Heat tracing cable state monitoring system and monitoring method based on wireless network transmission

A heating cable and wireless network technology, applied in signal transmission systems, information technology support systems, thermometers using electric/magnetic elements that are directly sensitive to heat, etc., can solve problems such as difficult construction, unit shutdown, and long construction period , to achieve the effect of reducing the difficulty of engineering construction, improving operational reliability and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

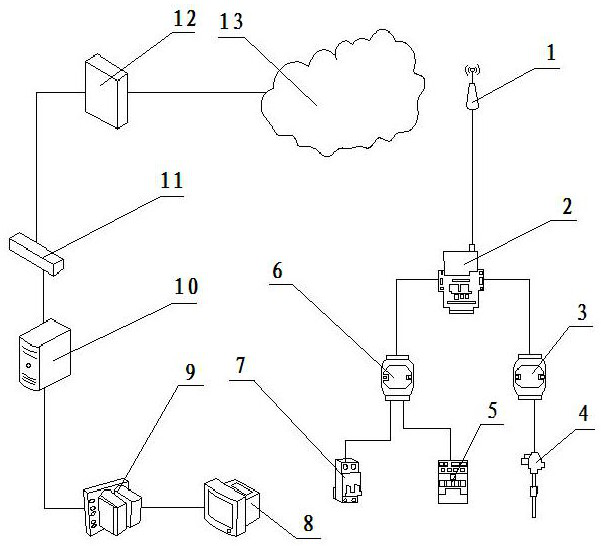

[0020] A heating cable state monitoring system based on wireless network transmission, which consists of: Pt100 thermal resistance temperature measuring element 4, characterized in that: the Pt100 thermal resistance temperature measuring element is connected to the temperature acquisition system 3, and the temperature Acquisition system is connected with wireless acquisition terminal DTU, and described wireless acquisition terminal DTU is connected with Internet 13 by antenna 1, and described wireless acquisition terminal DTU is connected with state acquisition system 6, and described state acquisition system is respectively connected with state relay 7, The heating cable structure 5 is connected, the Internet is connected to the firewall 12 through the telecommunication network, the firewall is connected to the switch 11, the switch is connected to the data communication server 10, and the data communication server is connected to the computer control system 9 , the computer c...

Embodiment 2

[0022] According to the monitoring method of the heating cable status monitoring system based on wireless network transmission described in Embodiment 1, the method includes the following steps:

[0023] (1) Fix the Pt100 thermal resistance temperature measuring element in contact with the instrument tube to monitor the temperature of the instrument tube, and connect the lead wire to the RTD acquisition card in the monitoring box;

[0024] (2) Each heating cable incubator is equipped with a heating state relay connected to the normally open contact of the contactor in the incubator, and the normally open contact of the state relay is connected to the DI acquisition card in the monitoring box;

[0025] (3) A status relay is connected in series with each heating cable power circuit in the incubator, and the normally open contact of the status relay is connected to the DI acquisition card in the monitoring box;

[0026] (4) The DI acquisition card and RTD acquisition card in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com