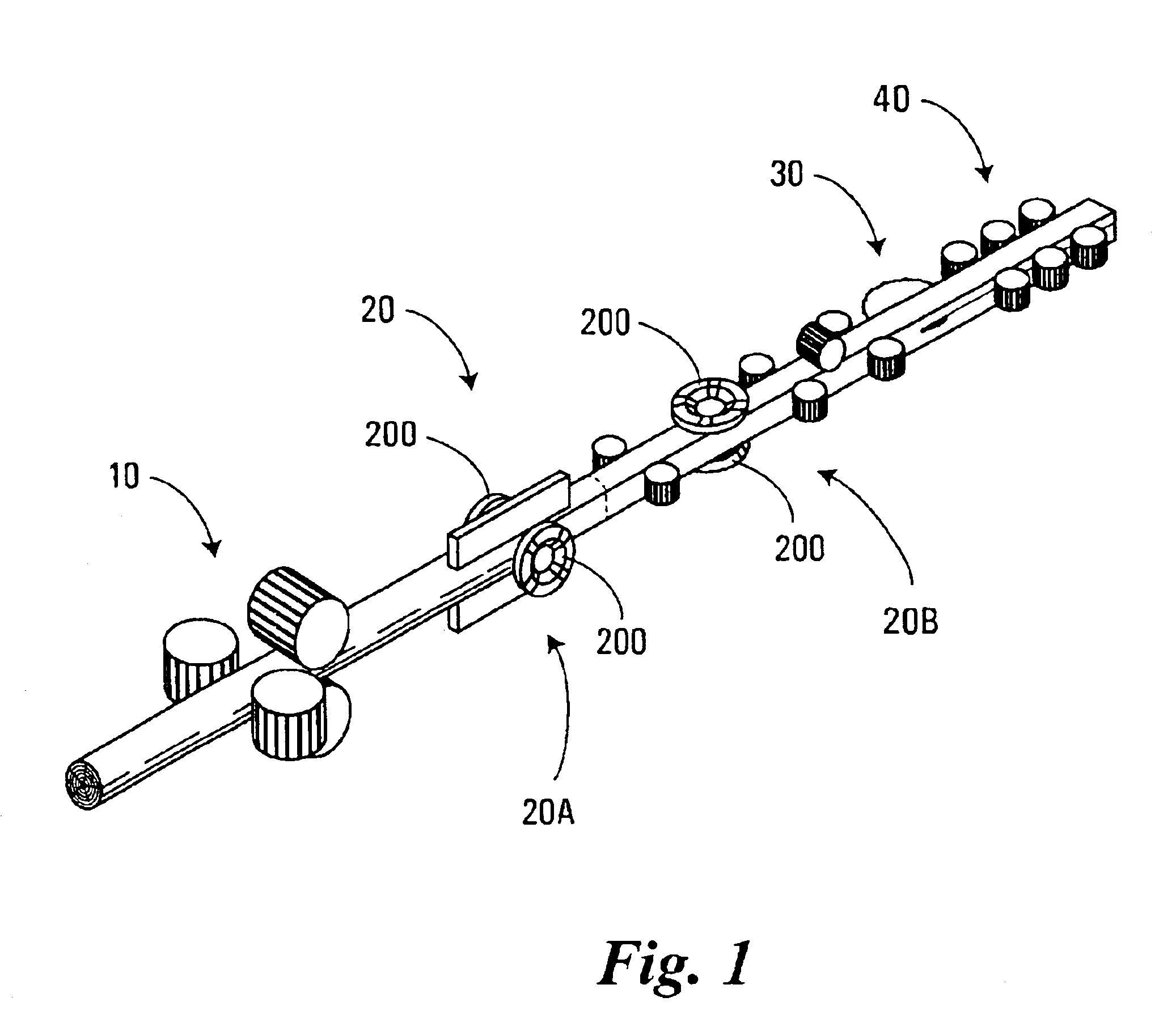

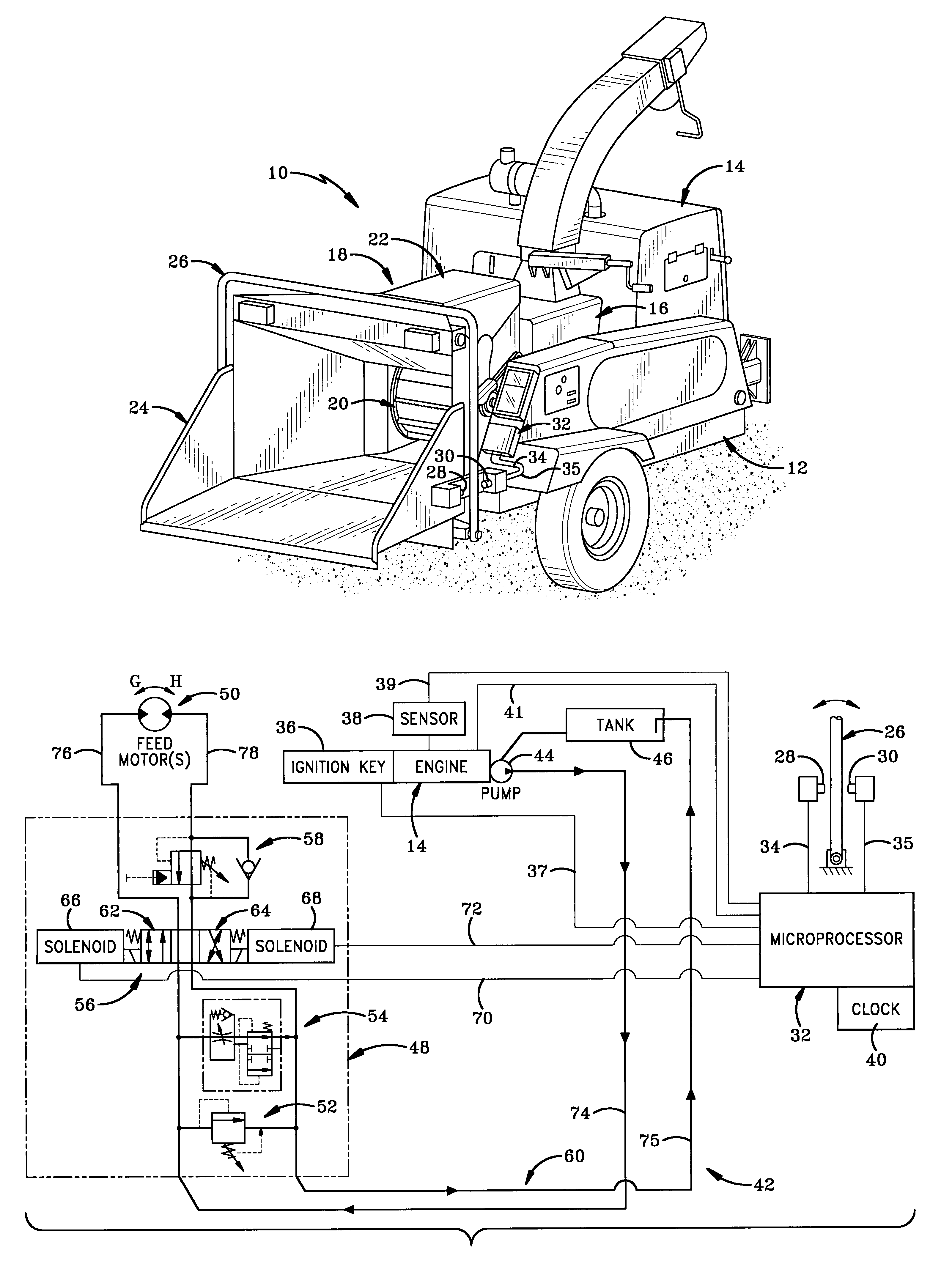

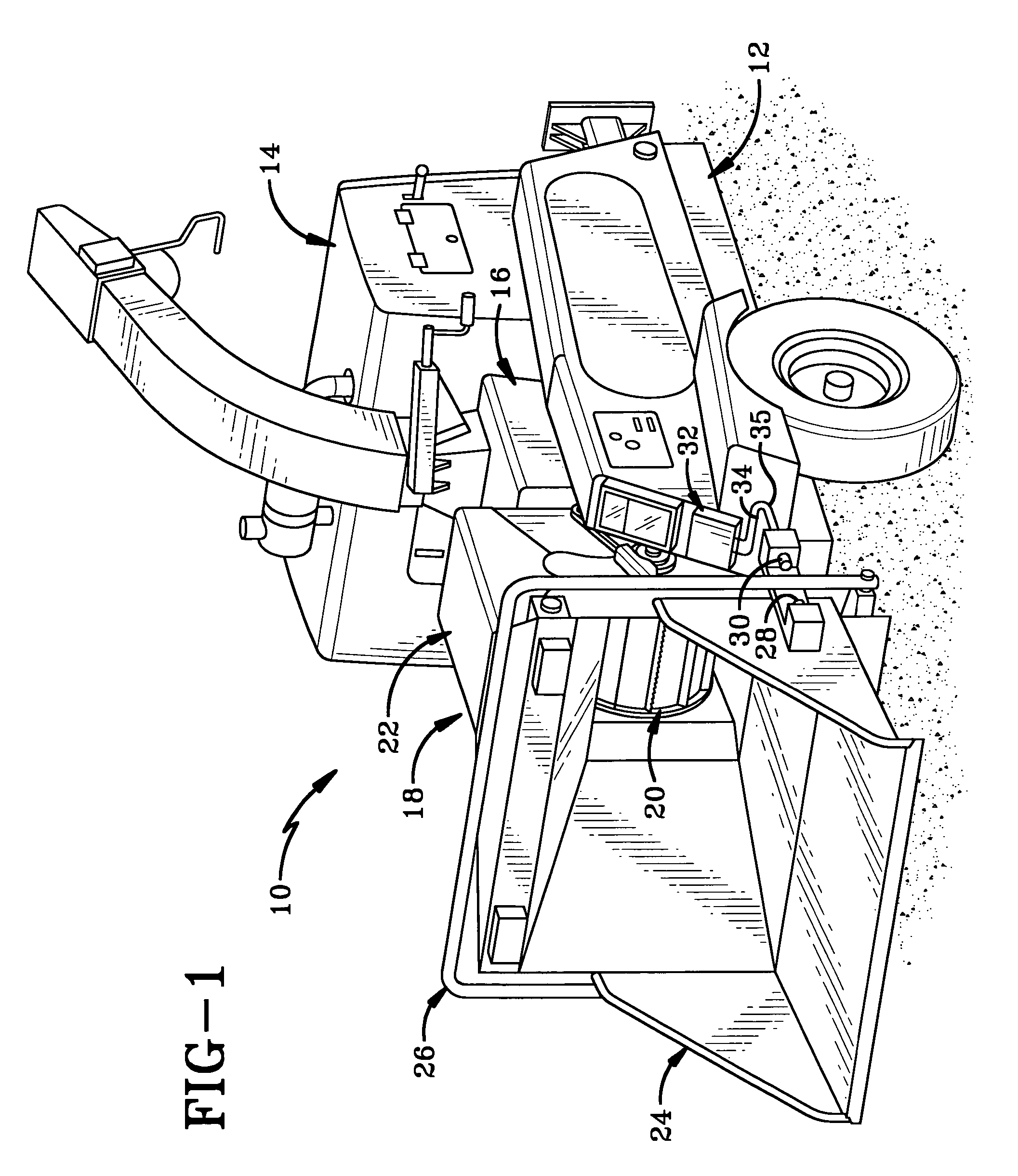

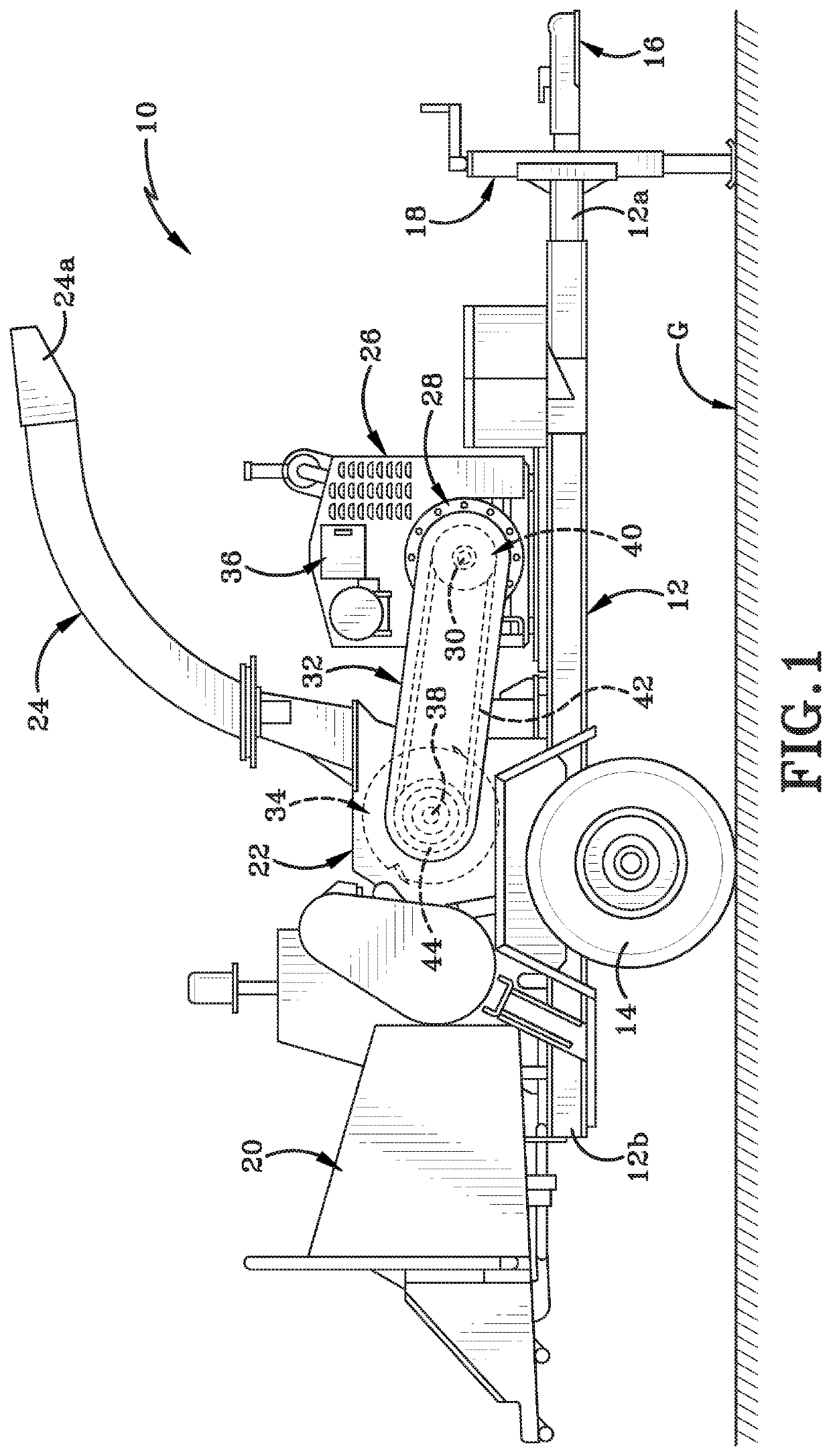

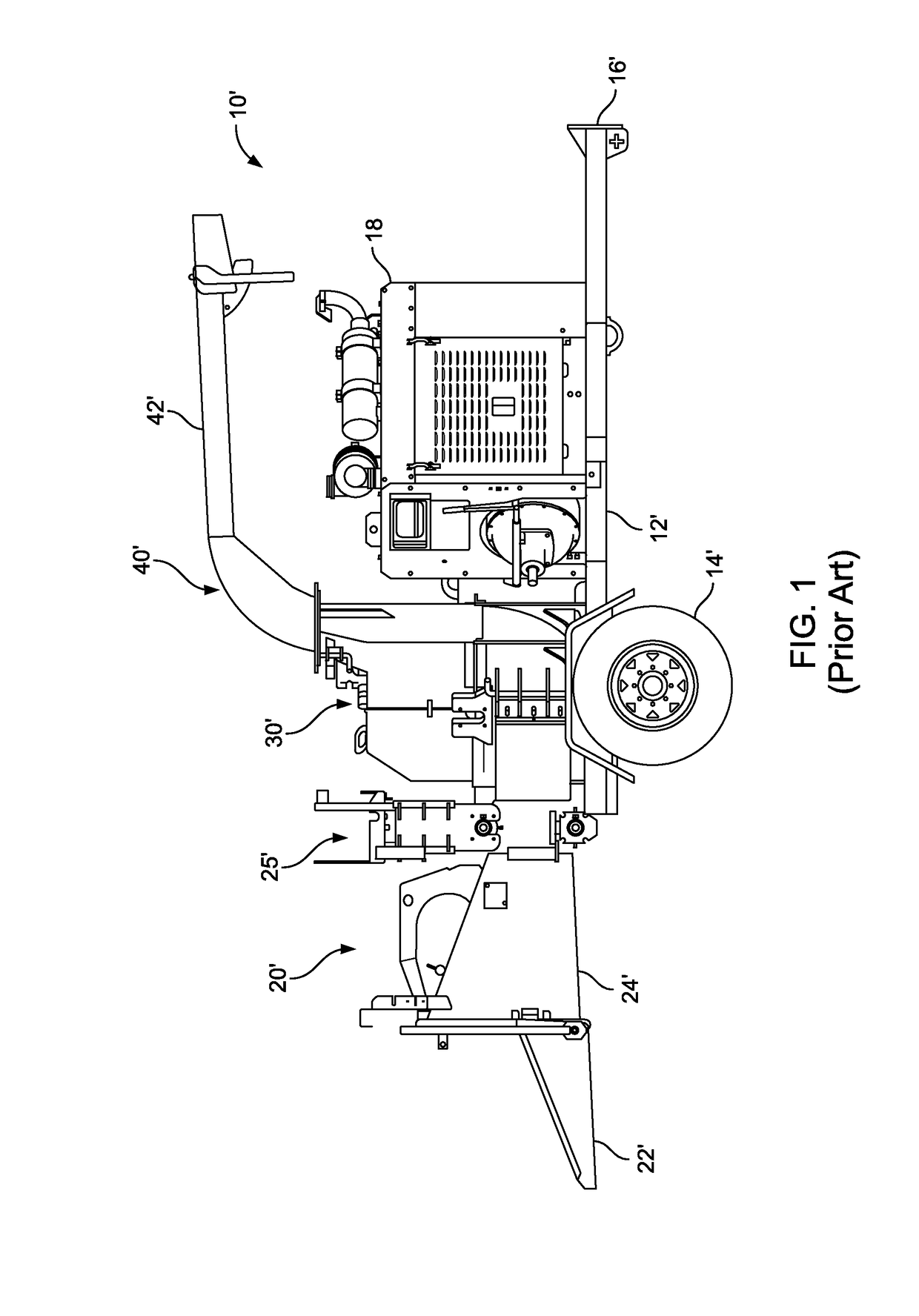

Brush chipper and methods of operating same

InactiveUS7011258B2Mechanism can be overcomeEliminate resistancePlant waste comminutingReed/straw treatmentHydraulic motorControl engineering

An improved brush cutter having an upper feed control member with stop, forward, neutral, and reverse positions also has a lower feed stop member with selectable sensitivity. Another aspect of the invention is to predict the feed roller shutoff point according to the rate of engine deceleration. According to another aspect, when the feed rollers stop feeding material into the cutters, to overcome drag on the cutters, a controller stops the feed rollers and then reverses them for a short time, and then reverses the rollers again if the problem is still present. To prevent jamming, a pressure switch senses when oil in a hydraulic motor system for rotating the feed rollers is too high and the controller momentarily reverses the feed rollers and then causes them to go forward, a cycle which can occur several times until the feed rollers are no longer stalled. By another aspect of the invention, the controller senses characteristics of the brush cutter and chooses an operating system based on the characteristics sensed. The controller can also sense if the brush chipper has not been used for a predetermined period of time and automatically reduce the idle speed of the engine until the brush chipper is used again, and then automatically return the engine to a normal idle speed before the feed rollers will pull brush into the brush chipper.

Owner:VERMEER MFG CO

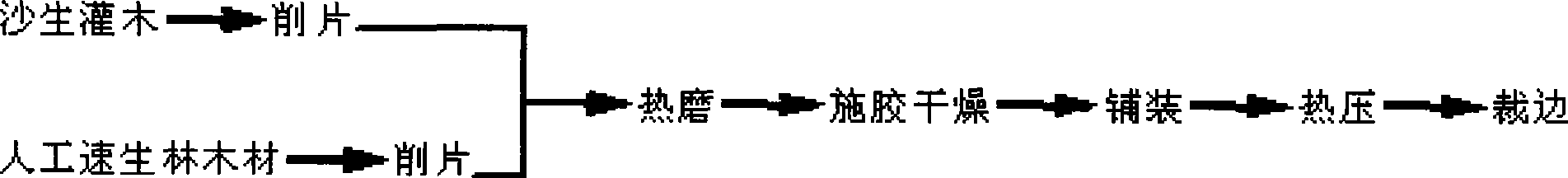

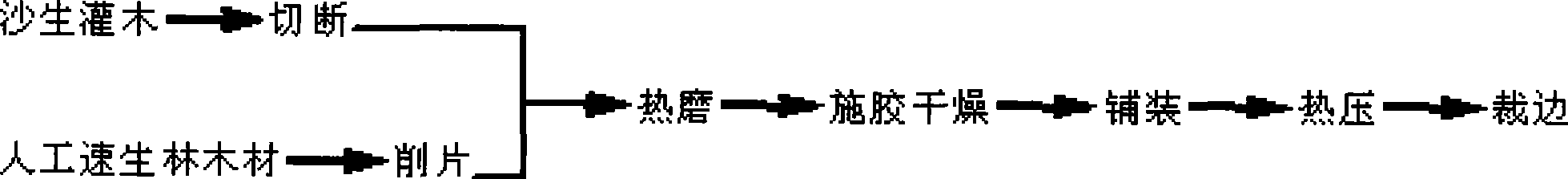

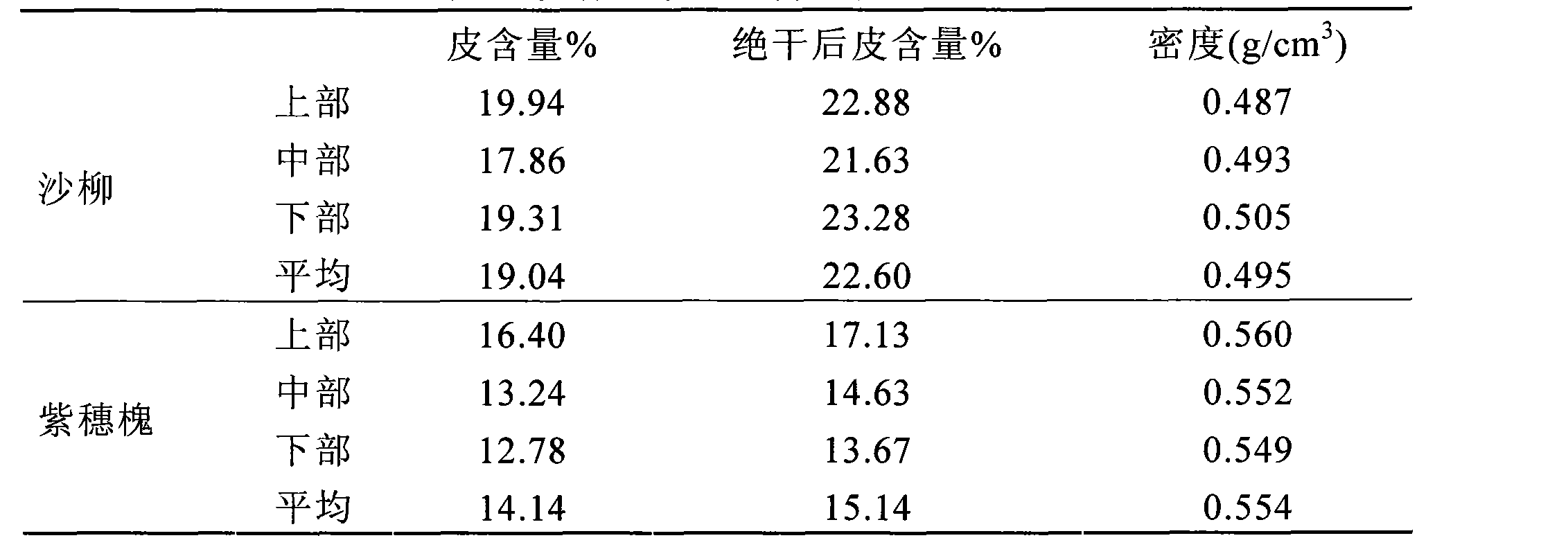

Desert shrub composite fibre board and method of manufacturing the same

InactiveCN101486216AReduce skin contentQuality improvementDomestic articlesFlat articlesFiberMaterials preparation

The invention discloses a composite fibreboard of psammophyte bush. A manual fast-growing forest timber is mixed in the psammophyte bush to prepare mixed fibre by a mixed jordaning method; and the mixed fibre reduces the bark content of the psammophyte bush and improves the fibre quality of the psammophyte bush, thereby improving the quality of the fibreboard. The invention also provides a method for manufacturing the composite fibreboard of the psammophyte bush; the method comprises the main steps: (1) material preparation; (2) hot grinding; (3) adhesive application and drying; (4) pavement; (5) hot pressing; (6) edge trimming, and other working procedures; in the material preparation section, wooden chips of the psammophyte bush with length of more than 10 cm are controlled within 5 percent; or the psammophyte bush is cut into small sections of crabsticks with the length of between 1.5 and 5.0 cm; and the wood chips or the crabsticks and the wood chips of the fast-growing forest timber are mixed to solve the problems that uncut strips of the psammophyte bush wind a cutter wheel of a drum-type chipper and block a tub wheel and a screen, and the like.

