Desert shrub composite fibre board and method of manufacturing the same

A sand-grown shrub and composite fiber technology, which is applied in the manufacture of tools, flat products, and other household appliances, can solve the problems of wood chip silo bridging, failure of normal feeding, and impact on production, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Psammosan shrub reinforced floor-based composite fiberboard

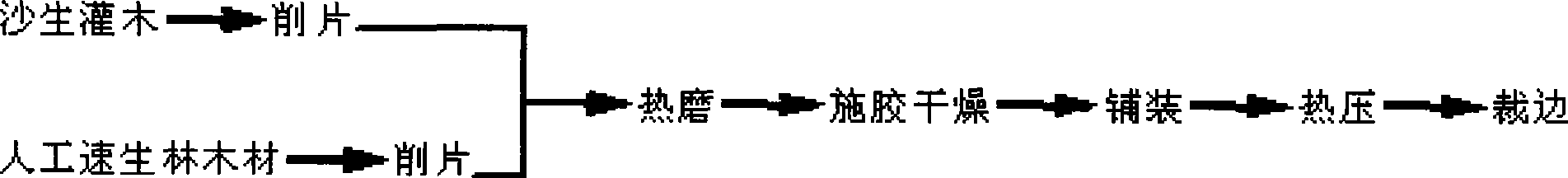

[0026] The following is attached figure 1 , take salix, amorpha and poplar 3 kinds of woods as raw materials to further illustrate specific features and technical means of the present invention, and the specific manufacturing method comprises the following steps: (one) preparing materials, (two) heat grinding, (three) applying Glue, drying, (4) paving, (5) hot pressing, (6) edge trimming, shaving, hot grinding, sizing drying and hot pressing, etc. The moisture content of raw materials in the main sections, the steam pressure of the hot mill , sizing amount, the addition amount of curing agent, the addition amount of waterproofing agent, hot-pressing temperature, hot-pressing time and hot-pressing pressure etc., through systematic research, obtain following concrete embodiment.

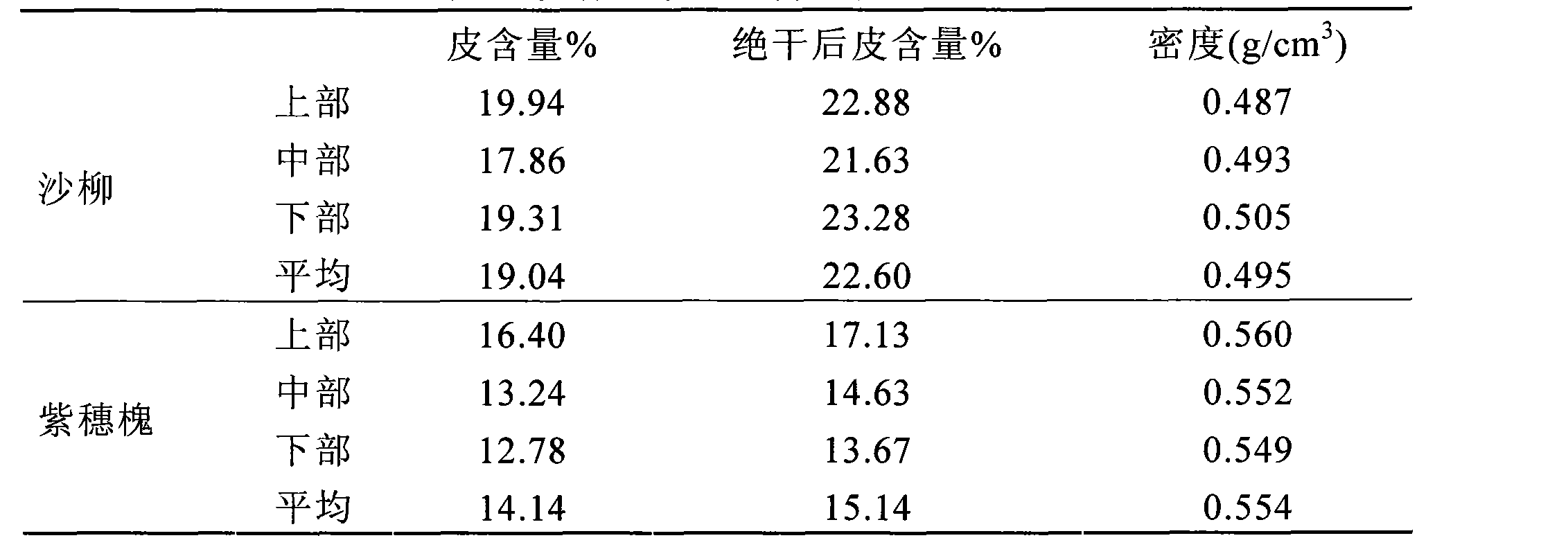

[0027] The sand shrub composite fiber board provided by the present invention, wherein the raw materials include main ma...

Embodiment 2

[0050] Example 2 sandy shrub composite medium density fiberboard

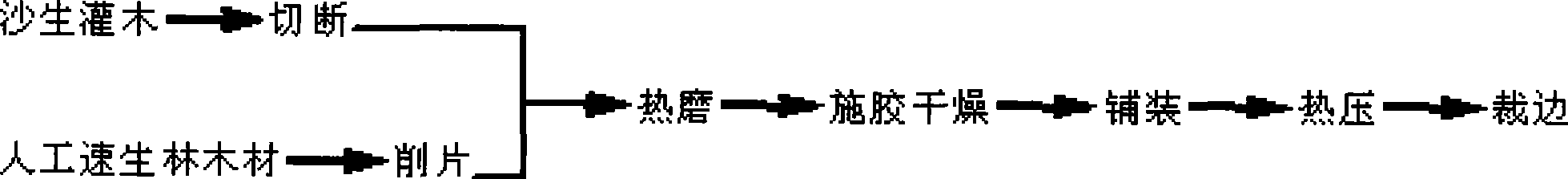

[0051] The following is attached figure 2 , take caragana, amorpha and birch 3 kinds of woods as raw materials to further illustrate specific features and technical means of the present invention, and the specific manufacturing method comprises the following steps: (one) preparing materials, (two) thermal grinding, (three) sizing , drying, (four) paving, (five) hot pressing, (six) specific embodiments below trimming.

[0052] The sand shrub composite fiber board provided by the present invention, wherein the raw materials include main materials and auxiliary materials, wherein the main materials are composed of three kinds of fibers of Caragana, Amorpha and birch, wherein: Caragana fibers account for 20% of the dry weight of the main materials, Amorpha amorpha accounts for 40% of the dry weight of the main ingredient, and birch fiber accounts for 40% of the dry weight of the main ingredient. The adhesive in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com