Knife chain type chipping machine

A chain and planing technology, which is applied in the manufacture of thin wood chips, wood processing equipment, manufacturing tools, etc., can solve the problems of not being able to cut thick wood chips, not planing thin shavings, and wasting electric energy, so as to avoid wasting electric energy and improve production effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

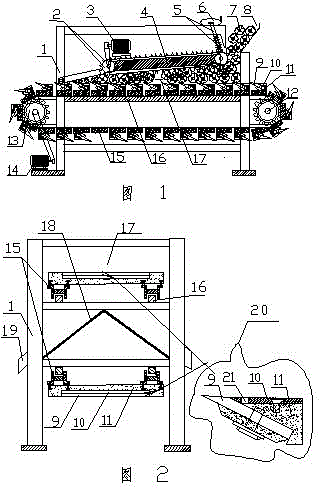

[0027] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples.

[0028] 1. It is the knife chain type planer body of the present invention. When implementing and using, first start the operation of the planer drive mechanism 14, drive the driving sprocket 13 to rotate through the double-row transmission chain, and the knife chain equipped with the planer 9, the bottom knife 10, and the planer holder 11 passes through the track 16 to drive the passive sprocket 13 to rotate. Wheel 12 runs together, and then starts the pressing mechanism driving device 3 again, makes the driving sprocket of the pressing mechanism and the row chain 2 with teeth run, and the effect of the pressing mechanism is to push down the wood section, so that the wood section is not allowed to move when planing. Jump and help the wooden section run forward. Rotate and adjust the handwheel 6 to control the pressing pressure re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com