Owner:张琪

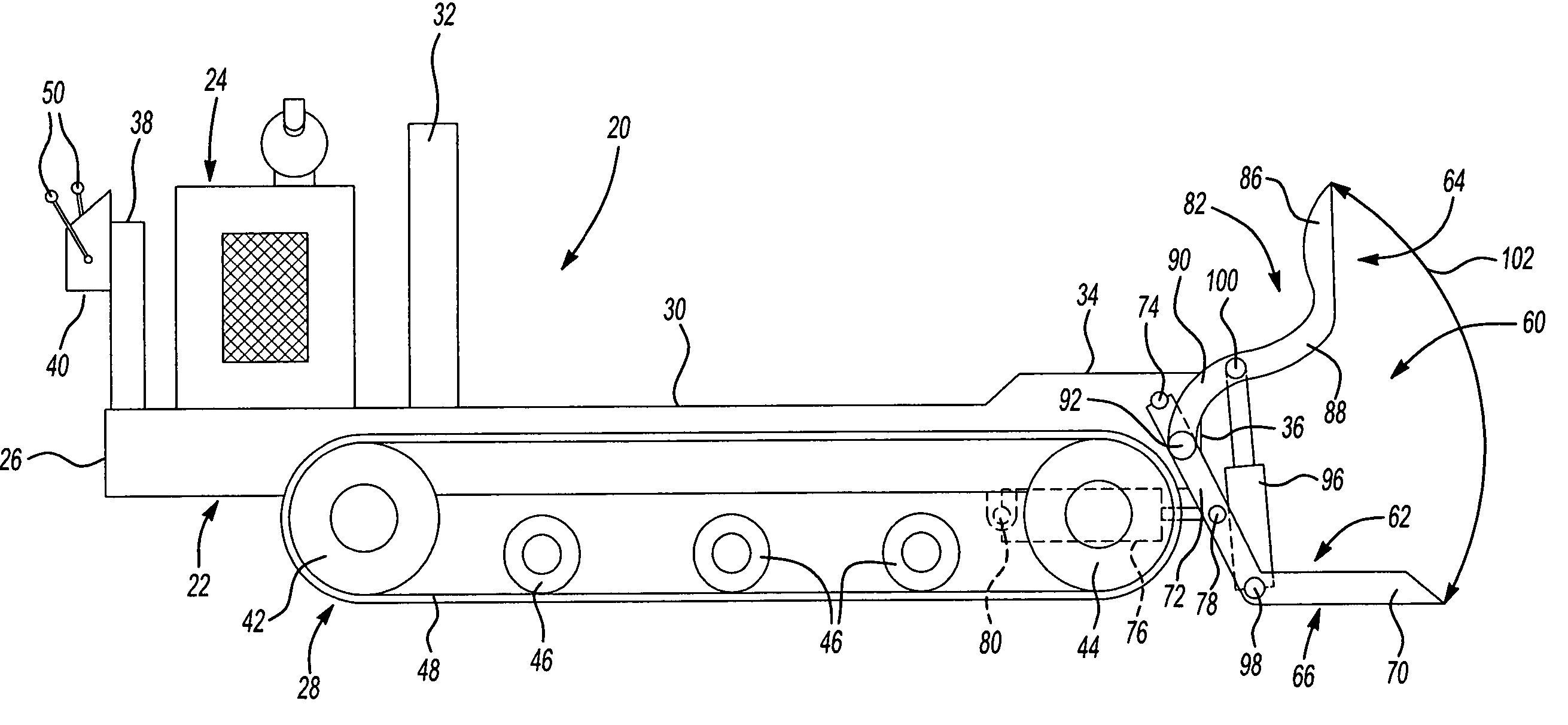

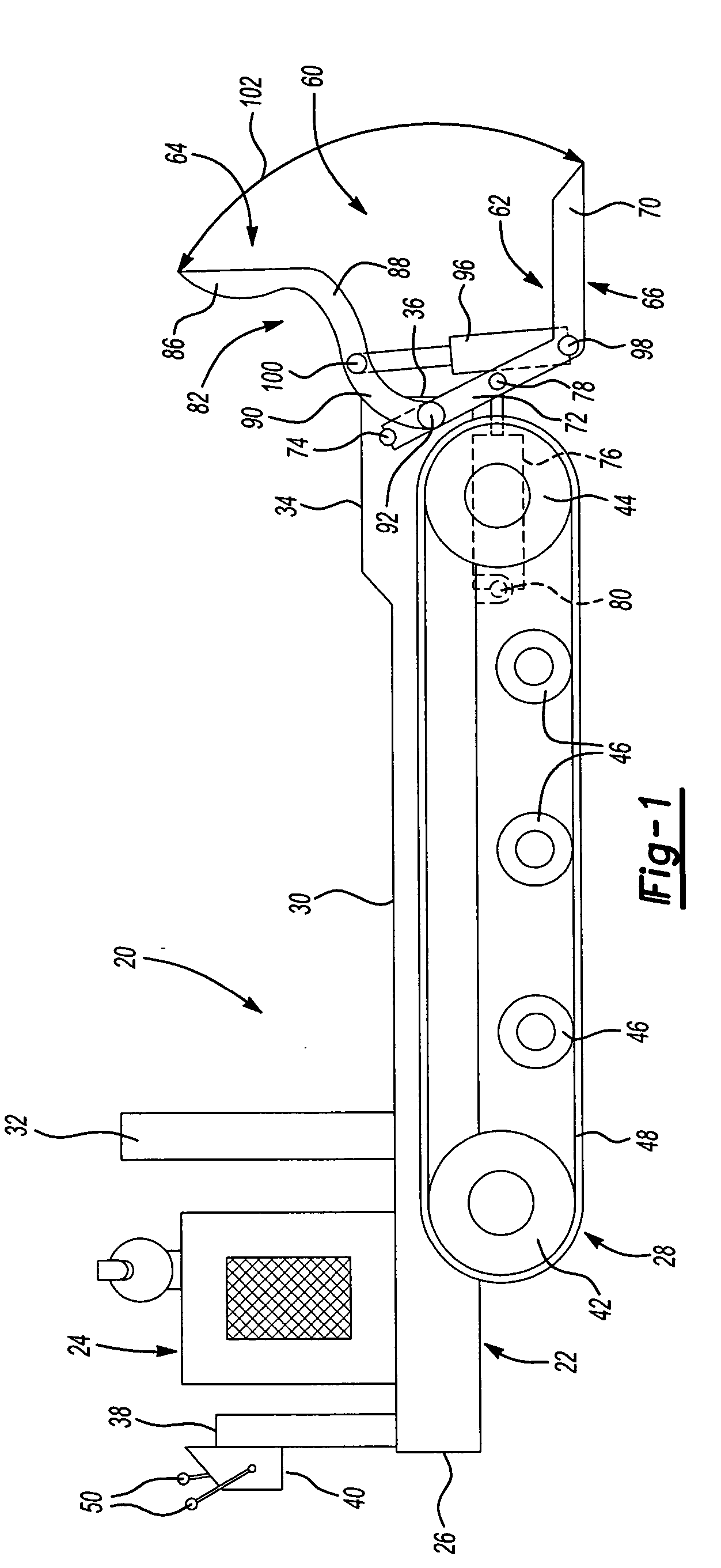

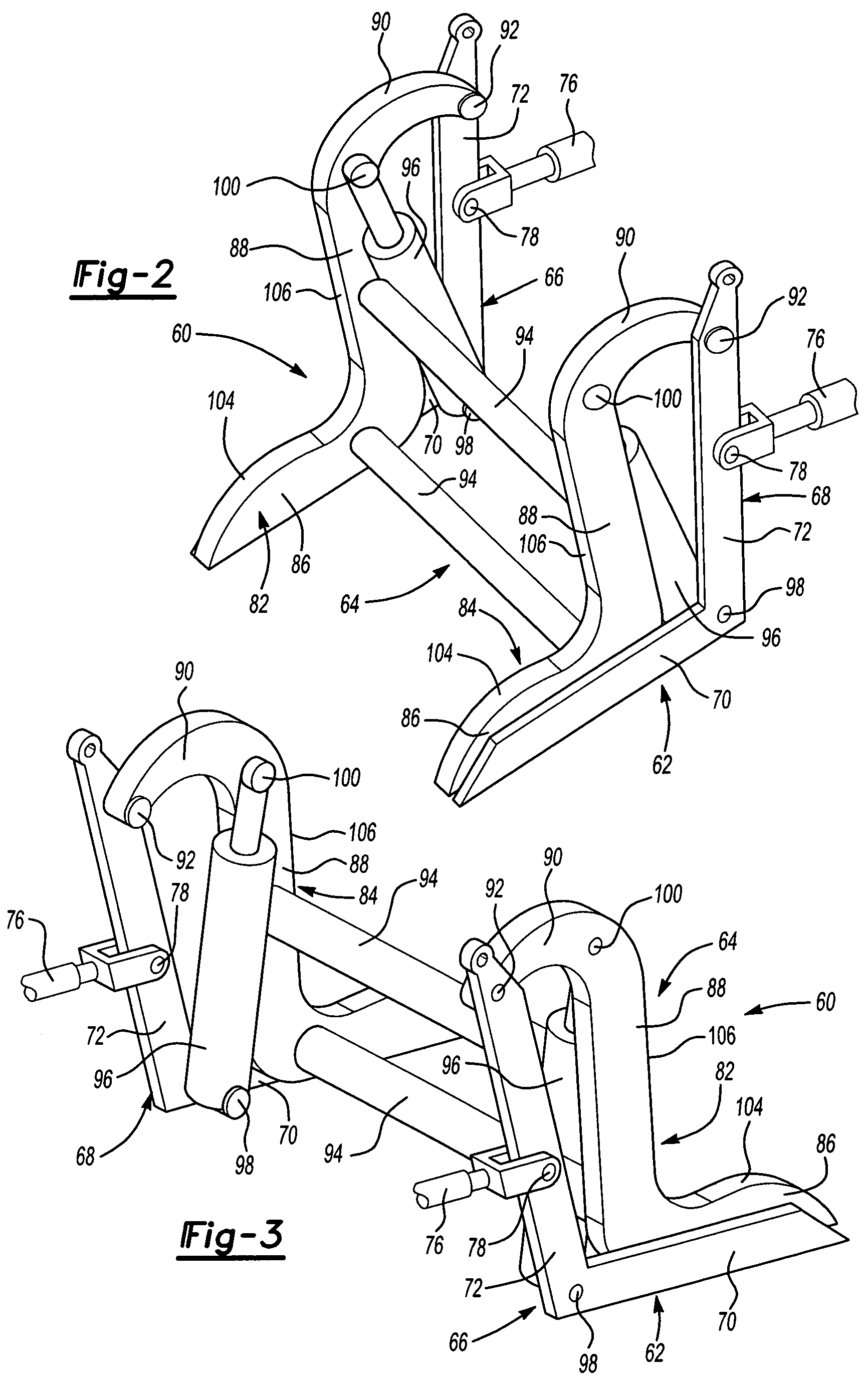

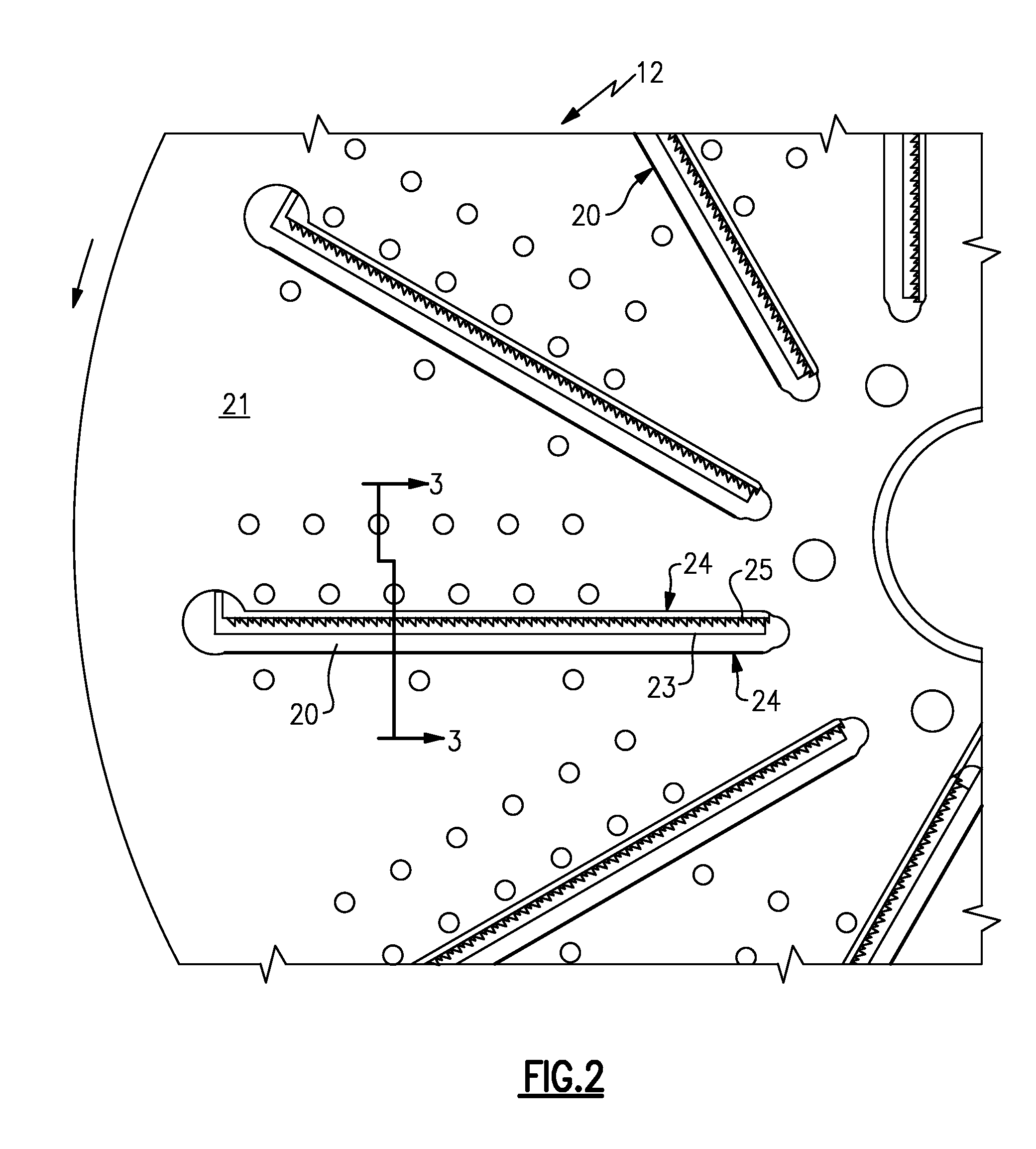

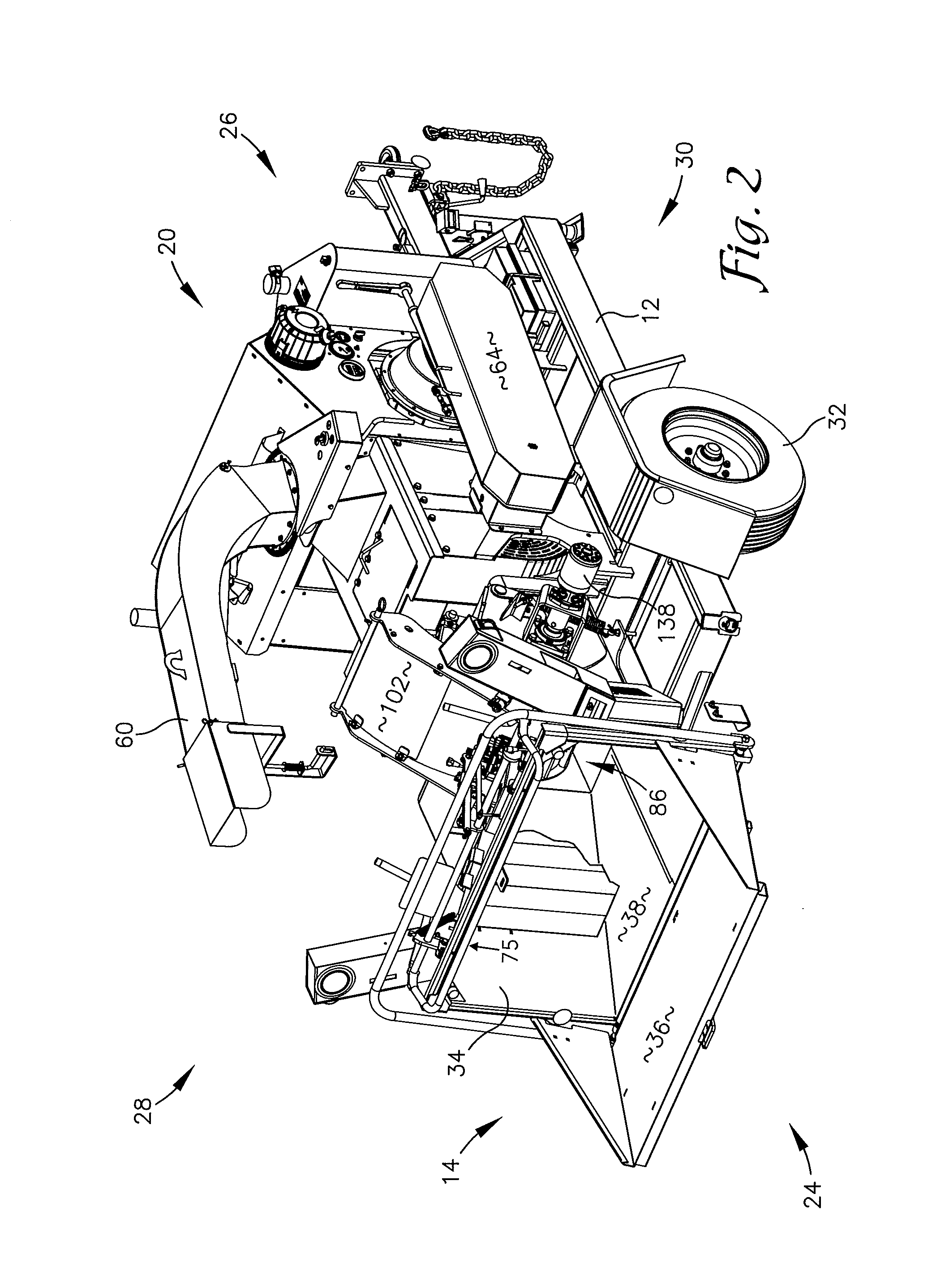

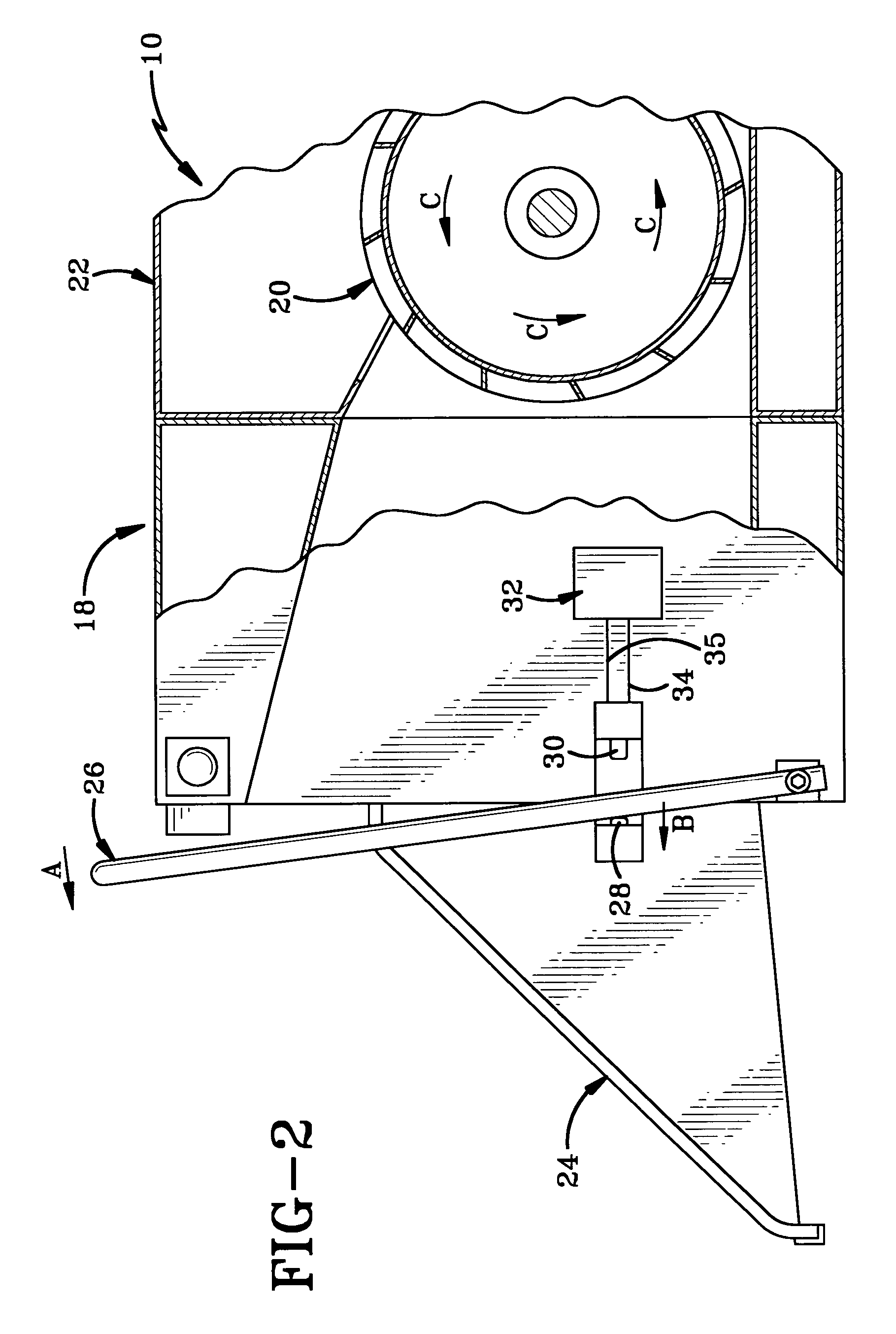

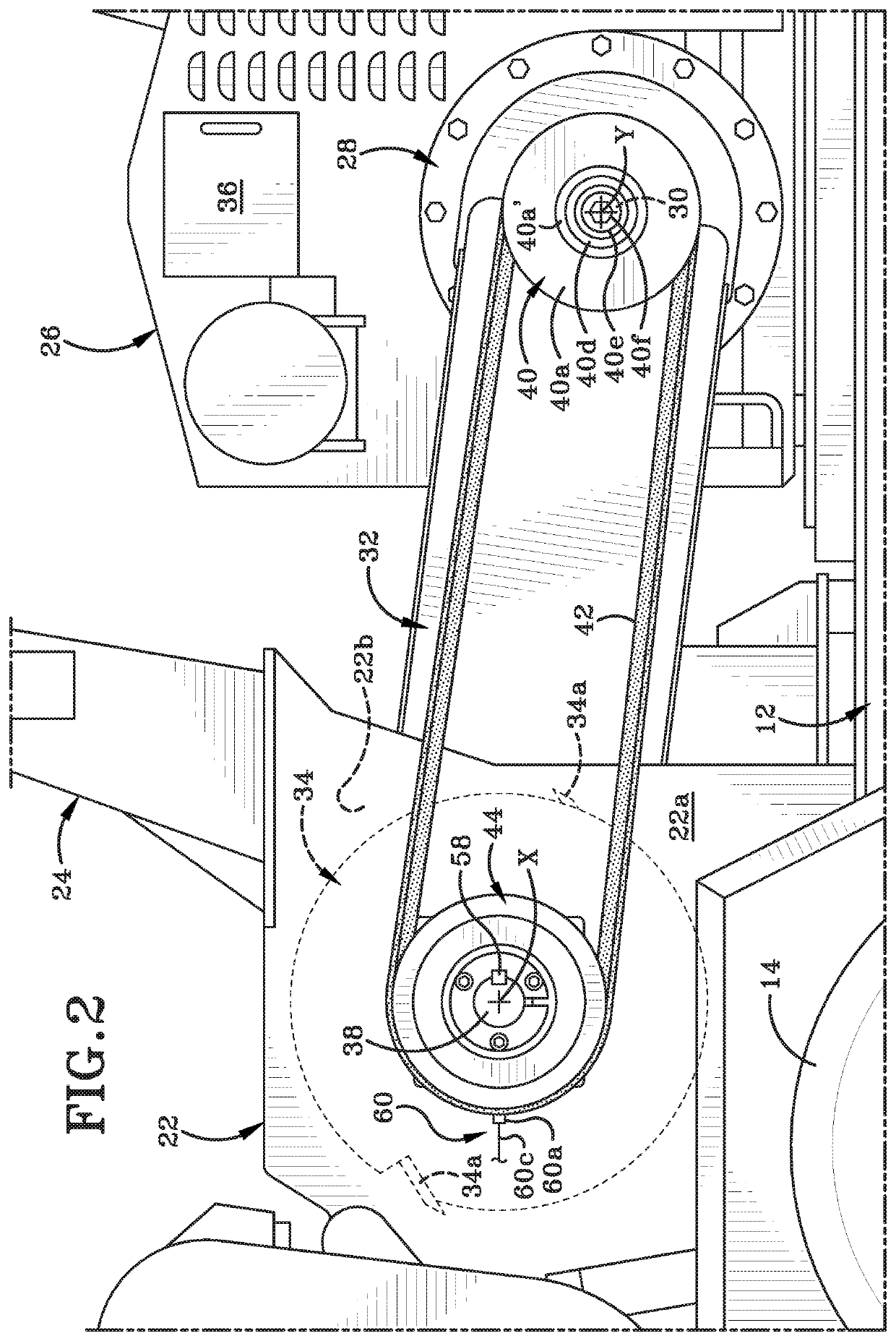

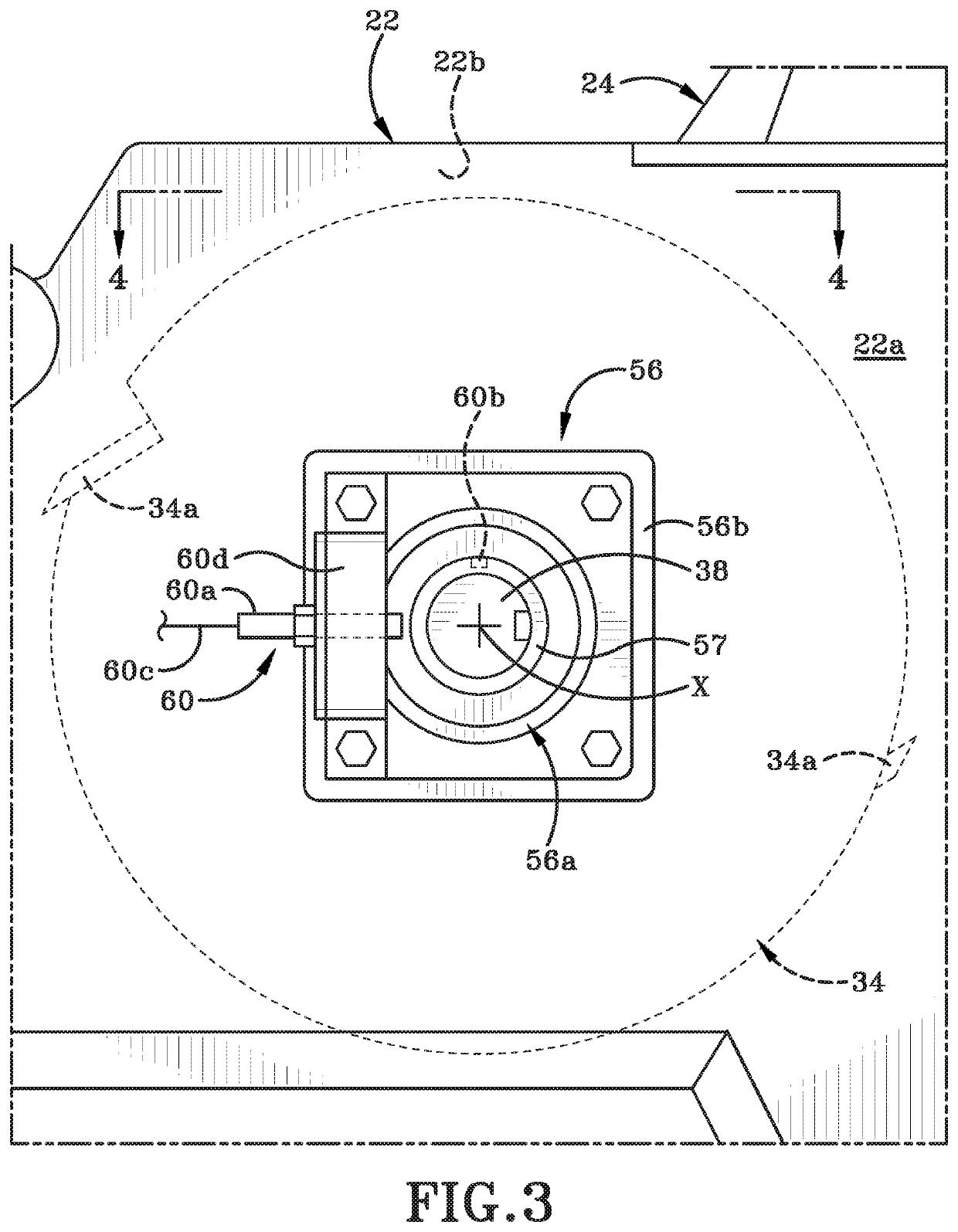

Chipper feed mechanism with pulsating down pressure

A wood chipper includes an engine and a cutting assembly. A rotatable feed wheel and a gap-bounding member define therebetween an adjustable gap through which feed material moves toward the cutting assembly. An electronic control unit (ECU) controls force applied to the feed wheel or gap-bounding member toward the feed material in response to an operational condition of the wood chipper. The ECU can maintain or vary the force in any desired manner. One option is to apply the force with a pulsating mechanism in a pulsating manner to enhance the feeding procedure. The pulsating mechanism is in communication with a sensor from which the ECU receives signals typically indicating an operational speed of the cutting assembly or the engine. An ECU logic circuit permits the pulsating force only if the operational speed exceeds a predetermined threshold.

Owner:ALAMO GROUP

Utility vehicle

A versatile mobile utility cart or vehicle using either tracks, wheels or both for suspension and steering with propulsion coming from but not limited to an internal combustion engine or an electric motor. The vehicle is meant to be a utility workhorse with the ability to load and unload itself as well as drag or carry materials. The vehicle can be configured in many ways to do many tasks with the main feature being labor savings. One of the unique features of the vehicle is a loading system called a fork and foot system. For transport the forks and feet system can be raised or detached individually or as a system, this is beneficial when unloading. The foot may remain attached and used for stability. Detaching the fork and foot system as a system allows the vehicle to be used for other tasks including but not limited to: a dump vehicle; a skidder; a reel carrier; a fork lift / carrier; and a prime mover or base for brush chippers, stump cutters, tree spades and more.

