Flow-guiding waterproof technology

A kind of technology, a flow-type technology, applied in the field of diversion waterproof technology, can solve the problems of short waterproof life and difficult construction, and achieve the effects of improving heat insulation effect, convenient construction and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

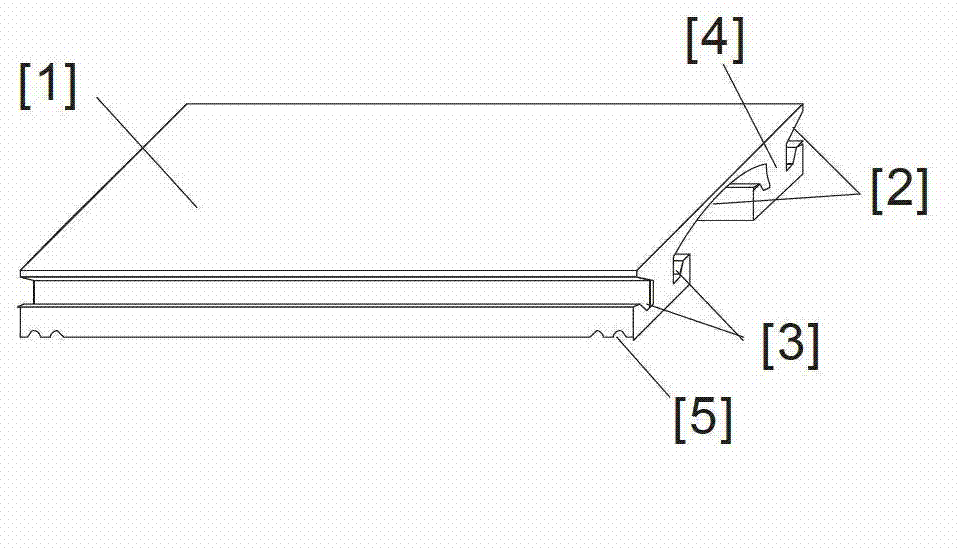

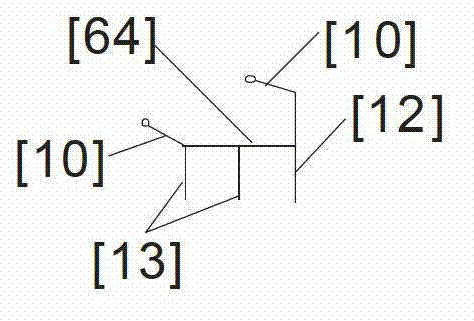

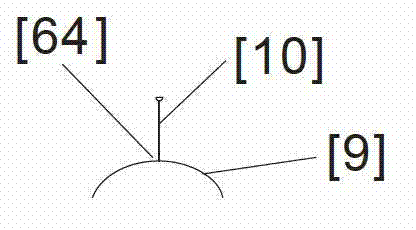

[0069] Example 1: Combining figure 1 , figure 2 , image 3 , Figure 4 , process one or more hydrophilic curved (or ∧-shaped) curved surfaces or slopes [2] with a suitable slope (or gradient) on the back surface of the waterproof prefabricated board [1] as a diversion structure, Process drainage ditches [3] under the diversion slope or curved surface [2] and on both sides of the rib beam [4], such as figure 2 As shown, when the anti-crack and anti-seepage level of the waterproof precast slab [1] reaches a certain requirement, the drainage ditch [3] inside the two rib beams [4] can be omitted; Processing width and depth are 3-10mm opening downward groove [5], and on the surface of the outer wall and groove [5] at the two ends of the drainage ditch [3] or at the two ends and two sides of the waterproof prefabricated board [1] Add a layer of hydrophobic material (such as asphalt, paint, silicone oil, etc.) In the U-shaped drainage groove [7], if figure 1 As shown; in orde...

Embodiment 2

[0075] Example 2: Combining Figure 33 , Figure 31 , it is on the basis of embodiment 1, etc., adding an arc-shaped or ∧-shaped diversion surface [66] longitudinally on the inner side of the waterproof prefabricated plate [1] and two rib beams [4], and the curved surface [66] and the rib beam [4] Add grooves [65] between 4] to prevent the seepage rainwater on the guide surface [66] from flowing to the rib beam [4]. When the seepage rainwater is diverted to both sides by the middle guide surface [2] and After reaching the diversion curved surface [66], the leaked rainwater will be diverted by the diversion curved surface [66] to the two ends of the waterproof prefabricated board [1] and then drip down to complete the waterproof task, and the inner gutter [3] can be omitted ], easy to process.

[0076] In this embodiment, in order to reduce the drainage pressure of the outer drainage ditch [3], it can be increased above the outer drainage ditch [3]. Figure 33 , Figure 31 ...

Embodiment 3

[0077] Example 3: Binding Figure 13 , Figure 14 , Figure 19 , Figure 26 , it is based on the embodiment 1, 2, etc., the bottom of the drainage ditch [3] of the waterproof prefabricated panel [1] is connected together through the hidden plate [22], so that the diversion slope or curved surface [2] is completely hidden ,Such as Figure 13 , Figure 14 As shown, the appearance of the waterproof prefabricated board [1] is better, and it can be directly used as a roof, so that the waterproof prefabricated board [1] can be used not only for the waterproofing project of the roof, but also for the waterproofing project of each floor, so that the waterproof prefabricated board [1] 1] has a wider scope of use and a wider range of uses. When processing waterproof prefabricated panels with no diversion structure in the middle, the available cross-sections are as follows: Figure 26 The mold processing shown is composed of a side mold [46] with a slightly thicker bottom, a round ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com