Reed composite fiber board and manufacture method thereof

A composite fiber and reed fiber technology, which is applied to flat products, other household appliances, household components, etc., can solve problems such as high toughness, blockage of pneumatic conveying pipes, winding of fan impellers, etc., and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

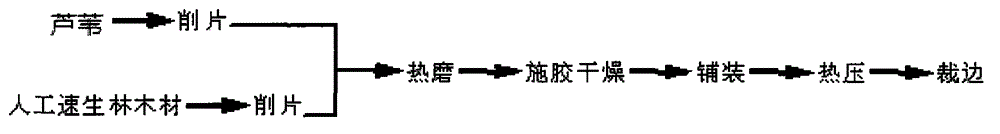

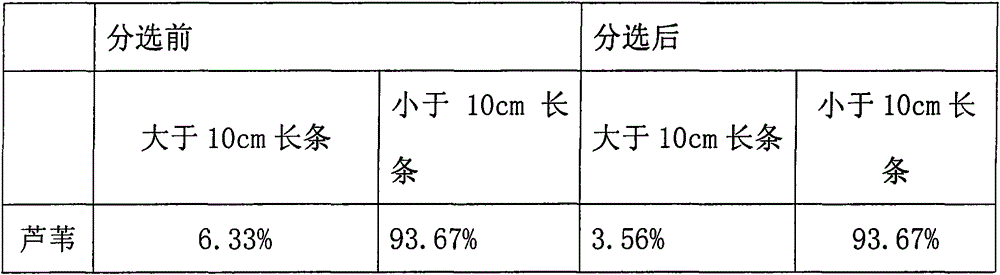

Method used

Image

Examples

Embodiment 2

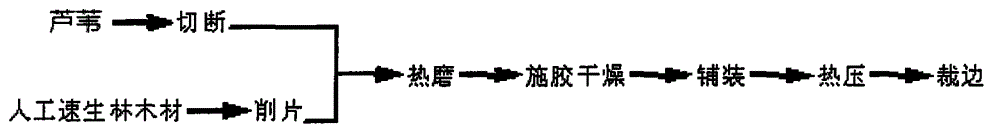

[0045] The following is attached figure 2 , with two kinds of woods of reed and birch as raw material further illustrate concrete feature and technical means of the present invention, concrete manufacture method comprises the following steps: (one) prepare material, (two) hot grinding, (three) sizing, drying, (four) ) paving, (five) hot pressing, (six) specific embodiments below trimming.

[0046] The reed composite fiber board provided by the present invention, wherein the raw materials include main materials and auxiliary materials, wherein the main materials are composed of reed fibers and birch fibers, wherein: reed fibers account for 40% of the dry weight of the main materials, and birch fibers account for 10% of the main materials. 60% of dry weight. The adhesive in the auxiliary material is an isocyanate adhesive, and its sizing amount, that is, the solid content of the adhesive is 5.0% of the dry weight of the main material, and the amount of paraffin wax added to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com