Owner:GREEN KEVIN J

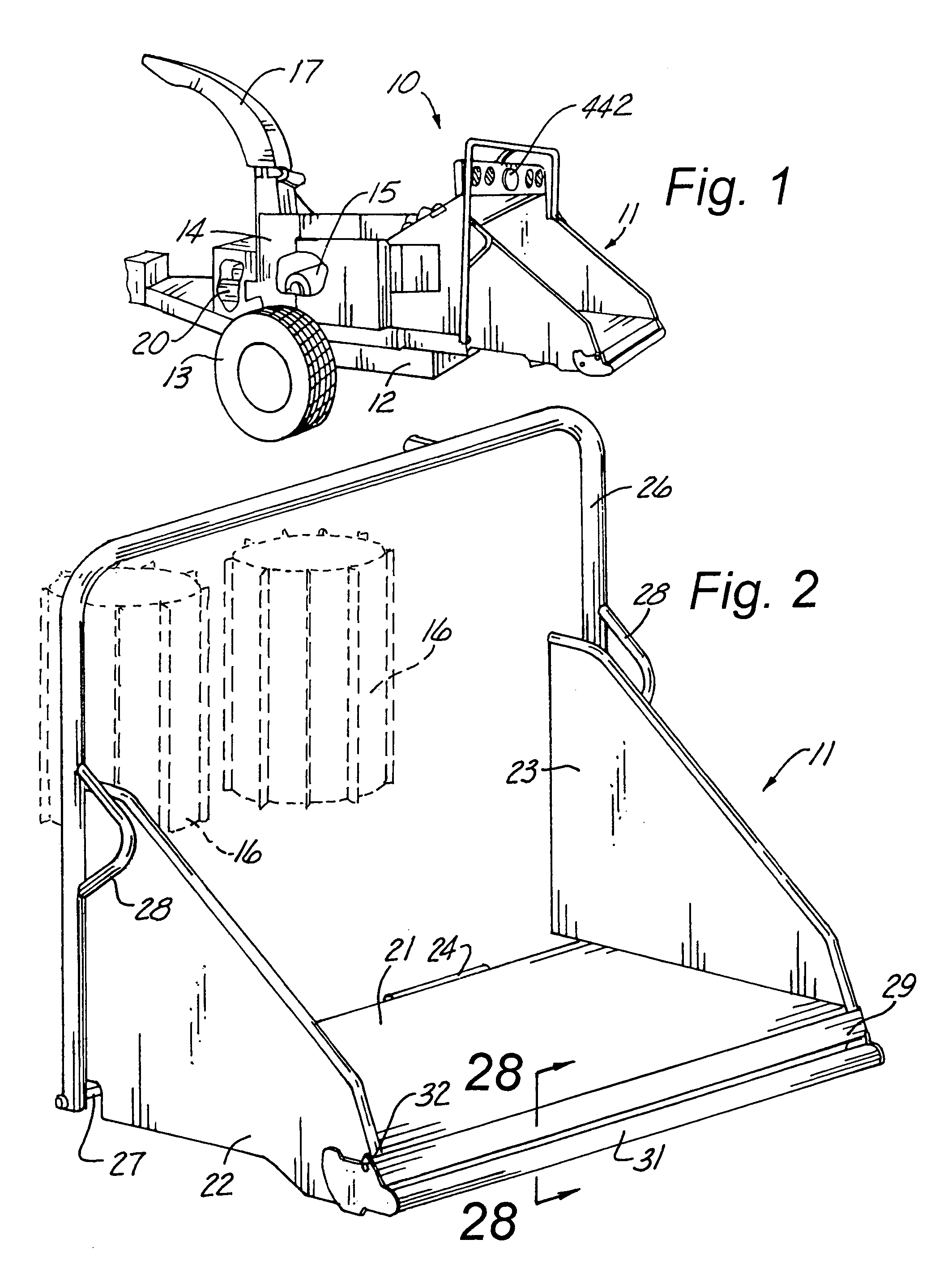

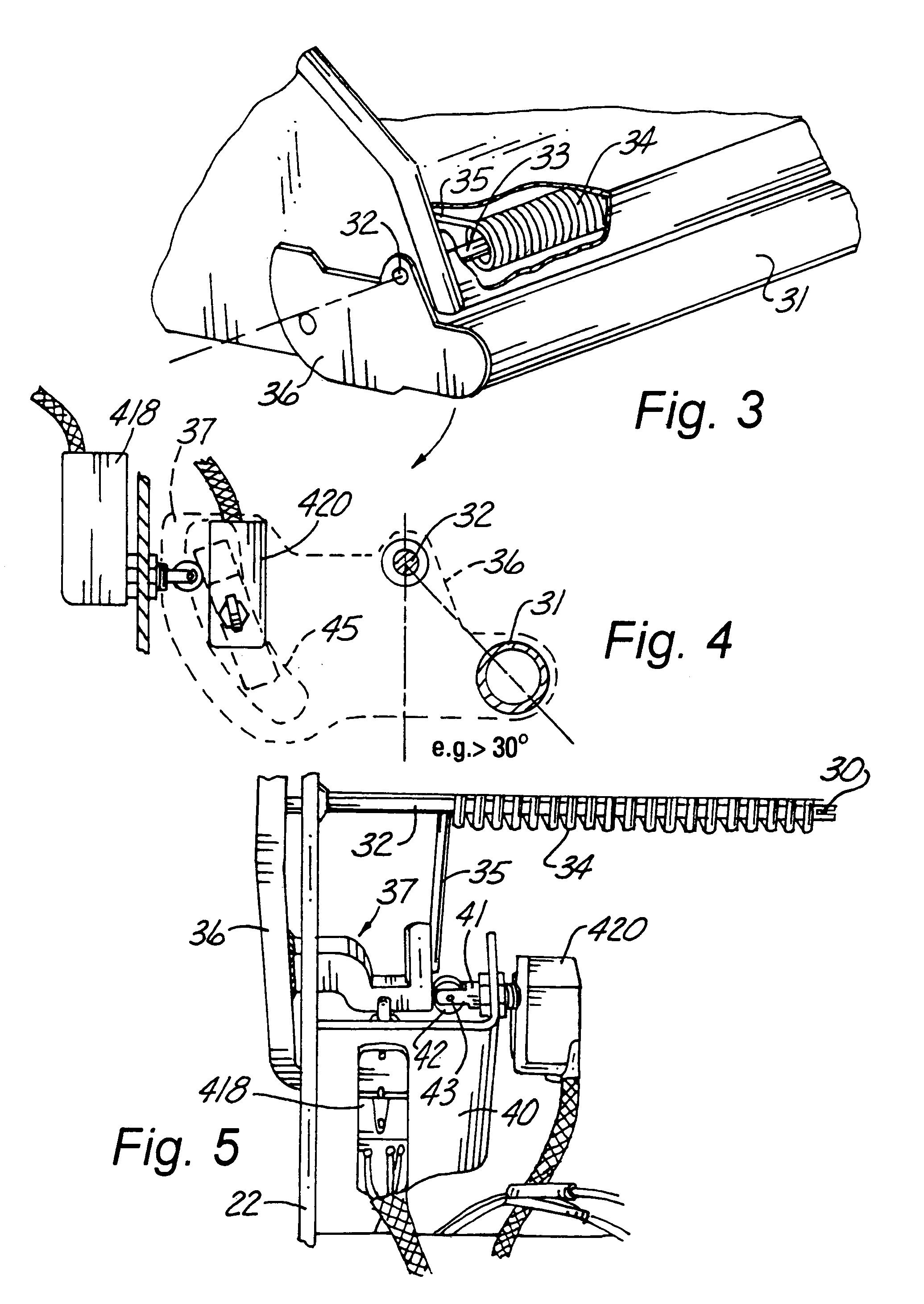

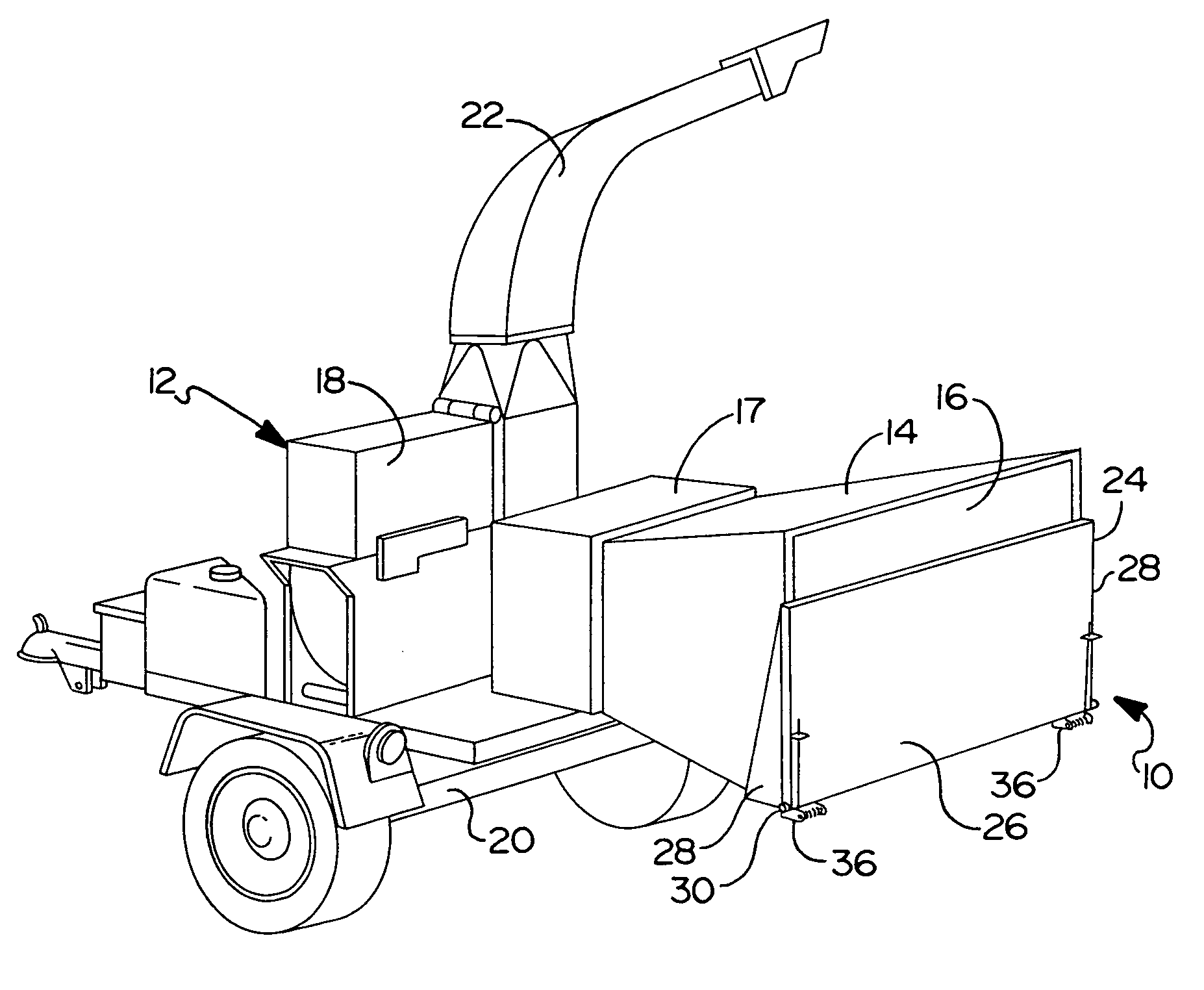

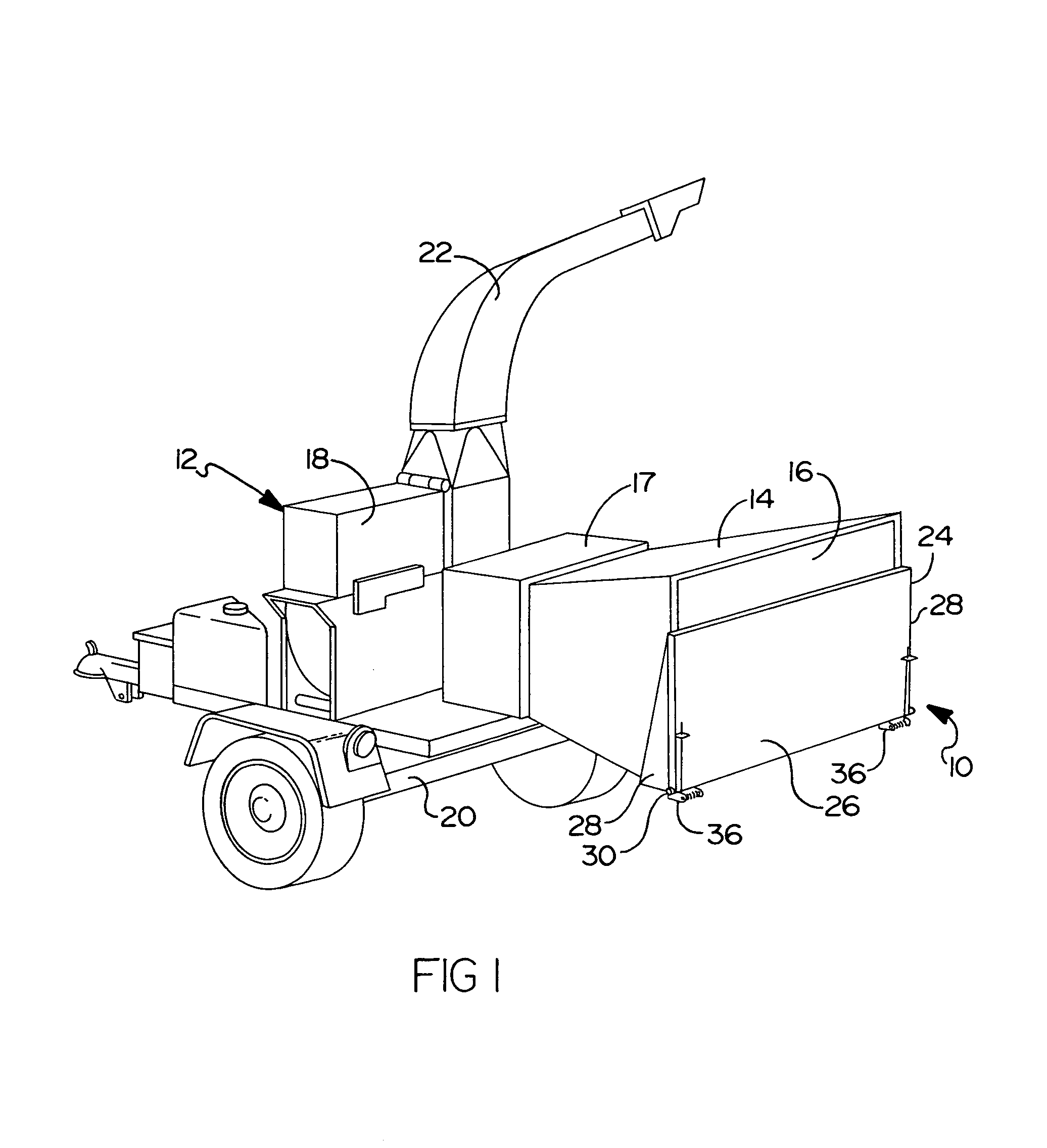

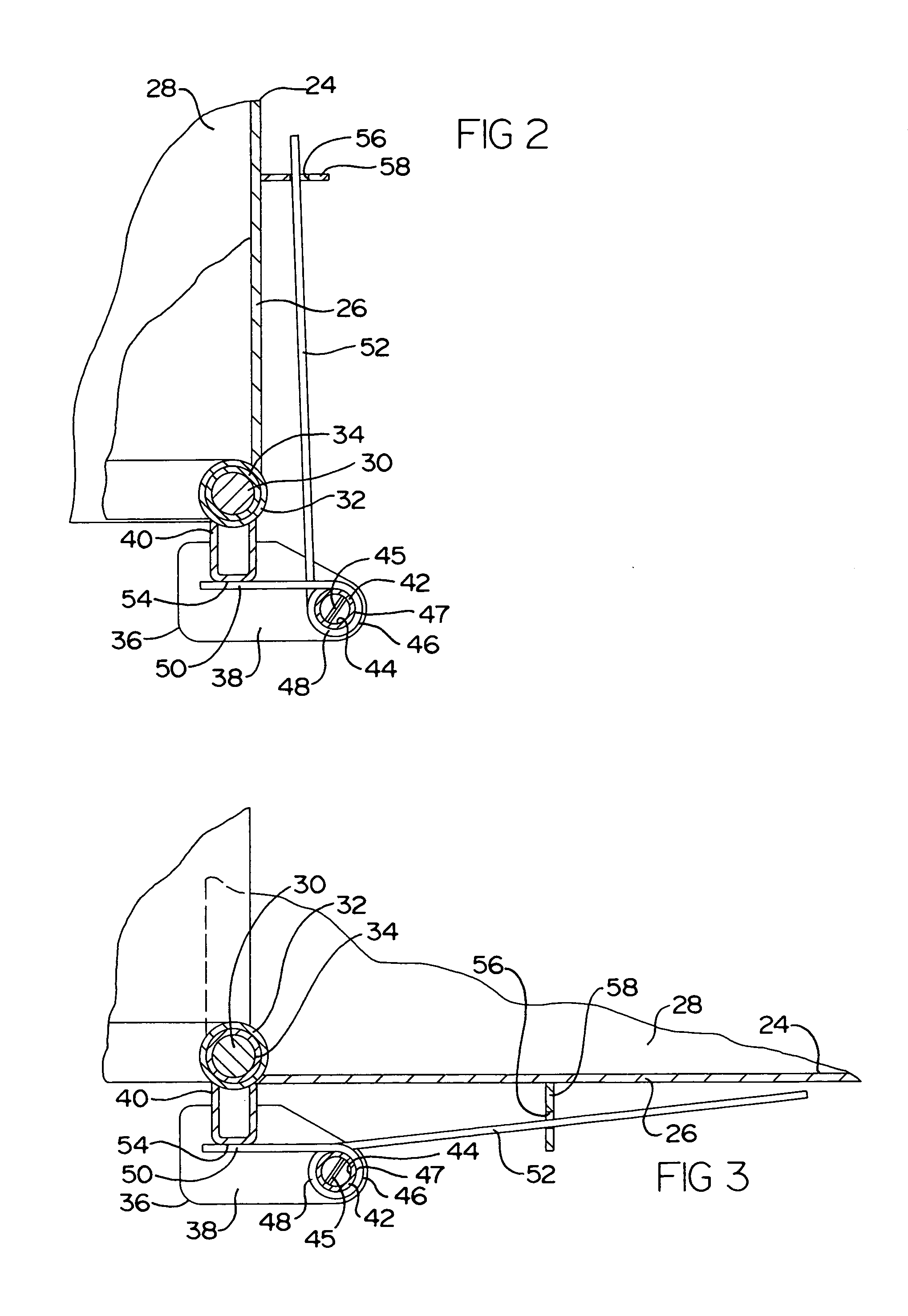

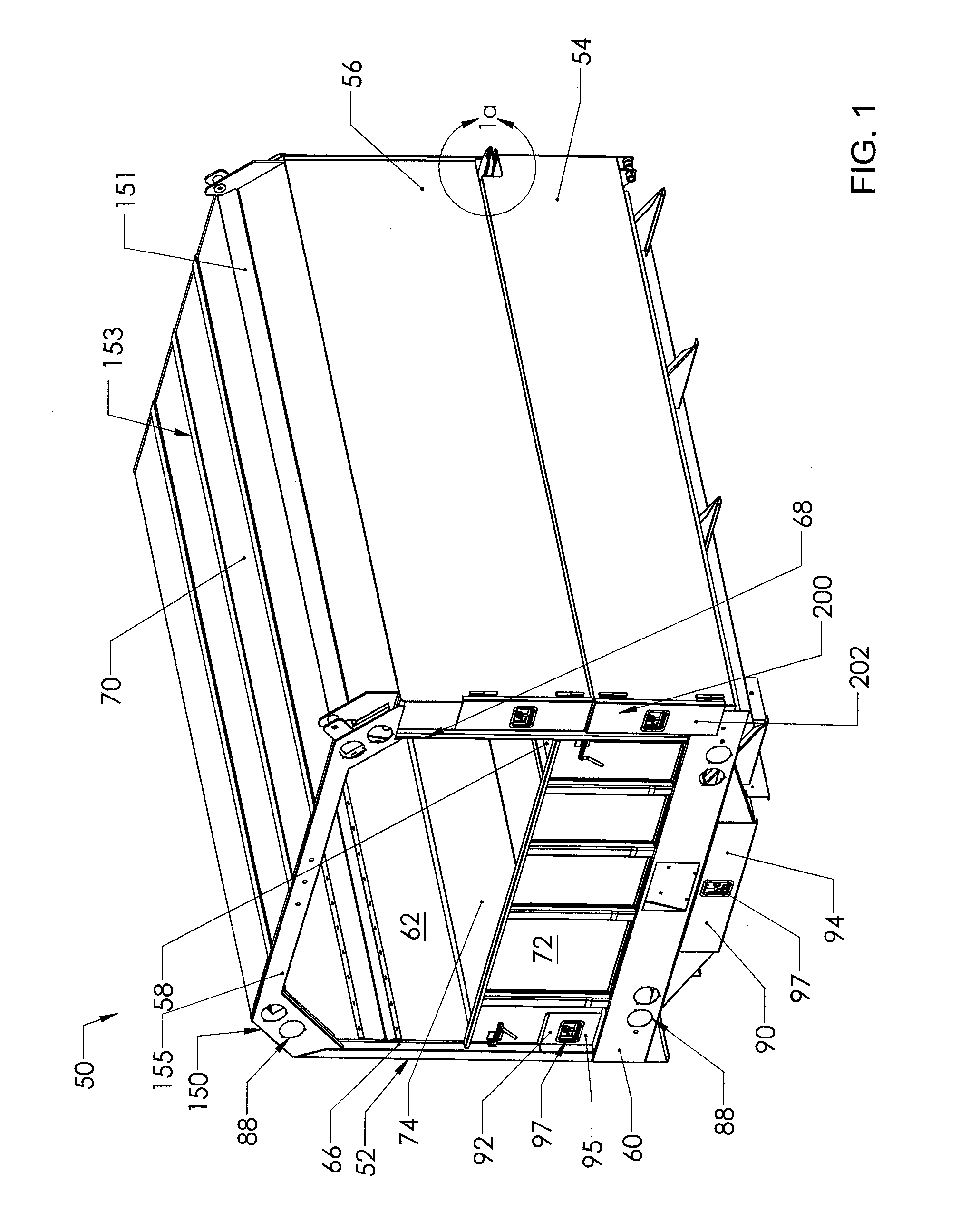

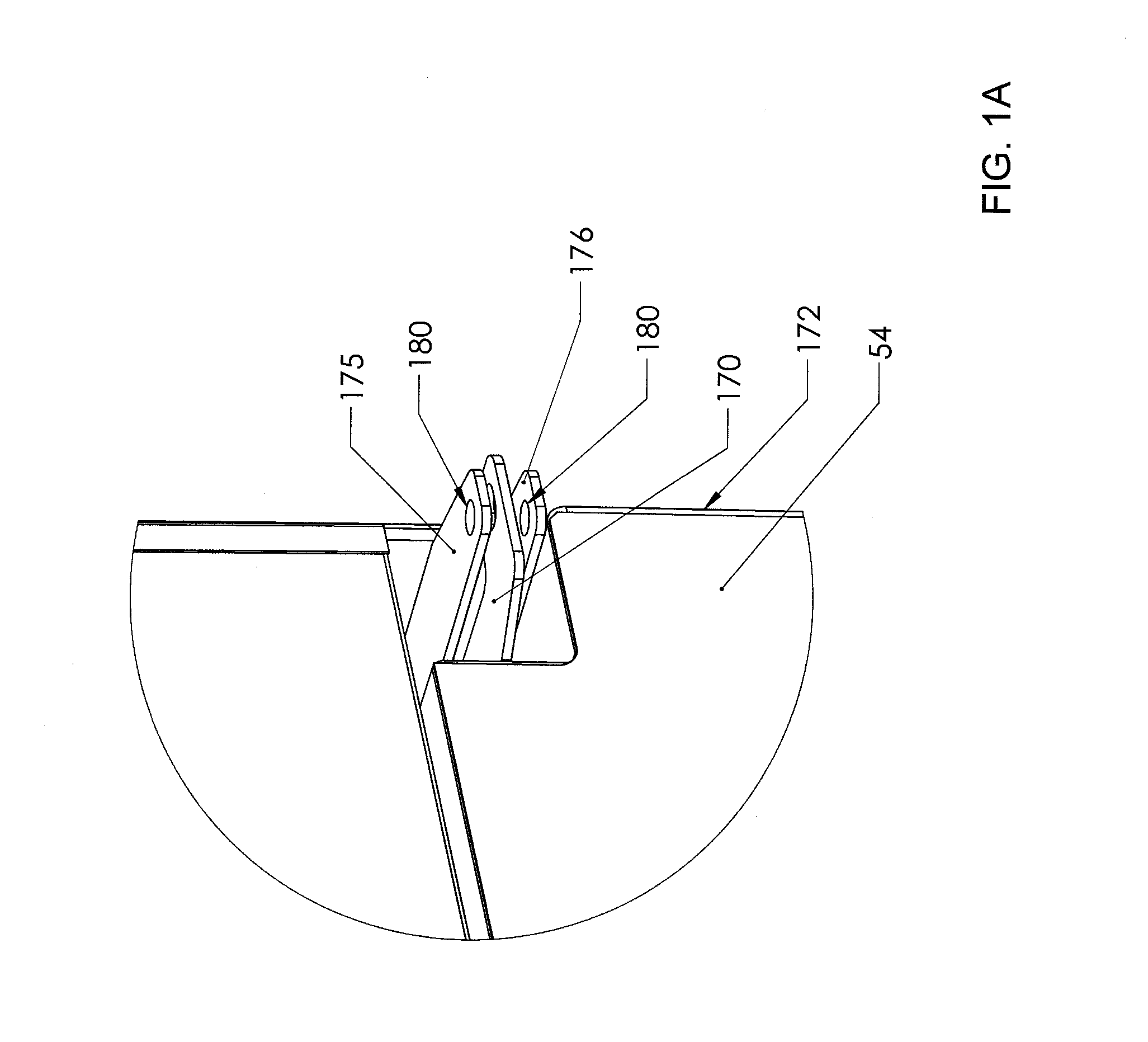

Spring assist assembly for infeed pan of wood chipper

InactiveUS7121488B1Easy to appreciateRaise and lower the infeed panGrinding machine componentsCocoaEngineeringMechanical engineering

An assist assembly for an infeed pan of a wood chipper includes at least one assist mount adapted to be connected to the wood chipper. The assist assembly also includes at least one assist member connected to the assist mount and adapted to operatively engage the infeed pan to assist an operator in handling a bulk weight of the infeed pan when the infeed pan is raised and lowered by the operator.

