Welding method and welding device for outer ring weld joints of steel pipe piles

A welding method and welding device technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of high labor intensity of the operator, inability to ensure the stability of the welding operation of the outer ring weld, low welding quality and welding efficiency, etc. , to achieve the effect of improving work efficiency and welding quality, simple and quick adjustment up and down, and fast moving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

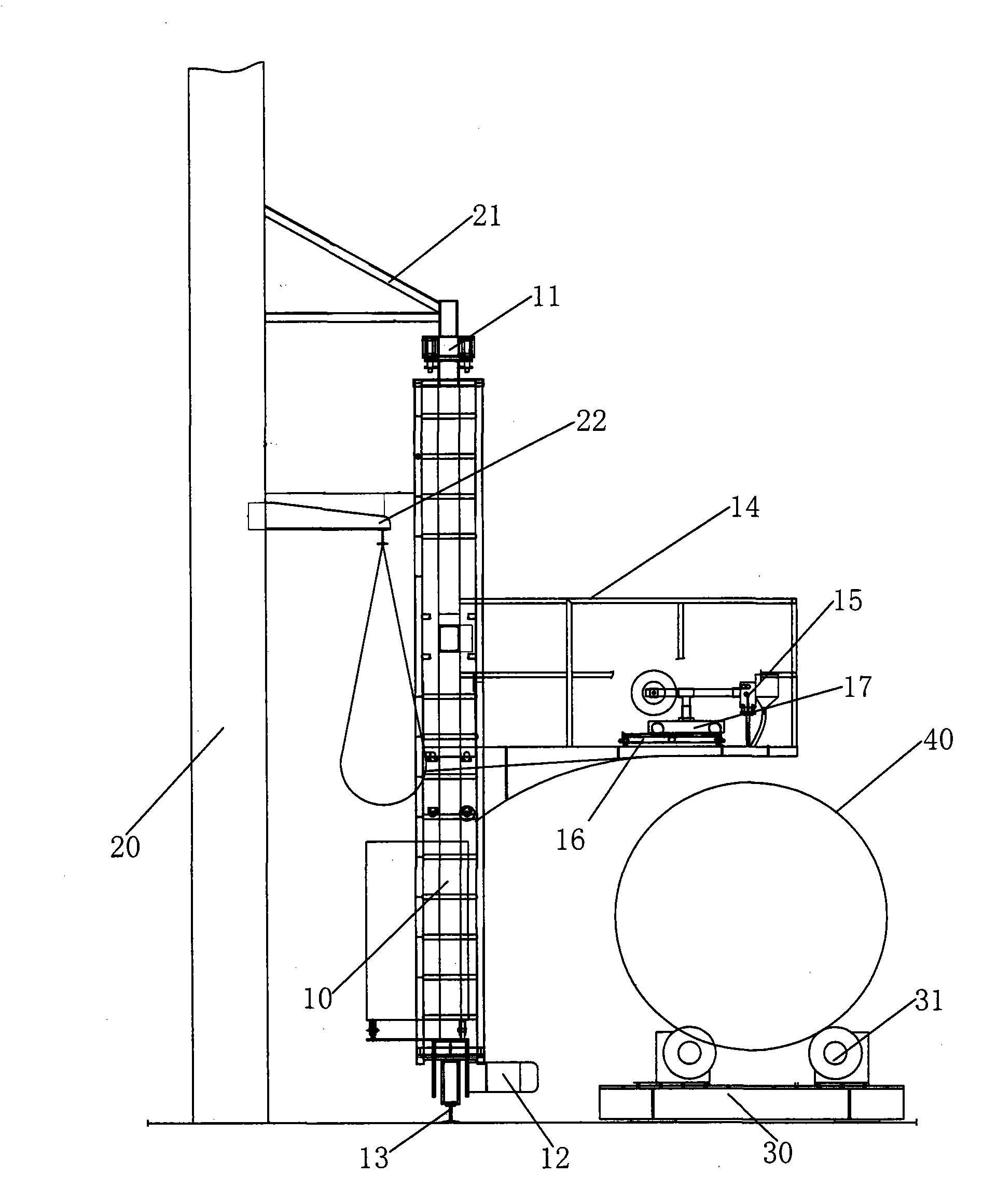

[0024] The welding method for the outer ring weld of steel pipe piles includes placing the butt jointed steel pipe piles on a rotating support device, and adopting a movable operating table, on which the welding equipment is arranged, and starting from the butt joint of steel pipe piles. The welding operation of the outer ring weld is carried out on the upper part or on the side part. The specific operation is as follows: the docked steel pipe piles are supported by the oppositely arranged idler rollers with adjustable center distance, and under the rotation of the idler rollers, the docked steel pipe piles rotate synchronously. The center-to-center distance of the supporting rollers set opposite to each other can be adjusted to realize reasonable support and rotation drive for steel pipe piles of different diameters and specifications. The movable operating platform includes a main door frame in the guide rail, the upper part and the lower part of the main door frame are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com