Owner:BANDIT IND

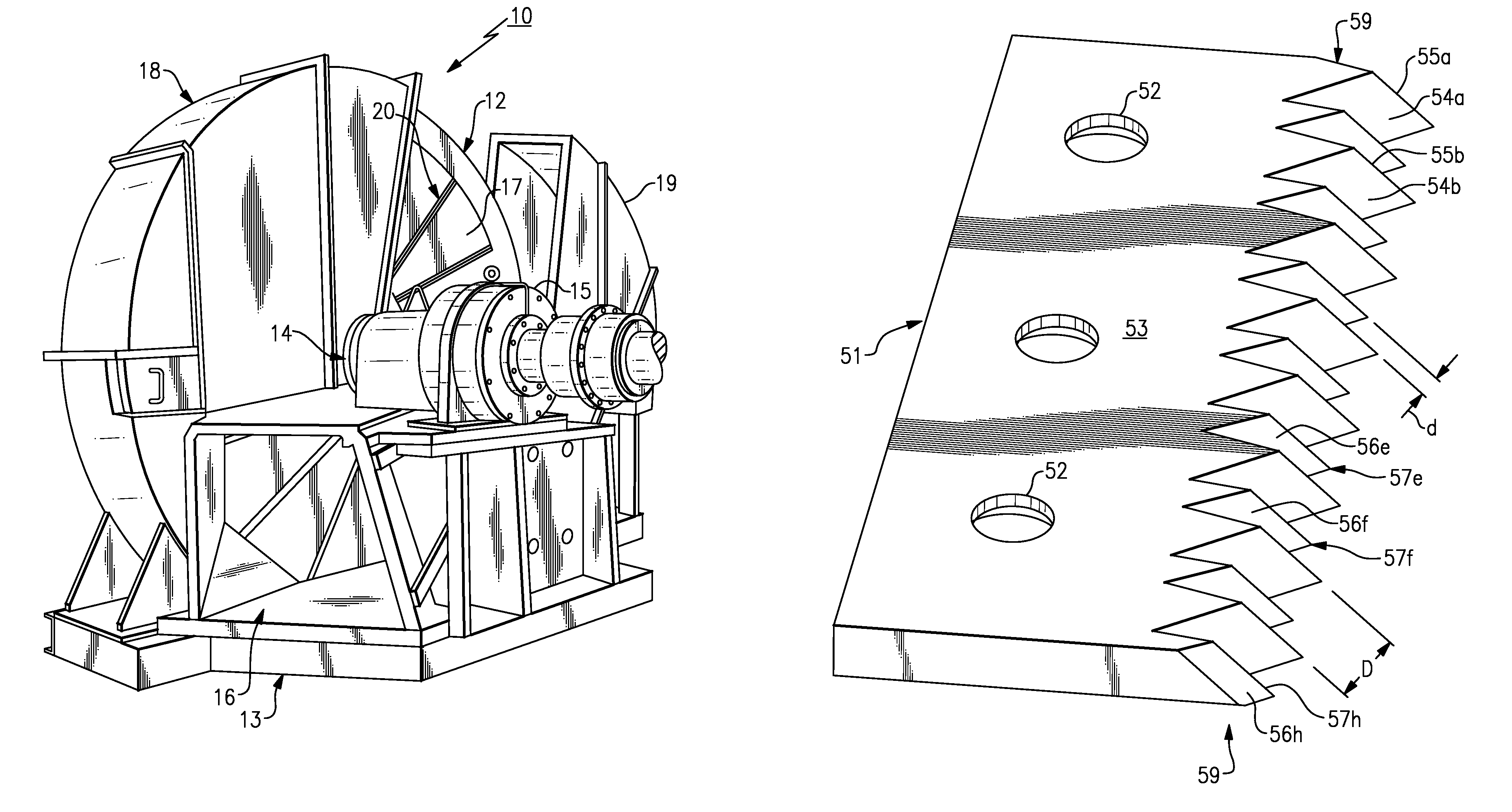

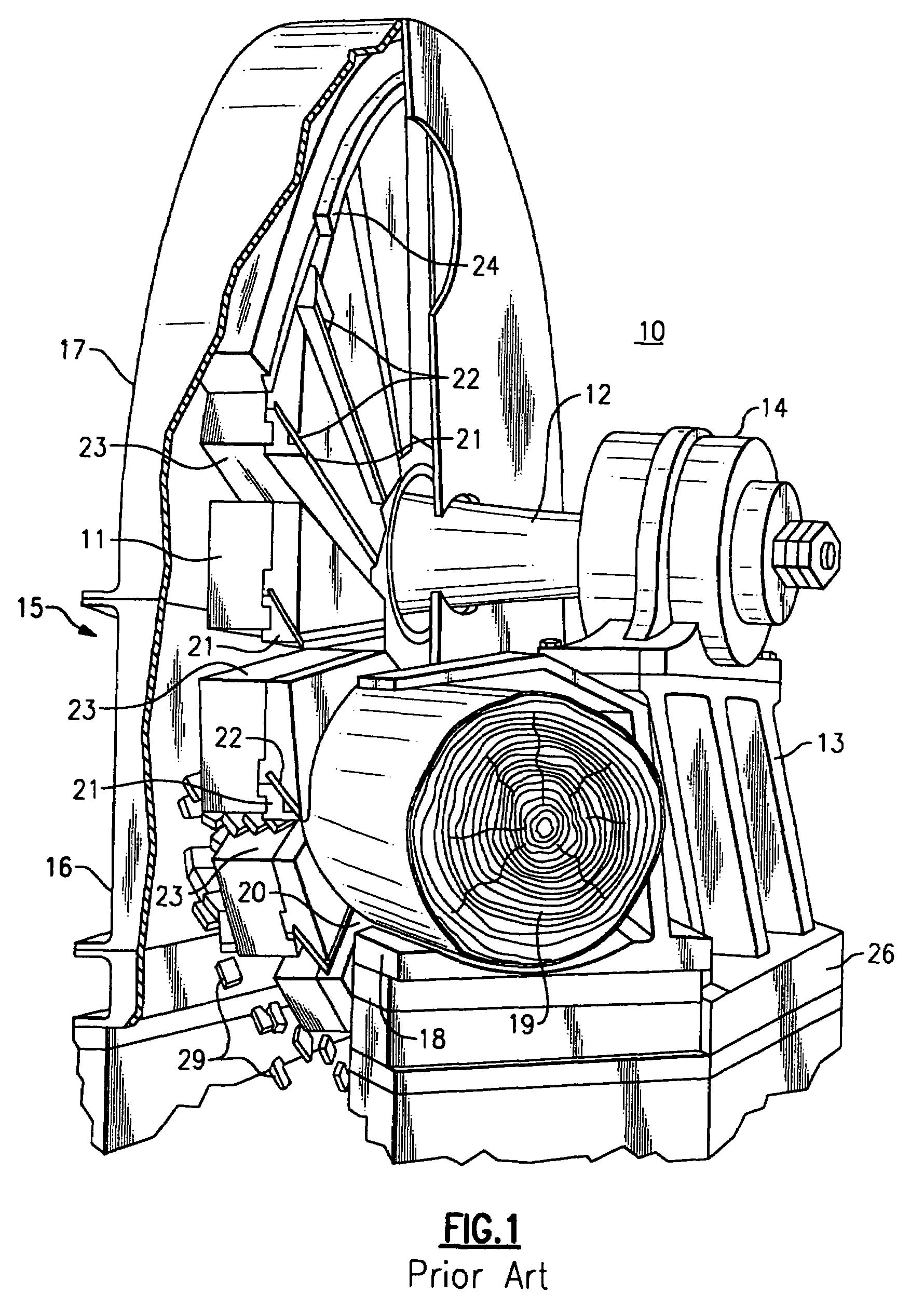

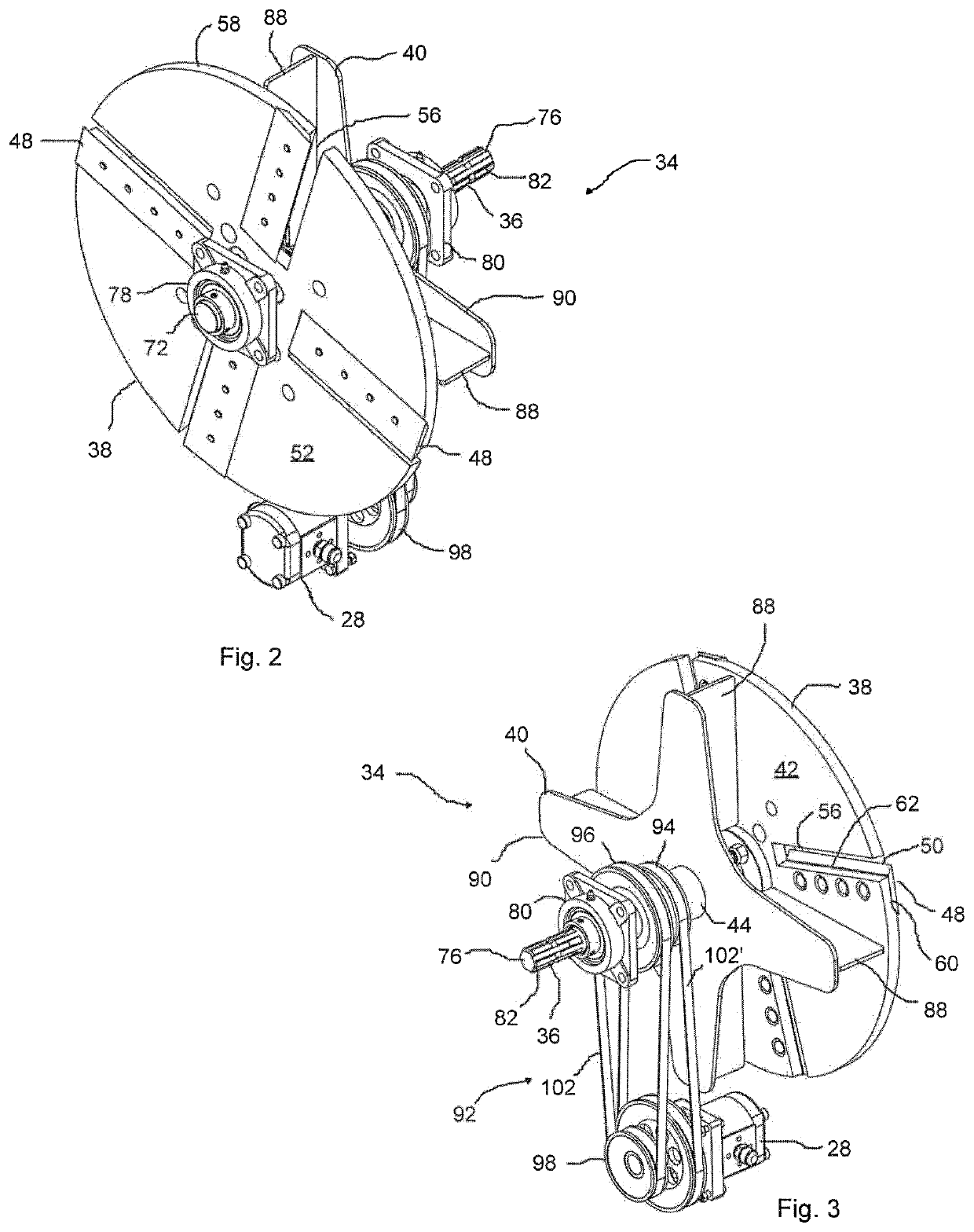

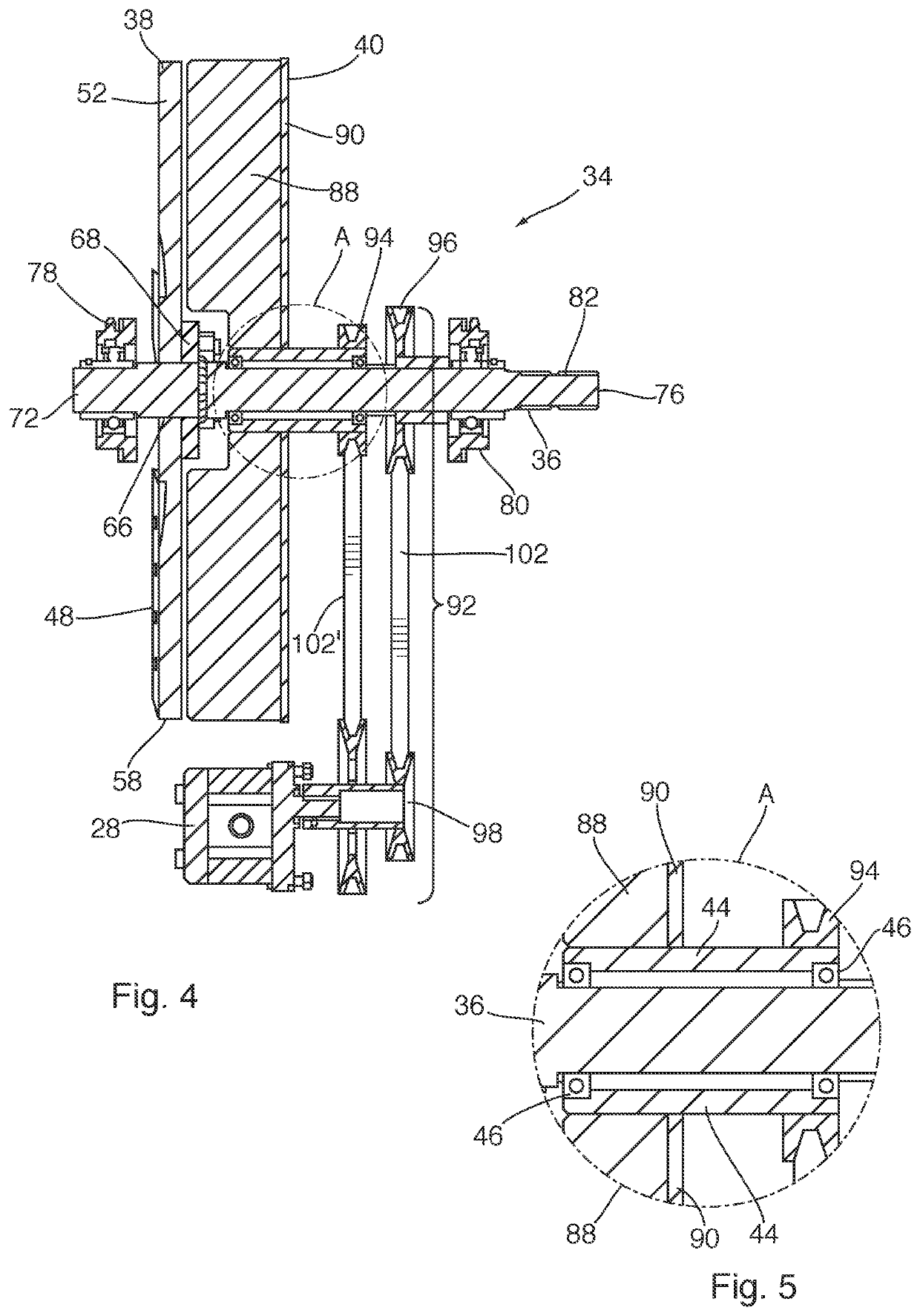

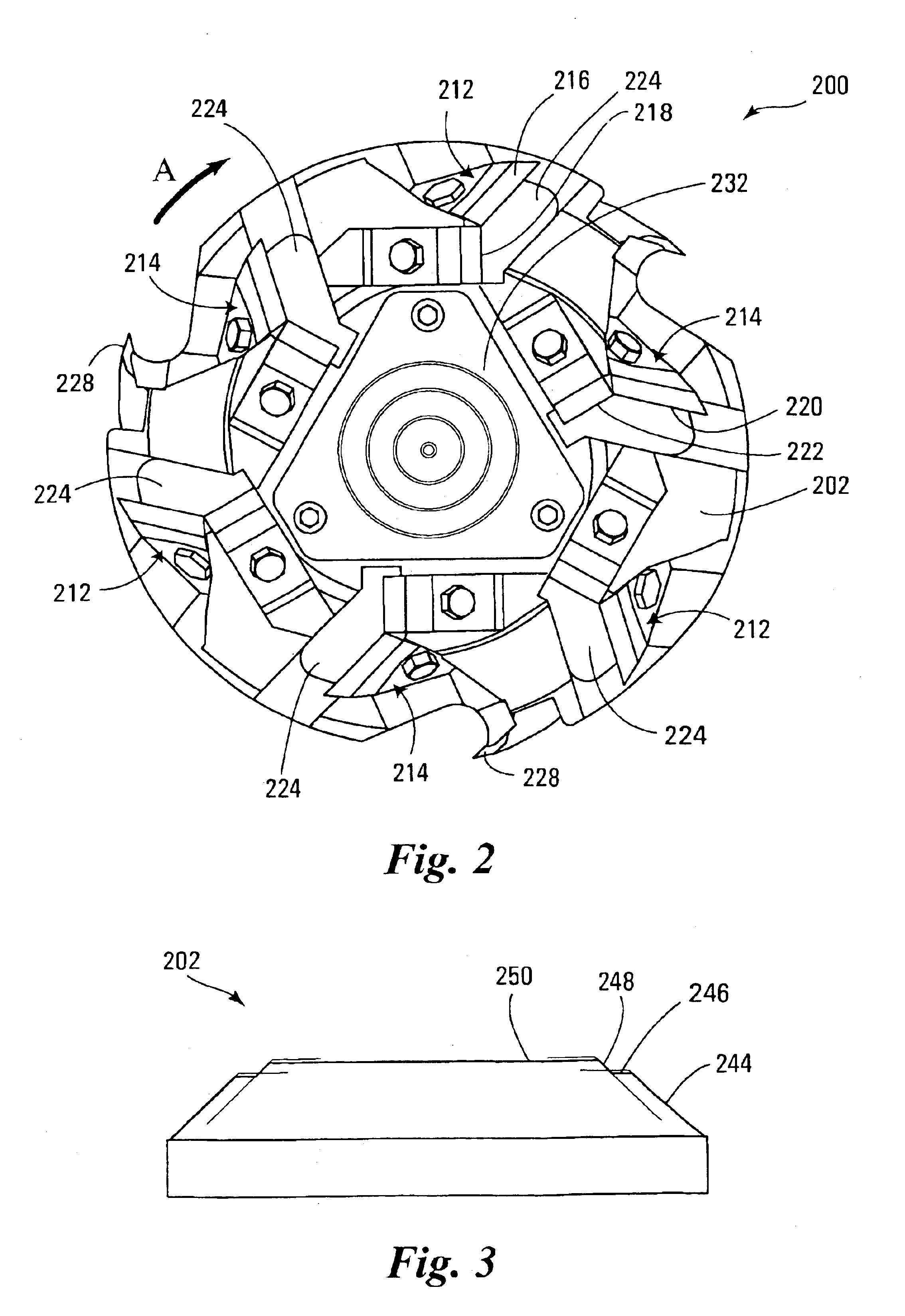

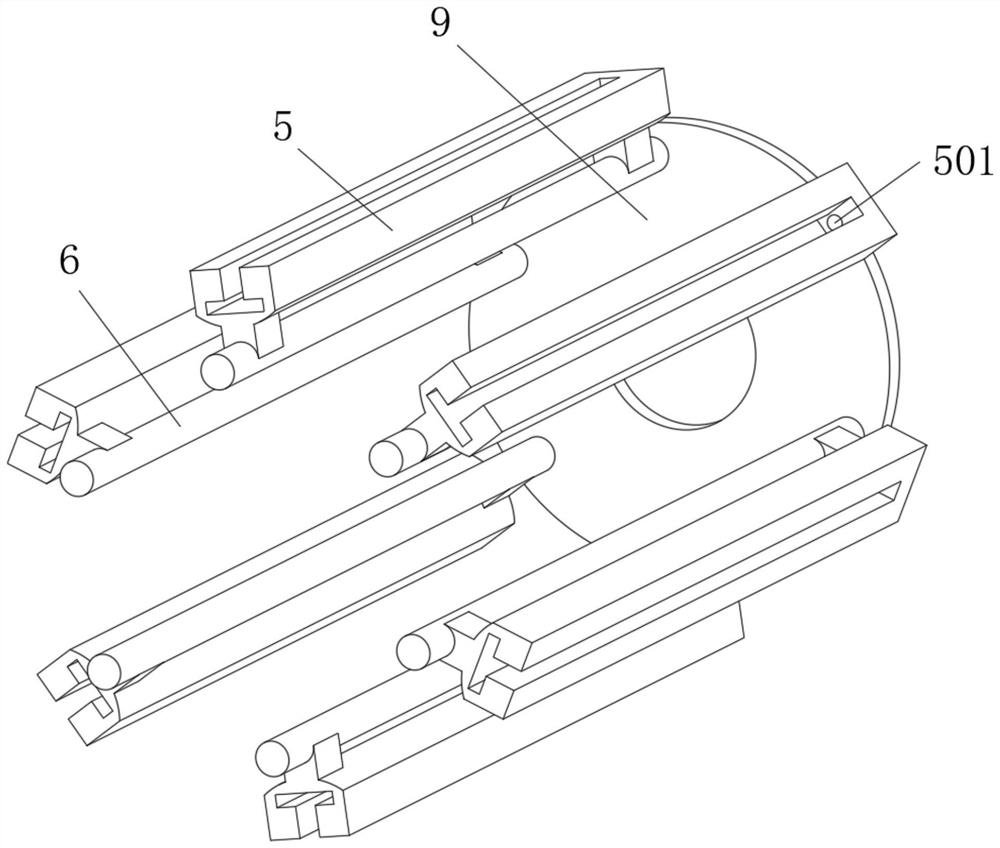

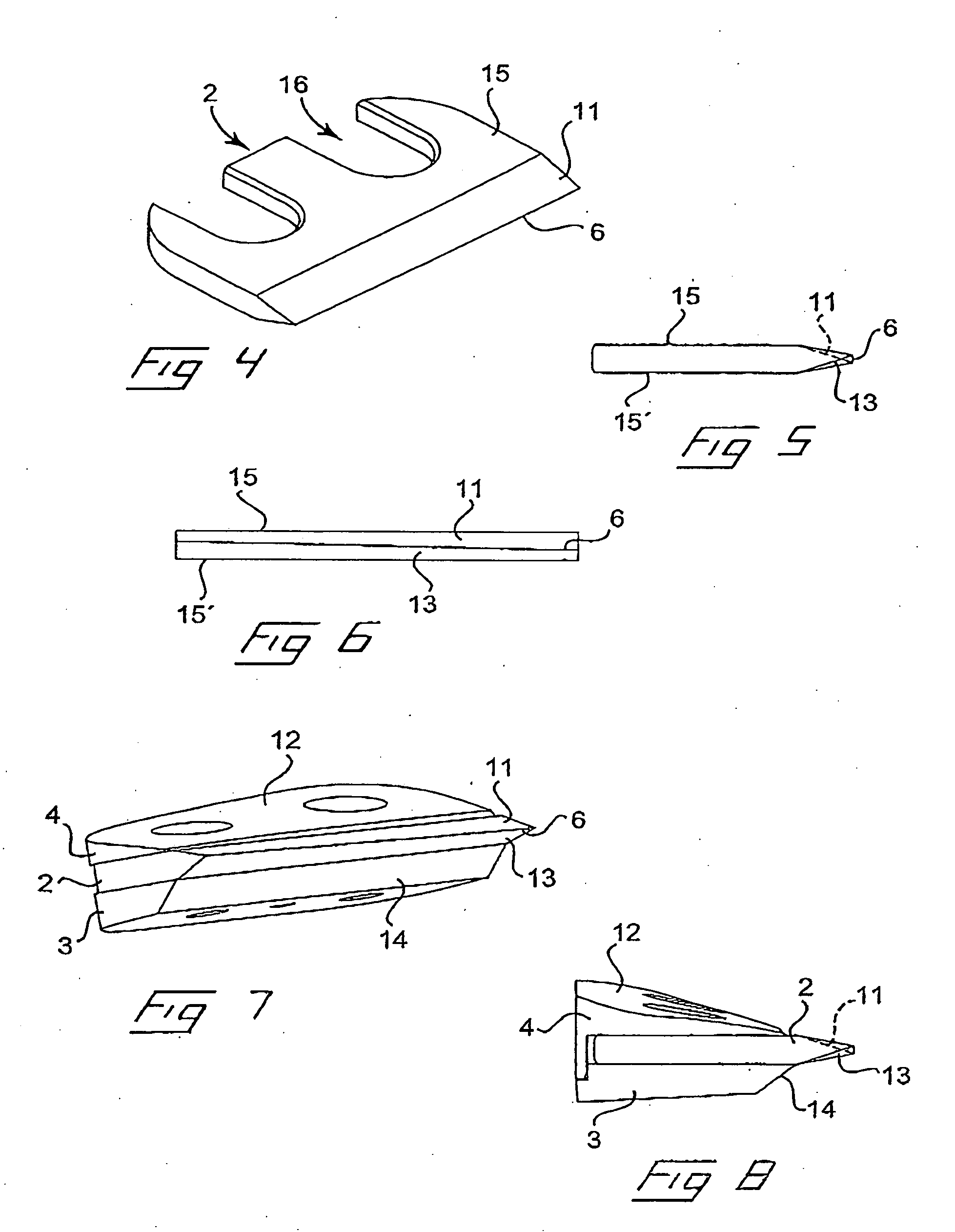

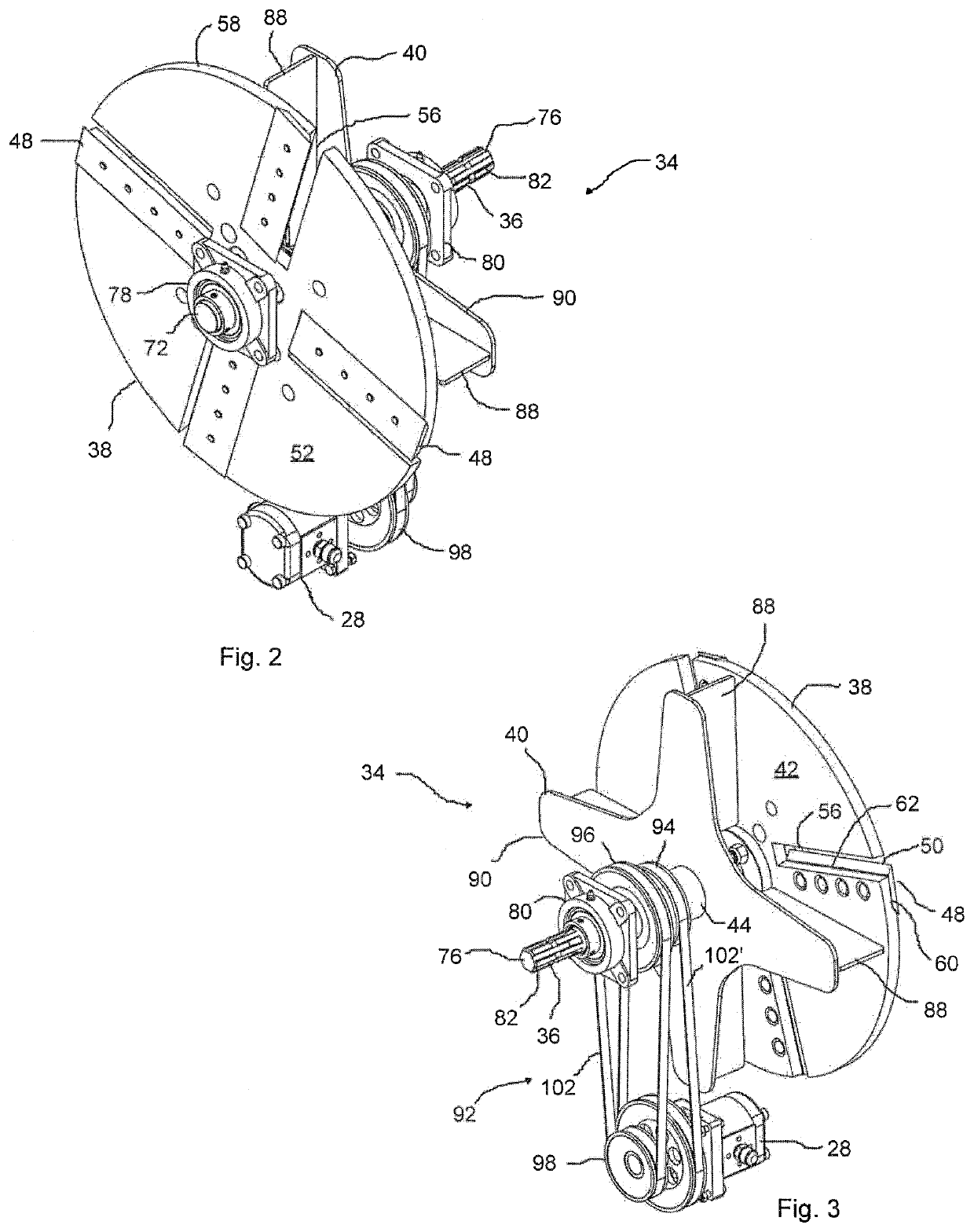

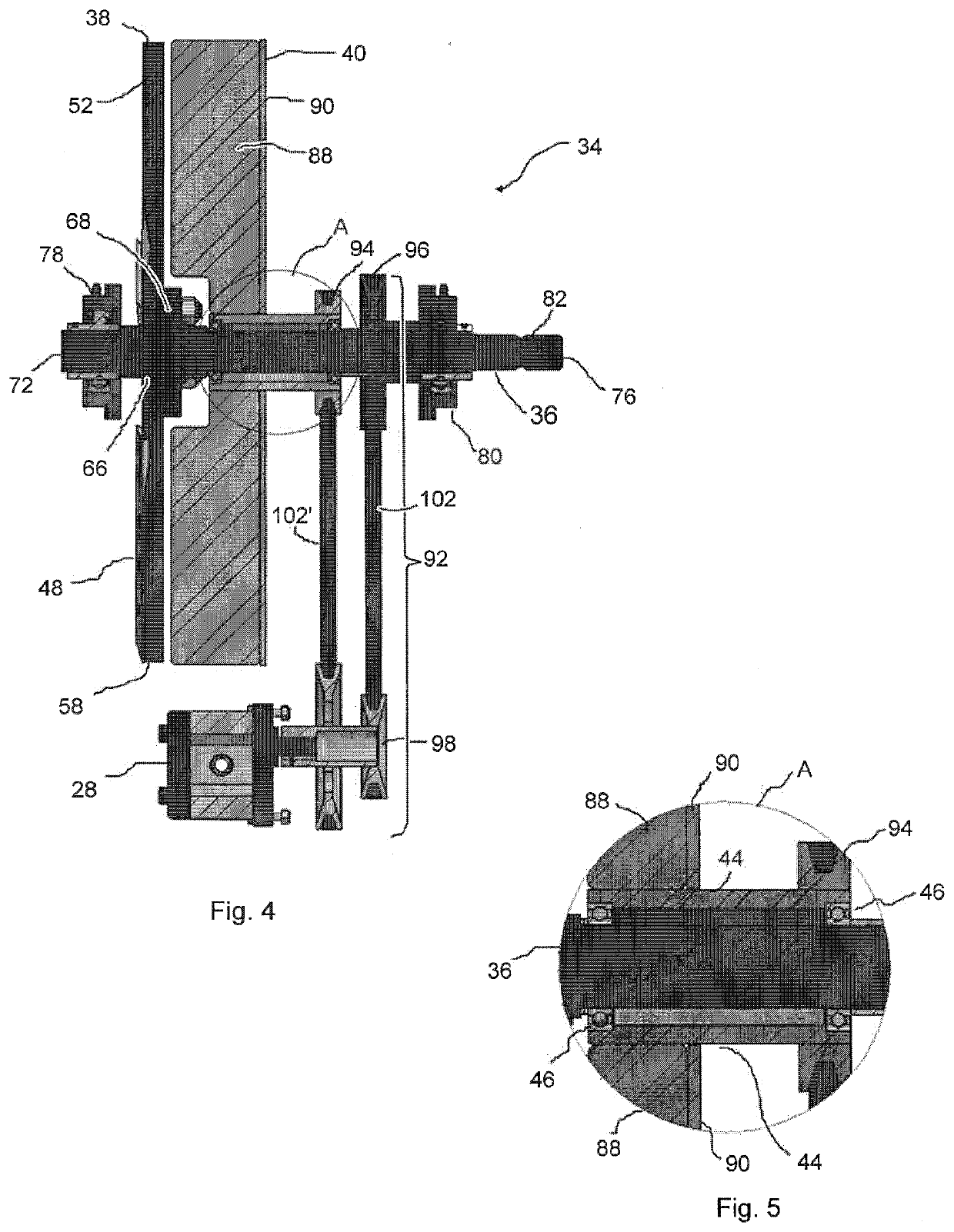

Primary and counter knife assembly for use in wood chipper

ActiveUS8051887B2Simple designSmall sizeGas current separationMulti-purpose machinesEngineeringContact element

A wood chipper having a rotatable disc that contains a series of slots that pass through the disc. A primary chipper knife is located at the entrance of each slot which separates slices from a work piece and directs the slices through the slot. A counter knife unit is mounted within each slot for engaging the slices leaving the primary chipper knife to reduce the size of the chips as they move through the slot. The counter knife unit contains a first series of spaced apart chip contact elements that have a first height to contact the slices as they leave the primary chipper knife to reduce the size of the slices. The counter knife further contains a second series of chip contact elements that have a second height that is less than that of the chip contact element in the first series. Each contact element in the second series is arranged to contact chips leaving the contact elements in the first series to further reducing the size of the chips.

Owner:CEM MACHINE

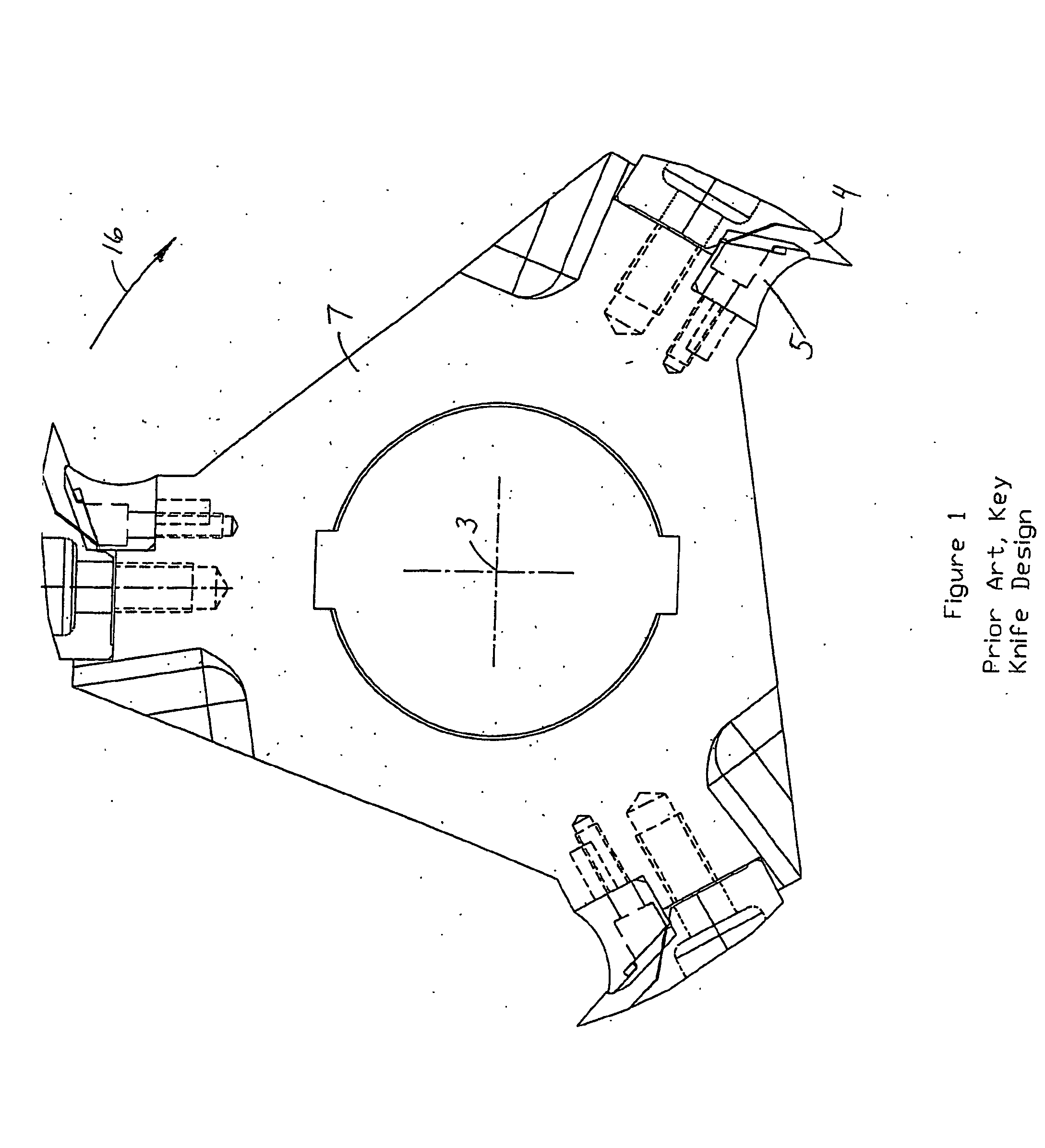

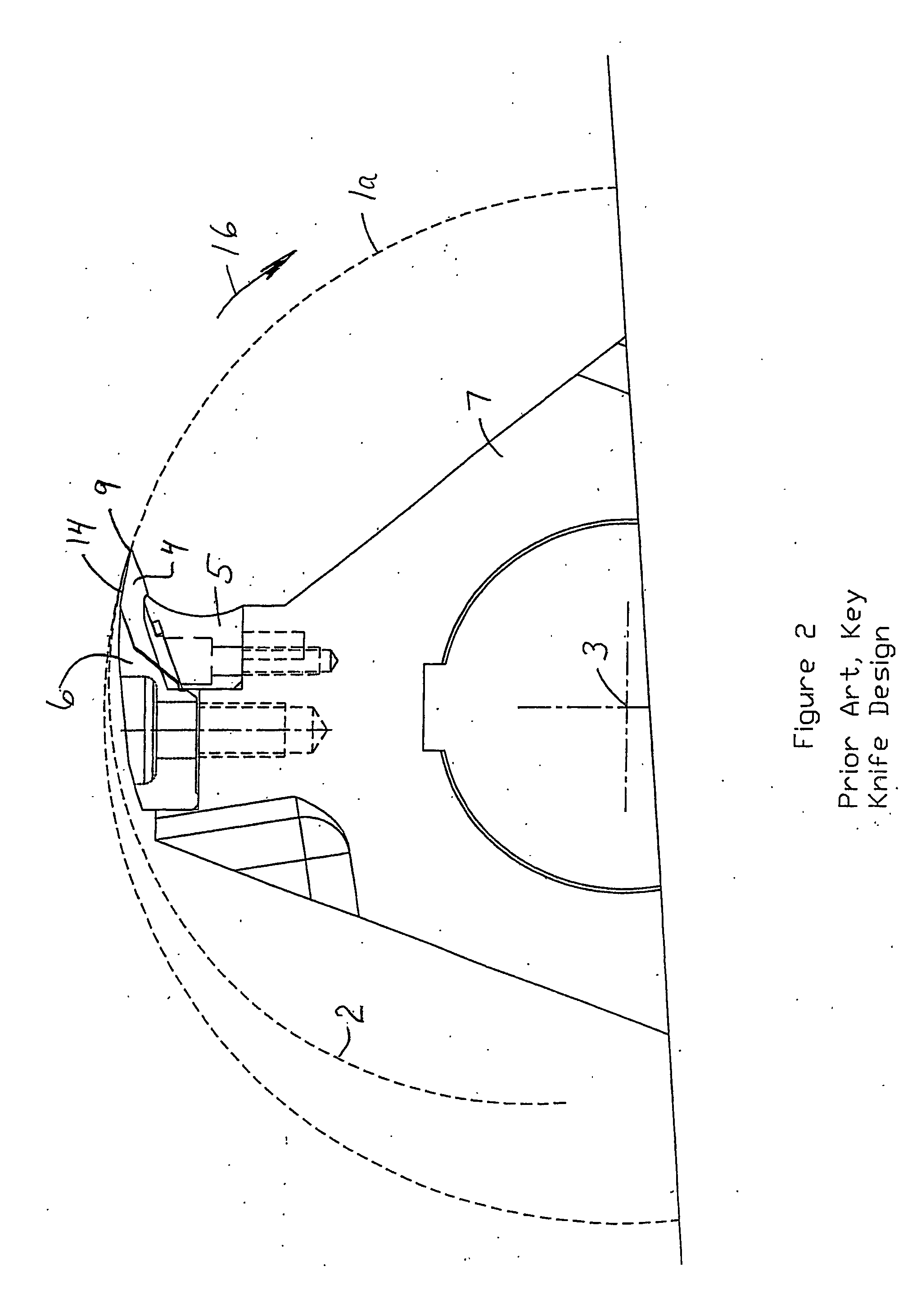

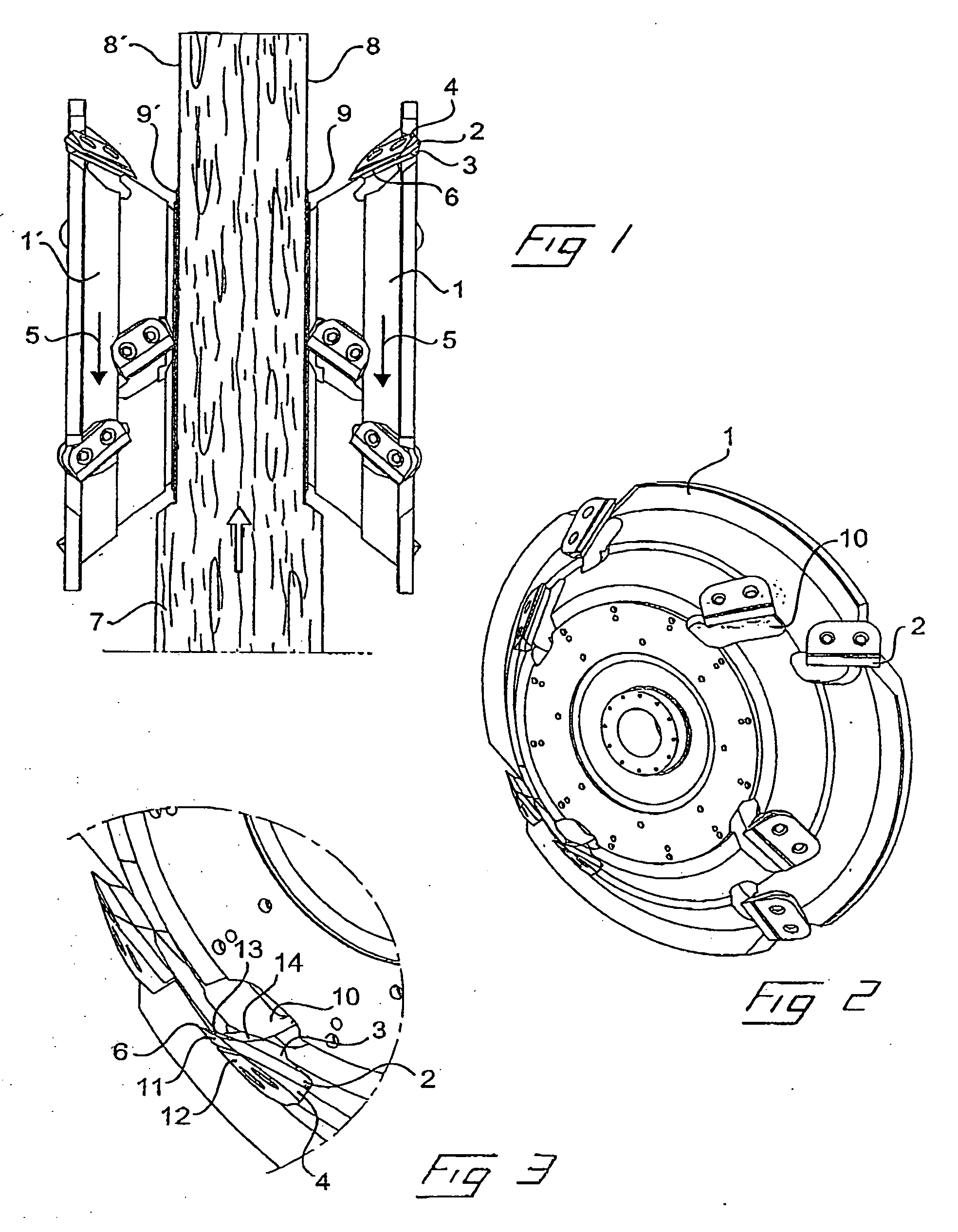

Chipper knife

A chipper knife (4) for mounting to a rotatable chipper head (7) includes a body having first and second cutting edges (9), a continuous chip deflecting and shaping surface (13) extending between the first and second cutting edges, and a mounting portion to permit the body to be mounted to the rotatable chipper head for rotation in a rotary direction.

Owner:COE NEWNES MCGEHEE USA

Chipper feed mechanism with pulsating down pressure

A wood chipper includes an engine and a cutting assembly. A rotatable feed wheel and a gap-bounding member define therebetween an adjustable gap through which feed material moves toward the cutting assembly. An electronic control unit (ECU) controls force applied to the feed wheel or gap-bounding member toward the feed material in response to an operational condition of the wood chipper. The ECU can maintain or vary the force in any desired manner. One option is to apply the force with a pulsating mechanism in a pulsating manner to enhance the feeding procedure. The pulsating mechanism is in communication with a sensor from which the ECU receives signals typically indicating an operational speed of the cutting assembly or the engine. An ECU logic circuit permits the pulsating force only if the operational speed exceeds a predetermined threshold.

Owner:ALAMO GROUP

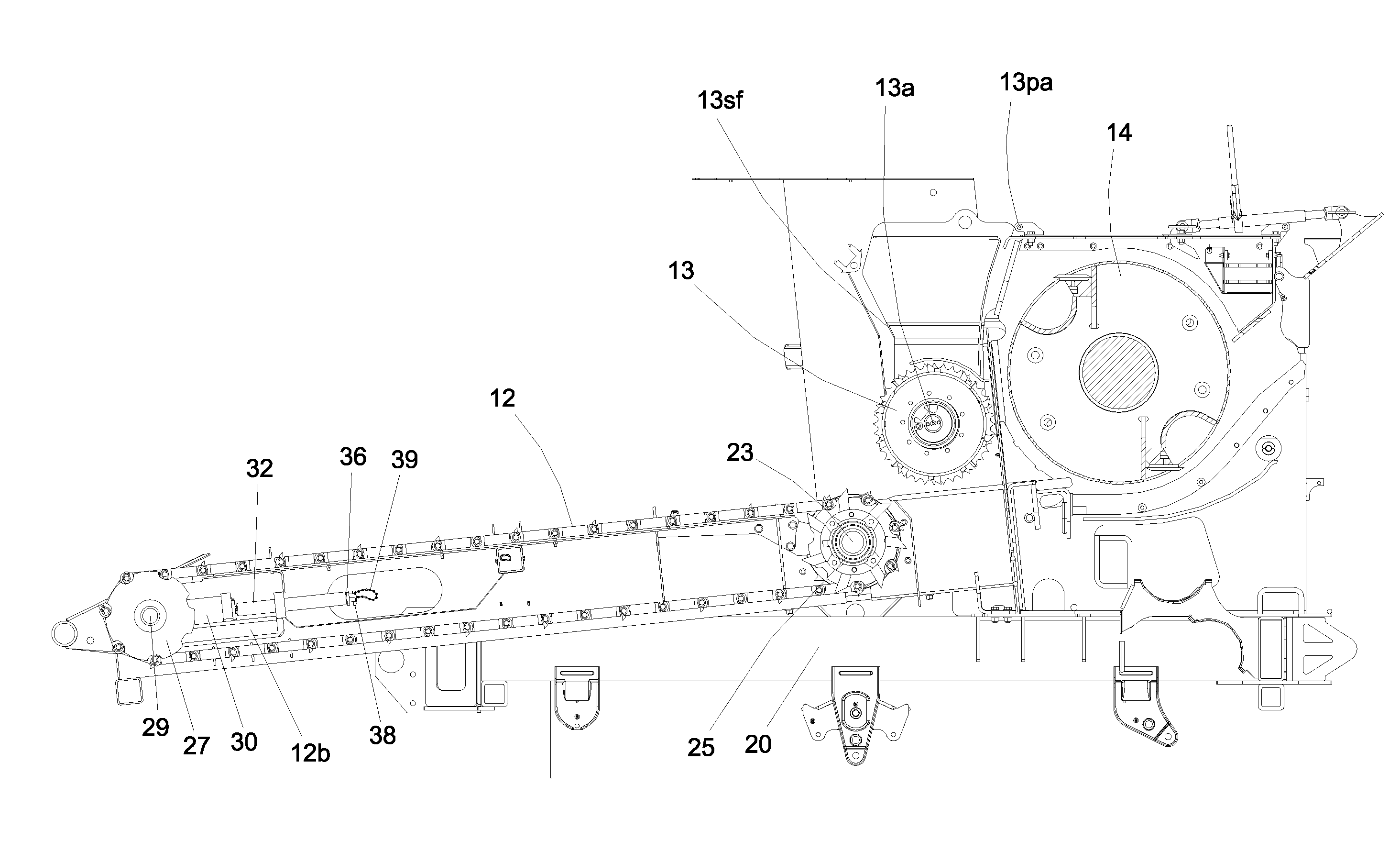

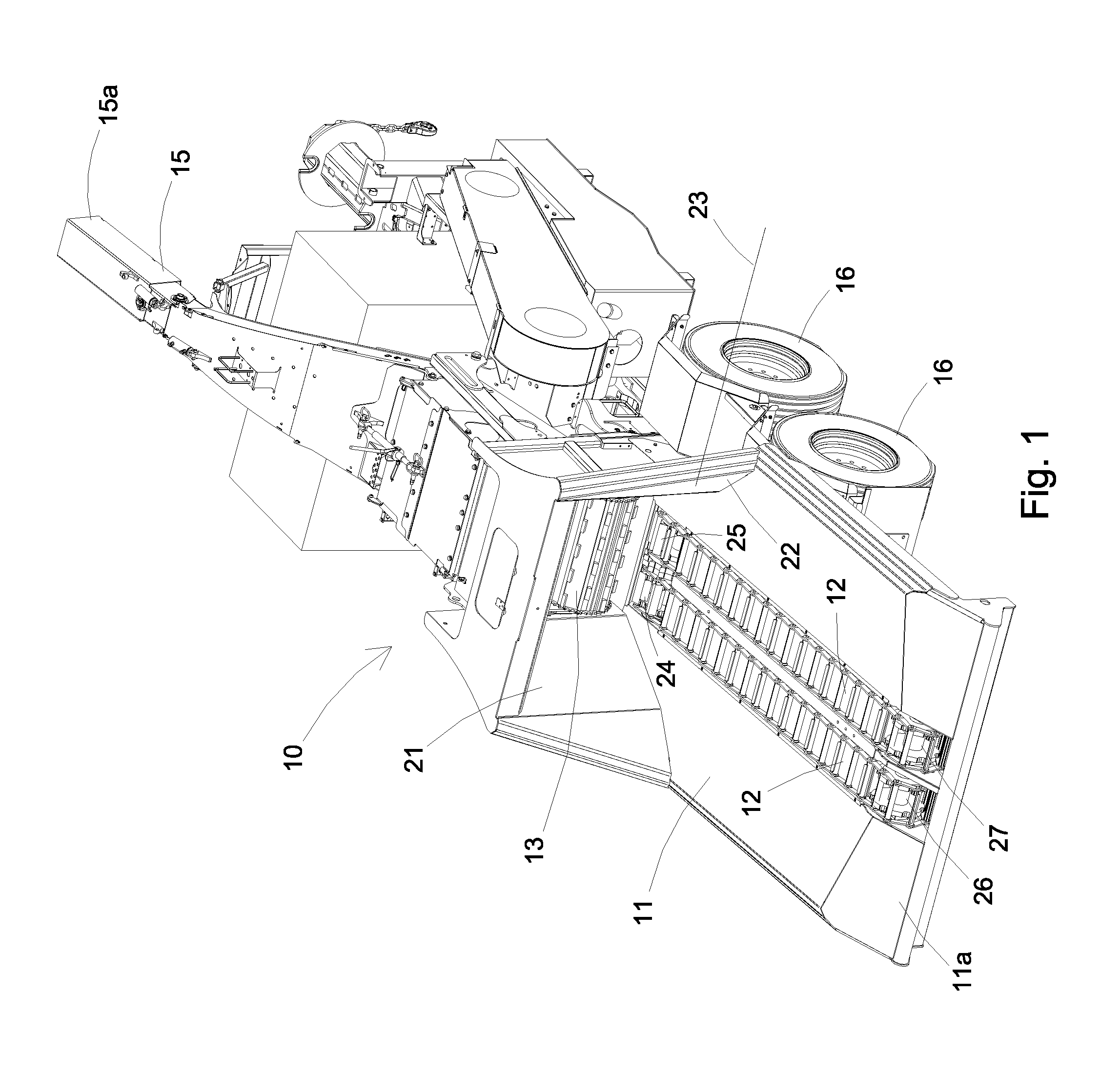

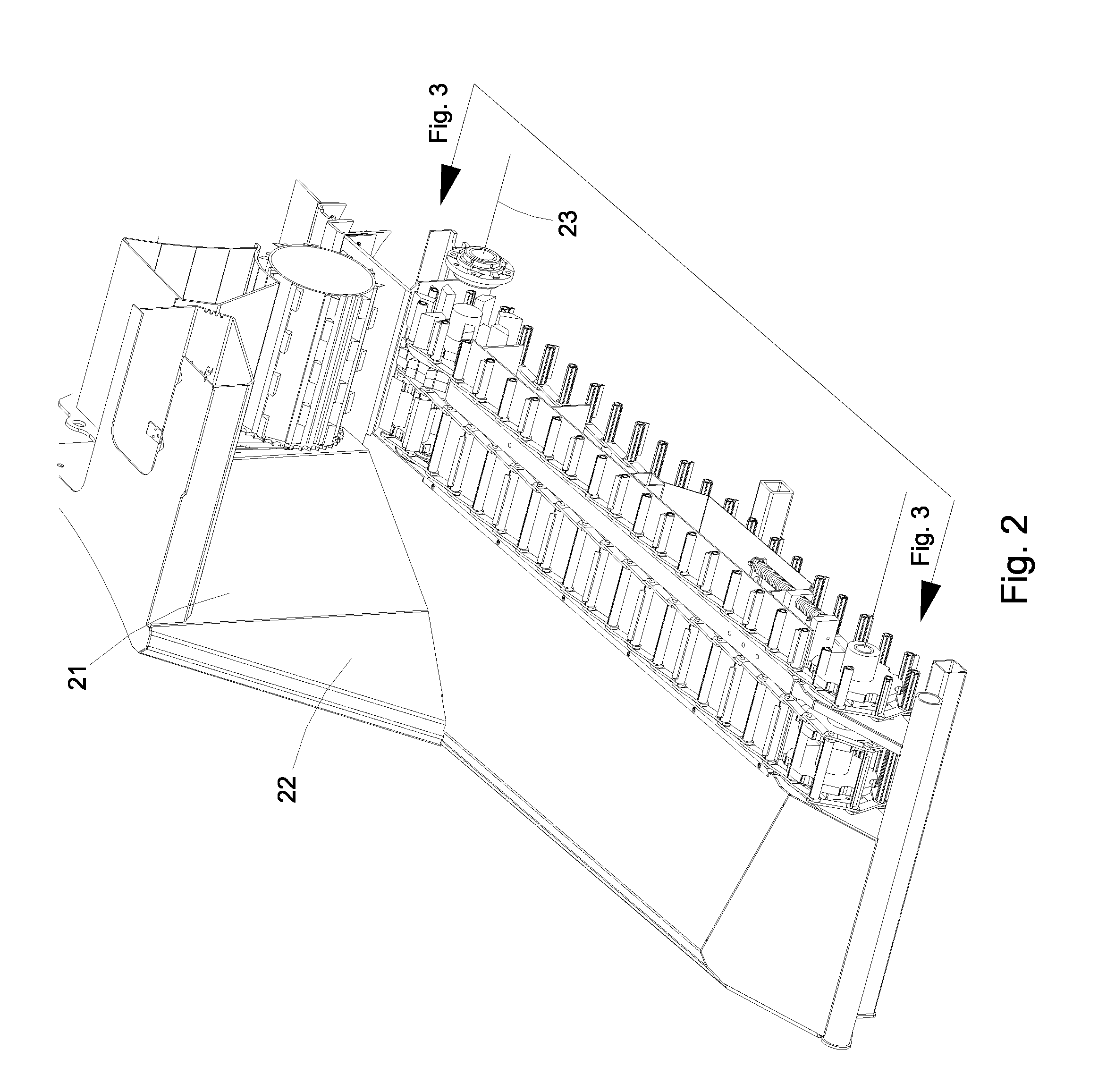

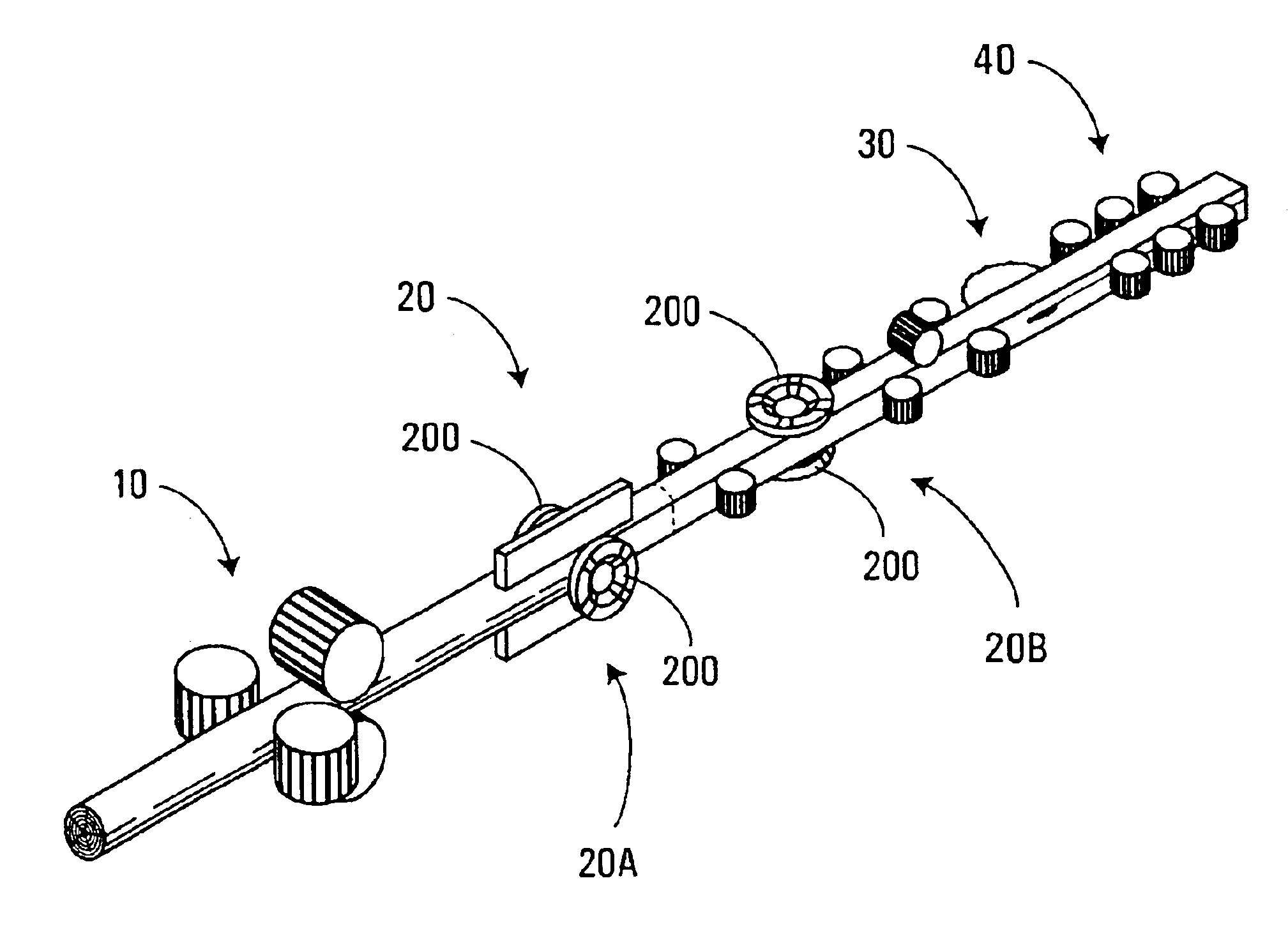

Individual Feed Chain Tension System for Tree Chipper

InactiveUS20130037170A1Quick and easy independent adjustmentEasy to adjustWood feeding arangementsConveyorsChain lengthEngineering

A log and / or tree chipper has an individual feed chain tension system for multiple chains. A mechanism is provided for quick and easy independent adjustment for differences in chain length. Therefore, if a tail pulley is damaged, one section can be repaired while not requiring all of the drag chains to be split and the whole tail pulley removed. To keep the adjustment from moving out of adjustment after the adjusting step, a push bolt lock slips over adjusting bolts and the push bolt lock can be held in place with lynch pins.

Owner:VERMEER MFG CO

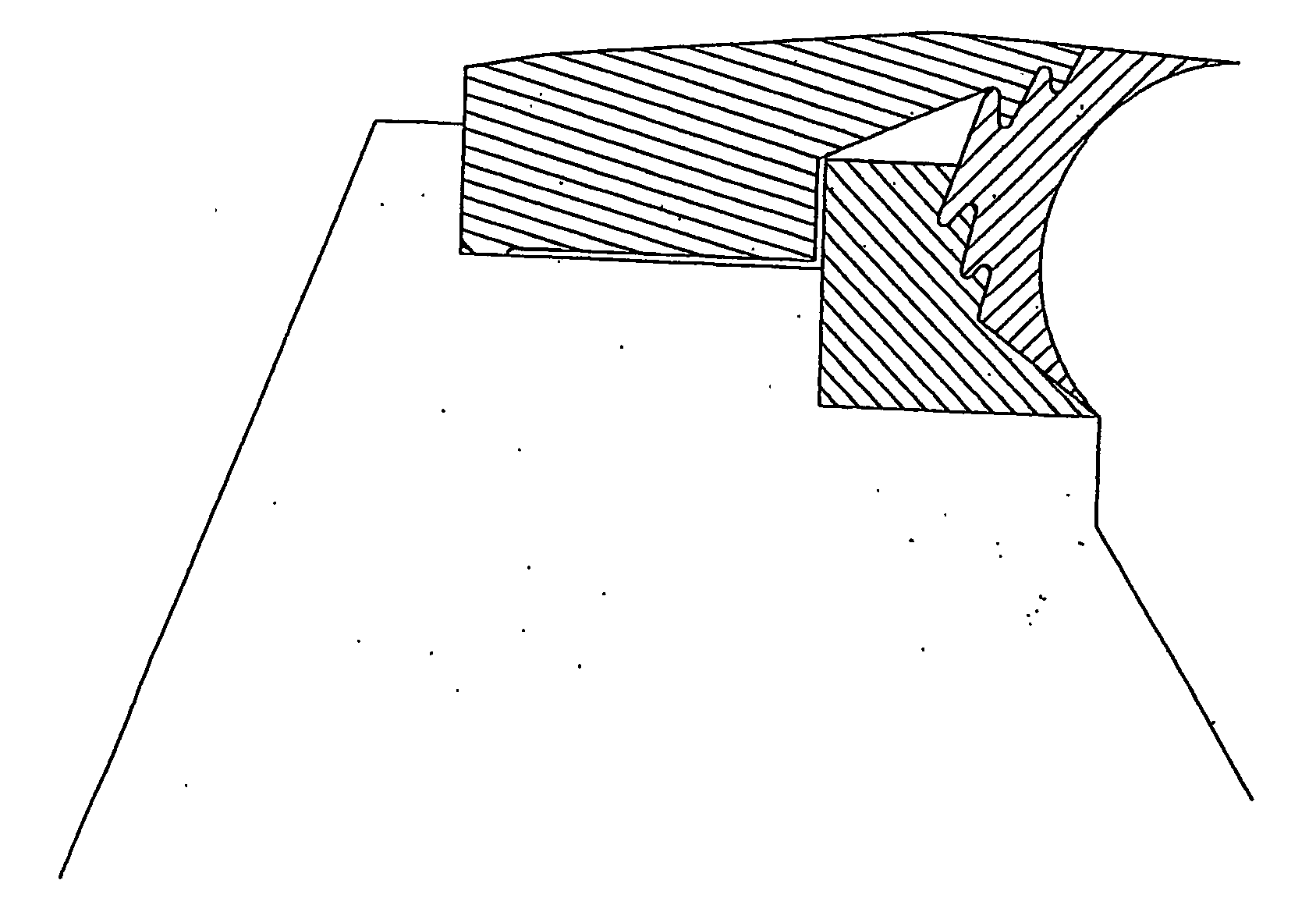

Stationary bedknife for disc chipper apparatus

A disc cutting apparatus for chipping wood chips from a log includes a chipper frame, a rotary cutting disc having a plurality of substantially radially disposed knife assemblies in relation to a proximal facing side of the disc and a feed spout into which a log is fed into the chipper apparatus. The apparatus further includes a bedknife, the bedknife having a first surface and an opposing second surface that is nonparallel to the first surface such that a wedge is produced between the first surface and the second surface for fitting within a corresponding nonparallel gap in the chipper frame. The bedknife further includes at least one secondary trimming edge for more complete reduction of wood chipped and for reducing the size of slivers formed.

Owner:CEM MACHINE

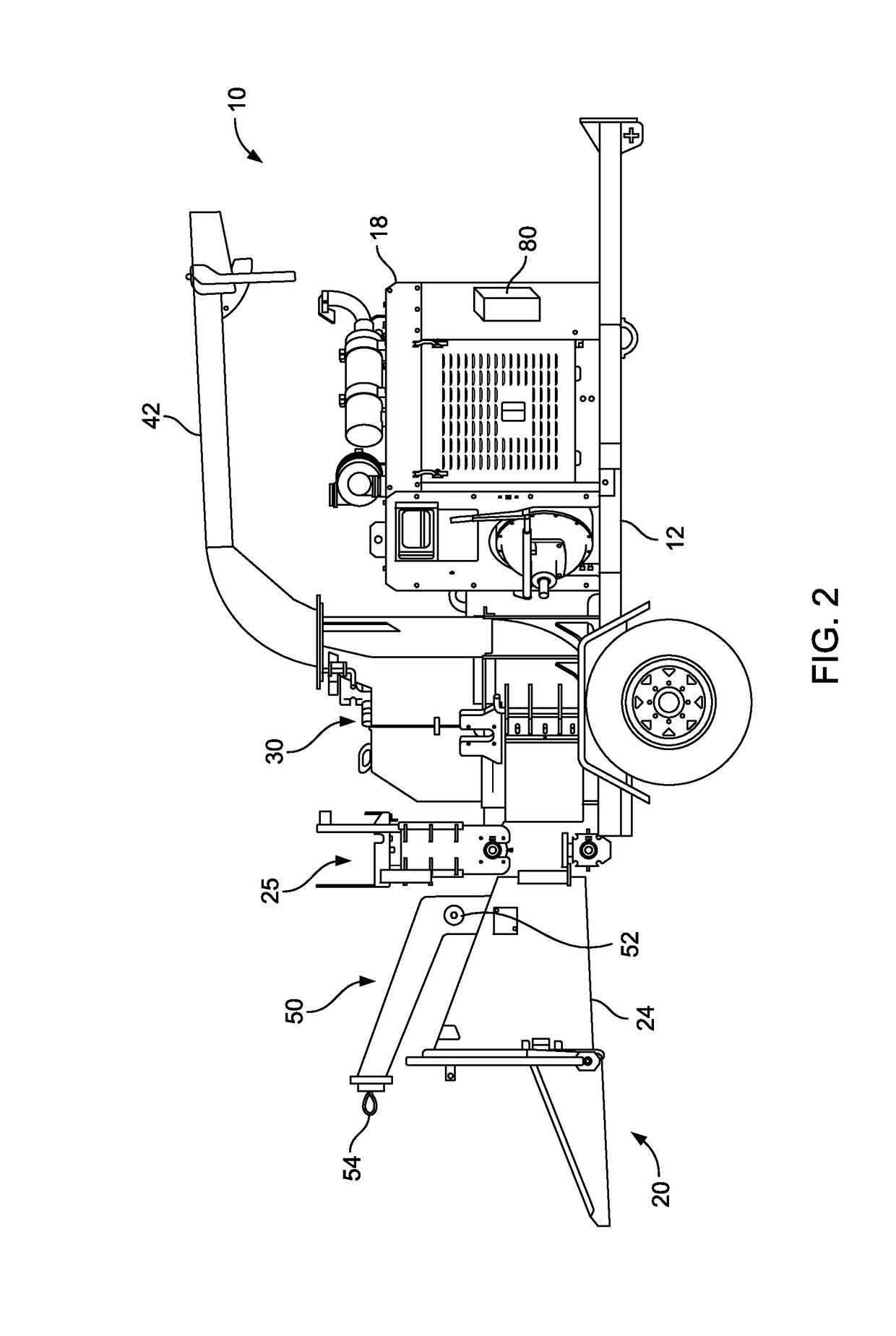

Advanced system recovery for feed system

A feed system for a woodchipper including a material-interface member for feeding material into a chipping mechanism of the woodchipper, an actuator for moving a material-interface member into interfacing and non-interfacing positions with the material, a sensor for detecting an operational parameter of the woodchipper, and a controller to direct the actuator. The controller operates by receiving the operational parameter of the woodchipper, establishing a normative operating value, and determining if the woodchipper is a first status or a second status based on a comparison between the operational parameter and the normative operating value. If the woodchipper is a first status, the controller instructs the actuator to move the material-interface member into the interfacing position. If the woodchipper is a second status, moving the material-interface member into a non-interfacing position.

Owner:ALTEC INDS

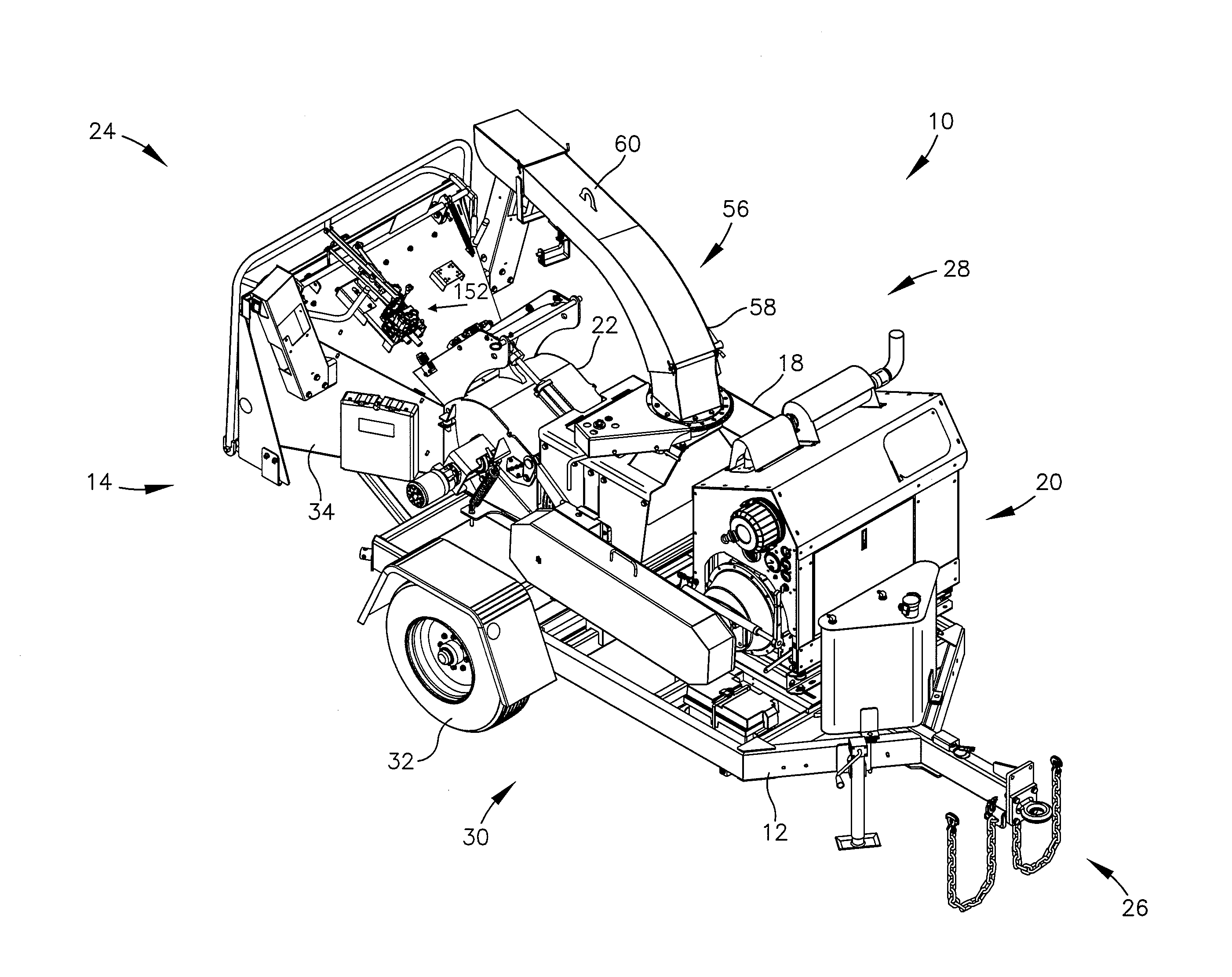

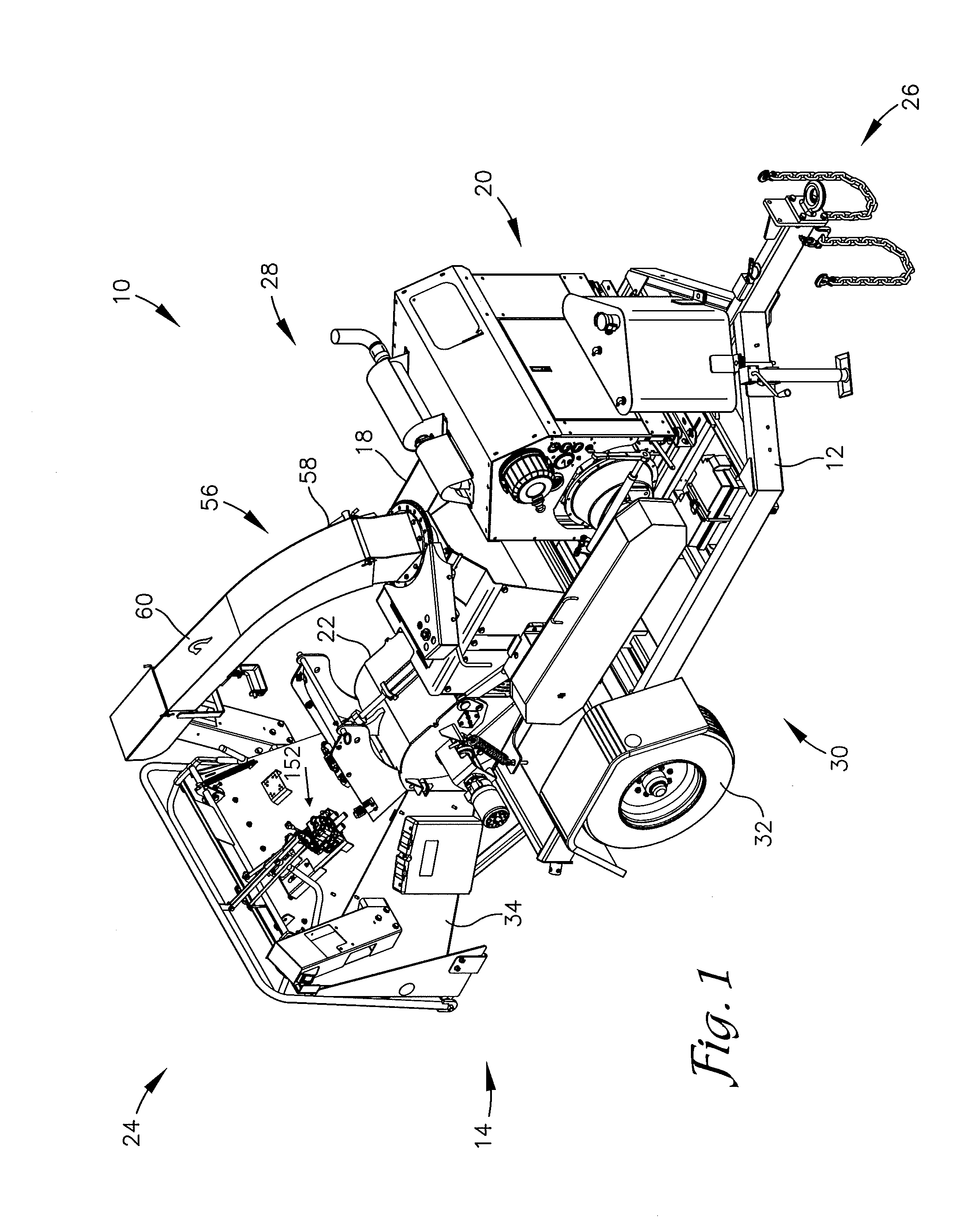

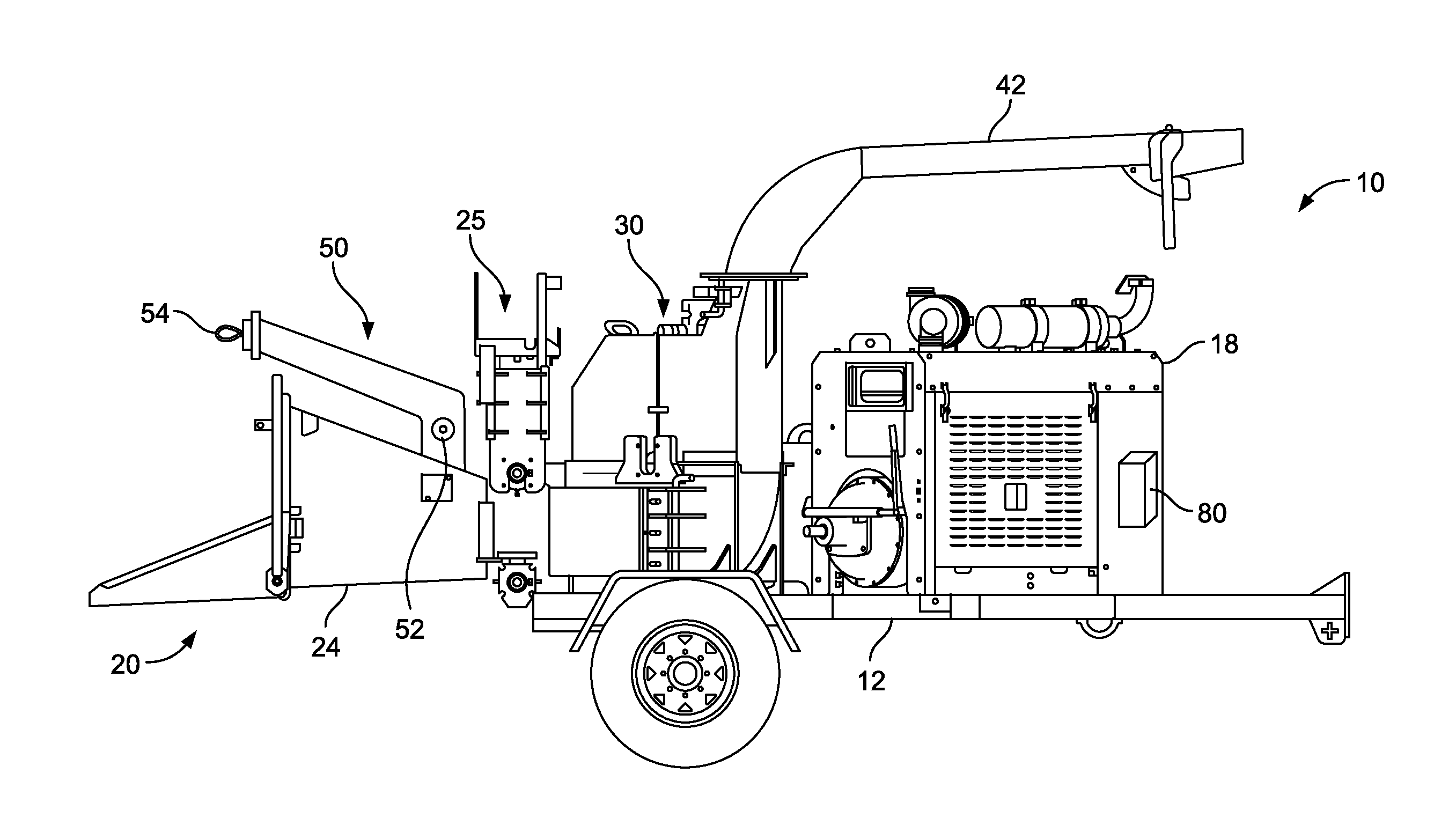

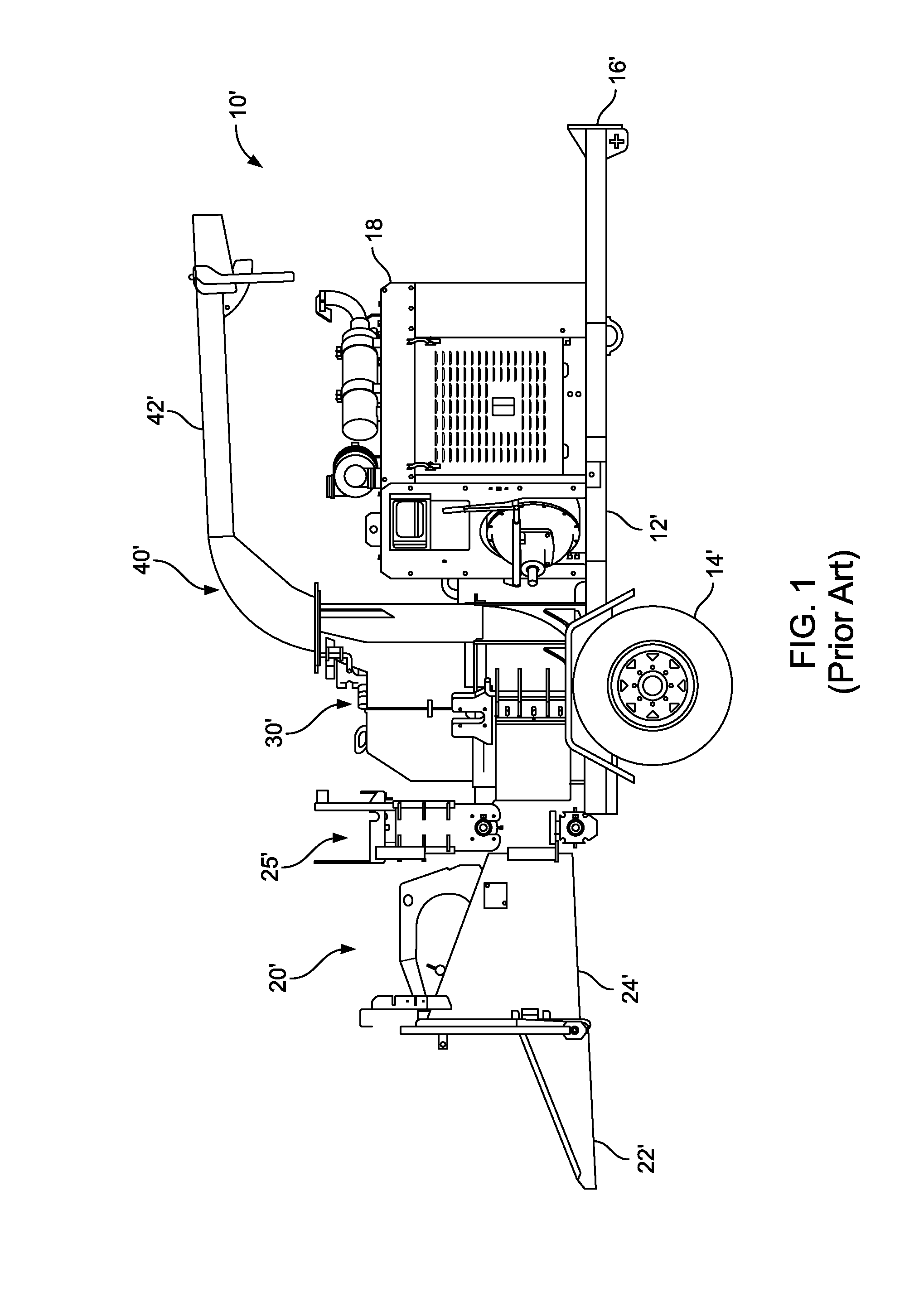

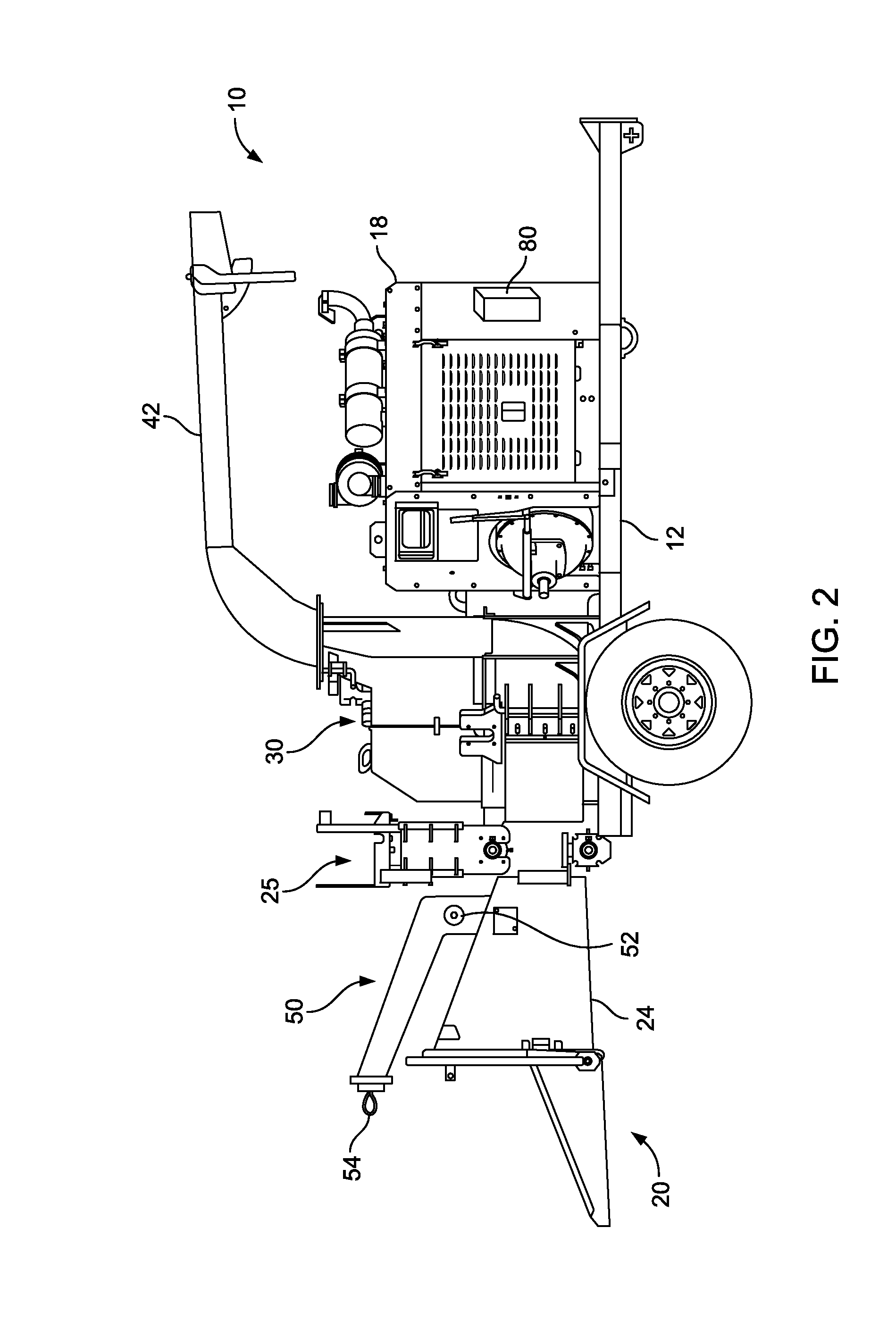

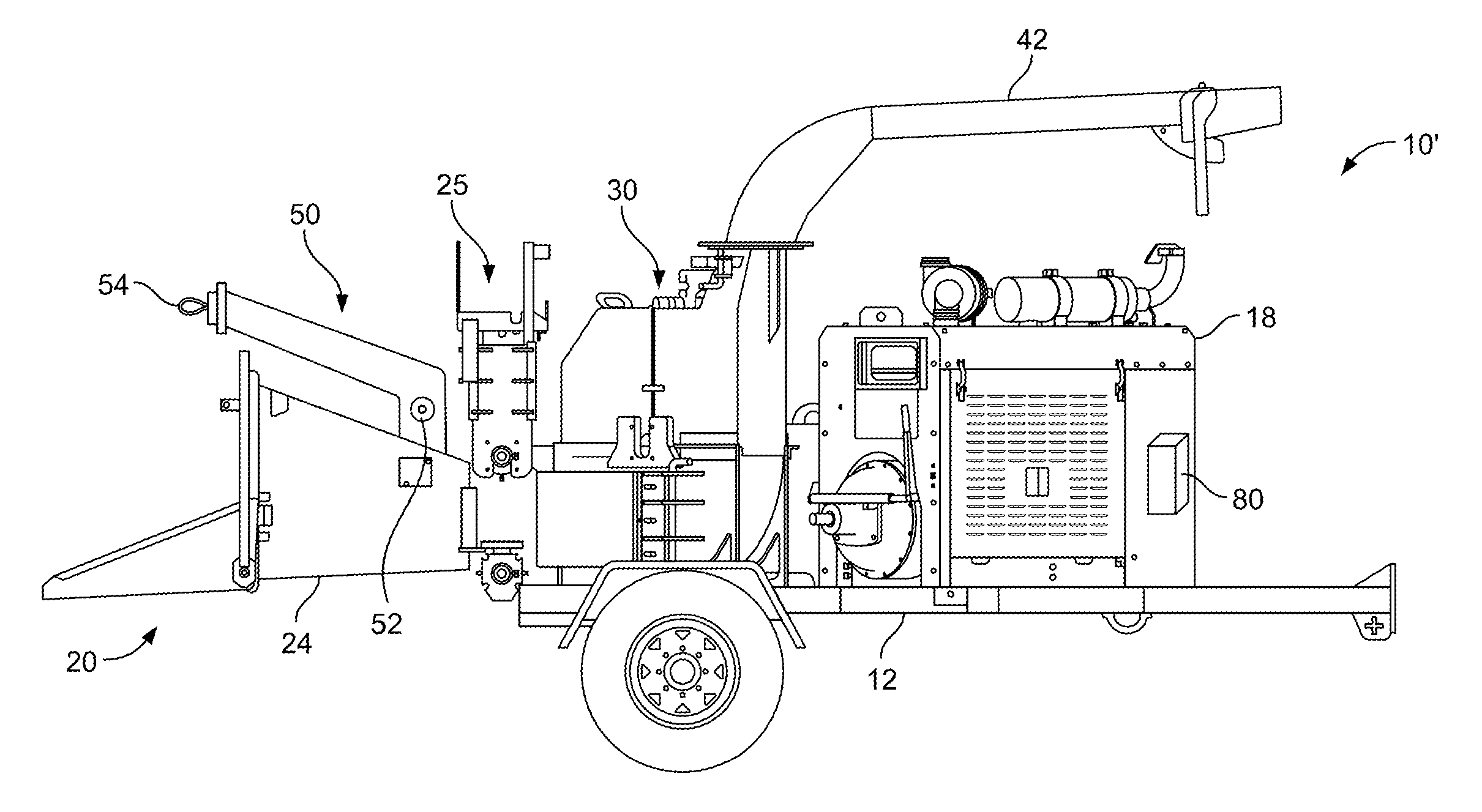

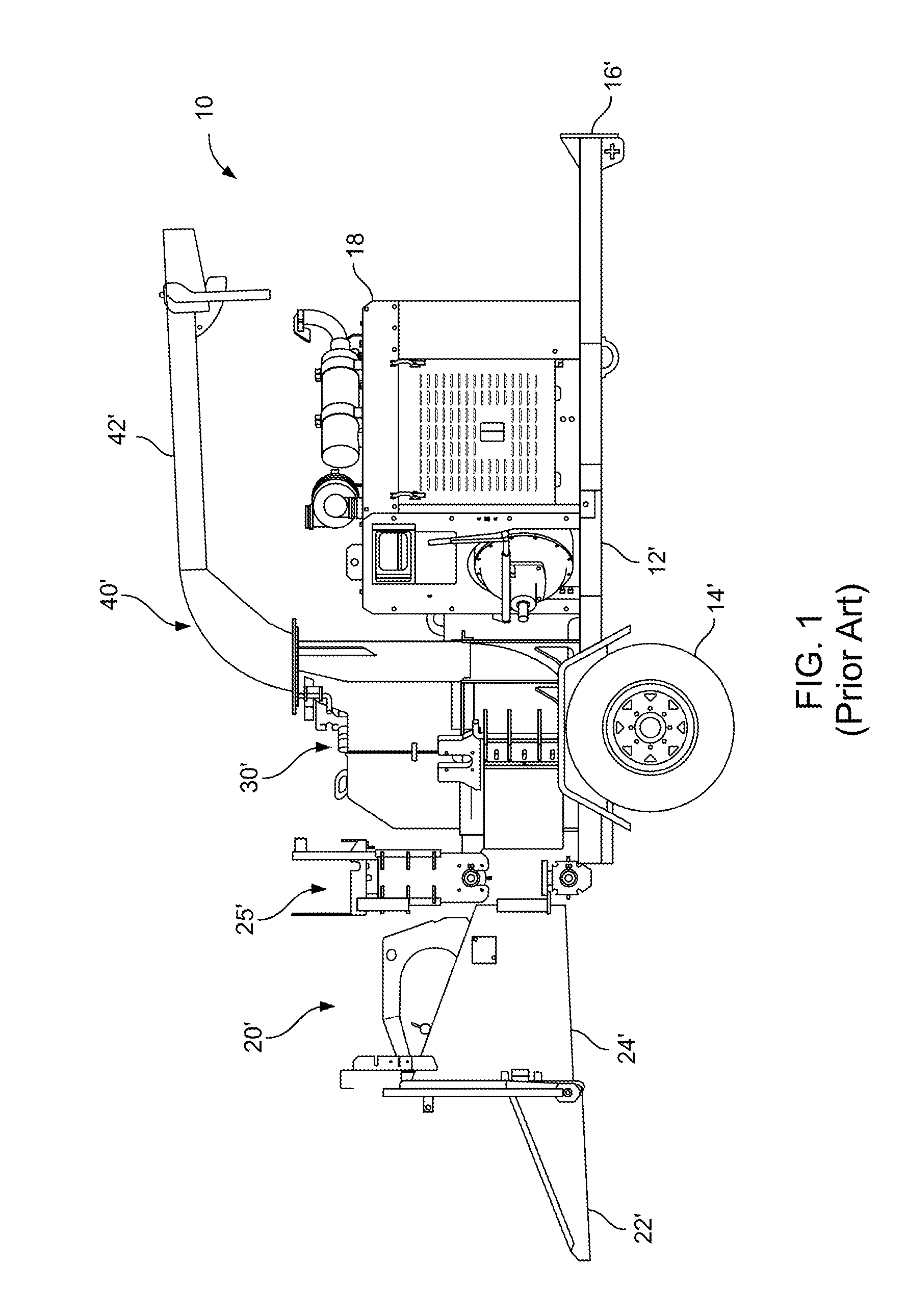

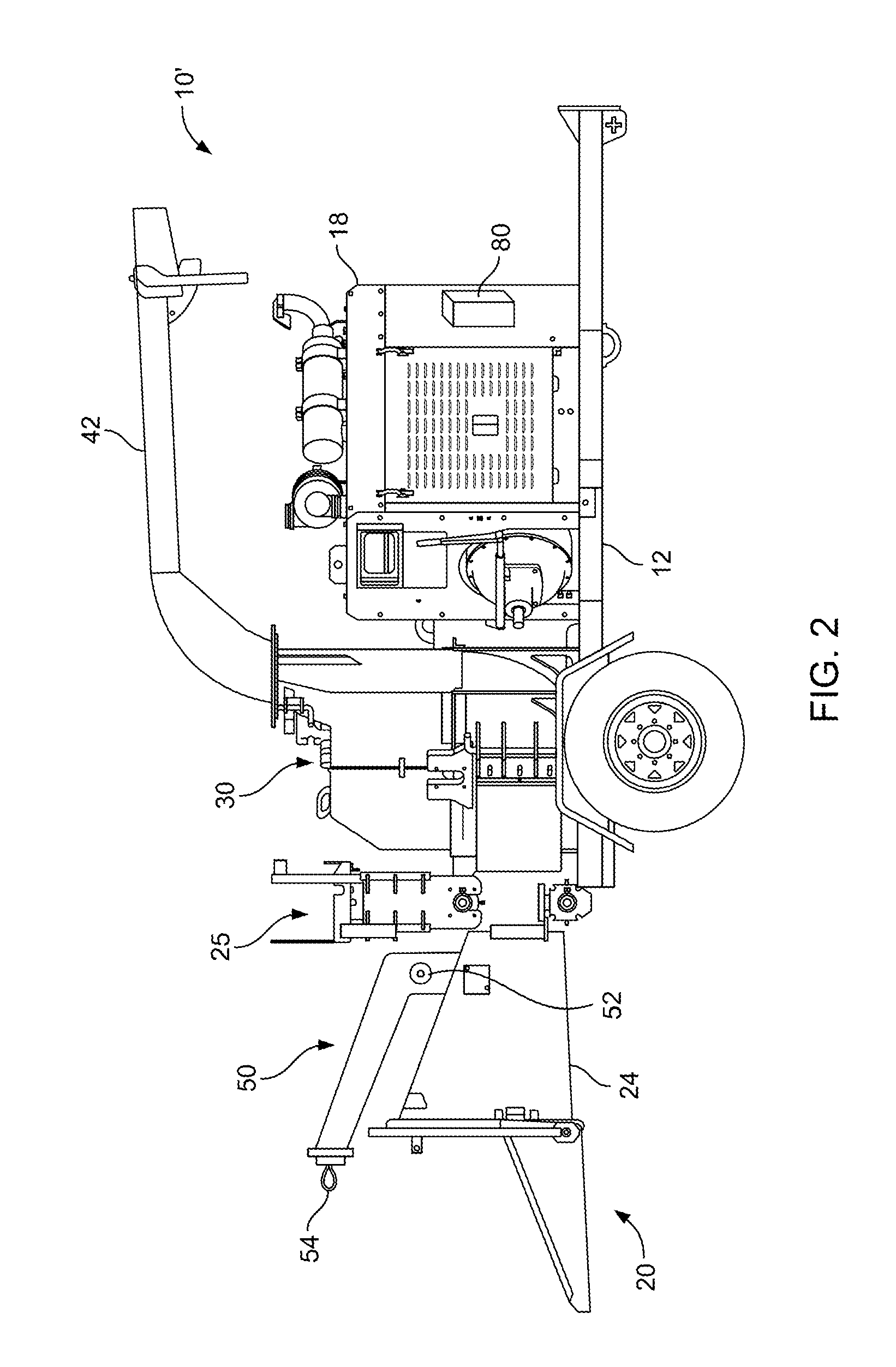

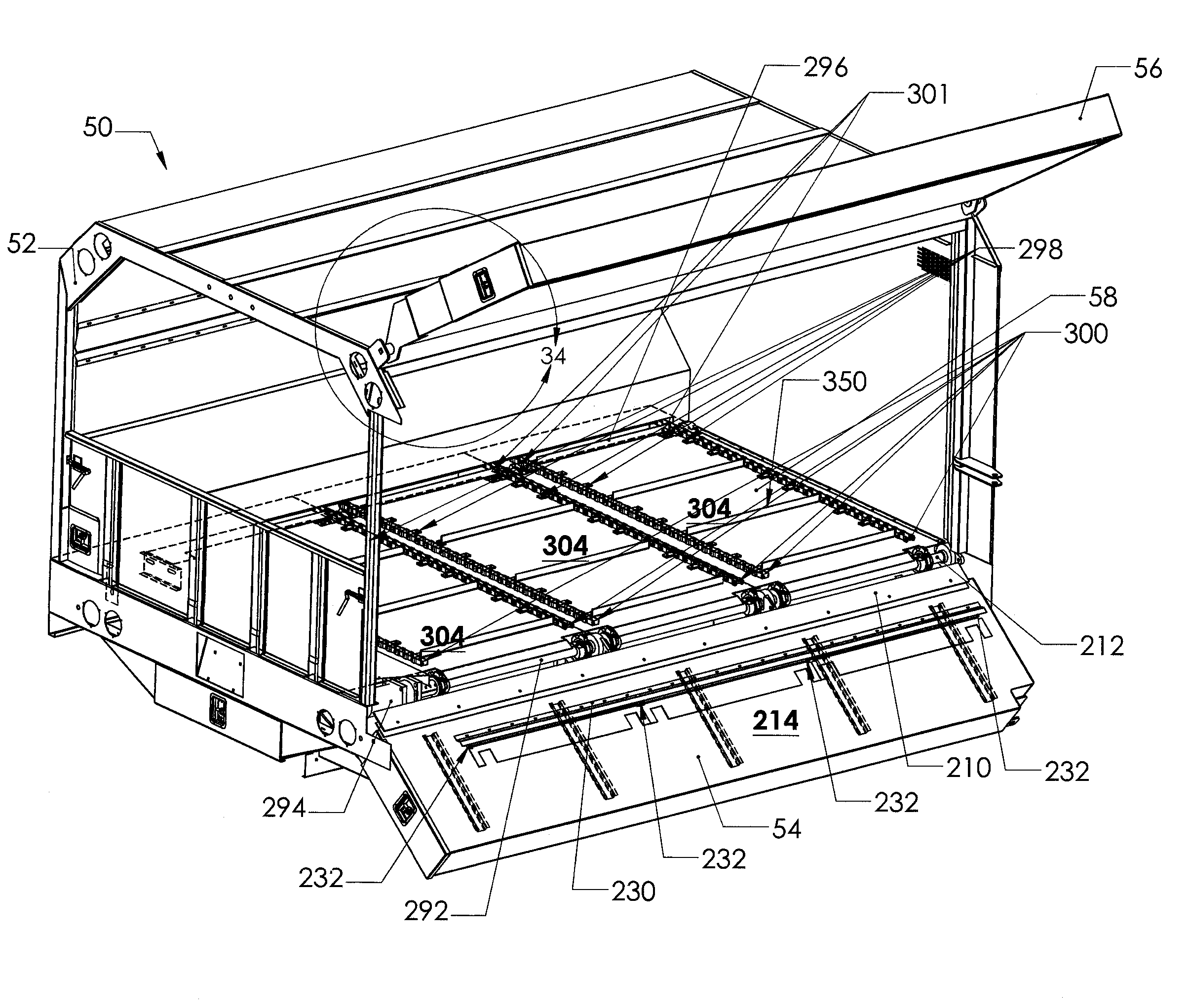

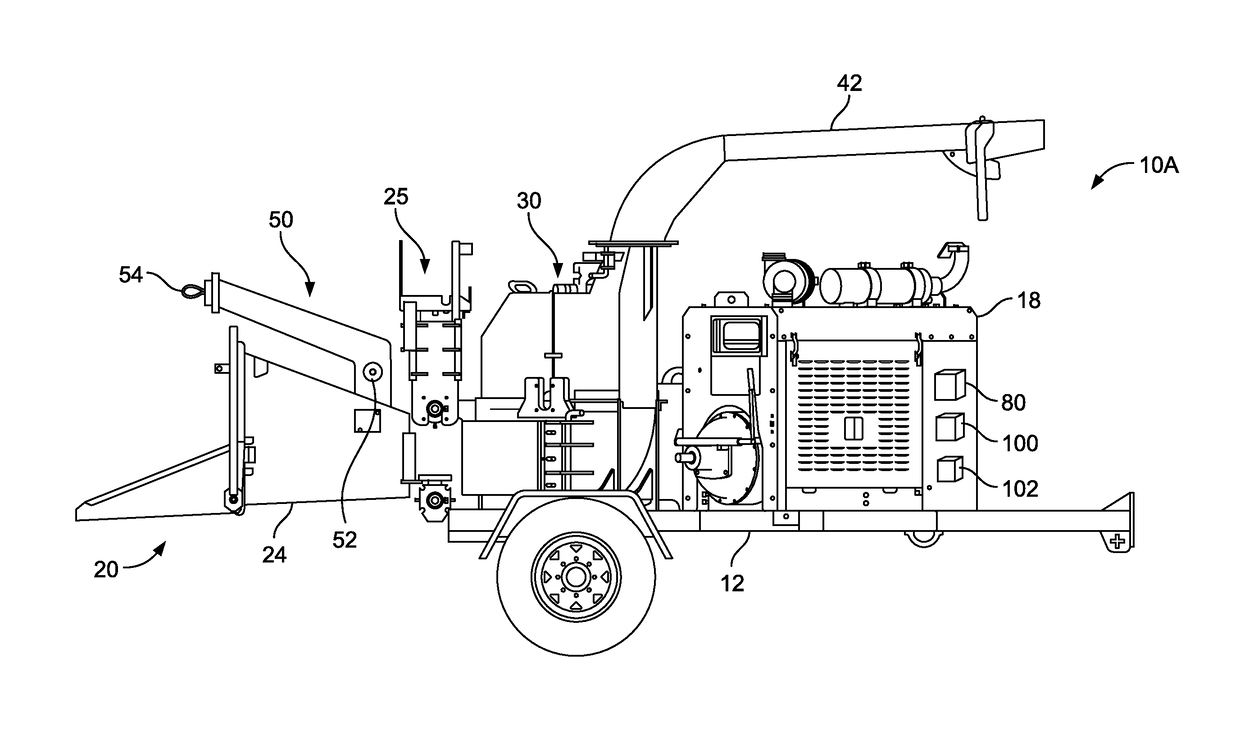

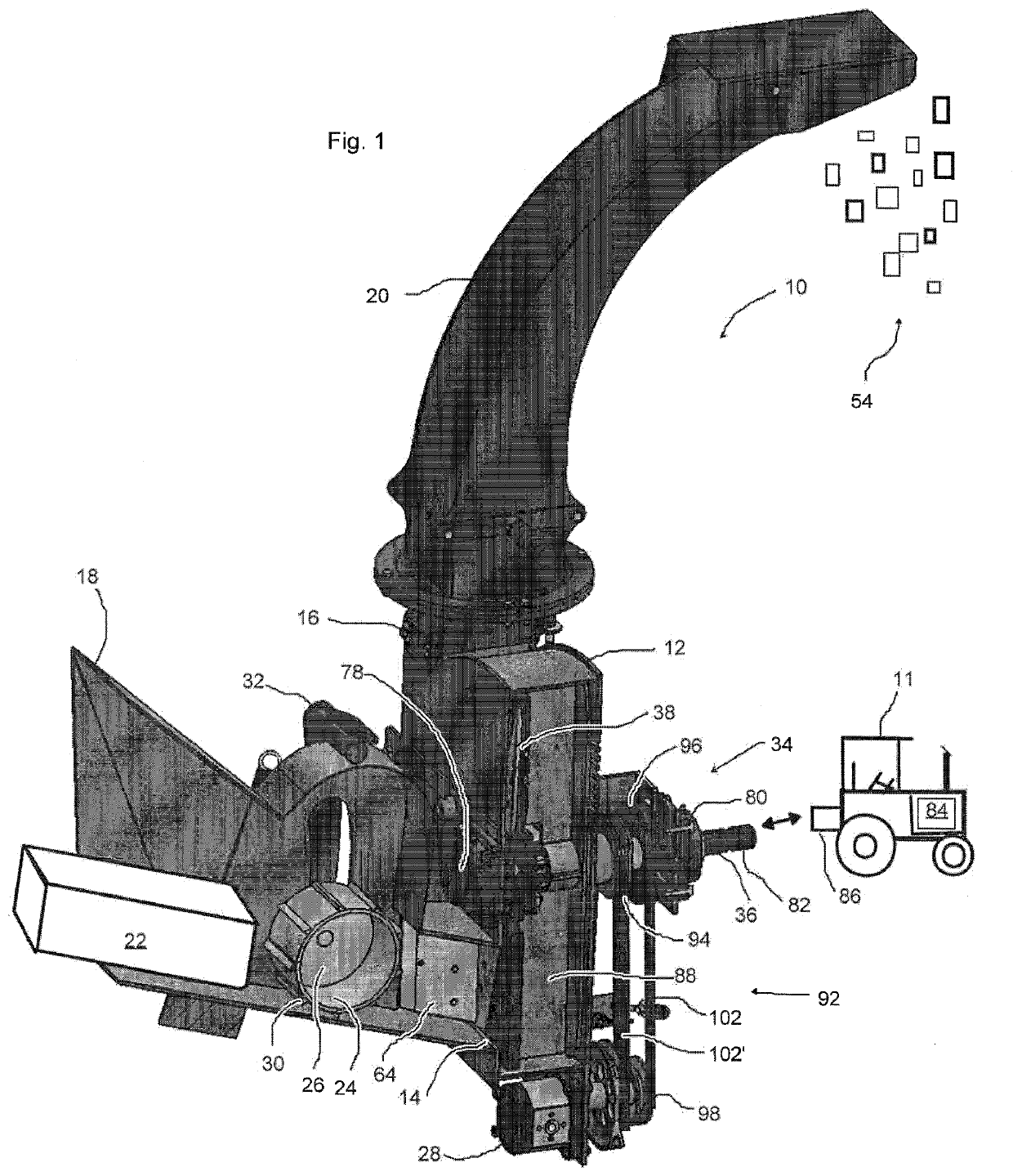

Wood chipper, control system therefor, and method thereof

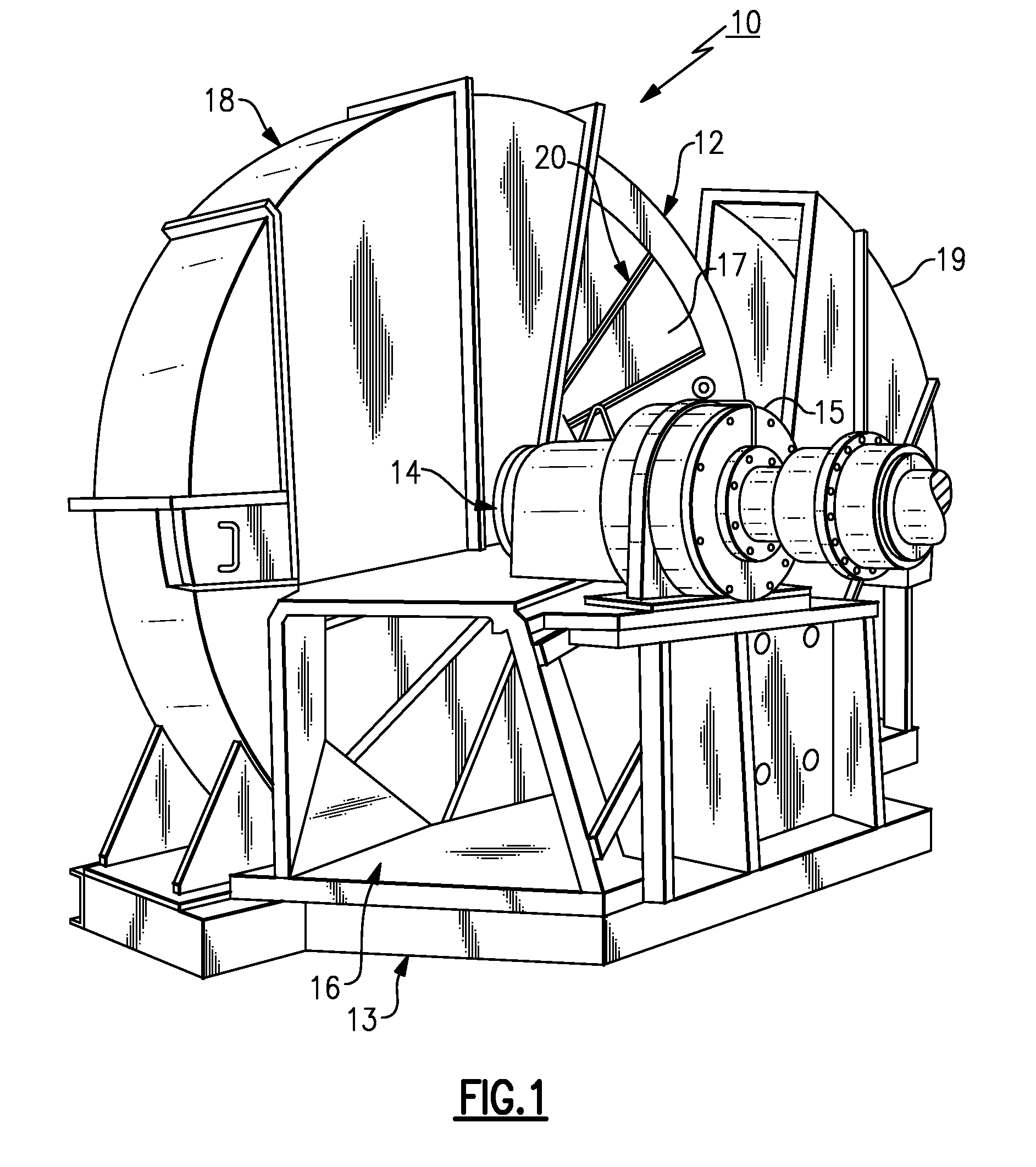

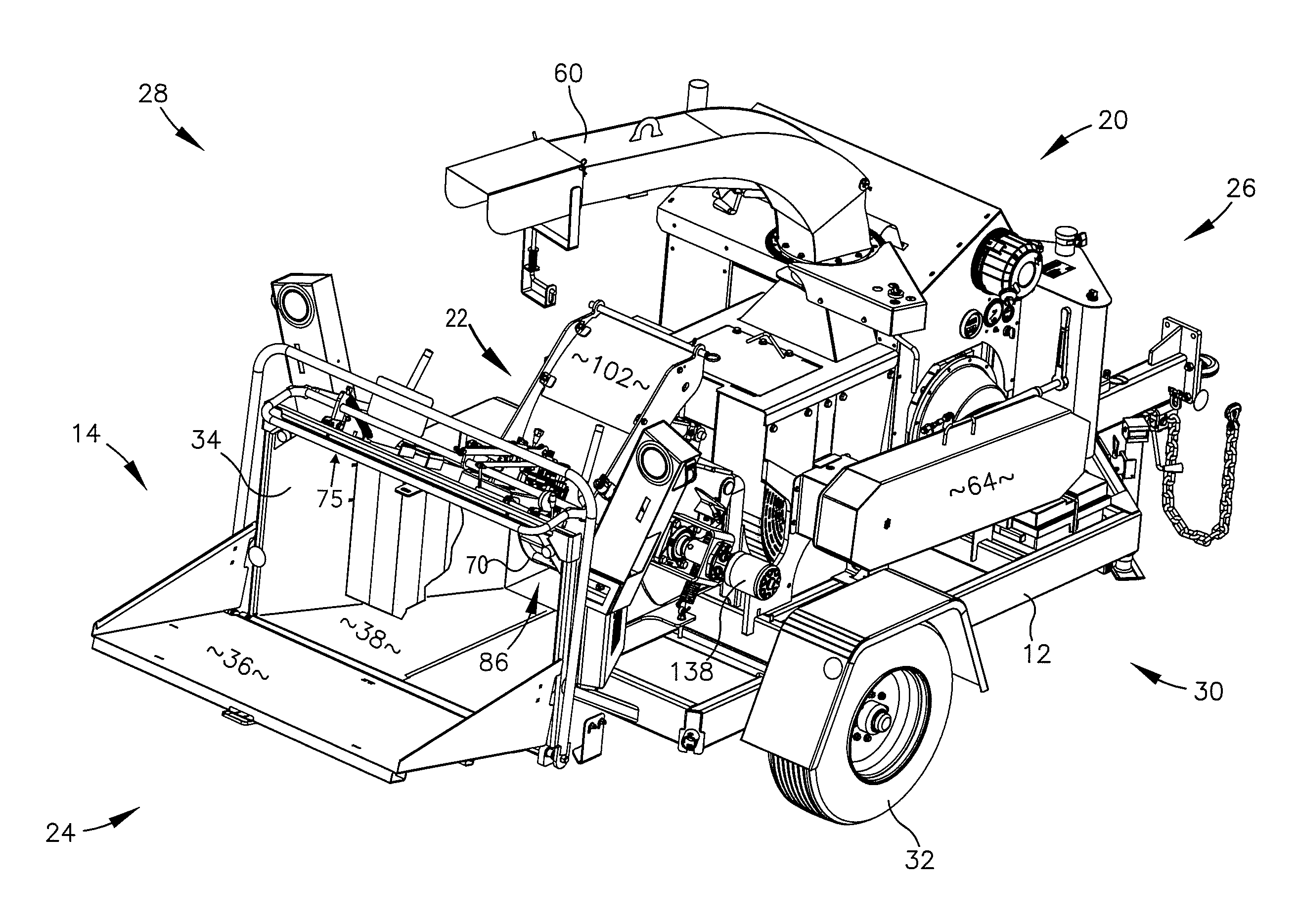

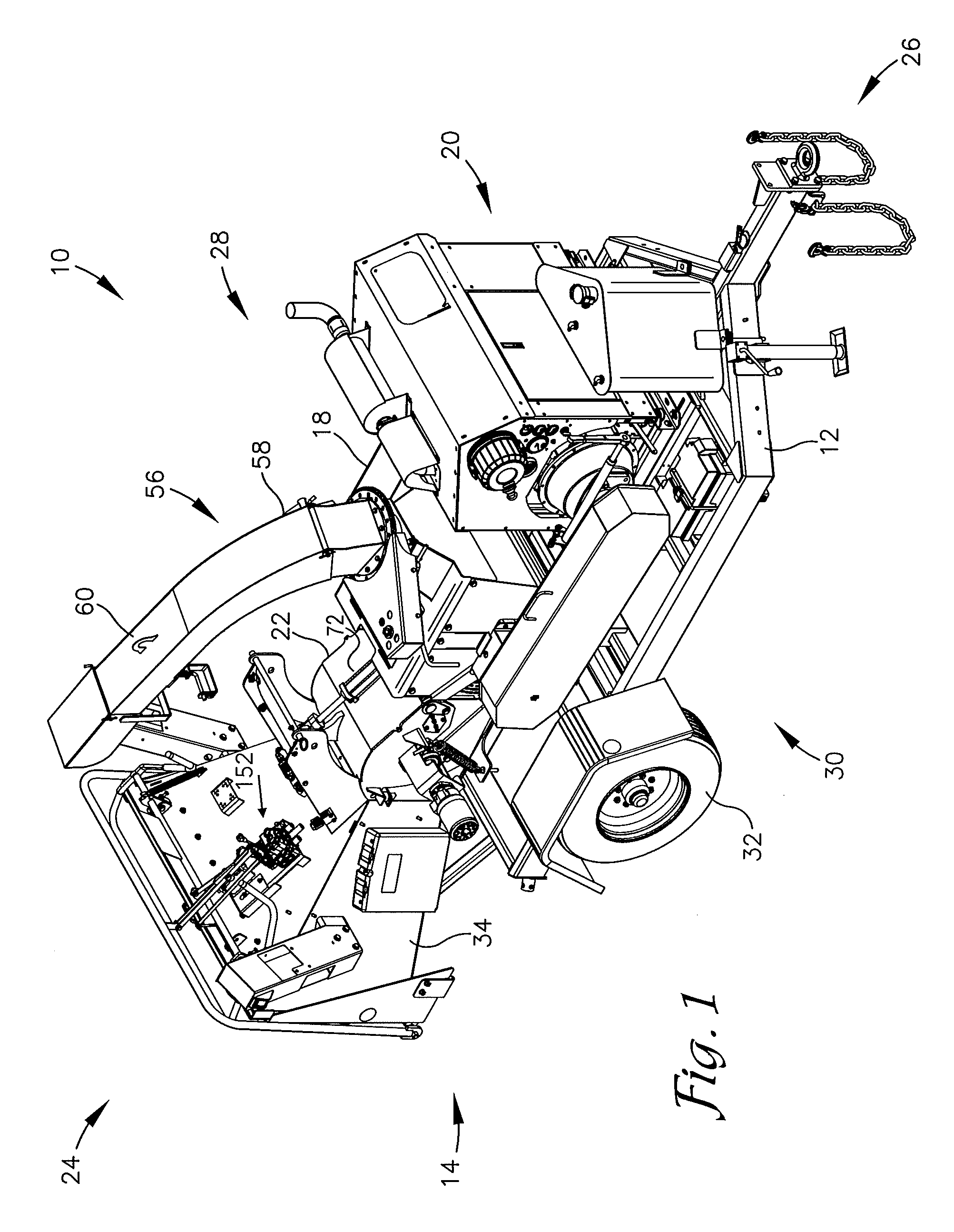

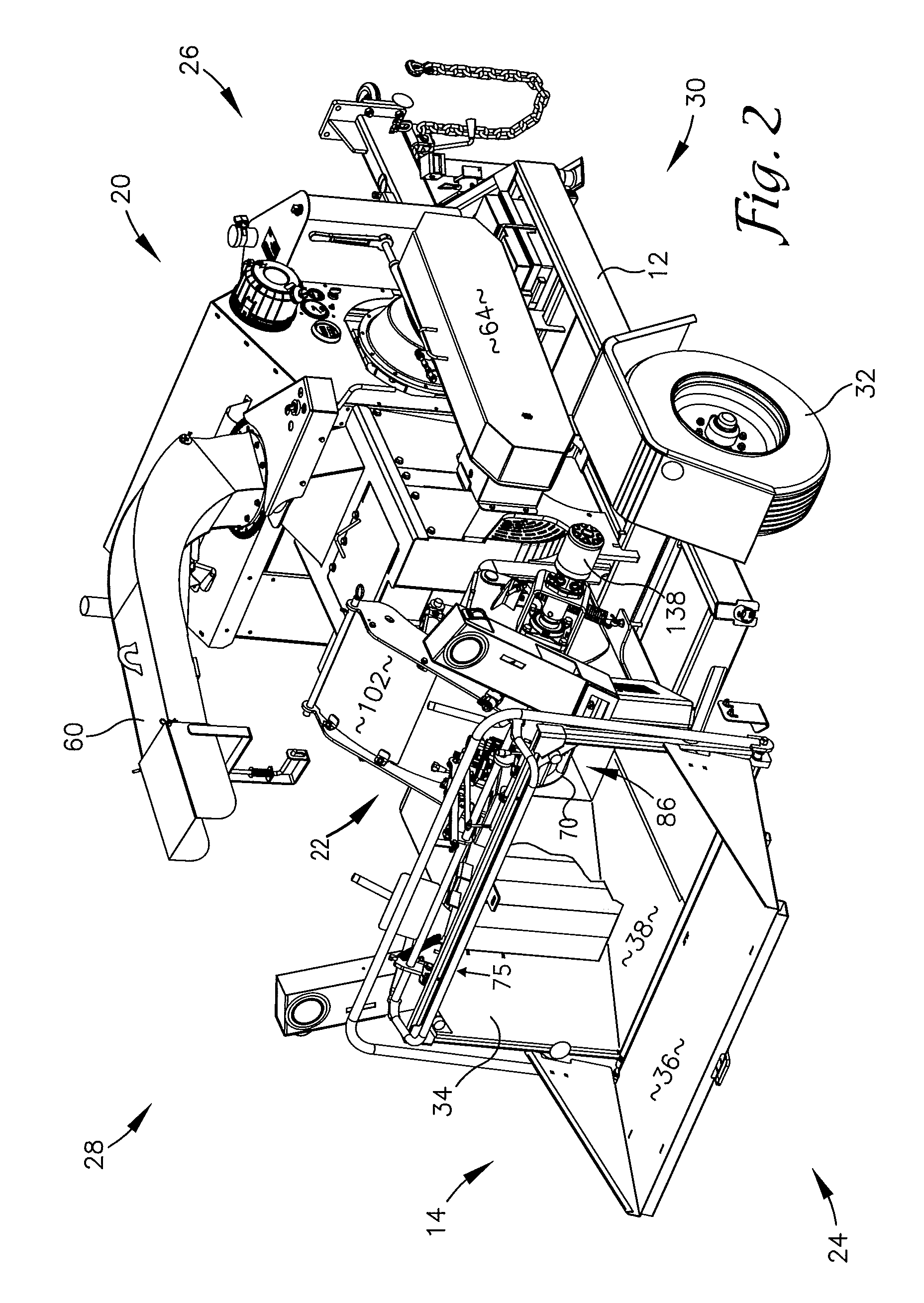

ActiveUS20130334346A1Reduce stepsPrecision positioning equipmentPlant waste comminutingControl systemWinch

A wood chipper comprises a frame, an infeed system, a rotatable cutting system, and at least one feed wheel disposed between the infeed system and the cutting system to feed wood material to the cutting system. The wood chipper also includes a winch comprising a winch line having a first end, and a collar disposed adjacent the first end of the winch line. The wood chipper further includes a detector adapted to detect a first and a second position of the winch line, wherein the detector is adapted to allow operation of the at least one feed wheel and prohibit operation of the winch when the first position of the winch line is detected, and to allow operation of the winch and allow operation of the at least one feed wheel in a predefined manner when the second position is detected. The wood chipper further comprises a bypass for operation of the at least one feed wheel.

Owner:BANDIT IND

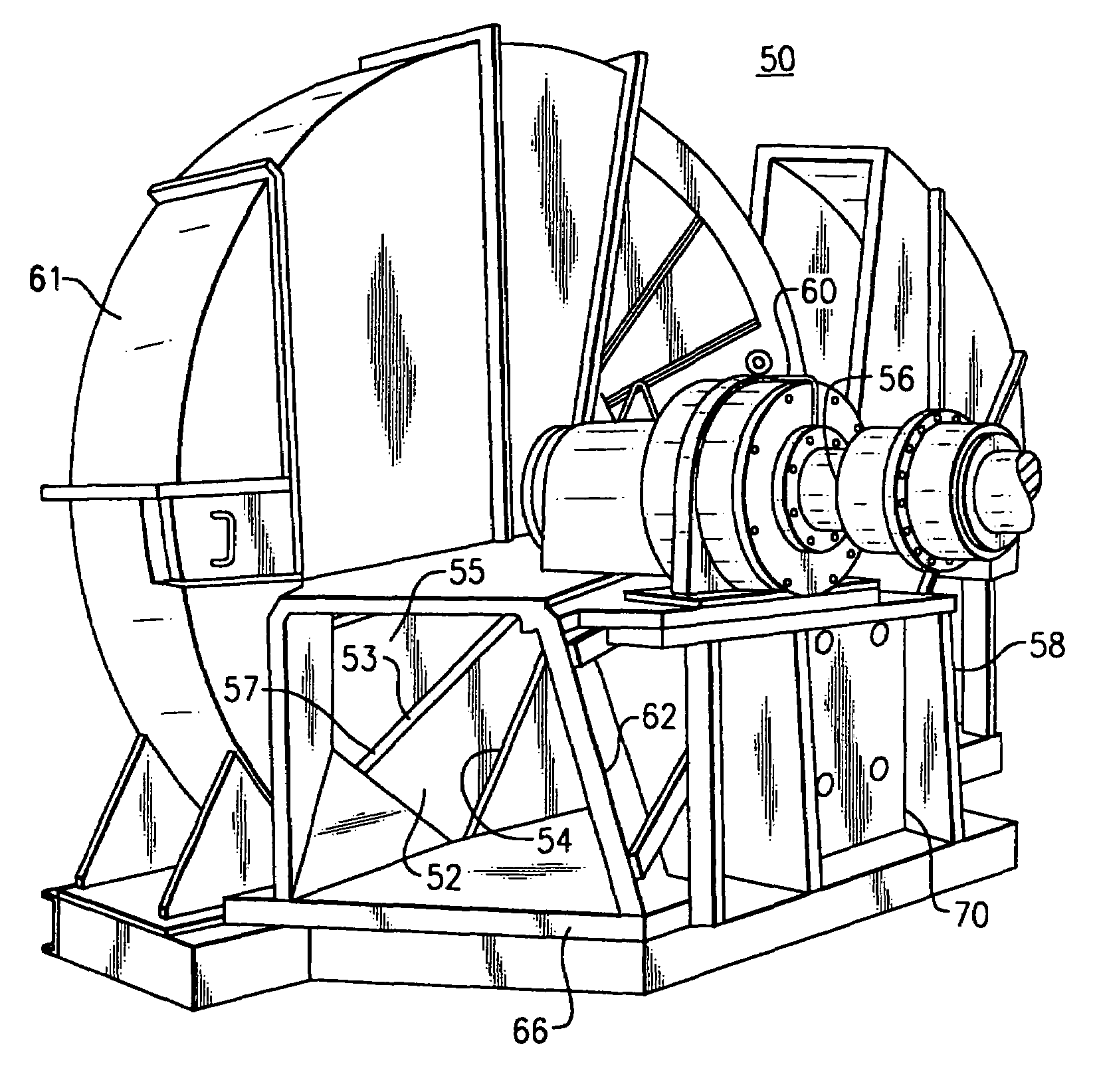

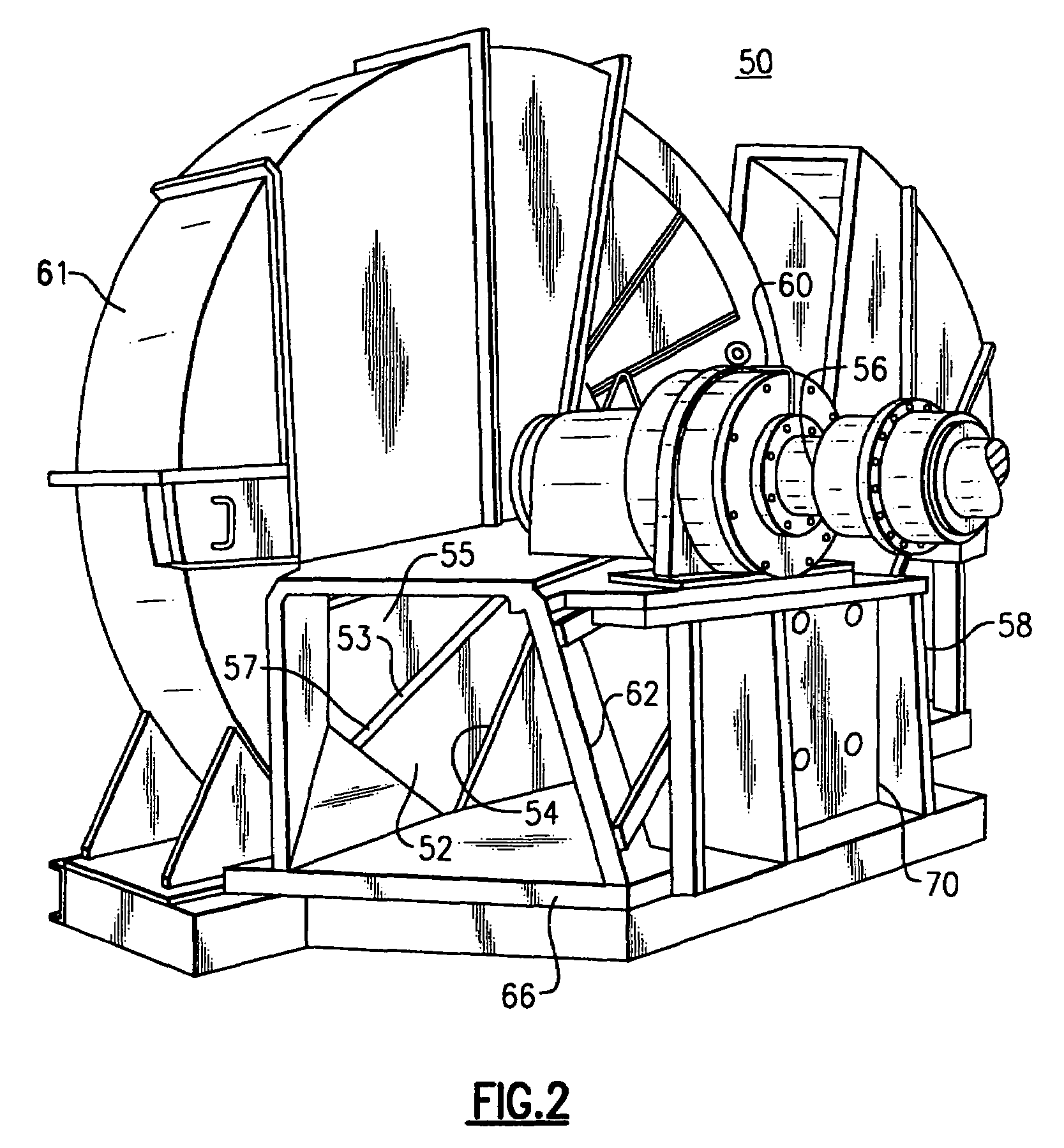

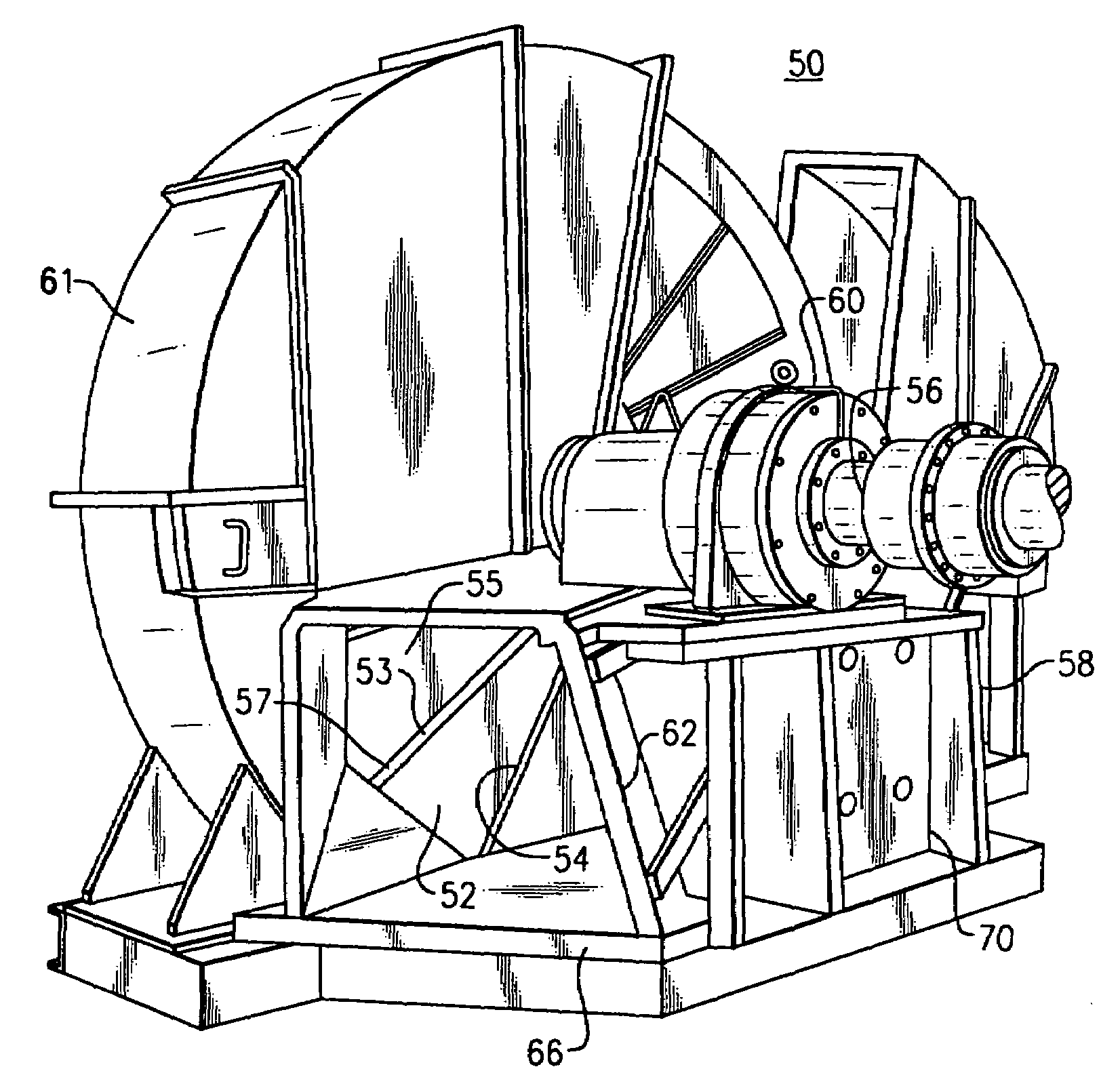

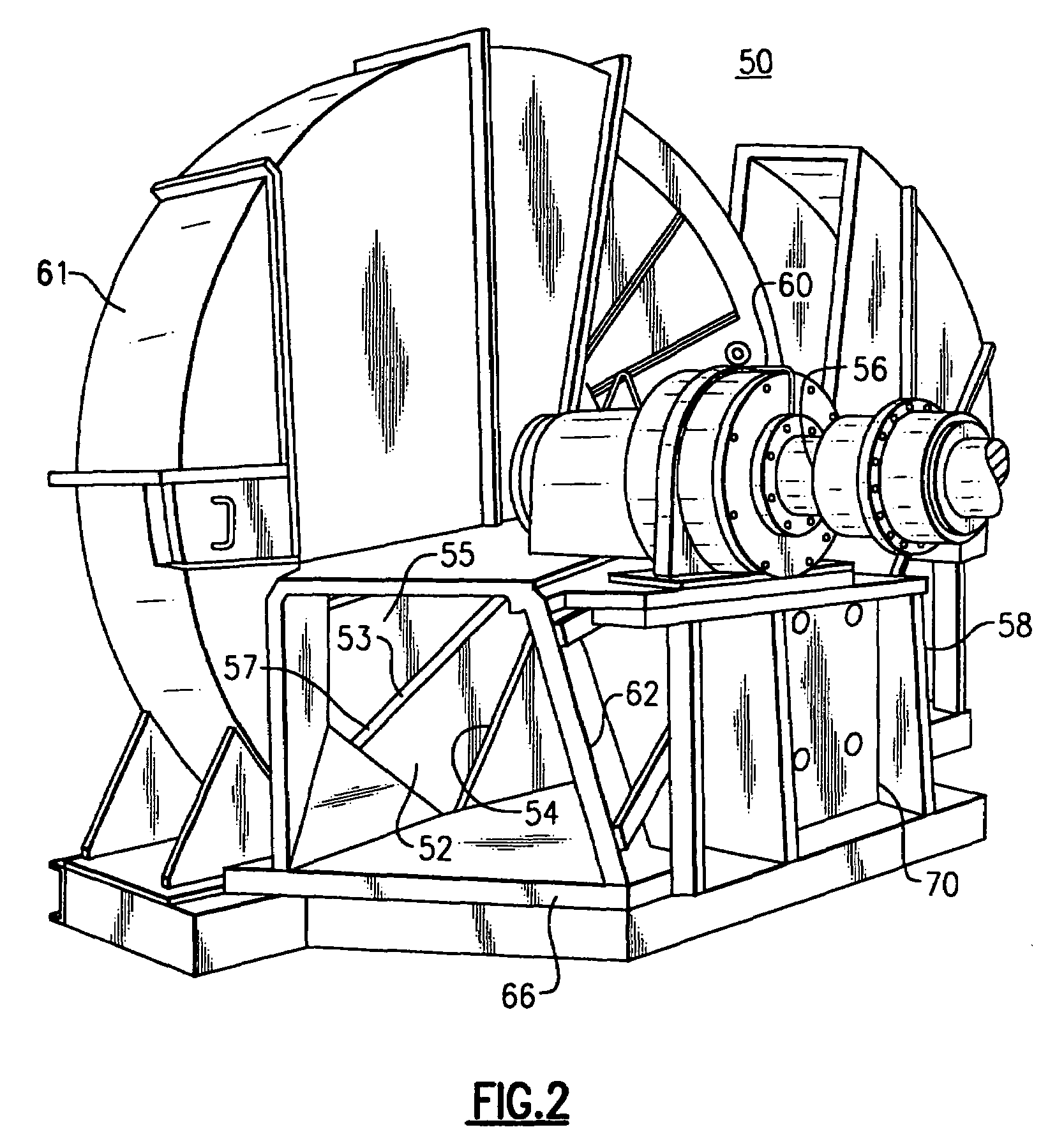

Flywheel and paddle assembly for a chipping or shredding apparatus, and an apparatus incorporating same

A flywheel and paddle assembly for a chipping or shredding apparatus, including a wood chipper, a brush chipper, and a leaf shredder. The assembly has a flywheel attached coaxially to a drive shaft. The flywheel has at least one aperture extending from the front side to the back side, and carries at least one knife adjacent to the at least one aperture. The knife presents a knife edge on the front side of the flywheel. A paddle is rotatably mounted coaxially to the drive shaft adjacent to the back side of the flywheel. The paddle is configured to rotate on the drive shaft independently of the flywheel. A chipping or shredding apparatus incorporating the aforesaid flywheel and paddle assembly is also disclosed.

Owner:WOODLAND MILLS INC

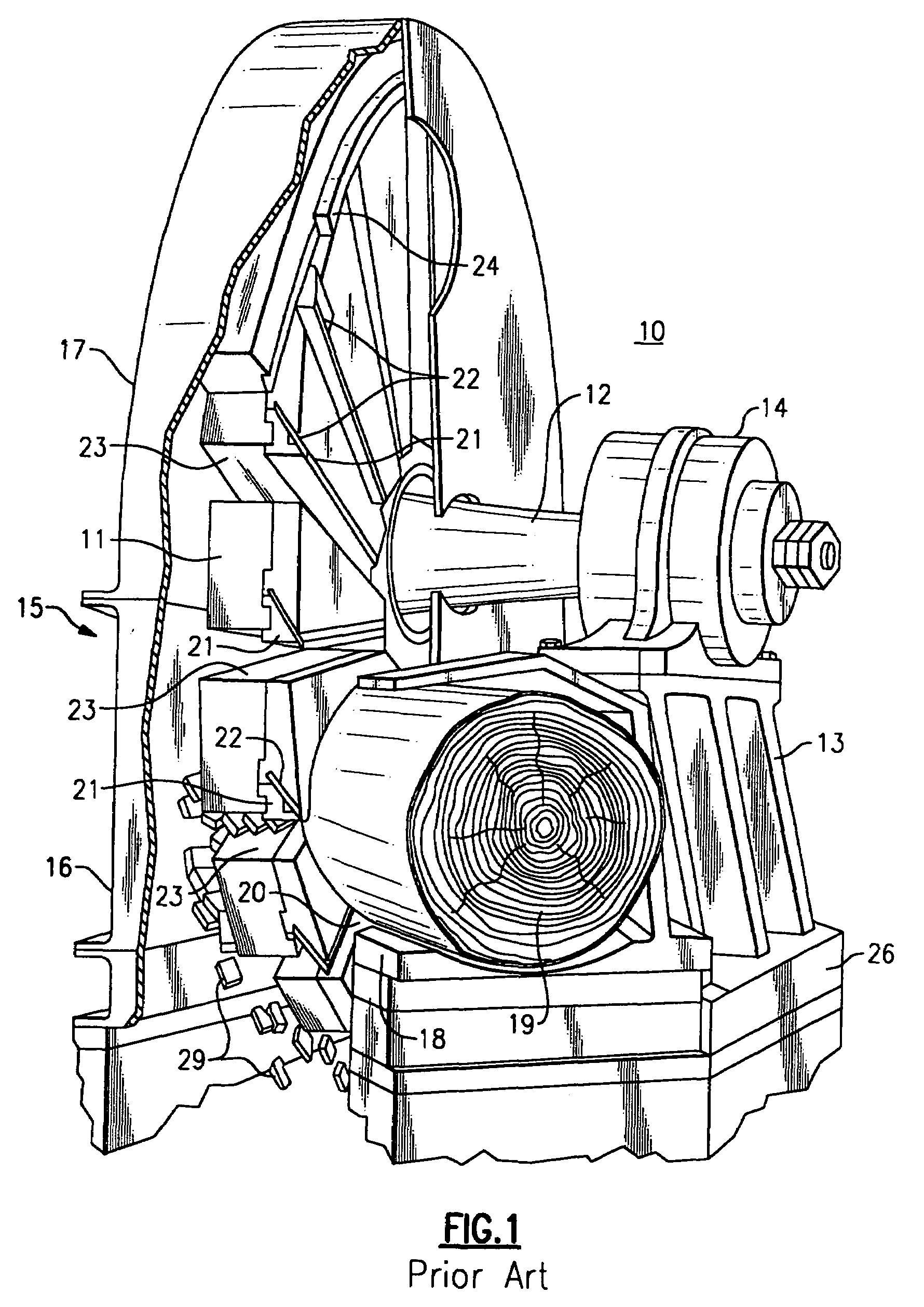

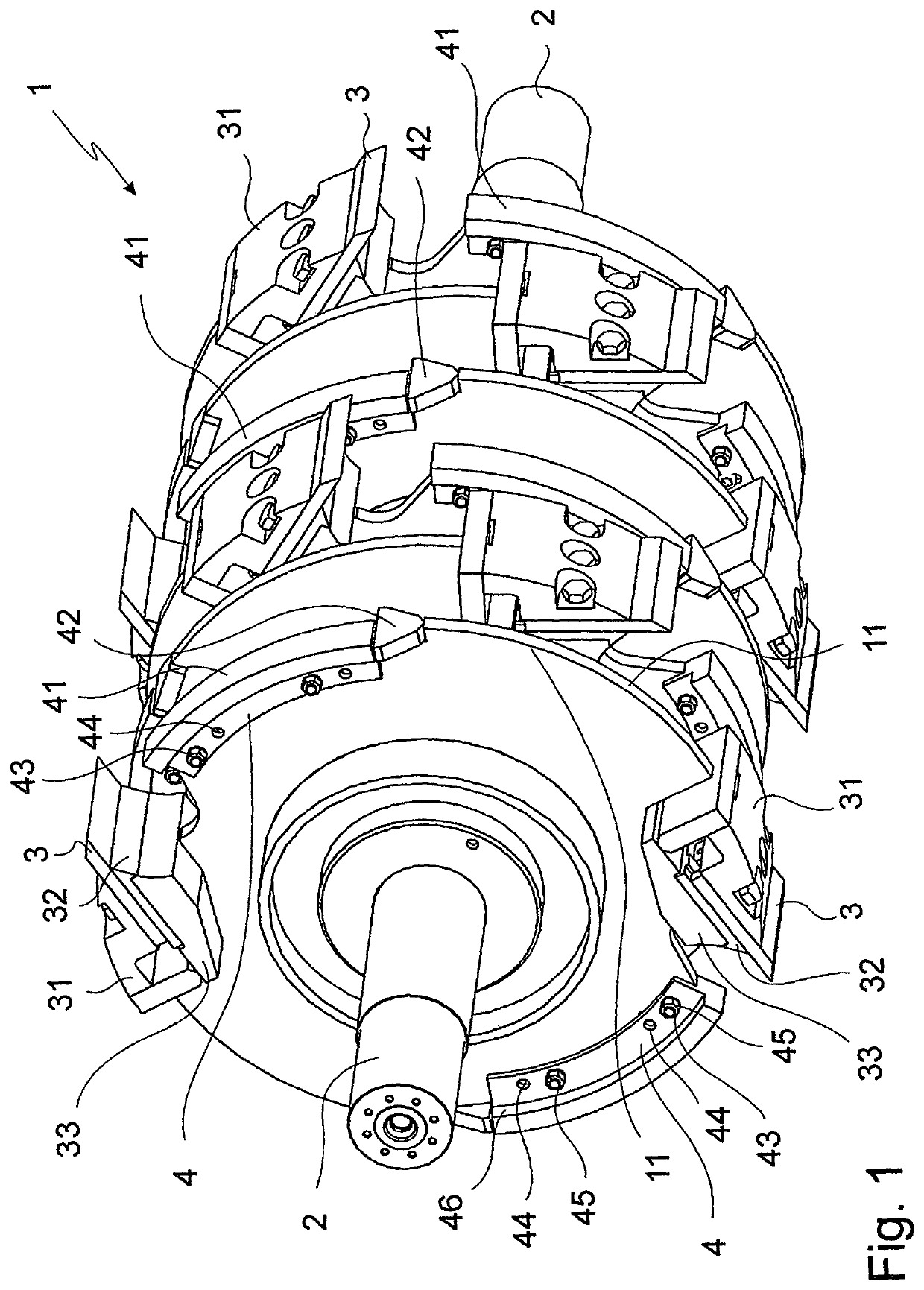

Canter chipper head

InactiveUS6923227B2Raise the gradeReduce vibrationMulti-purpose machinesProfiling/shaping machinesEngineeringMechanical engineering

The present invention provides a canter chipper head that comprises a rotor suitable for rotation about a rotation axis. The rotor has a lateral side and a frontal side, and includes a first cutting assembly and a second cutting assembly that are each mounted to the rotor. During rotation, the first cutting assembly defines a first lateral cutting surface around the rotation axis, and a first frontal cutting surface that is generally transverse to the rotation axis. The first lateral cutting surface and the first frontal cutting surface perform a primary cut in a log. The second cutting assembly defines a second lateral cutting surface around the rotation axis, and a second frontal cutting surface that is generally transverse to the rotation axis. The second lateral cutting surface and the second frontal cutting surface perform a secondary cut in the log that is deeper than the primary cut.

Owner:EQUIP HYDAULIQUE BOREAL

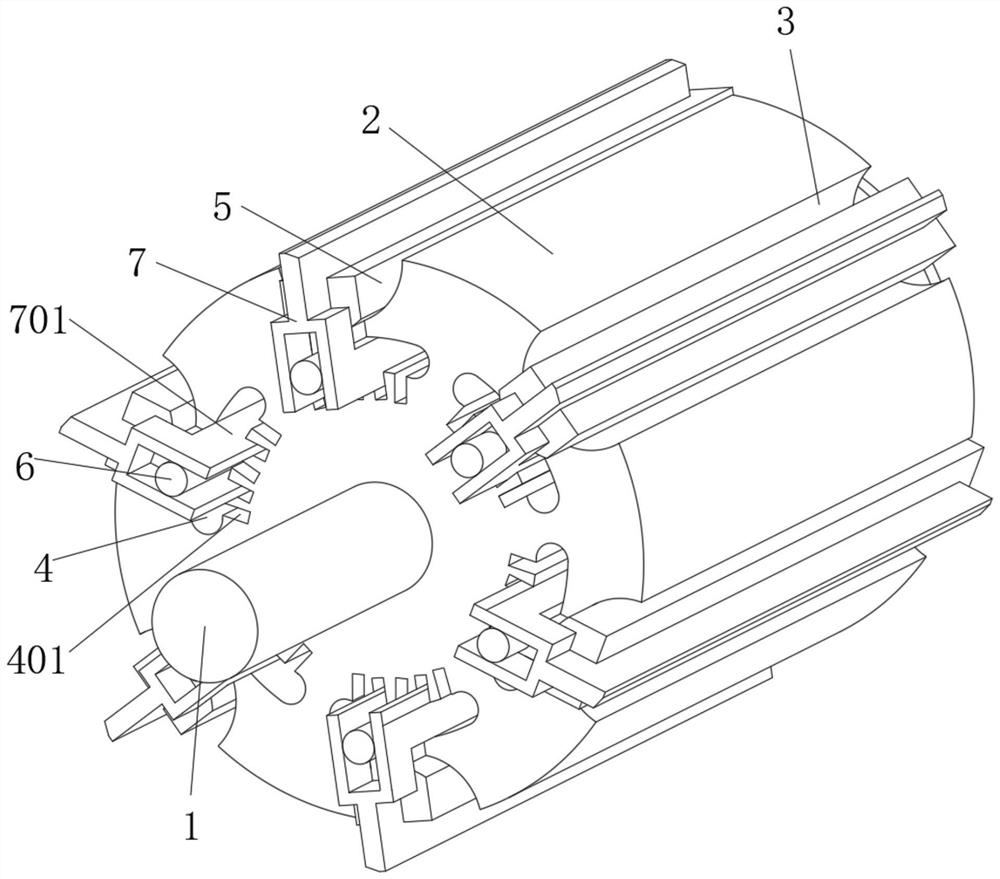

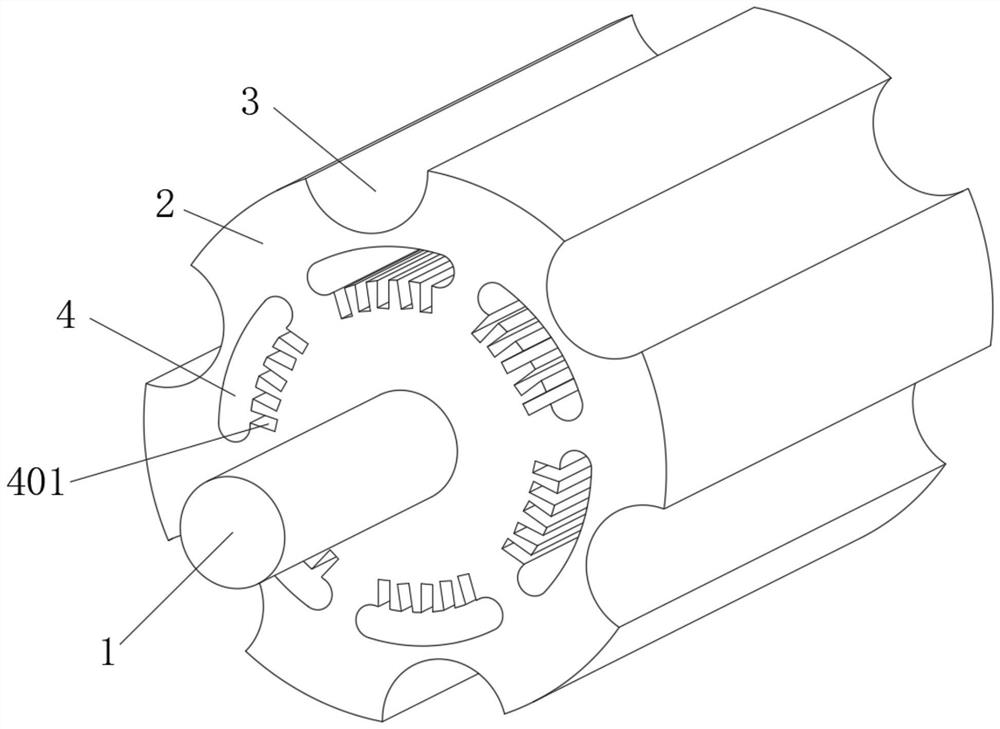

Drum chipper for wood processing

ActiveCN112248170APrevent disengagementConvenient card connectionVeneer manufactureButt jointWoodchips

The invention relates to the technical field of wood processing, and discloses a drum chipper for wood processing. The drum chipper comprises a transmission rod, a knife roll, a knife rest, a rotatingrod, a knife and a rotating disc. The transmission rod is fixedly connected with the center of the knife roll in a sleeving mode, six uniformly distributed arc-shaped grooves are formed in the outerring of the knife roll, a through angle groove is formed in the inner side of the knife roll, a butt joint groove is formed in one side of the angle groove, the bottom of the knife rest is fixedly connected with the rotating rod, one end of the rotating rod is fixedly connected with the rotating disc, and a positioning hole is formed in the end, close to the rotating disc, of the knife rest. By arranging the knife rest and the rotating rod, the angle of the knife rest can be adjusted under the driving of the rotating rod, so that the angle of the knife on the knife rest is adjusted, and the thickness of a cut wood chip can be controlled; and the rotating rod can only drive the knife rest to perform circular motion by arranging the angle groove, and the possibility that the knife rest is separated from the knife roll is avoided.

Owner:永康市东汇科技有限公司

Wood chipper, control system therefor, and method thereof

ActiveUS20130025744A1Precision positioning equipmentPlant waste comminutingControl systemAgricultural engineering

A wood chipper comprises a frame, an infeed system, a rotatable cutting system, and at least one feed wheel disposed between the infeed system and the cutting system to feed wood material to the cutting system. The wood chipper also includes a winch comprising a winch line having a first end, and a collar disposed adjacent the first end of the winch line. The wood chipper further includes a detector adapted to detect a first and a second position of the winch line, wherein the detector is adapted to allow operation of the at least one feed wheel and prohibit operation of the winch when the first position of the winch line is detected, and to allow operation of the winch and allow operation of the at least one feed wheel in a predefined manner when the second position is detected.

Owner:BANDIT IND

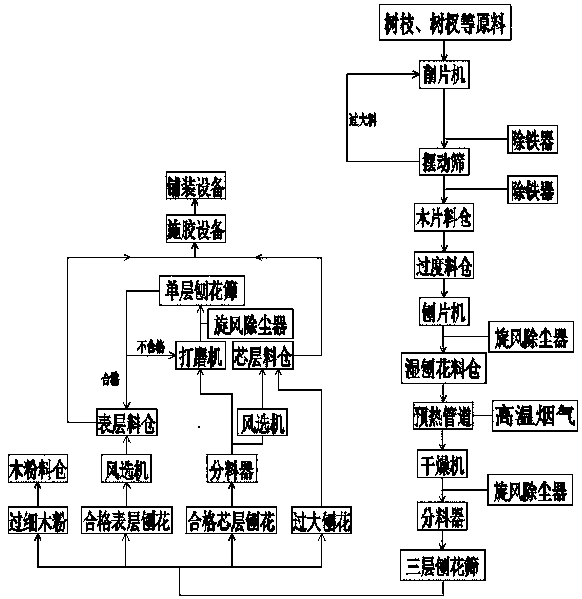

Ultra-strong shaving board production process

InactiveCN110682393AHigh static bending strengthImprove inner bonding strengthWood veneer joiningDomestic articlesDust controlCyclonic spray scrubber

The invention discloses an ultra-strong shaving board production process. The ultra-strong shaving board production process comprises the steps that (1), raw materials are chipped and conveyed to a swing screen, and metal components are excluded in the conveying process; (2), after the swing screen screens the raw materials, large wood chips are returned to a chipping machine for reprocessing, andthe qualified wood chips enter a wood chip stock bin and then enter a transition stock bin; (3), after the wood chips are flaked, the wood chips enter a wet shavings stock bin; (4), wet shavings arepreheated through a preheating pipeline and then enter a dryer for drying; (5), after drying, the shavings are subjected to dust removal through a cyclone dust collector, and then the shavings are separated through a material separation device and enter a three-layer shavings screen for screening; and (6), the three-layer shavings screen screens out large shavings, qualified core layer shavings and qualified skin layer shavings. By the adoption of the ultra-strong shaving board production process, the static bending strength and the inner gluing strength of shaving boards are greatly improved,the physical and mechanical properties are improved, the density is relatively reduced, raw materials are saved compared with similar products, the cost input is reduced, the energy consumption is reduced, and the function of saving glue is achieved.

Owner:临沂兴滕人造板机械有限公司

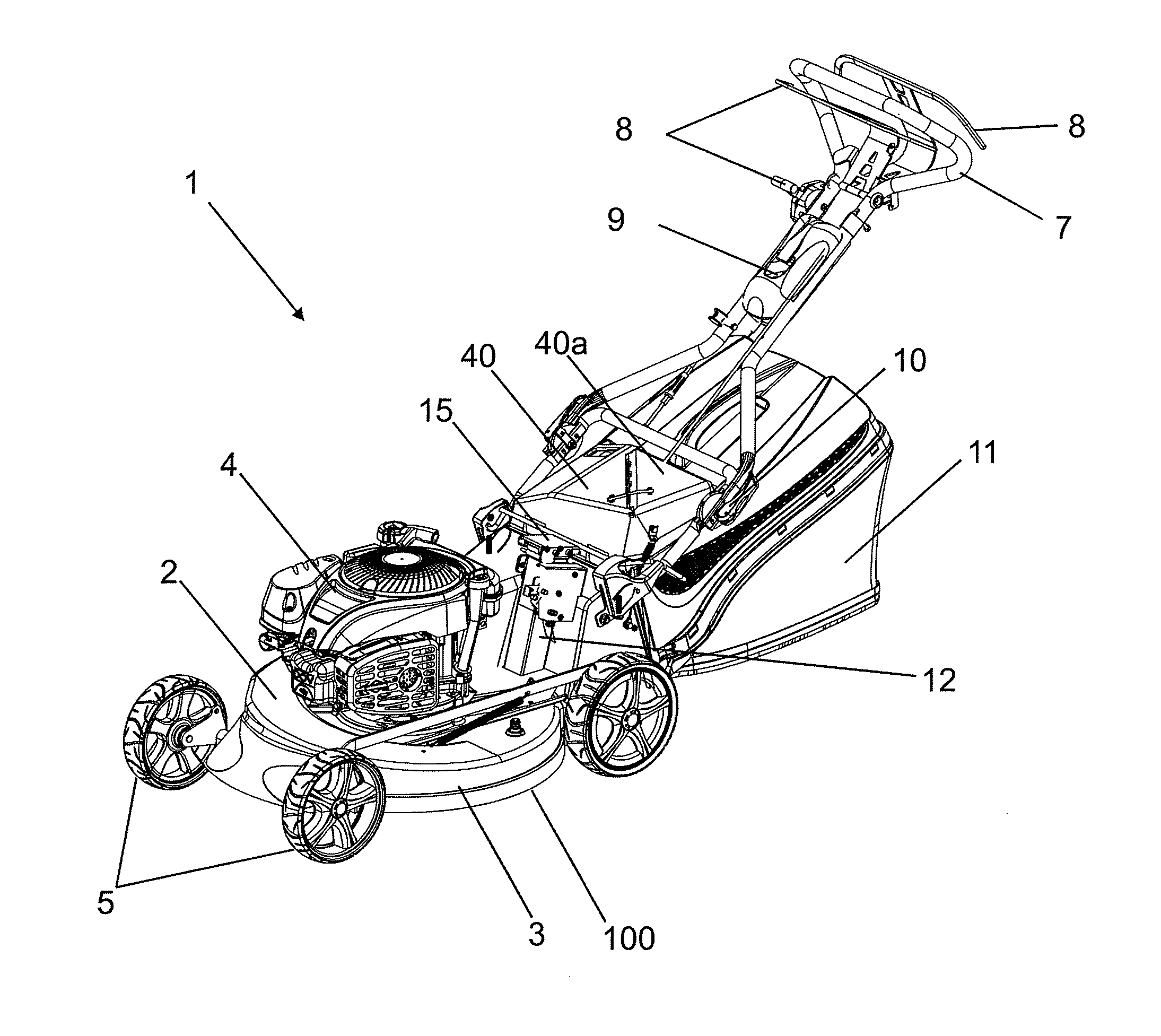

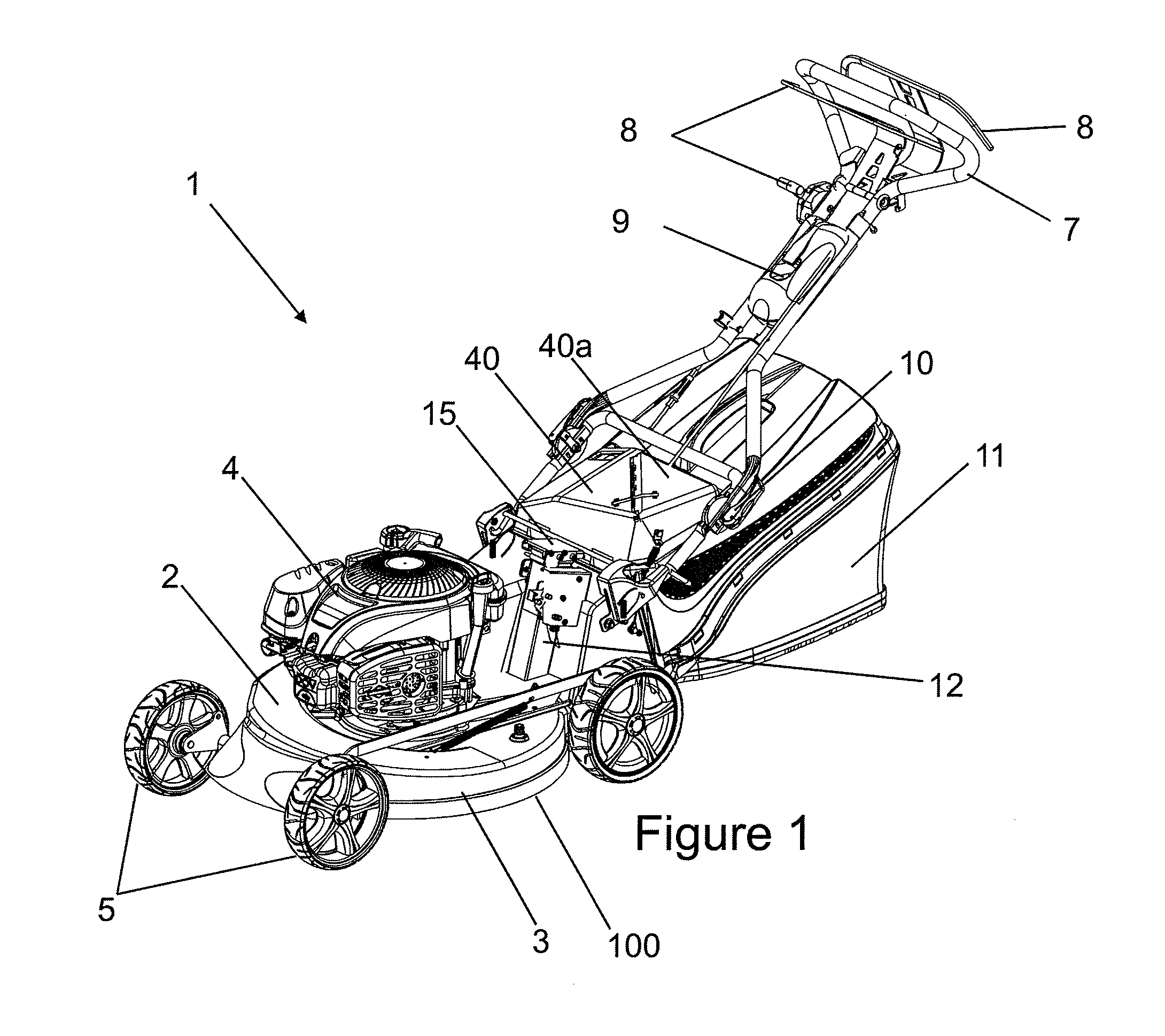

Lawnmower safety

The invention relates to safety improvements for mowers incorporating a chipper, and / or catcher. In one aspect the invention provides safety improvements that only allow operation of the chipper when the mower is below a predetermined threshold ride height. In another aspect, the mower includes one or more side skirts to prevent body parts from entering the cutting zone under the mower. In a still further aspect, the mower has a rear flap including a sub-flap. The mower is arranged so that the sub flap remains closed when a catcher is installed.

Owner:MASPORT

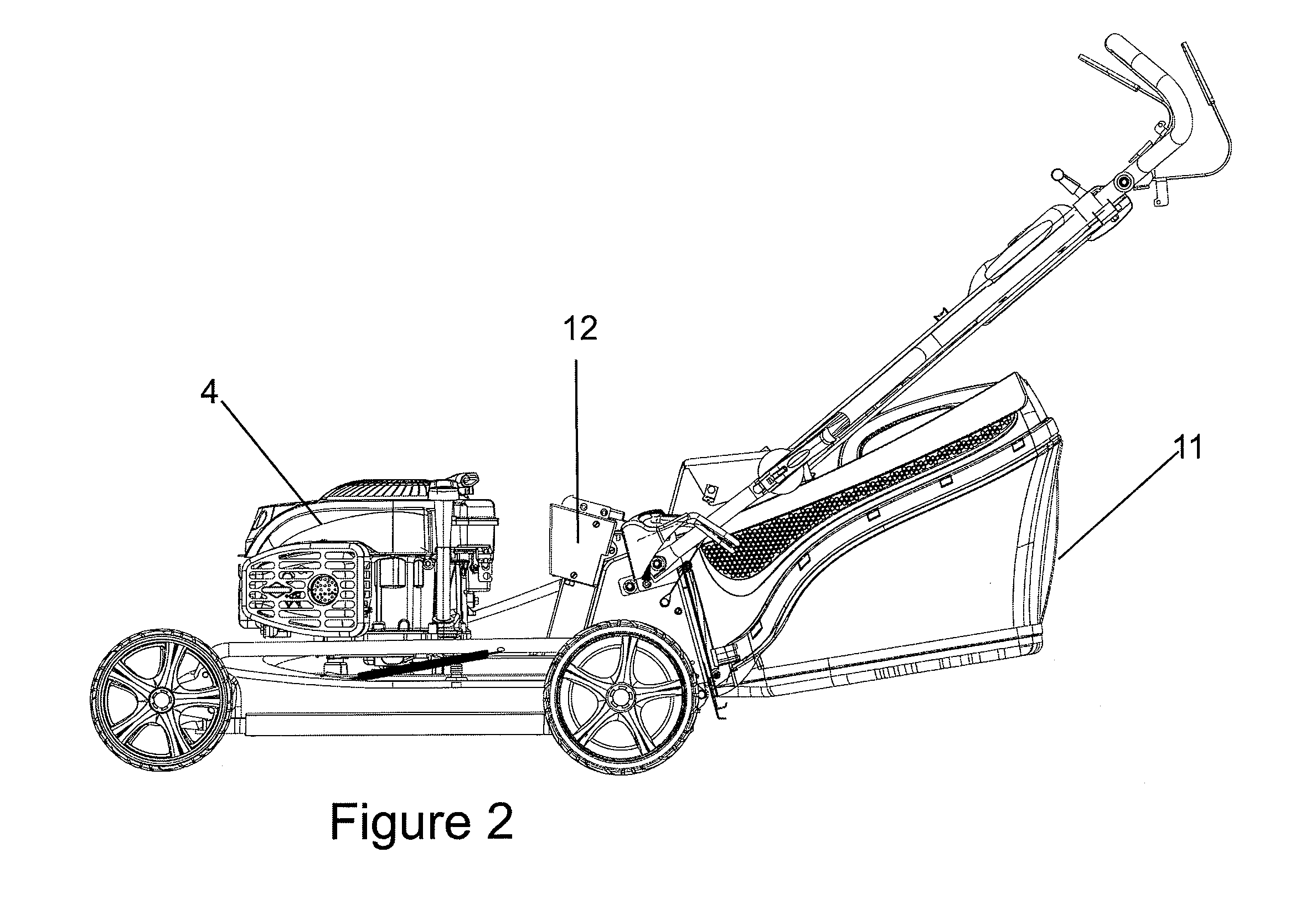

Method of operating a wood chipper and power transmission system for use therewith

ActiveUS7658215B2Automatic control devicesPrecision positioning equipmentElectric power transmissionDrivetrain

A wood chipper includes a control system for controlling feed wheel rotation and engine operation to provide safety features and a fuel-saving mechanism. The control system allows the engine to start only when the feed wheel is in neutral; stops and / or reverses rotation of the feed wheel in response to an increased load on the engine; and dethrottles the engine if the feed wheel remains in neutral for a predetermined period of time. A pair of electric switches are activatable by the feed bar whereby an electronic control unit (ECU) can determine the position of the feed bar based on activation or non-activation of the switches and control the feed wheel and engine in light thereof. The ECU controls a pair of directional control valves via respective solenoids to control flow of hydraulic fluid to control rotation of a feed motor which drives the feed wheel.

Owner:ALAMO GROUP

Crushing method for recycling bark resources

ActiveCN102009422AHigh yieldReduce energy consumptionWood working apparatusRaw material divisionEngineeringCrusher

The invention discloses a crushing method for recycling bark resources, which comprises the following steps of: (1) collecting barks and conveying to a belt conveyer; (2) conveying the barks to bark crushing equipment by using the belt conveyer; and (3) crushing the barks by using a drum chipper, and conveying the barks to a bark storehouse through the belt conveyer. By adopting the drum chipper, the bark crushing capacity and efficiency can be improved, the energy consumption can be reduced, particularly longer barks which contain bast fibers and are high in toughness and hardly crushed by the conventional crusher can be treated, and the energy consumption is reduced greatly.

Owner:湖南骏泰新材料科技有限责任公司

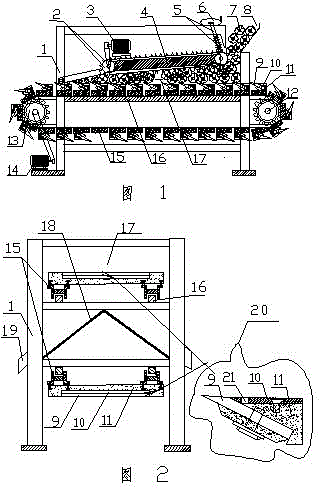

Knife chain type chipping machine

InactiveCN105522633AAchieving lateral cuttingOvercome the defect of excessive power consumption in end-to-end cuttingVeneer manufactureWood shavingsFiber

The invention relates to chipping machine, in particular to a knife chain type chipping machine which can cut small-diameter wood into various thicknesses and lengths of ships and thin wood shavings. The knife chain type chipping machine is characterized in that a surrounding knife chain type cutting mechanism is adopted, so that the simultaneous transverse cutting of dozens and hundreds of chipping knives is realized, and the knife chain type chipping machine can be used for cutting thick chips and can also be used for chipping the thin wood shavings. In the using process, raw materials are sawn into wood segments, and then the wood segments are sent to the chipping machine through a transport machine continuously; the wood segments and the chipping knives form a chipping angle with least resistance, and the thicknesses of the wood segments are 2-5mm; the secondary processing and steaming time is short, and the process of chipping the thick chips into the thin wood shavings can be saved. Compared with the chipping machine on the market, the knife chain type chipping machine can save more than 30 percent of electricity, and the chips and wood shavings can keep an intact fiber morphology.

Owner:向喜娃

Stationary bedknife for disc chipper apparatus

ActiveUS20080035242A1Easy to useCutting operation of rotaryMulti-purpose machinesCocoaCircular discEngineering

A disc cutting apparatus for chipping wood chips from a log includes a chipper frame, a rotary cutting disc having a plurality of substantially radially disposed knife assemblies in relation to a proximal facing side of the disc and a feed spout into which a log is fed into the chipper apparatus. The apparatus further includes a bedknife, the bedknife having a first surface and an opposing second surface that is nonparallel to the first surface such that a wedge is produced between the first surface and the second surface for fitting within a corresponding nonparallel gap in the chipper frame. The bedknife further includes at least one secondary trimming edge for more complete reduction of wood chipped and for reducing the size of slivers formed.

Owner:CEM MACHINE

Side-Discharge Chipper Body

InactiveUS20110222996A1Avoiding added equipment and operational stepConveyorsWood working apparatusEngineeringTruck

A side-discharge chipper body to be mounted on vehicle used to pull a tree limb chipper. The side-discharge chipper body includes a forestry box adapted to receive chipped landscape materials from a chipper, a side door pivotally mounted to the forestry box, and a conveyor assembly disposed within the forestry box and adapted to discharge chipped landscape material stored within the forestry box out the side door. The side-discharge chipper body can be mounted to a truck chassis. A chipper can be towed behind the vehicle with the side discharge body to provide a landscape removal system.

Owner:KNAPHEIDE MFG

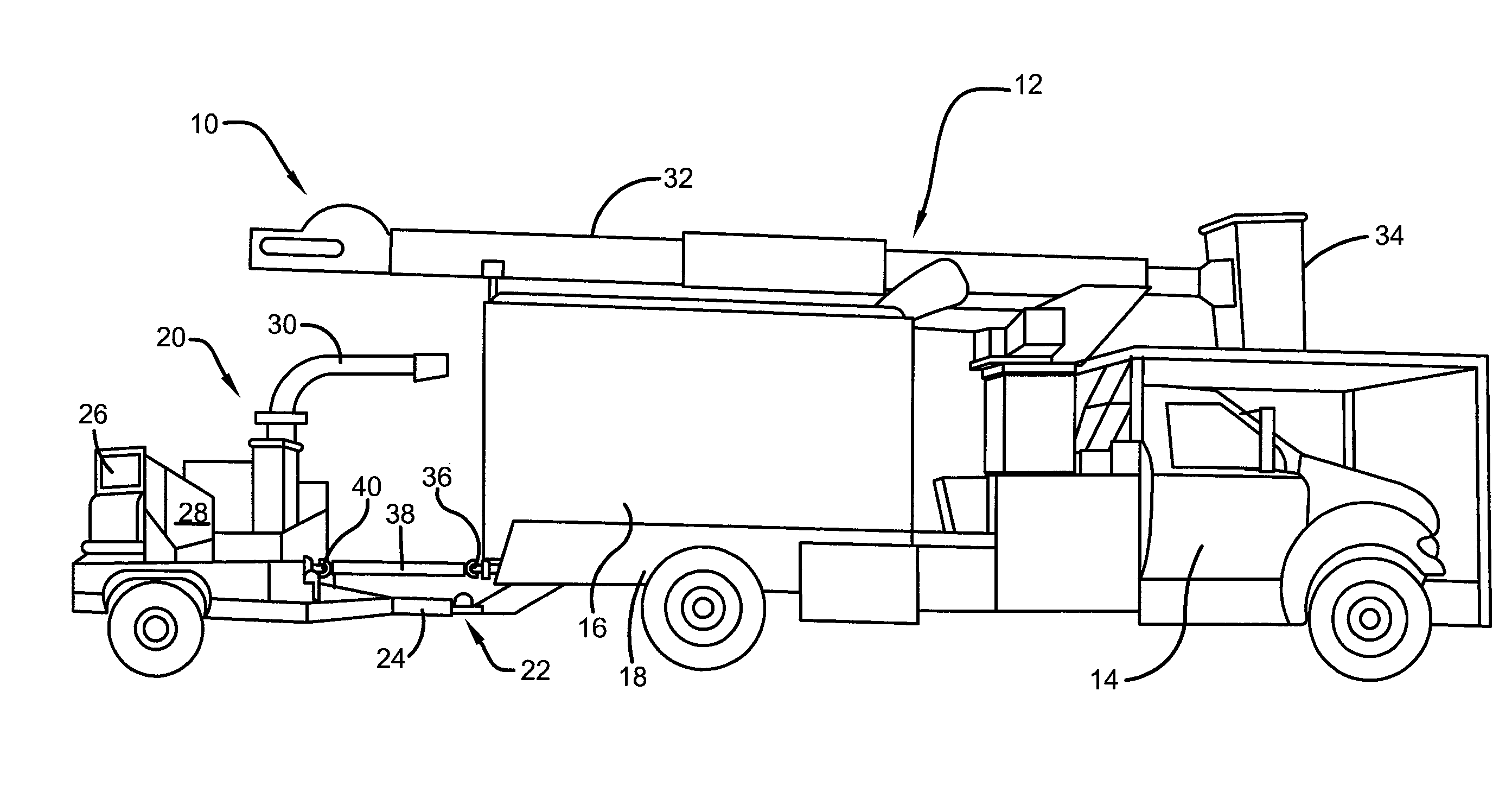

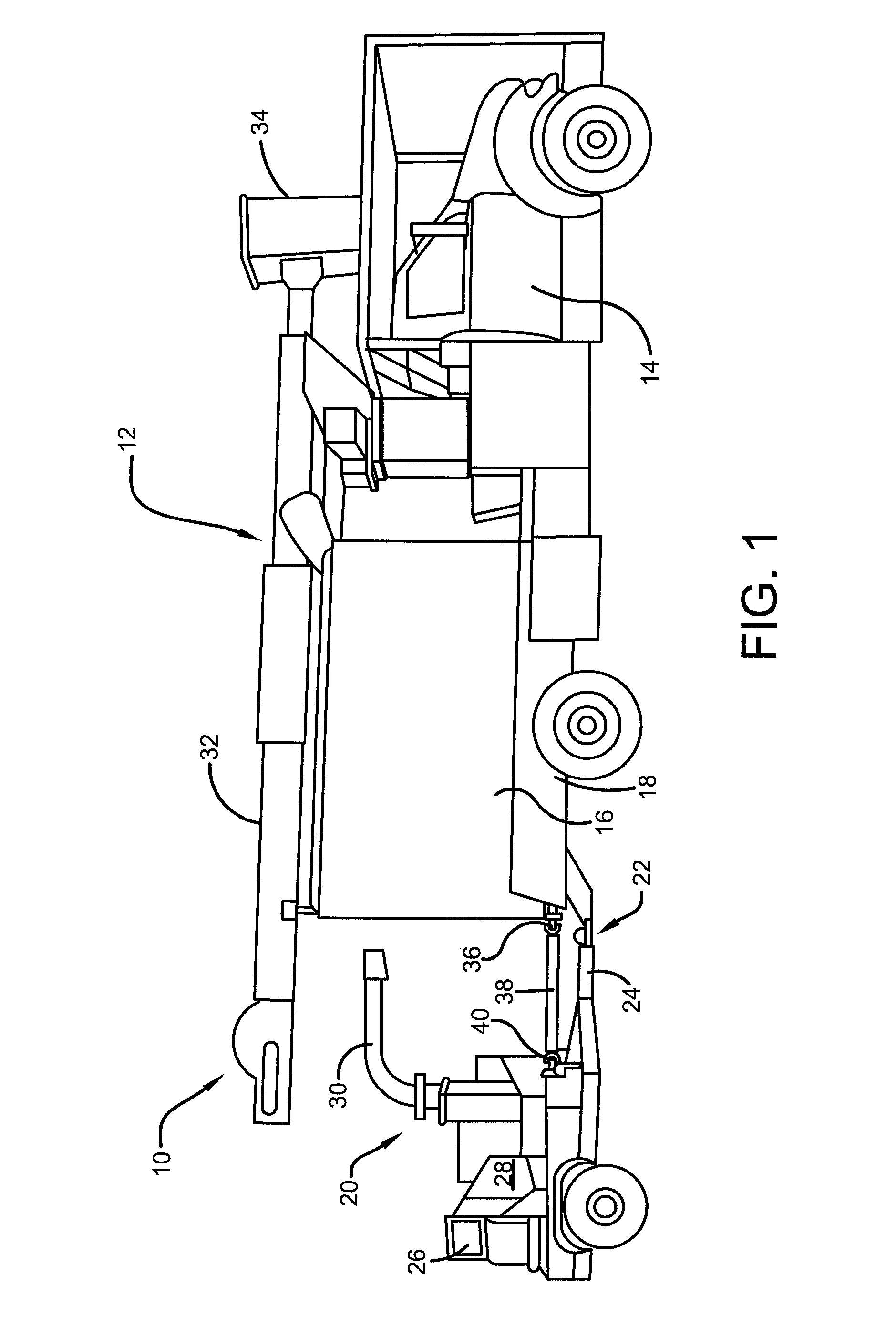

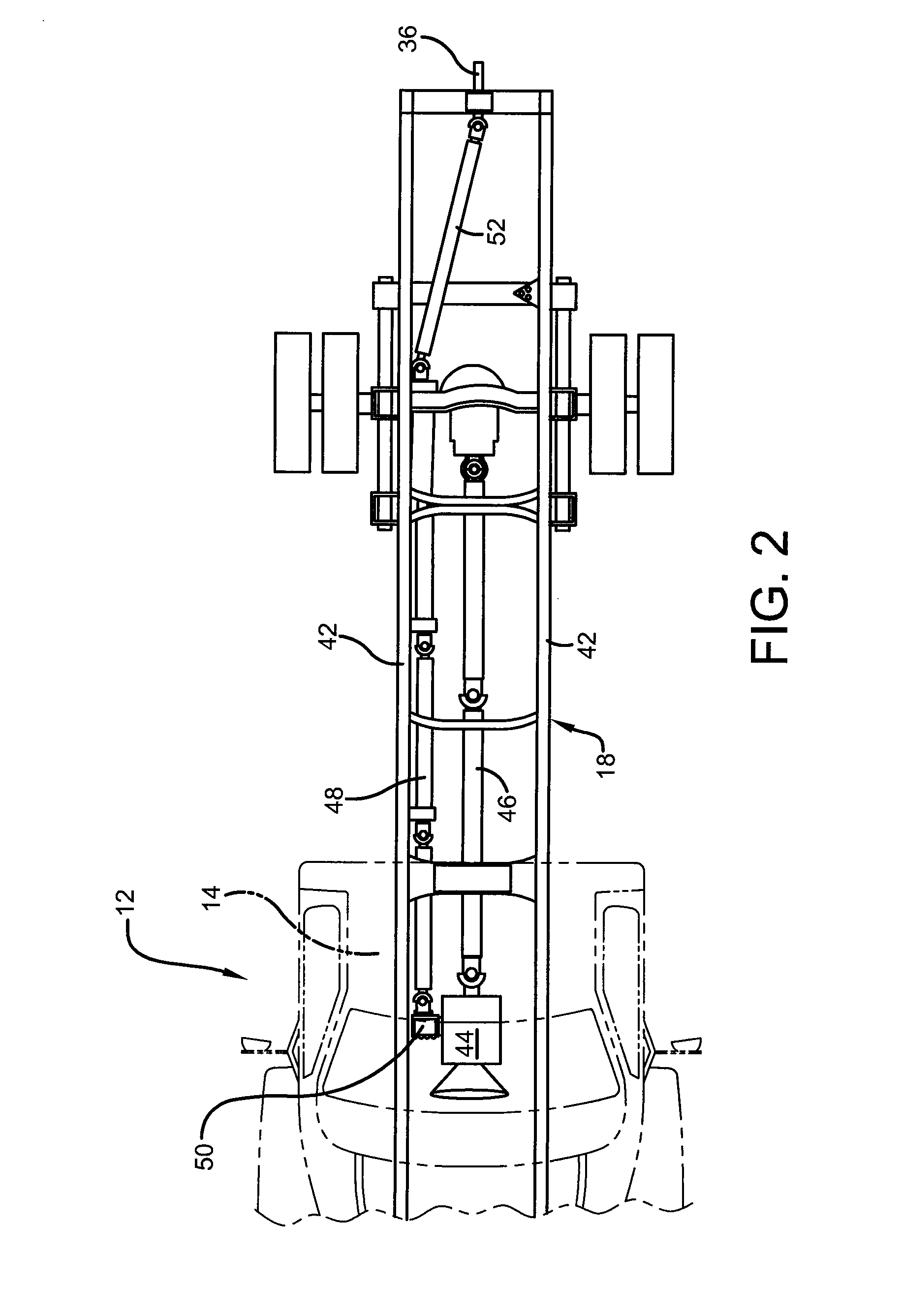

Chipper truck and trailer

InactiveUS20150102147A1Eliminate needEconomical to useMowersPlant waste comminutingDrive shaftEngineering

A chipper truck and trailer assembly for tree trimming and removal includes a truck having a cab and a bed frame. The truck also has a chipper box mounted thereon and open at an end thereof. A trailer is removably connected to the end of the truck adjacent the open end of the chipper box and maintains thereon a chipper unit with a feed chute and a discharge chute. The feed and discharge chutes are at an obtuse angle to each other such that operator may stand alongside the trailer, rather than behind it. The discharge chute is directed into the chip box. A drive shaft interconnects an auxiliary PTO taken from the truck transmission and a power input to the chipper unit.

Owner:ANDERSON DENNIS A

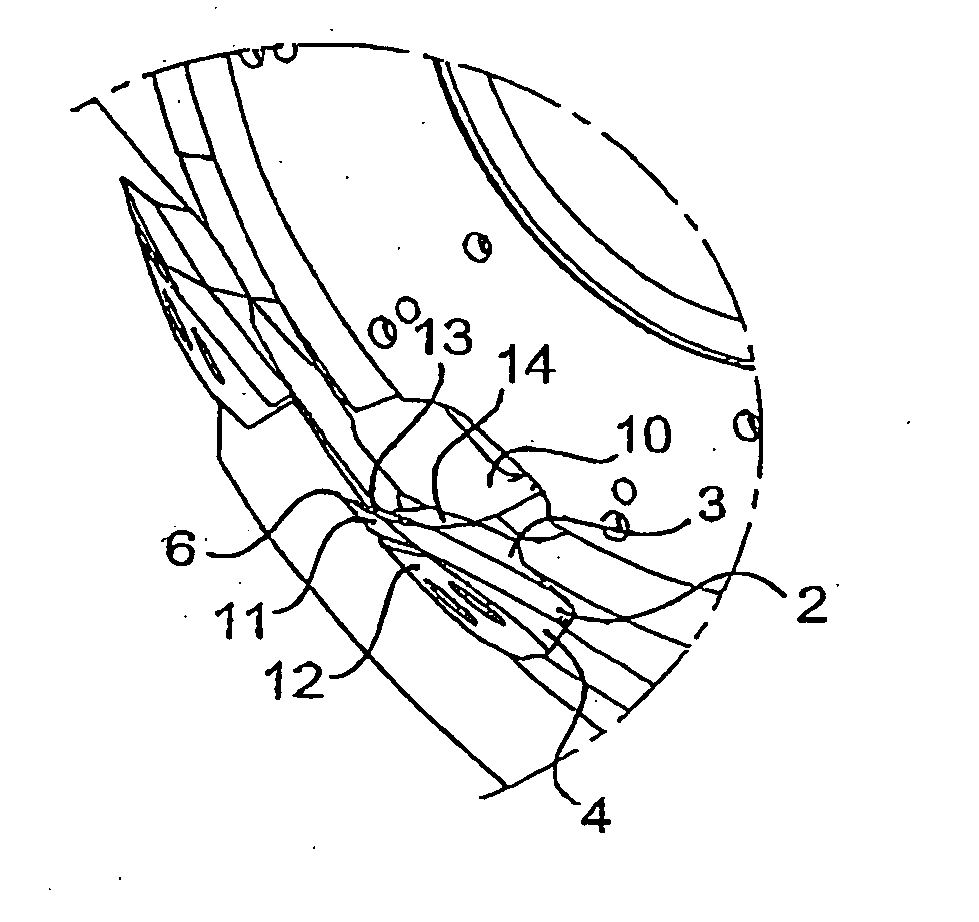

Chipper knife

InactiveUS20050166998A1Degraded in cutting propertyImprove suppression propertiesMulti-purpose machinesProfiling/shaping machinesEngineeringConoid

The invention relates to a chipper knife with at least one cutting edge (6) along at least one of its side edges. The chipper knife is adapted to be mounted in chippers of the kind which are used to cut chips of a desired size and shape from pieces of wood or timber (7) and which comprise a tool, in the form of a plane or conical disc, which is arranged for rotation about an axis of rotation and on which a plurality of such chipper knifes (2) are mountable in such manner that one end of the cutting edge of the chipper knife is located closer to the axis of rotation of the tool than the opposite end of the cutting edge. The cutting edge (6) of the chipper knife is formed between a timber-guiding surface and a chip-guiding surface, the timber-guiding surface having a varying angle along its length in relation to a plane of rotation in such a way that the angle is greater at the end of the cutting edge located closest to the axis of rotation decreases in the outward direction. The chip-guiding surface of the chipper knife also has a varying angle along its length in relation to a plane of rotation in such a way that the angle is smaller at the end of the cutting edge located closest to the axis of rotation and increases in the outward direction in order to obtain a cutting edge angle between the timber-guiding surface and the chip-guiding surface (13) that is essentially constant along the whole length of the cutting edge.

Owner:IGGESUND TOOLS

Wood chipper with drum speed monitoring system and centrifugal clutch

ActiveUS20210268513A1Reduce the required powerReduce the possibilityPlant waste comminutingWood working apparatusAgricultural engineeringControl theory

A wood chipper having a rotatable drum configured to reduce the size of wood fed into the wood chipper; a sensor configured to sense a speed of rotation of the rotatable drum; and a controller operably connected to the sensor. The controller is configured to cut power to the rotatable drum when the speed of rotation of the rotatable drum drops below a pre-set threshold value. The controller is operably engaged with a centrifugal clutch that is engaged to enable the rotatable drum to be rotated. When the speed of drum rotation drops below the threshold value because debris is slowing down rotation of the drum, the centrifugal clutch is disengaged by dropping engine speed. Disengagement of the centrifugal clutch cuts power to the drum and rotation thereof ceases so that the debris may be cleared.

Owner:ALAMO GROUP

Wood chipper, control system therefor, and method thereof

A wood chipper comprises a frame, an infeed system, a rotatable cutting system, and at least one feed wheel disposed between the infeed system and the cutting system to feed wood material to the cutting system. The wood chipper also includes a winch comprising a winch line having a first end, and a collar disposed adjacent the first end of the winch line. The wood chipper further includes a detector adapted to detect a first and a second position of the winch line, wherein the detector is adapted to allow operation of the at least one feed wheel and prohibit operation of the winch when the first position of the winch line is detected, and to allow operation of the winch and allow operation of the at least one feed wheel in a predefined manner when the second position is detected. The wood chipper further comprises a bypass for operation of the at least one feed wheel.

Owner:BANDIT IND

Advanced system recovery for feed system

A feed system for a woodchipper including a material-interface member for feeding material into a chipping mechanism of the woodchipper, an actuator for moving a material-interface member into interfacing and non-interfacing positions with the material, a sensor for detecting an operational parameter of the woodchipper, and a controller to direct the actuator. The controller operates by receiving the operational parameter of the woodchipper, establishing a normative operating value, and determining if the woodchipper is a first status or a second status based on a comparison between the operational parameter and the normative operating value. If the woodchipper is a first status, the controller instructs the actuator to move the material-interface member into the interfacing position. If the woodchipper is a second status, moving the material-interface member into a non-interfacing position.

Owner:ALTEC INDS

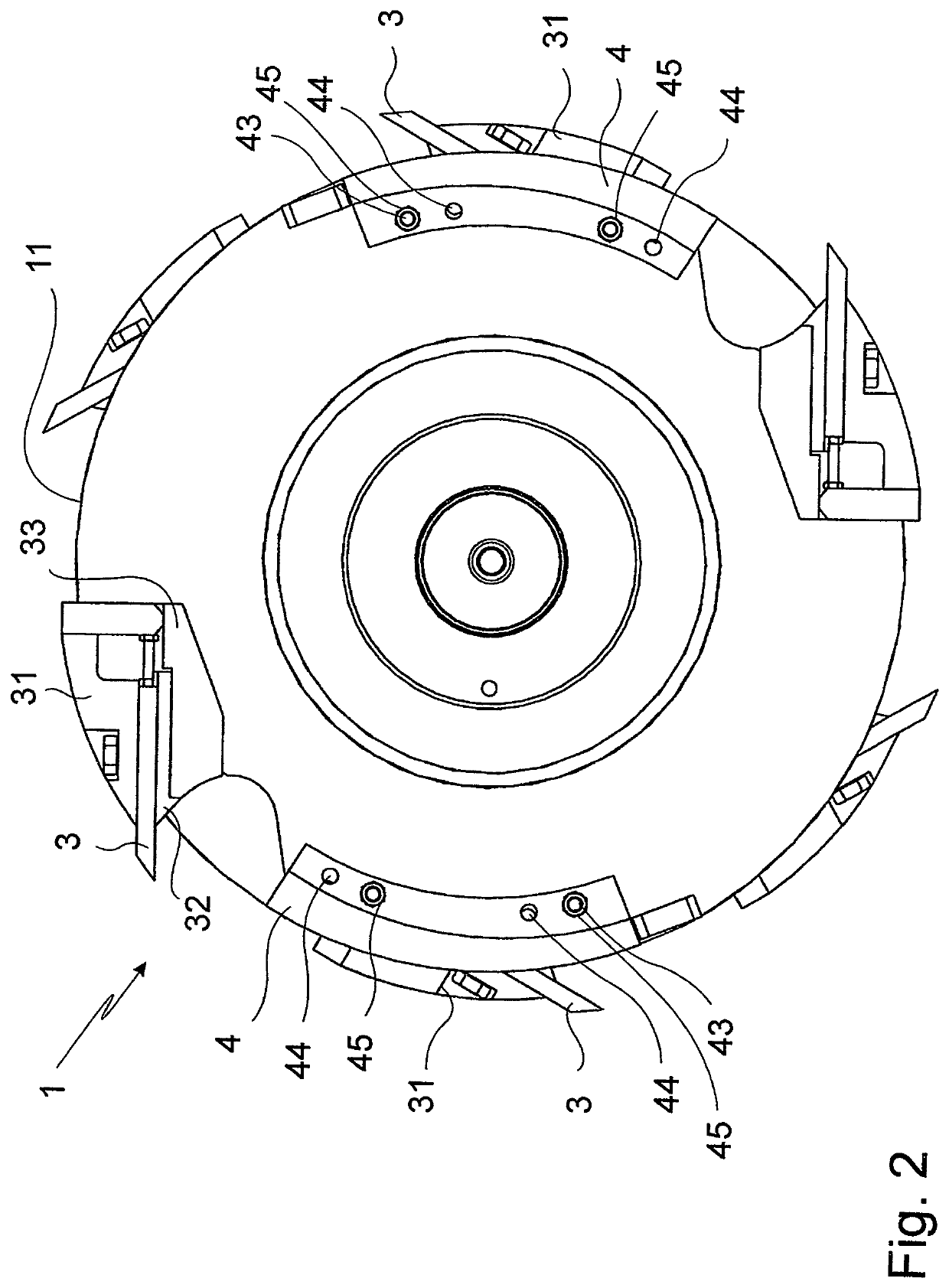

Drum for a chopping device, in particular a precision chipper

A drum for a precision chipper, said chipping device comprising: a shaft on which the drum is arranged, wherein cutting tools are provided on the outer circumference of the drum in blade holders, which cutting tools are used to chop the material to be chipped; at least one distancing piece, which has a support surface or contact surface for the material to be chipped on the drum, the height of which distancing piece being used to determine the chip size, wherein the vertical position of the distancing piece on the drum can be set or adjusted. The distancing piece, when viewed in cross-section, has an approximately T-shaped form such that it can be placed on the outer edge of the drum disk by means of a positively locking surface of the distancing piece, said surface being formed on the face pointing towards the drum by the inner radius of the distancing piece.

Owner:DOPPSTADT FAMILIENHOLDING GMBH

Flywheel and paddle assembly for a chipping or shredding apparatus, and an apparatus incorporating same

A flywheel and paddle assembly for a chipping or shredding apparatus, including a wood chipper, a brush chipper, and a leaf shredder. The assembly has a flywheel attached coaxially to a drive shaft. The flywheel has at least one aperture extending from the front side to the back side, and carries at least one knife adjacent to the at least one aperture. The knife presents a knife edge on the front side of the flywheel. A paddle is rotatably mounted coaxially to the drive shaft adjacent to the back side of the flywheel. The paddle is configured to rotate on the drive shaft independently of the flywheel. A chipping or shredding apparatus incorporating the aforesaid flywheel and paddle assembly is also disclosed.

Owner:WOODLAND MILLS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com